The price of distribution box depends on many factors. Type, material, size, and capacity all play a crucial role. Labor, permits, and additional features can also increase the price of distribution box. Basic plastic boxes found online may cost less than $1, while high-capacity or specialized units can reach thousands of dollars. Buyers should carefully consider each aspect before making a decision.

Key Takeaways

- The type and use of a distribution box change its price a lot. Pick one that matches what you need to save money and stay safe.

- The material is important. Plastic boxes are cheaper. Metal and concrete boxes last longer and protect better. They work best outside or in hard places.

- Bigger boxes with more space cost more to buy, ship, and store. Choose a size that fits what you need now and later.

- Labor, permits, and where you put the box can make it cost more. Plan ahead and check local rules to stop delays and extra costs.

- Extra things like safety features and system integration help the box work better but cost more. Think about what you need now and in the future.

Price of Distribution Box: Key Factors

Type and Application

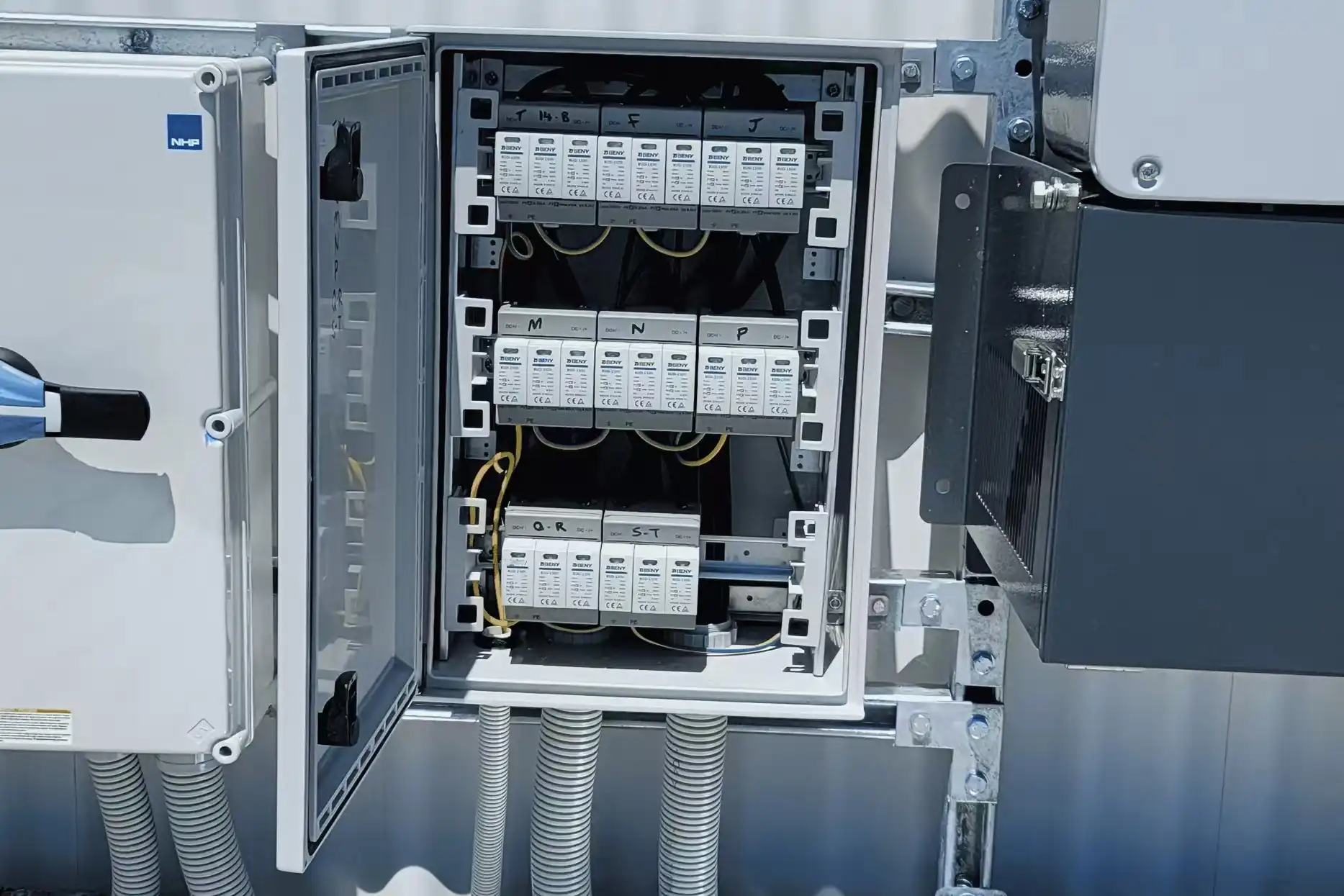

The type of distribution box affects how much it costs. Boxes for homes usually cost between $10 and $100 at stores like Amazon or Home Depot. Industrial electrical boxes are made for more circuits and higher voltages. These can cost from $200 to over $2,000. Septic distribution boxes are used in wastewater systems. They usually cost $20 to $150, depending on their size and how complex they are. Portable distribution boxes are used for events or building sites. These start at $50 and can go over $500 for stronger models.

