You can use the a and b contacts of circuit breaker to check its state. These a and b contacts of circuit breaker help you monitor and control the breaker without needing to open the main panel. Utilizing the a and b contacts of circuit breaker enhances safety for everyone and reduces the risk of equipment failure. Recent studies show that monitoring the a and b contacts of circuit breaker provides real-time updates, allowing you to prevent prolonged power outages. This also helps protect your electrical system from damage. Many experts emphasize that understanding the a and b contacts of circuit breaker is crucial for maintaining safe and efficient electrical systems.

Key Takeaways

- ‘a’ contacts turn on when the breaker is closed.

- ‘b’ contacts turn on when the breaker is open.

- These contacts help us know if the breaker is on or off.

- Checking and testing ‘a’ and ‘b’ contacts often is important.

- This helps stop damage to equipment and keeps things safe.

- Using both contacts together gives better control and checks.

- It helps find problems faster and makes systems work better.

- Taking care of contacts, like cleaning and replacing them, is needed.

- This makes the breaker last longer and stops unsafe problems.

- Using these contacts in panels, alarms, and smart systems is good.

- It makes things safer and helps stop power loss and big problems.

Importance of a and b Contacts of Circuit Breaker

Role in Circuit Breaker Operation

You use a and b contacts of circuit breaker to check if your system is on or off. These contacts help you open or close the breaker. The ‘a’ contact lets electricity flow and stops it if there is a problem. The ‘b’ contact tells you if the breaker is open or closed. When the breaker opens, the ‘a’ contact stops the trip coil from working. The ‘b’ contact closes so you can safely close the breaker again. Relays and lights show you what is happening with the contacts. This helps you know the breaker’s position and avoid mistakes.

Contribution to Electrical Safety

These contacts help keep your system safe. How the contacts are made changes how fast they move apart during a problem. A 2024 study showed that single series contacts push away harder and move faster than parallel ones. At 625 A, the series type had 131.19% more push and 448.97% more turning force. This means the contacts break the circuit faster and protect your equipment. You can also check how far and fast the contacts move. These checks help you find problems early and stop dangerous failures.

Tip: Check your contacts often to keep your system safe.

Use in Control and Automation Systems

You use a and b contacts of circuit breaker in many automatic systems. These contacts send signals to alarms, control panels, and monitors. You can set up a light to show if the breaker is open or closed. In new systems, these contacts are in smart grids and factories. Engineers use the contact data to watch for problems and fix them before they get worse.

- Using these contacts gives you many good things:

- Updates right away

- More reliable systems

- Faster fixes for problems

- Better control of big systems

The right contacts and good checks make your system safer and work better.

‘a’ Contacts of Circuit Breaker

Definition and Basic Function

You use ‘a’ contacts, also called normally open auxiliary contacts, to know when a circuit breaker is closed. When you close the breaker, these contacts close too. This action lets current flow through the control circuit. The ABB technical manual explains that contacts in a breaker fall into three groups: arcing, auxiliary, and main contacts. The ‘a’ contacts belong to the auxiliary group. They help you make or break the circuit and keep the airflow inside the breaker steady. Eaton’s technical resources also describe how these contacts work with movable and stationary parts. They open and close the circuit, which protects your system from overcurrent and short circuits. You can trust ‘a’ contacts to give you a clear signal about the breaker’s position.

Note: ‘a’ contacts only close when the breaker is closed. This makes them important for safety and control.

How ‘a’ Contacts Operate

You see ‘a’ contacts change state as soon as you operate the breaker. When you close the breaker, the ‘a’ contacts close at the same time. This action sends a signal to your control system. Several performance metrics help you understand how these contacts work:

- Contact timing tells you the exact moment the contacts change state. This helps you keep all parts of the breaker in sync.

- Contact travel and speed show you how far and how fast the contacts move. You can measure stroke, opening speed, and rebound.

- Mechanical motion tests use special tools to check stroke, velocity, and overtravel. These tests help you spot problems early.

- Control circuit tests measure the current and voltage in the operating coil. You can see if the electrical and mechanical parts work well together.

- Dynamic Resistance Measurement (DRM) checks the resistance of the contacts while they move. This test shows you if the contacts have wear or damage.

You can use these tests to make sure your ‘a’ contacts work right every time.

Typical Applications of ‘a’ Contacts

You find ‘a’ contacts in many control and safety systems. You use them to:

- Show the breaker’s closed position on a control panel.

