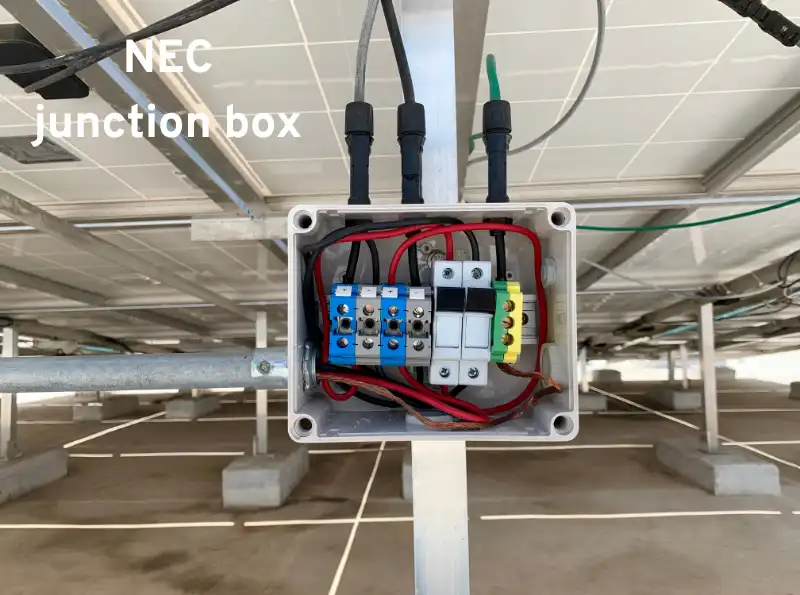

The NEC code of junction box keeps your electrical work safe and reliable. You must use approved materials, choose the right size box, and make sure you ground everything correctly. Always install your boxes where you can reach them later. Many people miss these steps and face problems during inspections.

Tip: Double-check your work to avoid common mistakes and keep your project up to code.

Key Takeaways

- Pick the right junction box material. Use metal or plastic. Think about where it will go and what wiring you have. This helps keep things safe and strong. – Always choose a box that fits all wires, clamps, and devices. This stops things from getting too hot or breaking. – Make sure to ground all metal boxes the right way. Use approved methods. This keeps you safe from shocks and fires. – Put junction boxes where you can reach them later. Do not hide them behind walls or ceilings. – Put covers on every box. Follow special rules for wet or dangerous places. This keeps wiring safe and follows the code.

NEC Code of Junction Box: Materials and Construction

Approved Materials

You need to pick a junction box made from the right stuff. The NEC code of junction box says you can use metal or plastic. The material must not catch fire. Metal boxes are often stainless steel or aluminum. These metals do not rust easily. Plastic boxes must be tough for where you put them. They should keep out water, sunlight, and other dangers. Always match the box to the place you will use it. For outside or wet spots, use boxes that do not rust. This makes your work last longer and keeps it safe.

Note: Check the label on the box. Make sure it is okay for where you want to use it.

Construction Standards

The NEC code of junction box has rules for how boxes are made and put in. Here are the main things you must do:

- Only use metal or certain plastics that do not burn.

- Pick materials that do not rust or get damaged by water or sun.

- The box must be big enough for all the wires inside. A normal 4-inch square box is about 1-1/2 inches deep. It holds about 21 cubic inches. This fits a few 14-gauge wires. People use this size for switches and outlets.

- In dangerous places, use boxes that close tightly. This stops vapors from getting out. These boxes must be grounded and have safety labels.

- Put boxes where you can reach them later. Make sure each box is tight and does not move.

- Always use covers that fit well. This keeps people from touching live wires by mistake.

- Ground metal boxes with a screw or another approved way. The ground wire must not be broken.