What you use the box for also changes the price. People at home might pick a simple plastic or metal box for inside. Factories need boxes that are safer and can hold more circuits, so they cost more. Septic systems need boxes that do not rust or get damaged by water. Generator transfer switches are a special kind of distribution box. They can cost $300 to $1,500, depending on what they do and how much power they handle.

Tip: Buyers should pick the right type and use for their distribution box. This helps them save money and keeps their system safe.

Material Choices

The material of the box changes how strong it is and how much it costs. Plastic boxes are light and cheap. Many simple ones cost less than $10 on Amazon or eBay. Metal boxes are made from steel or aluminum. They protect better and last longer. Metal boxes start at about $20 and can cost hundreds for big or weatherproof ones. Concrete boxes are used in septic systems. They are the strongest but also the most expensive. These can cost $100 to $400 or more, especially if they are custom made.

Here is a table that compares materials and their usual prices:

| Material | Typical Price Range | Common Applications |

|---|---|---|

| Plastic | $1 – $50 | Home, light-duty, septic |

| Metal | $20 – $500+ | Industrial, outdoor, heavy |

| Concrete | $100 – $400+ | Septic, underground |

You should pick the material based on where you will use the box. Outdoor or factory places often need metal or concrete for safety and to last longer.

Size and Capacity

How big the box is and how much it can hold changes the price. Bigger boxes with more spaces for circuits or higher flow cost more. This is because they use more materials and are harder to make. For example, a small 4-circuit box may cost $15. A big 40-circuit panel can cost more than $300. Septic boxes that can handle more water or have more outlets also cost more.

Online stores show that bigger and heavier items cost more to ship and store. This is true for distribution boxes too. The table below, using Walmart Fulfillment Services data, shows that larger and heavier items have higher costs:

| Item | Packaged Dimensions (LxWxH) | Unit Weight (lb) | Fulfillment Cost (USD) | Storage Cost (USD/month) |

|---|---|---|---|---|

| Mountain Bike | 49.0 x 7.7 x 26.4 in | 25.6 | 28.95 | 4.32 |

| Office Chair | 22.85 x 9.85 x 20.09 in | 36.3 | 16.95 | 1.96 |

| Queen Mattress | 43.0 x 17.0 x 17.0 in | 55.8 | 36.15 | 5.39 |

| Grill | 39.0 x 16.54 x 20.47 in | 71.2 | 38.55 | 5.73 |

This information shows that bigger and heavier distribution boxes cost more to buy, ship, and store. Online sellers often add these extra costs to the price, so buyers pay more in the end.

Note: When picking a distribution box, buyers should think about how much they need now and later. Buying one that is too big wastes money. Buying one that is too small can mean paying more to upgrade later.

Labor and Installation

Standard vs. Complex Jobs

Labor costs are a big part of the total price. Simple jobs, like swapping out a box or using an old outlet, are fast. These jobs usually take less than one hour to finish. Electricians charge a basic fee for these quick jobs. This fee is often between $80 and $100. Harder jobs, like adding a new circuit or upgrading a panel, take longer. These jobs need more skill and can last hours or all day.

Electricians charge $40 to $100 for each hour they work. General contractors might add 10% to 20% to the total bill. Equipment and materials make up 30% to 40% of the cost. Here are some usual labor and install prices:

- Putting in a new circuit: $250 to $900

- Upgrading an electrical panel: $1,300 to $4,000, based on size

- Adding new wiring: $7 to $10 for each foot

- Installing conduit: $4 to $8 for each foot

- Renting an excavator: $300 to $550 per day

- Digging trenches: $600 to $1,200, including work and tools

Note: Getting a 200-amp electrical service can cost $750 to $2,000. If you need to move the panel or change a lot of wires, it can cost over $4,000.

Site Conditions

Site conditions can change labor and install costs a lot. If there is hard rock underground, work can slow down. This means more time and money. If workers find toxic waste, the job may stop. Cleanup can be very expensive. When the site is tough, it is harder for workers to do their jobs. This makes the project slower.

