The full name of ACB in electrical systems is Air Circuit Breaker (ACB). This device keeps electrical circuits safe. It stops power when there are faults. This helps stop equipment damage and downtime. Knowing the ACB Electrical Full Name and what it does helps keep things safer. It also makes operations more reliable.

- Industries use ACBs because they can stop big faults fast.

- Smart ACBs have sensors that watch things in real time. This helps stop power loss in important places.

Key Takeaways

- ACB means Air Circuit Breaker. It is a device that protects electrical circuits. It stops power when there are faults. This helps prevent damage and keeps systems safe.

- Air Circuit Breakers use air to stop electrical arcs. They can handle high currents. This makes them good for low-voltage systems. You can find them in factories, buildings, and data centers.

- ACBs have smart features like sensors. They also have remote monitoring. These help find problems early. They make maintenance easy. This keeps systems reliable.

- ACBs can handle bigger currents than other breakers. They give stronger protection. But they need more regular checks and care.

- Using Air Circuit Breakers makes things safer. It lowers fire risks. It also helps eco-friendly power systems. They do not use harmful chemicals.

ACB Electrical Full Name

What Does ACB Stand For

The ACB Electrical Full Name means Air Circuit Breaker. In electrical engineering, this is the official name for a type of circuit protection device. The short form “ACB” is known in electrical codes around the world.

- ACB stands for Air Circuit Breaker. Engineers and electricians everywhere use this term.

- This short form helps people find the device quickly in technical papers and diagrams.

Air Circuit Breaker Definition

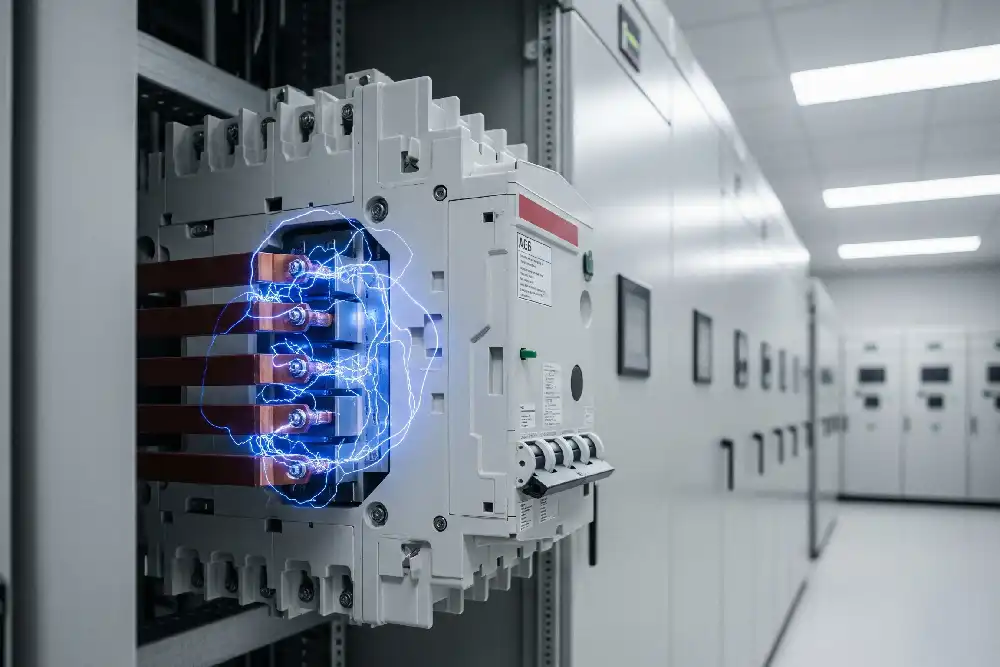

An Air Circuit Breaker is a switch that uses air to stop the arc. It keeps circuits safe from too much current, short circuits, and earth faults. The ACB Electrical Full Name is found in technical books and standards. This shows it is important in power systems. The device stops current by opening its contacts when it finds a problem. It uses air to put out the arc that happens. This makes ACBs good for low-voltage jobs and keeps people safe in many places.

Note: The ACB Electrical Full Name is always used in official papers to talk about this kind of circuit breaker.

Main Function

The main job of an Air Circuit Breaker is to stop electricity when something is wrong. These problems include too much current, short circuits, and faults. The ACB Electrical Full Name shows its job: to break the circuit using air to stop the arc.

Air Circuit Breakers keep equipment safe and lower fire risk by stopping bad currents. They also separate circuits to stop damage from stray currents and different metals. New ACBs use better materials and smart tech to work better and last longer.

More people use Air Circuit Breakers now because they are reliable and give better protection in factories, businesses, and homes. Companies keep making ACBs better, so they work well and are easy to fix.

