Motor Control Centers use three main types of circuit breakers. These are Motor Circuit Protectors (MCPs), thermal-magnetic circuit breakers, and molded case circuit breakers (MCCBs). MCPs are often found in MCC buckets. They usually work with separate thermal overload relays. Picking the right breaker keeps equipment and people safe. It also meets strict safety rules like NEC and UL. These circuit breakers help turn off equipment safely. This stops electrical dangers in the Motor Control Center.

Key Takeaways

- Motor Control Centers use three main circuit breakers. These are Motor Circuit Protectors (MCPs), thermal-magnetic breakers, and molded case circuit breakers (MCCBs). Each one helps keep motors and circuits safe.

- Picking the right breaker size and type is very important. It keeps motors safe, stops fires, and follows safety rules like UL489 and IEC 60947-2.

- MCPs stop short circuits and work with thermal overload relays. Thermal-magnetic breakers give basic protection. MCCBs give strong and adjustable protection for bigger motors.

- Modular MCC buckets make it easy to control and fix motors. You can upgrade motors without stopping the whole system. This makes things safer and more efficient.

- New solid-state breakers make things safer and cut down on downtime. They let you watch systems in real time. This makes Motor Control Centers more reliable and easier to take care of.

Motor Control Center Circuit Breaker Roles

Protection Functions

Circuit breakers in a Motor Control Center keep motors and circuits safe. They notice when too much current goes through a circuit. If there is an overload or short circuit, the breaker shuts off power fast. This stops electrical faults from hurting motors or wires. Studies show these devices are very important for safety. They stop fires and equipment problems by blocking dangerous currents. Circuit breakers also help protect workers from electric shock. Many industries use these breakers to keep their Motor Control Center working well. As technology gets better, some centers use Continuous Thermal Monitoring to spot issues early. This helps avoid downtime and makes the system work better.

Tip: Always make sure the circuit breaker fits the motor’s size and type. This gives the best protection and keeps the Motor Control Center safe.

Integration in MCC Buckets

Every Motor Control Center uses a modular setup called MCC buckets. These buckets hold the circuit breaker and other control parts for each motor. This lets workers control and protect each motor by itself. If one motor needs fixing, workers can turn off just that bucket. They do not have to stop the whole system. The modular design makes it simple to change or upgrade parts. Circuit breakers fit inside these buckets and work with other devices to protect the motor. This flexible system helps factories and plants work better. It also makes repairs safer and quicker, since each bucket can be handled alone.

Types of Circuit Breakers

Motor Circuit Protectors (MCPs)

Motor Circuit Protectors are special circuit breakers for motors. You will see them a lot in Motor Control Center buckets. MCPs are made to stop short circuits. They do not stop thermal overload by themselves. A thermal overload relay works with the MCP to keep the motor from getting too hot.

MCPs have trip curves made for motors. These curves help the MCP act fast when there is a problem. They ignore normal starting surges. If a short circuit happens, the MCP can turn off power very quickly. MCPs also stop problems from spreading to other equipment.

Note: MCPs can have smart features like IoT and predictive maintenance. These features help motors last longer and reduce downtime.

The table below shows how MCPs compare to other breakers in Motor Control Centers:

| Feature | Motor Circuit Protector (MCP) | Molded Case Circuit Breaker (MCCB) | Standard Circuit Breaker |

|---|---|---|---|

| Motor-Specific Protection | High (tailored trip curves) | Low (general purpose) | Limited |

| Sensitivity to Motor Faults | High (instantaneous fault detection) | Medium | Low |

| Thermal Overload Monitoring | Advanced (motor-specific) | Limited | Basic |

| Selective Coordination | Better (adaptive profiles) | Moderate | Limited |

| Application Focus | Motor protection in MCCs | Broader electrical protection | General circuits |

MCPs are good at stopping current fast and exactly. They help keep the Motor Control Center safe and working well.

Thermal-Magnetic Breakers

Thermal-magnetic breakers use two ways to protect circuits. The thermal part reacts to slow overloads. The magnetic part reacts to sudden, high currents. These breakers are used in many places, including Motor Control Centers.

In a Motor Control Center, these breakers protect motors and other equipment. They are not as special as MCPs. But they still give good protection for many loads. The thermal part uses a bimetal strip that bends when hot. The magnetic part uses a coil to trip the breaker during a fault.

Tip: Thermal-magnetic breakers are simple to use and install. They fit well in MCC buckets.

These breakers give basic motor protection. They work best for small motors or less hard jobs. For bigger or more sensitive motors, MCPs or MCCBs are better.