- Trigger alarms or lights when the breaker closes.

- Start or stop other equipment based on the breaker’s state.

- Send signals to remote monitoring systems.

In modern systems, you often see ‘a’ contacts used with automation and smart grids. You can connect them to programmable logic controllers (PLCs) to automate switching and safety checks. When you combine a and b contacts of circuit breaker, you get a full picture of the breaker’s status. This helps you make better decisions and keep your system safe.

🛠️ Tip: Always test your ‘a’ contacts after maintenance to make sure they send the right signals.

‘b’ Contacts of Circuit Breaker

Definition and Basic Function

You use ‘b’ contacts to know if the breaker is open. These are also called normally closed auxiliary contacts. When you open the breaker, the ‘b’ contacts close. This lets current flow in the control circuit only when the breaker is off. ‘b’ contacts give a clear signal that power is not flowing. They help you make sure it is safe before you work or reset things.

Note: ‘b’ contacts close only when the breaker is open. This helps you avoid mistakes and keeps things safe.

How ‘b’ Contacts Operate

‘b’ contacts change right away when you move the breaker. When you open the breaker, the ‘b’ contacts close and send a signal. This tells you the breaker is open and safe. The way ‘b’ contacts work has a few steps. A new study used fast cameras to watch the contacts. The study found four main steps before the arc goes out. It starts with a fast arc and ends when the arc stops. Scientists also used special microscopes to look at the contacts. They saw that more current and bigger gaps make the contacts wear out faster. You can use this to check your ‘b’ contacts and plan repairs.

Dynamic Resistance Measurement (DRM) gives even more details. DRM shows how the contacts move, the voltage drop, and the current. This helps you find problems like worn or bent contacts. You can test timing, static resistance, and dynamic resistance together. This saves time and gives a better look at your contacts.

- DRM records how contacts move and the voltage drop.

- Fast cameras show how the arc forms and moves.

- Many finger contacts with springs help spread the current and lower damage.

- Faster contact speed and less arc energy help stop current better.

- The arc’s shape, like single or double columns, changes how well the breaker works.

- Longer arcs cause more wear and make contacts weaker.

You can use these facts to keep your ‘b’ contacts working longer.

Common Uses of ‘b’ Contacts

You see ‘b’ contacts in many safety and control systems. They help you know when it is safe to work. You can use them to:

- Show the breaker is open on a control panel.

- Turn on alarms or warning lights when the breaker opens.

- Stop machines from starting if the breaker is open.

- Send signals to remote systems for safety checks.

You can use ‘b’ contacts with a and b contacts of circuit breaker to see the full breaker status. This helps you make good choices and keep things safe.

How well ‘b’ contacts work depends on many things. The table below shows what affects them and how to keep them working:

