To test the automatic transfer switch safely, follow the manufacturer’s instructions. Always use the right safety equipment. You should use the switch every month. Do a full system test once a year. Most failures happen because of loose wiring, corrosion, or overloading. Regular checks and maintenance help you find these problems early. Some jobs, like a full load run or infrared checks, need a qualified professional. Always get ready and check each step for the best results.

Key Takeaways

- Always turn off all power before testing. Wear the right safety gear to protect yourself and your equipment.

- Test your automatic transfer switch every month. Do a full system test once a year. This keeps backup power ready.

- Use both manual and electrical tests to check the switch. Look at voltages and indicator lights for any problems.

- Check, clean, and tighten connections often. This stops failures from dirt, loose wires, or rust.

- Only trained or certified professionals should do hard tests or repairs. This keeps everyone safe and the system working well.

Safety Precautions

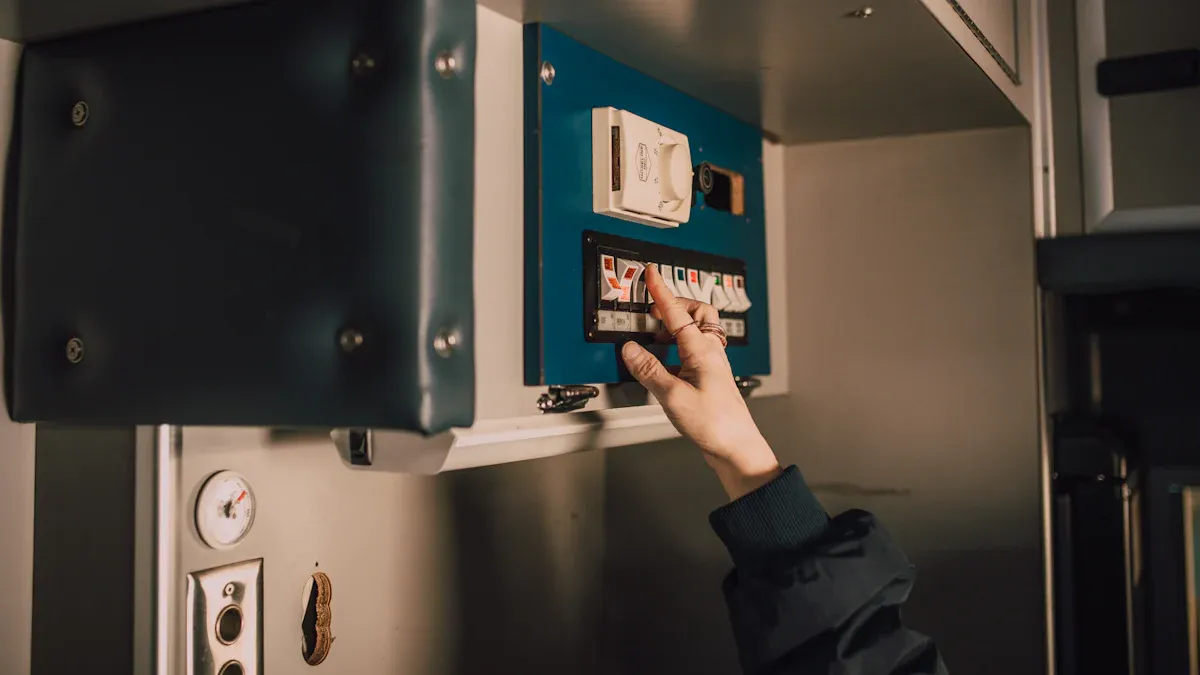

Disconnect Power

You must turn off all power before you test or fix your automatic transfer switch. This keeps you safe from electric shock and stops damage to equipment. Turn off the main utility power and the backup generator. Most manuals say to turn off the generator set before you open the ATS. This stops the generator from starting by mistake. If you do not do this, you could get badly hurt or even die. Your equipment could also break. Checking often and turning off power helps you find loose wires, rust, or heat damage early.

Tip: Never think a circuit is off. Always use a voltage tester to make sure the power is off before you touch any wires or terminals.

Use PPE

You need to wear personal protective equipment (PPE) when you work on an ATS. This means you should use insulated gloves, safety glasses, and flame-resistant clothes. PPE keeps you safe from electric shock, burns, and flying pieces. You should also block off the area to keep others safe. Only trained people should be in the work area. Many accidents happen when people do not use PPE or let untrained people near the equipment. Using PPE and keeping the area safe lowers the chance of getting hurt.

- Insulated gloves keep your hands safe from electric shock.

- Safety glasses protect your eyes from sparks or flying pieces.

- Flame-resistant clothes help stop burns.