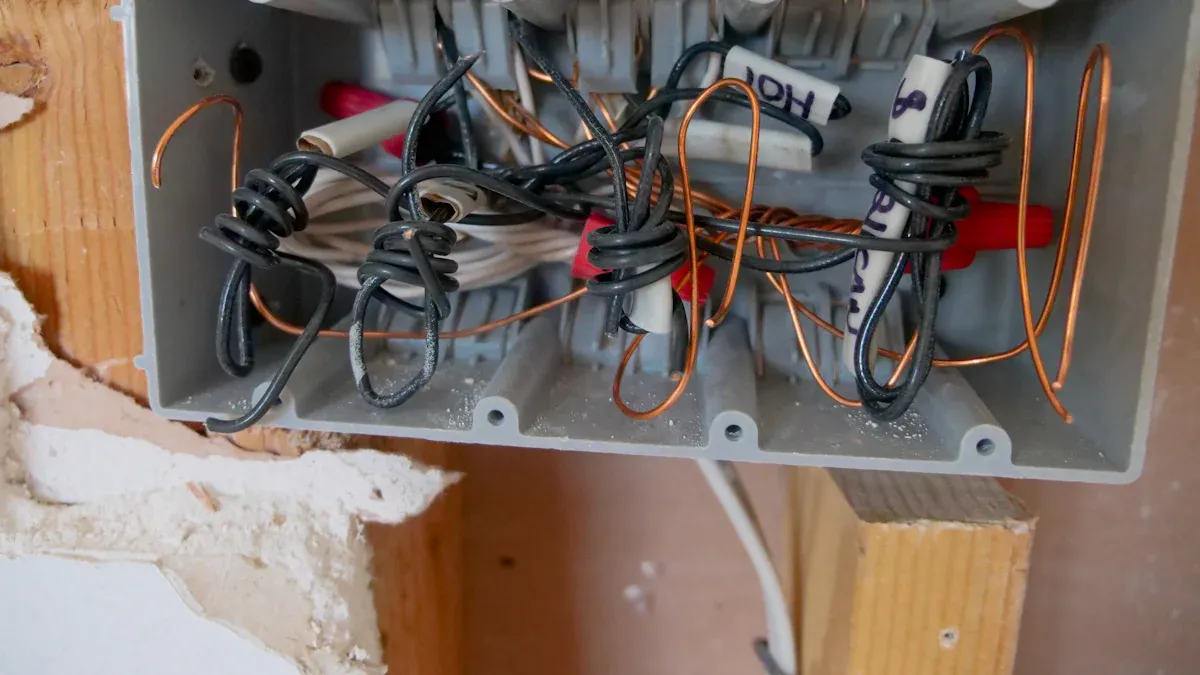

Tip: Do not put too many wires in a box. Too many wires can make it hot and hard to bend the wires.

Metal vs. Plastic Boxes

You have to choose between metal and plastic boxes for your job. Each one has good and bad points. The table below shows the main differences:

| Aspect | Plastic Junction Box | Metal Junction Box |

|---|---|---|

| Material Properties | Light, does not rust, does not carry electricity | Strong, carries electricity, can rust if not protected |

| Grounding & Safety | No need to ground the box itself | Must be grounded and bonded for safety |

| Installation | Easy to use and change | Heavier, may need special tools |

| Cost | Usually costs less | Usually costs more |

| Environmental Suitability | Good for wet or rusty places | Best for protecting wires and open areas |

Use metal boxes if you use metal-sheathed (BX) cable. Metal boxes are also good in unfinished basements or where wires need more protection. If you want a box that is easy to put in and does not rust, use plastic. Plastic is good with non-metallic sheathed cable (Romex). Some local rules say you must use metal boxes in some jobs or where you need extra strength.

Remember: Always follow the NEC code of junction box and local rules when picking your box. The right box keeps your wires safe and up to code.