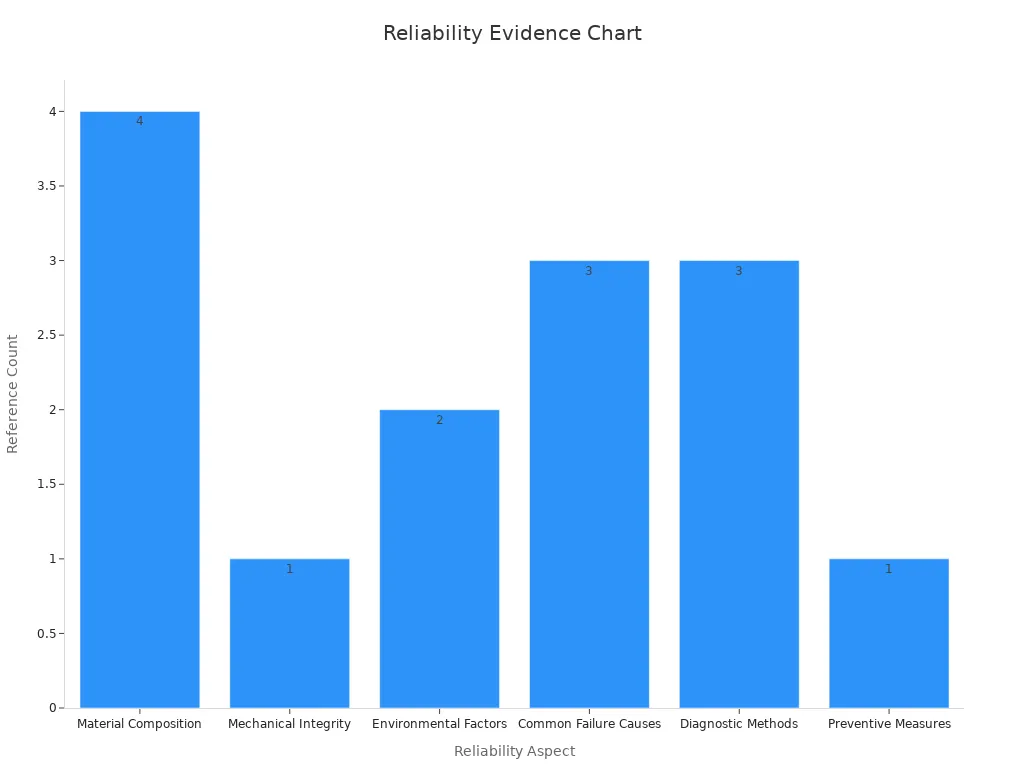

| Aspect of Contact Reliability | Key Points | Supporting References |

|---|---|---|

| Material Composition | Silver alloys, tungsten, and silver-tungsten blends last longer and work better | IEEE 2019; Materials Science Journal 2019; Springer 2020; Wiley 2018 |

| Mechanical Integrity | Good alignment and pressure are needed for the contacts to work well | Li et al., 2023 (Complex Intell. Syst.) |

| Environmental Factors | Water, dust, and chemicals make contacts wear out faster; places near the sea or factories are riskier | Antler, M. (1987), Springer publication |

| Common Failure Causes | Wear from arcs and stress; too much heat from high resistance; stress from bad alignment | IEEE 2019; ecampusontario.pressbooks; Li et al., 2023 |

| Diagnostic Methods | Look at the contacts, use heat cameras, test with electricity, and check how they work | ISA.org; ANSI NETA MTS 2023; Schneider Electric blog |

| Preventive Measures | Do regular checks, use good materials, control the environment, follow rules, and replace parts early | Industry best practices summarized in Checon blog |

🛠️ Tip: Check your ‘b’ contacts often, especially if your system is in a tough place. Regular checks help you find problems early and keep things safe.

Comparing a and b Contacts of Circuit Breaker

Key Differences

There are big differences between ‘a’ and ‘b’ contacts. They work in different ways and wear out differently. Both types use Dynamic Resistance Measurement (DRM) to check their health. You measure the resistance of main and arcing contacts for each one. Boxplot charts help you find problems like broken parts. If the resistance numbers change a lot, the contacts might be worn out or broken.

Here is a table that shows how experts compare these contacts:

| Parameter / Aspect | ‘a’ Contacts (CB-A) | ‘b’ Contacts (CB-B) | Notes / Interpretation |

|---|---|---|---|

| Measurement Method | DRM | DRM | Both use the same test method |

| Key Parameters Extracted | Main and arcing contact resistance | Main and arcing contact resistance | You get these from DRM curves |

| Degradation Variation | Some ‘a’ contacts show high wear | Some ‘b’ contacts show high wear | Wear can differ even in the same breaker |

| Visual Inspection Correlation | Confirms high wear in some ‘a’ contacts | Confirms wear differences in ‘b’ contacts | Visual checks match resistance findings |

| Mechanical Defect Indicator | Large resistance range means possible defects | Large resistance range means possible defects | Erosion and small gaps can hide problems |

| Usage Impact | High load use causes more main contact wear | Usage changes wear patterns | Main and arcing contacts may not wear out at the same rate |

A new study found that the shape of each contact changes how the arc moves. ‘a’ contacts often have two bright spots that grow but do not join. ‘b’ contacts have bright spots that are closer together. The shape and slots in the contacts change the magnetic field and the arc’s path. This means each contact type handles current and lasts a different amount of time.

Tip: Check both ‘a’ and ‘b’ contacts for wear. Each one can break in its own way.