How ACBs Work

Operation Mechanism

An Air Circuit Breaker has many important parts. These parts help control and protect electrical circuits. The operating mechanism opens and closes the contacts. This happens when the breaker finds a problem. The contacts move apart, and an arc appears between them. The trip mechanism finds issues like too much current. It makes the breaker open to stop the problem. The base frame holds all the parts in place.

| Component | Description |

|---|---|

| Poles | Fixed and moving contacts, bushings, isolating contacts, pneumatic blow nozzles |

| Arc Chutes | Blowout coils, splitter plates, runners, insulating plates, magnet pole pieces |

| Operating Mechanism | Controls opening and closing of contacts |

| Base Frame | Structural framework supporting all components |

The breaker also has disconnects for safe connections. It uses overcurrent protection devices to keep circuits safe. All these parts work together to make sure circuits stay safe and work well.

Arc Extinguishing

When the contacts in an Air Circuit Breaker move apart, an arc forms. The arc chute guides the arc and splits it into smaller pieces. This cools the arc and helps put it out fast. Magnetic blow-out assemblies use coils to make a magnetic field. This field pulls and moves the arc into the chute. This makes it easier to cool and stop the arc.

- The arc starts when contacts move apart.

- Arc chutes split the arc, making it last less time.

- Magnetic blow-out assemblies help move the arc to cool it faster.

- Mechanical devices stretch the arc, so it goes out more easily.

Tip: Arc extinguishing devices help stop damage and danger by putting out the arc safely.

Voltage Range

Air Circuit Breakers work best in low-voltage systems. Most ACBs can handle up to 690 volts. This makes them good for homes, businesses, and low-tension networks. Vacuum Circuit Breakers are used for higher voltages from 11 kV to 33 kV.

| Aspect | Air Circuit Breaker (ACB) | Vacuum Circuit Breaker (VCB) |

|---|---|---|

| Voltage Rating | Up to 690 volts (low voltage) | 11 kV to 33 kV (medium voltage) |

ACBs use air to put out arcs. This makes them cheaper and easy to take care of for low-voltage jobs. Their design helps them work safely in many places, like big buildings and factories.

Applications

Typical Uses

Air Circuit Breakers are important safety devices in electrical systems. They stop high currents to keep people and equipment safe. The table below shows where ACBs are used and what they do:

| Application Area | Description |

|---|---|

| Industrial Facilities | Protect medium-voltage systems from too much current and faults. This keeps power safe. |

| Commercial Buildings | Give protection for medium-voltage. Handle big currents and help things work well. |

| Data Centers | Keep medium-voltage systems safe. Make sure power does not stop and protect from faults. |

| High-Voltage Transmission | Air blast ACBs control arcs in high-voltage lines. This stops power cuts. |

| Medium-Voltage Industrial Plants | Air chute and magnetic blowout ACBs help control arcs and protect medium-voltage systems. |

Note: ACBs are used in low and medium-voltage networks. This makes them good for many electrical systems.

Industries

Many industries use Air Circuit Breakers to keep their electrical systems safe. The list below shows who uses ACBs most and why:

- Industrial and commercial places

- Buildings with lots of current

- Factories with big motors, generators, and transformers

- Places that need steady power

Industries with big machines and high energy needs pick ACBs. These breakers protect against electrical problems. They help stop expensive repairs or replacements. ACBs are safer than oil circuit breakers and need less fixing. They can handle big currents and stop arcs well. This makes them a top choice for factories. These features help keep circuits safe and working for a long time. This is important for places that need power all the time.

ACB vs Other Breakers

ACB vs MCCB

Air Circuit Breakers and Molded Case Circuit Breakers do different jobs. ACBs protect big machines in factories. MCCBs are better for homes and stores. They are different in size, how much current they handle, and how often you need to check them.

| Attribute | MCCB (Molded Case Circuit Breaker) | ACB (Air Circuit Breaker) |

|---|---|---|

| Ratings | Up to 3,200A | Up to 6,300A |

| Size | Compact, fits small panels | Large, handles heavy loads |

| Application | Residential, commercial, secondary protection | Industrial plants, substations, primary protection |

| Cost | Lower, simple design | Higher, complex construction |

| Maintenance | Basic inspections, minimal upkeep | Regular servicing, more components |

ACBs have more ways to protect circuits. They can delay, act fast, or ground faults. They also talk to other devices. MCCBs mostly stop too much current or short circuits. ACBs work with bigger currents, from 400A to 6,300A. This makes them good for main power panels. MCCBs work with 10A to 800A. They protect smaller parts of the system.

Tip: ACBs are bigger and need more care. MCCBs are smaller and easier to use.

MCCBs cost less, from $500 to $2,000. ACBs start at $1,000 and can be over $5,000. MCCBs do not need much care. ACBs need to be checked and fixed often.