Box Sizing and Fill

Box Sizing

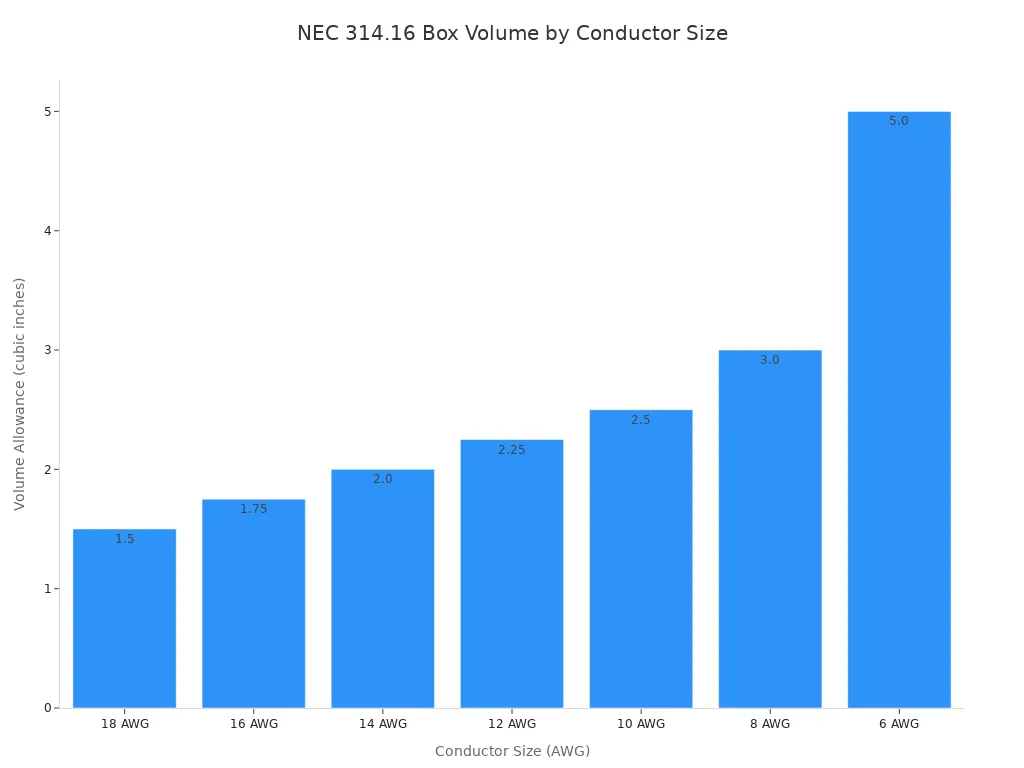

You must choose the right size junction box for your wires. The NEC code of junction box gives clear rules for this. If you use a box that is too small, the wires can overheat or get damaged. NEC 314.16 sets the minimum size for each box based on the number and size of conductors inside. Each wire needs a certain amount of space, measured in cubic inches. The table below shows how much space each wire size needs:

| Conductor Size (AWG) | Volume Allowance per Conductor (cubic inches) |

|---|---|

| 18 | 1.50 |

| 16 | 1.75 |

| 14 | 2.00 |

| 12 | 2.25 |

| 10 | 2.50 |

| 8 | 3.00 |

| 6 | 5.00 |

If you use conductors that are 4 AWG or larger, you must use a box that is big enough for those wires. Always check the box label for its volume rating. Never guess the size.

Tip: Always count every wire, clamp, and device when you choose your box size.

Fill Calculations

You need to calculate box fill before you install your junction box. This step keeps your wiring safe and up to code. NEC 314.16 explains how to do this. Each wire that ends or is spliced in the box counts as one allowance. Wires that just pass through also count once. You must also count clamps, device yokes, and grounding wires. Each item uses up space in the box.

Suppose you have a 4″ x 1 ½” metal box with a volume of 21 cubic inches. You plan to put in:

- Two #12 NM cables (four conductors)

- One #14 NM cable (two conductors)

- Two internal cable clamps

- One device yoke (like a switch)

- One luminaire stud

- Grounding conductors

Now, add up the space needed:

- Four #12 wires: 4 x 2.25 = 9.00 cu.in.

- Two #14 wires: 2 x 2.00 = 4.00 cu.in.

- Two clamps: 2.25 cu.in.

- Device yoke: 2 x 2.25 = 4.50 cu.in.

- Luminaire stud: 2.25 cu.in.

- Grounding wires: 2.25 cu.in.

Total: 9.00 + 4.00 + 2.25 + 4.50 + 2.25 + 2.25 = 24.25 cu.in.

This total is more than the box’s 21 cubic inch rating. You must use a bigger box.

Note: Always add up every item. If your total is more than the box rating, pick a larger box.

Conductor Length

You must leave enough free wire inside every junction box. The NEC code of junction box requires at least 6 inches of free conductor length inside each box. This rule comes from NEC 300.14. Measure from where the wire comes out of the cable sheath or raceway. If the box opening is less than 8 inches in any direction, each wire must stick out at least 3 inches from the box opening. This extra length helps you make safe and easy connections.

- Leave at least 6 inches of free wire inside the box.

- If the box opening is less than 8 inches, wires must extend at least 3 inches outside the opening.

- Wires that do not get spliced or connected do not need to follow this rule.

- Enough wire length makes your work safer and easier to inspect.

