You want a part that fits your project. You do not want just any part. Customized terminal blocks help you match your needs. They fit your electrical and mechanical needs. With these solutions, you can organize circuits well. You can add more connections in small spaces. These choices make wiring simple. They help keep things safe. They make fixing problems easier. You can pick features you want. You may choose protection or test points. Your system will work well and be easy to fix. Using customized terminal blocks saves time. It helps you get ready for changes later. Your connections stay strong.

Key Takeaways

- Pick a manufacturer with lots of experience and good help. Make sure they have the right safety certifications. This helps you get safe and reliable custom terminal blocks.

- Choose terminal block types that match your wiring needs. You can pick screw, spring clamp, or push-in terminals. Look for modular and marking options. These make installation and maintenance easier.

- Think about electrical, mechanical, and environmental needs. Check things like current rating, voltage, wire size, vibration, and temperature. This helps you pick the best terminal block for your project.

- Use engineering support and prototype services to test your design early. This can save you time and money before you start full production.

- Look at quality assurance, certifications, and testing reports. This helps you get safe, strong, and high-performing custom terminal blocks.

Choosing Manufacturer

Picking the right manufacturer is very important. It helps your terminal block customization work well. You need a partner who listens to you. They should make customer-specific products you can trust. This part tells you what to check when picking a manufacturer.

Experience & Expertise

Look for manufacturers with good engineering skills. These companies know how to make terminal blocks that last in hard places. They can make samples fast and keep costs low. Experts say you should look for these things:

- Make sure quality is high for safety and reliability.

- Pick terminal blocks that follow safety rules like UL or IEC.

- Choose companies with a good history of long-lasting products.

- Think about special designs, like test terminal blocks, for extra needs.

Companies like BlockMaster Electronics, Curtis Industries, and TE Connectivity have custom solutions. They have many years of experience.

Tip: Always see if the manufacturer does important tests and certifications.

Test Type / Certification Purpose / Description Salt Spray Test Checks if parts resist rust and keep good contact. Fire Behavior Certifications Makes sure materials pass fire safety rules like UL 94 and EN 45545-2. Glow Wire Test (IEC 60695-2-11) Tests how well materials handle heat and fire. Electrical, Mechanical, and Environmental Testing Checks if parts work under different stresses. Material Quality Controls Makes sure materials meet world industry standards.

Reputation & Support

You want a manufacturer with great support. Top companies give:

- Personal help and expert tips.

- Flexible design changes.

- Samples for testing.

- Technical papers and downloads.

- Help from start to finish.

- Easy ordering and shipping.

You also get online tools, CAD drawings, and help after buying. These things help you go from idea to finished terminal block easily.

Key Questions

Ask these questions when looking at manufacturers:

- Do they know how to make customer-specific products?

- What safety and quality certificates do they have?

- How fast can they make samples?

- What help do they give during and after making your product?

- Can you get technical info and samples before full production?

Picking the right manufacturer helps you feel calm. You know your terminal blocks will fit your needs and work well.