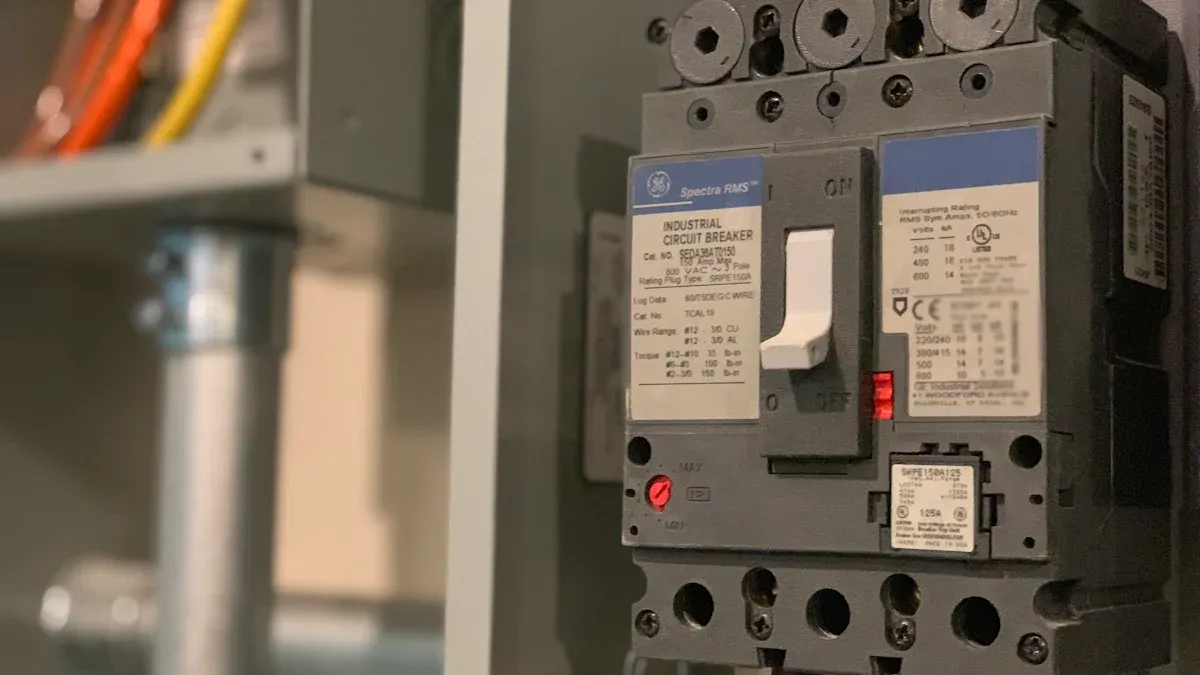

Molded Case Circuit Breakers (MCCBs)

Molded Case Circuit Breakers are strong and flexible. They protect circuits from overloads and short circuits. MCCBs can handle more current than standard breakers. In a Motor Control Center, MCCBs often protect big motors or groups of motors.

MCCBs have settings you can change. This helps workers match the breaker to the motor. MCCBs also meet safety rules like UL489 and IEC 60947. They come in different sizes for many uses.

The table below lists important things about MCCBs in Motor Control Centers:

| Performance Metric | Description and Validation Role |

|---|---|

| Insulation Resistance | Checks insulation between wires; must be higher than the guide for safety. |

| Contact Resistance | Shows if the breaker works right; low voltage drop is needed. |

| Overload Tripping | Tests if the breaker trips at 300% current to check overload protection. |

| Thermal Protection | Uses 3-4 times the rated current to test overload protection. |

| Rated Current | Lets you set the amp trip below the max to fit the motor. |

| Ultimate Short-Circuit Breaking Capacity (Icu) | Makes sure the breaker can stop fault currents safely; must be higher than the fault level. |

| Trip Curves (Types B, C, D, K, Z) | Show how the breaker trips for different uses, so it reacts right to surges. |

| Standards and Certifications | Must follow UL489, NEMA AB-1, IEC 60947, and have certificates to prove quality. |

| Frame Size | Pick the right size for space and load to make sure it fits. |

| Rated Insulation Voltage | Sets safe distances for operation. |

MCCBs use different trip curves for each job. The table below explains these trip curves:

| Trip Curve Type | Tripping Current Range (times rated current) | Tripping Time (seconds) | Typical Application and Protection Role |

|---|---|---|---|

| Type B | 3 to 5 | 0.04 to 13 | Good for resistive loads in homes or light industry; protects against small surges. |

| Type C | 5 to 10 | 0.04 to 5 | Used in business or industry with small motors, pumps, or transformers. |

| Type D | Higher surge tolerance | 0.04 to 5 | Best for big motors, battery charging, or medical gear; handles big surges. |

| Type K | High starting current handling | N/A | Made for motors and loads with high starting currents. |

| Type Z | 2 to 3 | 0.04 to 5 | Most sensitive; protects delicate electronics and medical gear from small surges. |

MCCBs give strong protection for many circuits in a Motor Control Center. They help keep the system safe and working well.