Tip: Leaving a little extra wire can help if you need to fix or change something later.

Grounding and Bonding

Grounding Metal Boxes

You have to ground every metal junction box for safety. The NEC says the equipment grounding conductor (EGC) must connect right to the metal box. This gives electricity a safe way out if something goes wrong. Use a grounding screw in a special hole or an approved clip. Do not connect the ground wire to a ground rod inside the box. The EGC must go back to the main panel and connect to the grounding bar.

- Use only approved connectors like wire connectors, compression connectors, or bonding bolts.

- Keep the grounding conductor whole and do not break it.

- The ground path must stay complete, even if you take out a device.

Tip: Always make sure your ground wire is tight and does not move. If the ground is loose, it can cause shocks or fires.

| NEC Section | Requirement Summary | Key Details |

|---|---|---|

| 250.110 | Metal boxes must be grounded | Use a grounding screw or approved way in a special or threaded hole |

| 250.148(C) | Connect the metal box to the EGC with its own connection | Size the EGC and bonding jumper using Table 250.122 |

| Continuity | Keep the ground path even if you remove devices | Do not break the ground when taking out switches or outlets |

Bonding Requirements

Bonding joins all metal parts so electricity cannot jump between them. The NEC lists a few ways to bond junction boxes:

- Listed pressure connectors

- Terminal bars

- Exothermic welding

- Machine screw-type fasteners with at least two threads

- Connections that are part of a listed assembly

Never use just solder for bonding. If your box has concentric or eccentric knockouts, you might need a bonding jumper unless the box says it is okay for bonding. Some surface-mounted boxes let you bond by touching metal to metal. Always follow what the box maker says.

Note: Bonding keeps all metal parts at the same electrical level. This helps stop shocks.

Ground Wire Connections

You must connect all ground wires together inside the junction box. The NEC says you can use a pigtail, which means twisting the ground wires and adding a short wire to the box or device. Make sure the ground wire is big enough for the largest breaker in the circuit. You do not have to cover ground wire splices with insulation.

| NEC Code Section | Requirement / Explanation |

|---|---|

| 250.148(A) | Connect all equipment grounding conductors together inside the box |

| 250.122(C) | Make the ground wire big enough for the largest breaker |

| 110.14(B), 250.8 | Use approved connectors for all ground wire splices; you do not need insulation on them |

| Practical Advice | Pigtail grounds are okay; count them in your box fill calculation |

Alert: Always check your ground connections before closing the box. Good grounding and bonding keep you and your home safe from electrical dangers.

Accessibility and Installation

Box Accessibility

You must install every junction box where you can reach it later. The NEC code of junction box says you cannot hide boxes behind walls, ceilings, or floors. You should never cover a box with drywall, paneling, or any part of the building. This rule helps you inspect, repair, or replace wires without damaging your home. If you use underground boxes, you must make sure you can get to them without digging up the ground or breaking concrete. Always secure the box and use a cover that stays in place. This keeps people safe from live wires and makes future work easier.

Tip: You do not need to leave boxes open. You can use screws or tools to remove covers, but you must not seal boxes in a way that makes them impossible to reach.

Clearance Requirements

You need to keep enough space around each junction box. NEC 110.26 gives you the minimum clearances:

- Keep at least 36 inches of space in front of the box.

- Leave 30 inches of width for working and using tools.

- Make sure you have 6 feet of headroom above the box.

- Do not block the area with furniture or storage.

- The box door or cover must open at least 90 degrees.

These clearances help you work safely and let inspectors check your wiring. Always plan your box locations before you start your project.

Concealed Wiring

If you use knob-and-tube wiring, you must follow special rules. NEC 300.15 says you need a junction box at every outlet, switch, or splice point. You must use fittings and connectors that match the wiring type. Never hide splices or connections inside walls without a box. The box must stay accessible after you finish the job. This rule stops fire hazards and keeps your wiring safe for years.

Alert: Always use a box for every splice or connection. Do not skip this step, even if the wiring is old.