Customized Terminal Blocks Options

Types & Configurations

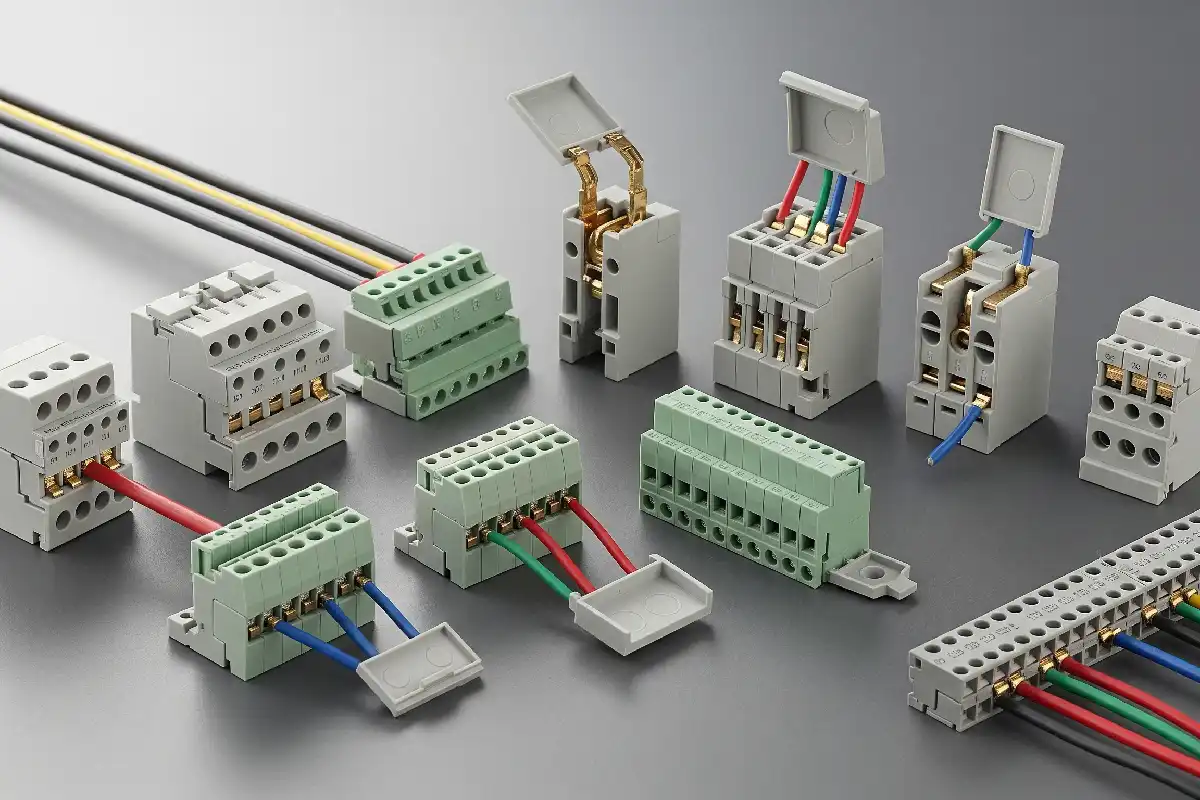

There are many types of customized terminal blocks. Each type works for different wiring jobs. Here are some common choices:

- Screw-type terminals make strong connections. You can use them with many wire sizes. They come in standard, spring-loaded, feed-through, horizontal, and vertical styles.

- Spring clamp terminals let you install wires fast. You do not need tools. These terminals keep wires tight, even if things shake.

- Push-in terminals help you put wires in quickly. You do not need to strip or twist wires. These terminals save time when you are busy.

- Other types include IDC, wire wrap, and solder terminals. These are used for special jobs in electronics and control systems.

- Modular designs let you group terminals together. You can put them on DIN rails, PCBs, panels, or other surfaces.

- Materials can be plastic, metal, ceramic, or composite. You can pick materials for heat, rust, or vibration protection.

- Smart terminals have sensors and digital communication. You can check connections as they work.

You see these choices from Phoenix Contact, Weidmüller, TE Connectivity, WAGO, and Molex. Today, small, light, and modular terminals are popular. These work well with smart technology and IoT.

Modular & Marking Features

Modular features help you keep wires neat. You can change your system easily. Marking features make it easy to tell wires apart. You can use colored housings or printed labels. These features help you avoid mistakes and save time.

Clear marks and modular designs help you work faster. You can find each terminal and wire quickly. This means fewer mistakes and faster fixes.

Here is a table that shows what modular and marking features do:

| Feature/Benefit | Explanation |

|---|---|

| Space-saving | You can fit many wires in a small space. |

| Enhanced organization | Multi-level terminals help you keep circuits apart. |

| Reduced wiring errors | Colors and numbers help you avoid mistakes. |

| Time-saving installation | Clear labels make wiring quick. |

| Flexibility and modularity | You can add or change terminals easily. |

| Reduced maintenance downtime | Neat layout and clear marks help you fix problems fast. |

You can use your own printers for marking. This helps you get terminals ready faster. You can also use special colors for different wires. These features help you with big systems that have lots of wires.