Review Instructions

You should always read the manufacturer’s instructions before you start. Each ATS model has its own steps for safe testing and fixing. The manual tells you how to check for heat, shaking, and dirt. It also explains how to clean the unit and what to do if you see damage. You need to follow all rules for monthly and yearly tests. Many standards, like NFPA 110 and UL 1008, say you must check and test often. These rules help your ATS work well and stay safe. If you do not follow the instructions, your equipment could break, stop working, or you could get in trouble.

Note: Make sure both power sources are ready before you start any test. This helps you finish all checks without stopping.

Test the Automatic Transfer Switch

Testing the automatic transfer switch is the most important part of making sure your backup power system works when you need it. You should follow each step carefully to avoid mistakes and keep your equipment safe. This section explains how you can test the automatic transfer switch using both manual and electrical methods. You will also learn how to check voltages and indicator lights to confirm everything works as it should.

Manual Test

You can test the automatic transfer switch by following these steps. This process helps you see if the switch moves power from the main source to the backup generator and back again.

- Close the generator set’s enclosure door to keep yourself safe.

- Make sure both the normal (utility) and emergency (generator) power sources are working.

- Turn the isolation handle anti-clockwise to the test position. This action activates the transfer switch and turns on the normal source indicator light.

- Turn and hold the transfer control switch clockwise to the transfer test position. The engine start timer will run for about 15 seconds until the generator starts. The emergency power source light should turn on.

- Watch for the transfer switch to move to the emergency position. The emergency light will turn on, and the normal source light will turn off.

- After a short delay, the switch will return to the normal position.

- If you want to retransfer right away, turn the transfer control switch anti-clockwise to skip the retransfer delay. The normal source light will turn on, and the emergency light will turn off.

- Turn the isolation handle clockwise to the connected position.

- Wait for the generator to stop. It should run without a load for at least 5 minutes to cool down.

Tip: Listen for any strange noises or vibrations during the test. These can be signs of problems inside the switch.

This manual test lets you see if the automatic transfer switch works as it should. You can also check if the indicator lights respond at the right times.

Electrical Test

You should also test the automatic transfer switch using electrical checks. This helps you confirm that both power sources provide the correct voltage and that the switch moves the load safely.

- Use a voltmeter to check the voltage from both the utility and the generator. The voltage should be between 220 and 240 volts AC at either 50 or 60 Hz.

- Look at the indicator lights. The utility and generator lights should show that both sources are ready.

- Start a transfer test by starting the generator. Watch the switch move the load from the utility to the generator and then back again.

- Make sure the switch works smoothly and does not get stuck.

Note: Always use insulated tools and wear PPE when you test the automatic transfer switch with live power.

Testing the automatic transfer switch with electrical checks helps you find problems with voltage, wiring, or the switch itself.

Check Voltages and LEDs

You need to check the voltages and LEDs to make sure the automatic transfer switch is working correctly.

- Measure the voltage between each phase. The readings should match the rated voltage for your system.

- Watch the LEDs or indicator lights. They should show which power source is active and if the load is connected.

- Check the transfer time. Most open-transition switches take a short time, usually less than a second, to move the load. Closed-transition switches can transfer power without any break. Fast transfer times are important in places like hospitals or data centers, where even a short power loss can cause problems.

- Write down the results of your test. Keep a record of voltages, transfer times, and any issues you find.

Tip: If you see the lights flicker or the voltage drops too low during the test, you may have a problem with your power sources or the switch.

Testing the automatic transfer switch in this way helps you make sure your backup power will work when you need it. You can catch problems early and fix them before they cause a power outage.

Inspection and Maintenance

Visual Inspection

You should start every maintenance session with a careful visual inspection. Look for anything that seems out of place or damaged. Use this checklist to guide you:

- Check for dirt, dust, or moisture inside the switch box.

- Look for signs of wear and tear on all parts.

- Watch for carbon tracking, which looks like black marks near contacts.

- Inspect for cracks, corrosion, or burnt spots.

- Make sure all terminals are tight and not loose.

- Look for any signs of overheating, such as melted insulation or discoloration.

- Examine wiring for damage or broken insulation.

Tip: Use a thermal or infrared scanner to find hot spots. This tool helps you spot overheating without turning off the power. You should do this at least once a year, and always when the switch is under normal or heavy load.

Cleaning and Lubrication

You need to keep your automatic transfer switch clean to help it last longer and work better. Always turn off the power before you start cleaning.

- Use a soft-bristled brush or a dry, non-abrasive cloth to remove dust and grime. Do not use blowers, as they can push dirt deeper into the switch.

- Remove arc chutes or barriers if you need to reach the contacts.