Other things that raise costs are:

- Delays from bad weather or worker strikes

- Changes to the job because of things found on site

- Waiting for inspections or rules to be checked

These problems can make workers wait and slow down the job. This means the project takes longer and costs more. Planning ahead and checking the site can help avoid these problems and save money.

Permits and Regulations

Permit Fees

Local governments usually want you to get permits before you put in or change a distribution box. These permits make sure the work is safe and follows the rules. Permit fees can make the project cost more. In many cities, a basic electrical permit costs between $50 and $200. For septic distribution boxes, the permit fee is often $100 to $500. The price depends on where you live and how big the system is.

Some places have one set price. Others decide the fee by the job’s value or the kind of property. For example:

| Permit Type | Typical Fee Range |

|---|---|

| Electrical (residential) | $50 – $200 |

| Electrical (commercial) | $150 – $500 |

| Septic system | $100 – $500 |

Tip: Homeowners should ask their local building office before they start. If you skip permits, you might get fined or have to wait longer.

Compliance Costs

Compliance costs are the money you spend to follow all the rules. Electricians and contractors must do the job safely and meet quality standards. Sometimes, the rules mean you need special materials or more inspections. You may also need to hire certified workers. Each step can make the total price go up.

Some common compliance costs are:

- Using materials that meet code

- Hiring licensed electricians or plumbers

- Setting up and passing inspections

- Fixing things if inspectors find problems

If a project does not pass inspection, the owner might have to pay to fix it. This can slow down the job and cost more money. Sometimes, insurance will not pay for work that does not follow the rules.

Note: Following all the rules and getting the right permits keeps people and property safe. It also helps you avoid big problems later.

Extra Features and Customization

Safety and Capacity Upgrades

Many people want extra features for more safety and power. Safety upgrades can include surge protection, lockable covers, and tamper-proof parts. These help stop accidents and keep equipment safe from harm. Some distribution boxes have circuit breakers or ground fault protection built in. These upgrades can add $20 to $200 to the price, based on how complex they are.

Capacity upgrades let the box handle more circuits or more power. For example, a regular box may hold 8 circuits. An upgraded one can hold 24 or even more. Bigger capacity means you have room to add more later. This upgrade usually costs $50 to $300 more. Some companies make modular boxes, so you can add circuits when you need them. These choices give you more options but cost more at first.

Tip: Buyers should think about what they need now and in the future. Getting upgrades now can save money and problems later.

Integration Needs

Integration needs can change the total price a lot. When a business connects the box to other systems, the job gets harder. For example, a big company linked its warehouse, transport, and order systems. This made deliveries faster by 13% and cut labor costs by almost 10%. The technical work to connect systems and share data in real time adds to the cost.

Integration costs are not just the price of the box. They also include setup fees, training workers, keeping things running, and possible downtime. If a company customizes too much, it may pay more and have trouble upgrading later. For example, some businesses improved their work by linking systems, but they also had hidden costs like moving data and setup problems. These stories show that integration—customization, compatibility, and moving data—can raise the total cost of distribution boxes in a bigger system.

Note: Planning for integration early helps avoid surprise costs and makes sure the distribution box works well with other systems.

The cost of a distribution box can change for many reasons. People should look at the type, material, and size before buying. Labor, permits, and special features also matter. It is smart to compare different choices to get the best deal. Experts can help you know the real price for the box and putting it in. Where you put the box, rules, and upgrades can change how much you spend.

Tip: If you plan early, you can stop surprise costs and pick the right distribution box for your project.

FAQ

What is the main factor that increases the price of a distribution box?

Material and capacity are big reasons for higher prices. Metal or concrete boxes cost more than plastic ones. Bigger boxes that hold more circuits also cost extra.

Do all distribution boxes require professional installation?

Most electrical and septic distribution boxes need a licensed worker to install them safely. Doing it yourself might not follow the rules. It can also be unsafe or fail inspection.

Can buyers save money by choosing a smaller box?

A smaller box is cheaper at first. But it might not work for you later. Upgrading later usually costs more than picking the right size now.

Are permits always necessary for installing a distribution box?

Local rules decide if you need a permit. Most electrical and septic jobs need permits for safety and to follow the rules. If you skip permits, you might get fined or pay more.

The following information may be of interest to you

What Makes Distribution Boxes and Fuse Boxes Different

The cost to replace a 100 ampere circuit breaker panel

How to Replace the Distribution Panel and Wiring in Your Home

What Should You Know About Electrical Box Replacement Costs