ACB vs VCB

Air Circuit Breakers and Vacuum Circuit Breakers put out arcs in different ways. ACBs use air. VCBs use a vacuum inside a sealed part.

| Feature | Vacuum Circuit Breaker (VCB) | Air Circuit Breaker (ACB) |

|---|---|---|

| Arc Quenching Medium | Vacuum | Air |

| Voltage Range | 3.3kV to 36kV | Up to 1kV |

| Speed of Operation | Very fast (2–5 cycles) | Moderate (8–12 cycles) |

| Interrupting Capacity | High | Moderate |

| Size and Weight | Compact, lighter | Larger, bulkier |

| Maintenance | Low, sealed chamber | Moderate to high, exposed to air |

| Lifespan | Up to 30 years | 10–15 years |

VCBs are best for medium-voltage places like power plants. They stop problems fast and need little care. ACBs are good for low-voltage jobs and places that need to save money. They need more checks and do not last as long.

Note: VCBs last longer and work better in tough places. ACBs are better for low-voltage and cheaper setups.

Features and Benefits

Key Advantages

Air Circuit Breakers have many good points for electrical systems. Makers build ACBs to use air around us. This air is always there and does not run out. Because of this, ACBs are good for the planet and simple to care for. Workers can reach and change parts like arc chutes and contacts. They do this during planned checkups. This helps the breaker last longer.

- ACBs work with very high currents and big faults. This makes them great for large buildings and factories.

- Some types have trip units with microprocessors. These let you set trip points for special protection.

- You can connect ACBs to smart building systems and grids. This lets people watch them from far away, plan fixes, and control loads.

- ACBs can break big fault currents fast. This keeps equipment safe.

- The way they are built makes checking and fixing easy. This means less time lost and lower costs.

- ACBs do not use oil or chemicals. This makes them safer for nature.

Tip: Smart ACBs with digital tools help places watch energy use and fix things before trouble starts.

| Advantage | Description |

|---|---|

| High Current Capacity | Handles big fault currents in factories |

| Flexible Protection | Trip curves and time delays can be changed |

| Smart Integration | Lets you watch and fix from far away |

| Easy Maintenance | Parts are easy to reach and fix |

| Eco-Friendly | Uses air, no bad chemicals |

Safety Features

New Air Circuit Breakers have special safety parts to stop electrical dangers. These parts keep people, machines, and buildings safe from common problems.

| Safety Feature | Functionality | Key Characteristics |

|---|---|---|

| Overload Protection | Stops breaker if load gets too high. This stops fires and overheating. | Uses heat trip; settings can be changed. |

| Short Circuit Protection | Stops power right away if there is a short. | Uses magnet trip; can handle big faults. |

| Ground Fault Protection | Finds wrong ground paths and stops breaker. This stops shocks and harm. | Sensitive finding; works with RCDs. |

| Arc Fault Protection | Spots and stops bad arcs. | Smart sensors; uses AFCI tech. |

| Under/Overvoltage Protection | Stops breaker if voltage is not safe. | Senses voltage; uses surge protectors. |

| Remote Monitoring & Control | Lets you check status and control from far away. | Digital links; can trip and reset from a distance. |

| Mechanical Interlocks | Stops unsafe moves by making sure steps are done right. | Key locks; locking parts. |

| Diagnostic & Testing | Helps with checks and keeps breaker healthy. | Self-checks; built-in test tools. |

Note: Air Circuit Breakers follow world safety rules like IEC 60947-2. Their design makes sure only the closest breaker trips when there is a fault. This keeps other circuits working and cuts down on lost time.

Doing regular checks and tests helps ACBs stay safe and work well for a long time. Places that use these features have fewer risks and better work flow.

Knowing the ACB Electrical Full Name helps people pick the right safety device. Air Circuit Breakers have strong safety parts and can handle lots of current. They are easy to fix and keep working well. These breakers help meet safety rules in places like factories and data centers. They also work in big office buildings.

- ACBs stop problems like too much current or short circuits.

- Their design makes fixing them fast and keeps them working well.

Picking Air Circuit Breakers helps power move safely and easily in low and medium-voltage systems.

FAQ

What is the main difference between an ACB and other circuit breakers?

An Air Circuit Breaker uses air to stop arcs. Other breakers use things like molded cases or a vacuum. Each breaker works best for certain voltages and jobs.

What maintenance does an Air Circuit Breaker need?

Workers check the contacts and clean the arc chutes. They also test the trip parts. Doing this often keeps the breaker working well and makes it last longer. Regular checks help stop sudden problems.

What safety features do modern ACBs include?

Modern ACBs protect against too much current, short circuits, and ground faults. Many have remote checks, tools to find problems, and locks for safety. These features keep people and machines safe.

What voltage range can an ACB handle?

Most Air Circuit Breakers work in low-voltage systems up to 690 volts. Some special types can work with medium voltage. But ACBs are mostly used for low-voltage circuits.

What industries use Air Circuit Breakers most often?

Factories, big office buildings, and data centers use ACBs a lot. These places need strong protection for big electrical systems and important machines.

See also

Choose the appropriate ACB that suits your needs

MCCB and Air Circuit Breaker Comparison Guide

How Air Circuit Breakers and MCCB Stack Up

Pull type air circuit breaker AC690V