- Clean electrical contacts to get rid of oxidation.

- Apply the right lubricant only to moving or current-carrying parts if needed. Be careful not to damage the contacts.

Note: After cleaning, check that all covers are back in place and the switch is set to auto mode.

Tighten Connections

Loose connections can cause big problems. You should check and tighten all electrical connections during each inspection.

- Use a torque wrench to tighten terminals. The correct torque values are listed on the WCR label on your ATS unit. Always follow the manufacturer’s instructions.

- Make sure all terminals and connectors look normal and have no discoloration.

- Inspect wiring and insulation for any signs of damage.

Schedule: Test your transfer switch and generator every month. Run the generator for at least 30 minutes at 30% load. Listen for odd noises and check that all parts work as they should. This routine helps you catch problems early and keeps your backup power ready.

Who Should Test

Routine Checks

If you have the right training, you can do simple checks. Facility engineers or operators usually do these jobs. Look for dirt, loose wires, or things that look too hot. But you should know what you can and cannot do. Only trained service technicians can do work inside the switch. Authorized dealers or distributors should do inside checks during scheduled maintenance. Always follow the manufacturer’s instructions and wear the right safety gear when you test the automatic transfer switch.

Tip: Make sure you are trained before you open or check the ATS. NFPA 110 and NFPA 99 say only qualified people should do maintenance and testing.

Here are the things you need to do routine checks:

- You must be trained, qualified, and know what you are doing.

- You should know the manufacturer’s safety rules and steps.

- You need to know how to find common problems.

| Common Issue | Explanation |

|---|---|

| Tripped Circuit Breakers | Power surges can trip breakers and stop the ATS. |

| Transient Voltage | Spikes or drops in voltage can hurt ATS parts. |

| Damaged Wires | Worn or broken wires can stop power from flowing. |

| Bad Controller | A bad controller can send wrong signals or switch wrong. |

Professional Testing

You need a professional for hard tests or yearly checks. Certified technicians have special training and lots of experience. Many have certificates from groups like EGSA. EGSA gives tests at Apprentice and Journeyman levels. These tests cover electricity, generators, voltage regulators, and how to test the automatic transfer switch. Some companies give factory training and certificates. This training has both class and hands-on work. It makes sure technicians know the rules and can fix tough problems.

Note: Professionals use special tools and follow strict safety steps. They can find hidden problems and fix them before you lose power.

When to Call an Expert

Call an expert if you see any of these problems:

- The ATS looks damaged or worn out.

- There is water inside or on the switch.

- You see too much heat, like burned or cracked parts.

- There is a lot of rust or damage on the contacts.

You can do simple checks and cleaning yourself. For bigger problems, you need a trained electrician or someone with ATS training. If you do not call an expert, you could have power failures, safety risks, big repair bills, or even legal trouble. Experts use smart ways like predictive maintenance and remote monitoring to keep your system safe and working well.

Test the automatic transfer switch often to make sure your backup power works well and stays safe. This helps you find problems early and makes your equipment last longer. It also helps you follow safety rules.

- Write down what you do each time you test or fix the switch.

- Keep manuals and important papers in a place you can get to easily.

- Make a plan for when to check and clean the switch.

If you see a problem or need a harder test, ask a professional for help. Keeping good notes helps if you need to use your warranty or fix problems later.

Choose ONESTOP automatic transfer switch: With over 20 years of manufacturing experience, international certification assurance, and excellent quality, we help you comprehensively improve circuit safety protection.

FAQ

How often should you test your automatic transfer switch?

You should test your automatic transfer switch every month. This keeps your backup power ready. You should also do a full system test once a year. Write down each test in your maintenance log.

What signs show your ATS needs service?

Look for warning lights, strange noises, or a burning smell. If you see rust, loose wires, or melted parts, call a professional. These signs mean your switch may not work right.

Can you test an ATS without shutting off power?

You can do some checks with power on, like looking at indicator lights. For most tests, you must turn off power. This keeps you safe from electric shock. Always follow the manual.

What tools do you need to test an ATS?

You need a voltmeter, insulated gloves, and safety glasses. A torque wrench helps tighten connections. Use a thermal scanner to check for hot spots. Always use the right tools for each step.

Why should only trained people test an ATS?

Testing an ATS can be dangerous. Only trained people know how to stay safe and spot problems. They follow safety rules and use the right tools. This keeps you and your equipment safe.

The following information may be of interest to you

How to Perform Maintenance on Air Circuit Breakers in 2025

How to use ATS in conjunction with a generator

How to Safely Install an ATS for Backup Power

What Are Automatic Transfer Switches and Their Key Functions