Special Locations and Common Violations

Hazardous and Wet Locations

You have to follow extra rules for junction boxes in dangerous or wet places. These rules help stop fires, explosions, and shocks. The table below shows what you must do in these places:

| NEC Requirement Aspect | Description |

|---|---|

| Sealing Locations | Put seals where conduit goes into explosionproof boxes, between explosionproof boxes, and where conduit leaves dangerous areas. |

| Explosionproof Seal Criteria | Use explosionproof seals that melt at 200°F or more. The seal must block vapors and be as thick as the fitting size. |

| Prohibited Practices | Do not make wire splices or taps inside sealing fittings. |

| Conductor Fill Limits | Only fill sealing fittings up to 25% with wires. |

| Cable Sealing at Terminations | Seal cables that can carry gases or vapors into the dangerous area. Put sealant around each wire. |

| Vapor and Process Sealing | Use process seals to stop flammable gases from getting into the electrical system. |

| Moisture and Liquid Protection | Add drains if water might build up. Use insulation made for wet places if wires could get wet. |

| Additional Requirements | Bond all metal parts, not just ground them. Add surge protection. |

In wet places, use weatherproof boxes and covers. Make sure the box keeps water out. Use boxes with drain holes if needed. Always ground metal boxes and use wires made for wet places. Make drip loops in wires to keep water from running into the box.

Tip: Always check the box label to see if it is okay for outdoor or wet places.

Covers and Support

You must put a cover on every junction box. Never leave a box open. Covers keep people from touching live wires and keep out dust and water. Hold each box tightly in place. Attach it to a wall, ceiling, or other strong spot. Secure the box within 12 inches of where the cable or conduit goes in. This stops the box from moving and keeps wires safe.

Common Code Violations

Many people make the same mistakes with junction boxes. The table below lists common mistakes and how to avoid them:

| Common NEC Code Violations Related to Junction Boxes | How to Avoid Them |

|---|---|

| Using undersized junction boxes | Pick the right box size using NEC Section 314.16. |

| Neglecting grounding requirements | Ground all metal parts as the NEC code of junction box says. |

| Installing boxes in inaccessible locations | Put boxes where you can reach them for checking and fixing. |

| Overcrowding wires and devices | Check box fill and never put too many wires in a box. |

| Improper connectors and fittings | Use connectors and fittings that match the cable or conduit type. |

| Open or uncovered junction boxes | Always put covers on every box. |

Note: The most common mistake is using a box that is too small. Always check the box volume before you start.

Quick Reference Checklist

- Figure out box fill and size before you put it in (NEC 314.16).

- Hold boxes tight within 12 inches of cable or conduit entry.

- Keep all boxes easy to reach—never hide them behind walls or ceilings.

- Ground and bond all metal boxes and connect all ground wires.

- Leave at least 6 inches of free wire inside each box for splicing.

- Use weatherproof boxes and covers in wet or outside places.

- Use explosionproof or sealed boxes in dangerous areas.

- Do not overfill boxes, miss ground wires, or use the wrong box.

- Check for clear volume and rating marks on every box.

- Plan your work and ask a licensed electrician if you are not sure.

✅ Following this checklist helps you meet the NEC code of junction box and pass inspections.

When you follow the NEC code of junction box, you keep your home and family safe. If you miss steps or do not follow the code, you could cause a fire or shock. You might also fail inspections or have trouble with insurance. Always check your work two times. Use the checklist to help you remember each step. If you are not sure, ask a licensed electrician for help. Groups like the Electrical Safety Foundation International and the National Fire Protection Association have helpful guides. Always make following the code the most important part of your project.

FAQ

What happens if you use a junction box that is too small?

If you use a box that is too small, wires can overheat. This can cause a fire. Inspectors will not approve your work. Always check the box volume before you start.

Do you need to ground plastic junction boxes?

You do not need to ground plastic boxes. Plastic does not conduct electricity. You still need to connect all ground wires inside the box.

Can you cover a junction box with drywall or paneling?

Alert: Never cover a junction box with drywall or paneling. You must keep every box accessible for inspection and repairs. Hidden boxes break the NEC code and create safety risks.

How do you know if a box is rated for outdoor or wet locations?

Look for a label on the box. It should say “weatherproof” or “outdoor rated.” These boxes keep out water and protect your wiring. Always use the right box for the location.

The following information may be of interest to you

Why Ground Wires Matter: Differences from Neutral & Bonding Wires

Combiner box and junction box: main differences

How to dry and maintain wet circuit breakers

DC 1000V 2 in 1 Out Solar Junction Box

Choosing a suitable distribution box and what should be noted