Accessories & Integration

You can add accessories to make terminal blocks better. These extras help you install and fix things more easily. Here are some common accessories:

- Cable entry systems let you put cables through boxes without taking things apart.

- Push-in wiring uses levers and buttons. You get connections that do not shake loose or rust.

- Side entry terminals save space and stop wires from bending too much.

- Small blocks with IO-Link networking help you watch devices.

- Pin and socket modules give strong connections.

- Screw barriers work well where things shake a lot.

- Locking parts, test ports, and cross-connections help with fixing and sharing power.

- Pluggable modular systems let you change or grow your setup easily.

- Built-in parts like fuses, circuit isolation, and signal conversion make fixing problems simple.

Push-in technology lets you put wires in easily. Test taps let you check circuits safely. Side entry saves space. Locking parts and cross-connections help you copy power. Disconnect blocks with test points make checking easy. Power blocks use clamping and push-in for fast wiring.

What customized terminal blocks offer for unique installations

Customized terminal blocks help with special wiring needs. You can pick materials like polyamide or thermoset plastics for tough places. You can choose connection types for quick setup or for places that shake. Barriers can be made for safety and space. Modular designs let you change your system. Heat-resistant designs help with high power and heat. You can add custom printing for names and logos. Machines can put together blocks for strong connections.

You see these benefits in many jobs:

- Aerospace: Terminals work in very hot, cold, or shaky places. Flame-retardant materials and locks keep things safe.

- Automotive: Modular terminals save money and make changes easy. Rust-proof and small designs fit electric cars.

- Medical Devices: Terminals meet strict rules and fit in small spaces.

- Industrial Machinery: Terminals keep control panels safe and reliable.

- Automation and Robotics: Terminals help with tricky wiring and changing setups.

- Buildings: Terminals organize wires for lights, heat, and power.

Here is a table with key uses:

| Industry Sector | Use Case Description | Key Advantages Provided by Customized Terminal Blocks |

|---|---|---|

| Industrial Machinery | Used in control panels and machine wiring | Better safety, reliability, and easy changes |

| Control Panels | Central wiring for automation and electrical control | Easy setup and fixing, neat wiring |

| Automation and Robotics | Wiring for complex automated systems | Strong, flexible, and easy to change |

| Commercial & Residential Buildings | Electrical panels for lights, heat, and power | Safety, neat wiring, easy to fix |

| Automotive and Transportation | Handling car electrical systems | Works well with shaking, rust-proof, small size |

| Aerospace | Electrical connections in planes and satellites | Very reliable in tough places, flame-proof, saves space |

| Medical Devices | Power and signal connections in medical equipment | Meets safety rules, precise, fits small spaces |

You can use customized terminal blocks to solve wiring problems in many areas. You get safe, strong, and flexible solutions for your projects.

Application & Design Needs

Customized PCB Terminal Block

When you design a customized pcb terminal block, you need to look at many details. You must choose the right housing material. Polyamide nylon works well for many uses because it is strong, resists chemicals, and meets fire safety rules like UL94V-0. Metal parts, such as pins and clamps, often use plated copper alloys. These metals help stop rust and keep the terminal working in hot or cold places. You can also pick the color of the housing, add shielding, or use special printing for easy wire marking.

Modern terminal blocks for PCBs come in small sizes. They fit tight spaces and help you save money. You can use modular designs to build the exact block you need. Some companies let you use online tools to pick the number of poles, pitch, and color. You can get a finished product fast. This helps you match your electrical, mechanical, and design needs.