Selection and Compatibility

Sizing and Ratings

Picking the right circuit breaker for a Motor Control Center means you need to get the size and rating correct. The breaker’s rated current should be the same as what the motor needs. Experts say to choose a breaker with a rated current that is 1.5 to 2.5 times higher than the motor’s rated current. This helps the breaker handle many motor starts and short circuits.

International rules like IEC 60364 and IEC 60947-2 help guide which breaker to pick. These rules say devices must work together and protect each other. For example, main circuit breakers usually have a pickup range of 0.8 to 1.0 times the rated current. Their instant trip setting is 8 to 10 times the rated current. MCC circuit breakers have a pickup range of 0.6 to 0.8 times the rated current. Their instant trip setting is 4 to 6 times the rated current.

| Device Level | Pickup Range (x In) | Instantaneous Trip (x In) |

|---|---|---|

| Main Circuit Breaker | 0.8 – 1.0 | 8 – 10 |

| Feeder Circuit Breaker | 0.7 – 0.9 | 6 – 8 |

| MCC Circuit Breaker | 0.6 – 0.8 | 4 – 6 |

It is also important to use the right cable size and set the thermal relay correctly. Cables must carry the current safely. Thermal relays should be set between 1 to 1.2 times the motor’s rated current. These steps help keep the system safe and working well.

Tip: Always make sure the breaker meets standards like UL489 or IEC 60947-2 before you install it.

Replacement and Upgrades

When you replace or upgrade circuit breakers in a Motor Control Center, some problems can happen. Old breakers may not trip at the right current or may get stuck, especially if they have two poles. If the breakers are not made well, they can fail a lot. Some brands fail up to 50% of the time in tests. Breakers that do not trip right can cause fires, injuries, or damage.

Switching to new solid-state breakers can fix many of these issues. These breakers sense current better, test themselves, and are easier to set. Plants that use new breakers are safer, have less downtime, and spend less on repairs. New breakers also let workers watch the system in real time and check for problems from far away.

- More work gets done and things run smoother

- The plant and workers are safer

- There is less downtime and fewer repairs

- It is easier to watch and fix problems

A modular design in Motor Control Centers makes upgrades simple. This design helps the system last longer and meet new safety rules.

Motor Circuit Protectors, thermal-magnetic breakers, and molded case circuit breakers all help keep motors and circuits safe. Picking the right one is important for safety. It also helps meet UL and CSA rules. This makes sure everything works well. Industry reports say these things are important:

- Choosing the right breaker helps stop arc flashes and gives good electrical protection.

- Following rules and new technology help the market grow.

- Top companies care about making things safe and efficient.

For the best results, talk to experts or the company before you change or upgrade breakers.

FAQ

What is the main job of a circuit breaker in a Motor Control Center?

A circuit breaker in a Motor Control Center protects motors and wiring from too much current. It stops power quickly if it finds a problem, like a short circuit or overload.

What makes a Motor Circuit Protector (MCP) different from other breakers?

A Motor Circuit Protector (MCP) only protects against short circuits. It does not protect against overheating. Workers use a separate thermal overload relay with an MCP for full motor protection.

What should someone check before replacing a circuit breaker in an MCC?

They should check the breaker’s size, rating, and type. The new breaker must match the motor’s needs and follow safety standards. It helps to ask an expert before making changes.

What happens if the wrong circuit breaker is used in an MCC?

The wrong breaker can fail to protect the motor or wiring. This can cause fires, equipment damage, or safety risks for workers.

What standards do circuit breakers in Motor Control Centers need to meet?

Circuit breakers in Motor Control Centers must meet standards like UL489 or IEC 60947-2. These rules make sure the breakers work safely and reliably.

The following information may be of interest to you

Static Transfer Switch vs Automatic Transfer Switch Explained

Electric motor circuit breaker selection and usage

How to Match the Type of MCB to Your Electrical Load

Comprehensive analysis of miniature circuit breakers