When to Use Each Type

Pick ‘a’ or ‘b’ contacts based on what your system needs. The table below helps you choose:

| Contact Type | Intended Use Case | Operational Life | Fault Interruption Capability | Notes on Performance Metrics and Scenarios |

|---|---|---|---|---|

| a (Circuit Breakers) | Fault protection and rare switching | ~10,000 operations | Yes, designed for faults | Good for overload or fault protection; used in homes and factories |

| b (Contactors) | Frequent on/off switching, no faults | Up to 1,000,000 operations | No, not for faults | Best for regular switching; not for breaking fault currents |

Use ‘a’ contacts to know if the breaker is closed and ready. These are good for safety and control in homes and factories. Use ‘b’ contacts to know if the breaker is open and safe to touch. These are best for safety checks and stopping machines from starting by mistake.

The a and b contacts of circuit breaker help you see the full breaker status. Using both makes your system safer and more dependable.

Practical Applications of a and b Contacts of Circuit Breaker

Real-World Scenarios

You can find these contacts in many places. Factories use control panels to watch machines. When the breaker closes, the ‘a’ contact starts a conveyor belt. If the breaker opens, the ‘b’ contact turns on a warning light. This tells workers it is safe to check the machine. In power plants, these contacts send signals to alarms and remote systems. This helps people act quickly if something is wrong.

Many companies test their systems with these contacts. The table below shows how different businesses fixed problems and got better results:

| Company | Problem Found | Testing and Tools Used | Results and Good Ideas |

|---|---|---|---|

| Every.org | Two buttons on donation page confused people | Split into two pages, one button each; watched sessions | More donations by 26.5%; using session replays with other tools helps learn more |

| Bannersnack | Not enough people signed up on landing page | Used heatmaps to see clicks; tried bigger, brighter button | Sign-ups went up 25%; testing with heatmaps helped improve design |

| Turum-burum | People left checkout form because it was hard | Used surveys, session replays, heatmaps; made form easier | Conversion up 54.68%; more money per user; fewer people left the page |

| Swiss Gear | Many left the site on phones | Changed mobile menu; talked to users | Bounce rate down 8%; people stayed 84% longer; talking to users gave more ideas |

| Re:member | Not many credit card forms filled from partners | Watched sessions, click maps; made form easier to read | More forms filled, up 43% from partners, 17% overall; session replays and error checks helped |

These stories show that testing and watching your system helps a lot. You can use these ideas to make your own system better.

Best Practices for Use

You should always use safe steps with breaker contacts. These tips help keep your system working well:

- Check the breaker for damage before using it.

- Learn where the controls are on your breaker.

- Make sure the power is off with the right tool.

- Use the breaker the way the maker says.

- Wear the right safety gear and follow safety rules.

- Listen and look for anything strange when using it.

- Check the breaker after use to see if it worked right.

- Clean and check the breaker often. Change parts if needed.

- Test the contacts after fixing anything.

- Write down all checks and repairs.

- Keep learning about breakers and how to fix them.

🛡️ Tip: Check your system often and keep learning. This helps you find problems early and stay safe.

If you follow these steps, your breaker contacts will work well. Your system will run smoothly and safely.

You have learned that ‘a’ and ‘b’ contacts are different.

‘a’ contacts tell you when the breaker is closed.

‘b’ contacts let you know when the breaker is open.

Good contacts help your power stay on and protect equipment.

- Many businesses use online tools to find problems fast.

- Well-made contacts and regular checks stop power loss.

- Automatic systems help find issues and keep things working.

Always plan for these contacts and check them often to keep your system safe.

FAQ

What is the main difference between ‘a’ and ‘b’ contacts?

You use ‘a’ contacts to show when the breaker is closed. You use ‘b’ contacts to show when the breaker is open. Each contact gives you a clear signal about the breaker’s position.

Can you use both ‘a’ and ‘b’ contacts together?

Yes, you can use both contacts together. This setup gives you a full view of the breaker’s status. You can improve safety and control by using both types in your system.

How often should you check the contacts?

You should check the contacts during regular maintenance. Many experts suggest testing them every six months. If your system works in a harsh place, check them more often.

What problems can worn contacts cause?

Worn contacts can give false signals. You might think the breaker is open or closed when it is not. This can lead to unsafe work or equipment damage.

Do you need special tools to test these contacts?

You can use a multimeter to test basic contact function. For deeper checks, you may need tools like a dynamic resistance tester. Always follow safety rules when testing.

The following information may be of interest to you

Which RCCB Type is Right for You? Type A vs Type B

Why is Type A AC RCD not suitable for electric vehicle charging equipment?

The frame size of a 500 ampere circuit breaker

What is the recommended breaker size for Line 12 wiring