Here is a table that shows what you should check when you pick a terminal block for your PCB:

| Design Consideration | Description |

|---|---|

| Current Rating | Pick a rating at least 150% higher than your system’s max current. |

| Voltage Rating | Make sure the block can handle your highest voltage, including surges. |

| Pole Count | Choose the number of circuits you need, from 1 to 24 or more. |

| Pitch | Select the right spacing between poles, such as 2.54mm, 3.81mm, or 5.0mm. |

| Wire Size/Type | Match the wire size and type to the terminal, such as stranded or single-core. |

| Wire-Entry Orientation | Decide if you want horizontal, vertical, or 45° entry for easy wiring. |

| Wire-Securing Method | Pick screw, push-in, or push button for the best connection. |

| Module Type | Use interlocking modules for flexibility or single-piece for strength. |

| Wire-to-Housing Method | Choose direct insertion or pluggable for easy changes. |

| Safety Ratings | Look for UL, IEC, and flammability ratings like UL94V-0. |

| Operating Temperature | Make sure the block works in your temperature range. |

| Usability Enhancements | Add custom colors, labels, or markings for easy setup and repair. |

Tip: Matching the right metals in your terminal block helps stop corrosion and keeps your connections strong.

Electrical & Mechanical Specs

You need to check both electrical and mechanical specs when you pick customized terminal blocks. These specs help you make sure the block fits your project and works safely.

- Terminal blocks accept many wire sizes. You can use American Wire Gauge (AWG) to pick the right size. Smaller AWG means a thicker wire.

- You can choose from screw clamps, spring clamps, insulation displacement connections (IDC), or tab connections. Each type works best for certain wires and spaces.

- Wire entry angles can be 45°, 90°, or 180°. Pick the angle that fits your panel or PCB layout.

- The number of contacts, or poles, and the pitch (distance between contacts) matter for your wiring plan.

- Pluggable terminal blocks let you disconnect wires fast for easy repairs.

- Both electrical and mechanical specs must fit your system’s needs and space.

Electrical specs also include current and voltage ratings. Always pick a terminal block that can handle more current than your system needs. This helps prevent overheating. The voltage rating must be higher than your highest system voltage. The pole count tells you how many circuits you can connect. The pitch affects how much space you need and how much voltage or current the block can handle. You must also match the wire type to the terminal. Stranded wires work well with screw terminals. Single-core wires fit push-in types.

Mechanical specs include the way you secure wires, such as with screws or push buttons. You can pick interlocking modules for more flexibility or single-piece blocks for more strength. Pluggable blocks help with fast changes and repairs.

Environmental Considerations

You must think about the environment where you will use your terminal blocks. Many things can affect how well your terminal works.

- Vibration and shock can loosen wires. Machines like vibratory feeders shake a lot.

- Humidity can cause rust or static. Places with boilers or chemicals have high humidity.

- Extreme temperatures, from freezers to furnaces, can crack materials or weaken connections.

- Corrosive substances, like acids or salt spray, need special coatings or sealed blocks.

- Dust and dirt from machines can block connections.

- UV light outdoors can weaken plastic. You need UV-resistant materials.

- Explosive dust, like sugar powder, needs special safety steps.

You can use corrosion-resistant metals and high-temperature plastics for tough places. Strong construction helps your terminal last longer. Some blocks use eco-friendly materials and meet rules like RoHS or REACH. You can add features like fuses or LEDs for extra safety and function.

Note: Always check if your terminal block can handle the worst conditions in your project. This keeps your system safe and reliable.

What to Expect from Engineering Teams

Engineering teams help you get the right customized terminal blocks for your job. They work with you and the manufacturer to solve design problems. You can ask for prototypes and test them before you order a large batch. Teams check every detail, from size to safety rules. They talk with you often to make sure the block fits your needs. Companies like Curtis Industries use strict quality checks and follow ISO rules. This helps you get a block that works well and lasts a long time.

Options for Small Dimensions, Prototypes, and Small Series

You have many choices if you need small or special terminal blocks. Some companies offer DIN rail enclosures for prototypes and small runs. You can ask for custom holes, printed numbers, color-coded covers, and special labels. You can mix covers and add vents for cooling. Other companies let you change the pitch, number of poles, or add coding pins. You can get custom prototypes and small batches fast. This helps you test your design before you order a large number.

🛠️ Quick tip: Use prototype services to check your design. This saves time and money before full production.

Order & Quality Process

Quotation & Review

When you want a custom terminal, you ask for a quote. You tell the company what you need. They give you a price and how long it will take. The manufacturer looks at your drawings and details. You check if the design fits your needs. You want clear answers and quick replies. You see if the company can make what you want. You also ask for samples to test.

Lead Time & Tracking

You need to know how long making your terminal will take. Lead time changes if your design is hard or you need many pieces. You follow your order from start to finish. Many companies have online tools to help you track each step. You get news about making, shipping, and delivery. Fast lead times help you finish your project on time.

Tip: Ask for updates and tracking numbers often. This helps you plan and avoid waiting too long.

Quality Assurance

You want your custom terminal to be safe and work well. Manufacturers use good insulation to protect against electrical problems. They follow rules like UL, IEC, and ISO 9001. These rules show the company cares about safety. You look for machines that make parts with care. This helps stop mistakes and makes the terminal work better.

Here is a table with important certifications and checks:

| Certification / QA Procedure | Description and Importance |

|---|---|

| UL | Makes sure electrical products are safe and work well. |

| CE | Shows the product meets European safety and health rules. |

| RoHS | Limits bad substances to help the environment. |

| ISO 9001 | Focuses on making quality products. |

| ISO 14001 | Shows the company cares about the environment. |

| AS9100, MIL-STD | Needed for planes and military jobs. |

| Rigorous Testing Protocols | Includes tests for electricity, heat, and strength. |

Custom Terminal Testing

Testing is very important in this process. You want to see tests for electricity, heat, and strength. These tests find problems early and make sure your terminal works in hard places. You check what other customers say and read case studies. Good reviews mean the company makes strong products. You look for companies that keep getting better and do research.

- Some problems are hard designs, special rules, and high costs.

- You can fix these by picking companies that do research and make things faster.

Note: Always check the company’s credentials and ask for test reports before you buy.

You can get good results if you follow clear steps for terminal block customization. Use these steps as a simple checklist:

- Figure out what your project needs for electricity and the environment.

- Pick the terminal block type and features that fit best.

- Make sure everything matches, and check ratings and supplier certificates.

- Talk clearly with your manufacturer.

Getting updates and giving feedback often helps you stop mistakes and keeps your project moving forward.

| Key Takeaways for Customizing Terminal Blocks | Explanation |

|---|---|

| Voltage rating, Number of poles, Current rating | Make sure these match your project for safety and good work |

| Corrosion resistance | Helps the terminal last longer in tough places |

| Installation & Maintenance | Makes setting up and fixing things easier |

If you use these smart steps, you know what to expect and help your project do well for a long time.

FAQ

What is a customized terminal block?

A customized terminal block is a connector made for your project. You get to pick the size, shape, and features you want. This makes your wiring fit better and keeps it safe.

What features can you add to a terminal block?

You can add colors, special labels, test spots, or extra covers for safety. You can also choose materials that do not rust, get hot, or shake loose.

What industries use customized terminal blocks?

Factories, cars, planes, medical tools, and buildings all use customized terminal blocks. Each place needs special features to stay safe and work well.

What should you check before ordering a custom terminal block?

Check the current and voltage ratings, number of poles, and wire connection type. You also need to look at safety certificates and test results.

What are the benefits of using a custom terminal block?

Custom terminal blocks save space and help you make fewer wiring mistakes. They make repairs easier, keep things safe, and help your system last longer.

See also

Importing circuit breakers from China to the Middle East

Why Choose Customized Terminal Blocks for Unique Electrical Needs

How many wires can be connected to one terminal block

How to Pick the Ideal Terminal Block for Your Project

What You Should Know About Terminal Blocks and Their Other Names