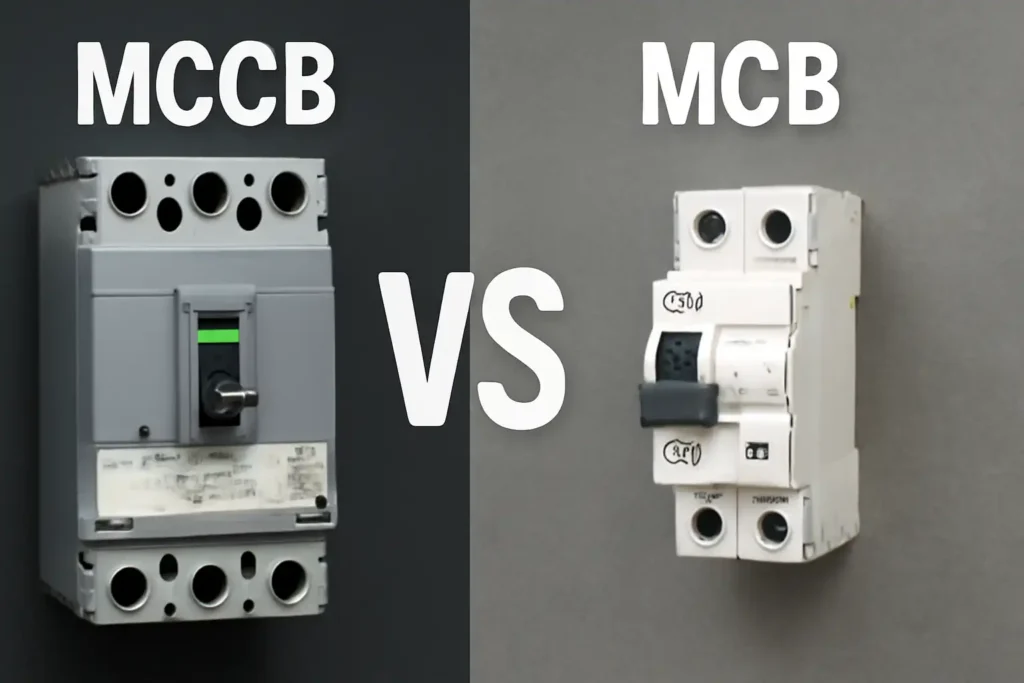

When protecting circuits, both MCCB (Molded Case Circuit Breaker) and MCB (Miniature Circuit Breaker) serve distinct purposes. MCCB is designed to handle higher currents and is commonly used in industrial applications, while MCB is suited for lower currents, making it a perfect fit for residential settings.

Here’s how MCCB and MCB differ:

-

MCB can handle currents ranging from 6A to 63A, whereas MCCB is capable of managing currents from 10A to 1600A.

-

The breaking capacity of MCB is limited to 15kA, while MCCB can support breaking capacities of up to 50kA.

-

In terms of short circuit protection, MCCB can protect against currents up to 100kA, significantly exceeding MCB’s limit of 10kA.

These distinctions highlight that MCCB is ideal for large systems, while MCB is more appropriate for home use.

Key Takeaways

-

MCCBs work well in factories and handle currents up to 1600A. MCBs are better for homes, managing currents from 6A to 63A.

-

Pick MCCBs for adjustable settings and handling fault currents up to 50kA. They are dependable for complicated systems.

-

MCBs are small and simple to install. They are great for homes and small businesses, protecting against overloads and short circuits.

-

Think about your circuit’s needs when choosing a breaker. MCCBs are flexible for high-power use, while MCBs are cheaper for daily use.

-

Check current ratings and breaking capacity to make sure the breaker is safe and works well.

Detailed Comparison of MCCB and MCB

Functionality and Purpose

MCCB and MCB have different jobs in circuit protection. An MCB, or miniature circuit breaker, keeps small circuits safe from too much current or short circuits. It has fixed settings, so it shuts off power if the current goes over a set limit. This makes it great for homes and small businesses with low electrical needs.

MCCB, or molded case circuit breaker, is made for bigger systems. It lets you adjust the settings to match your circuit’s needs. This makes MCCBs perfect for factories or places with high and complicated electrical use.

MCBs are best for homes and small businesses. MCCBs work well for factories and other big systems.

Size and Design

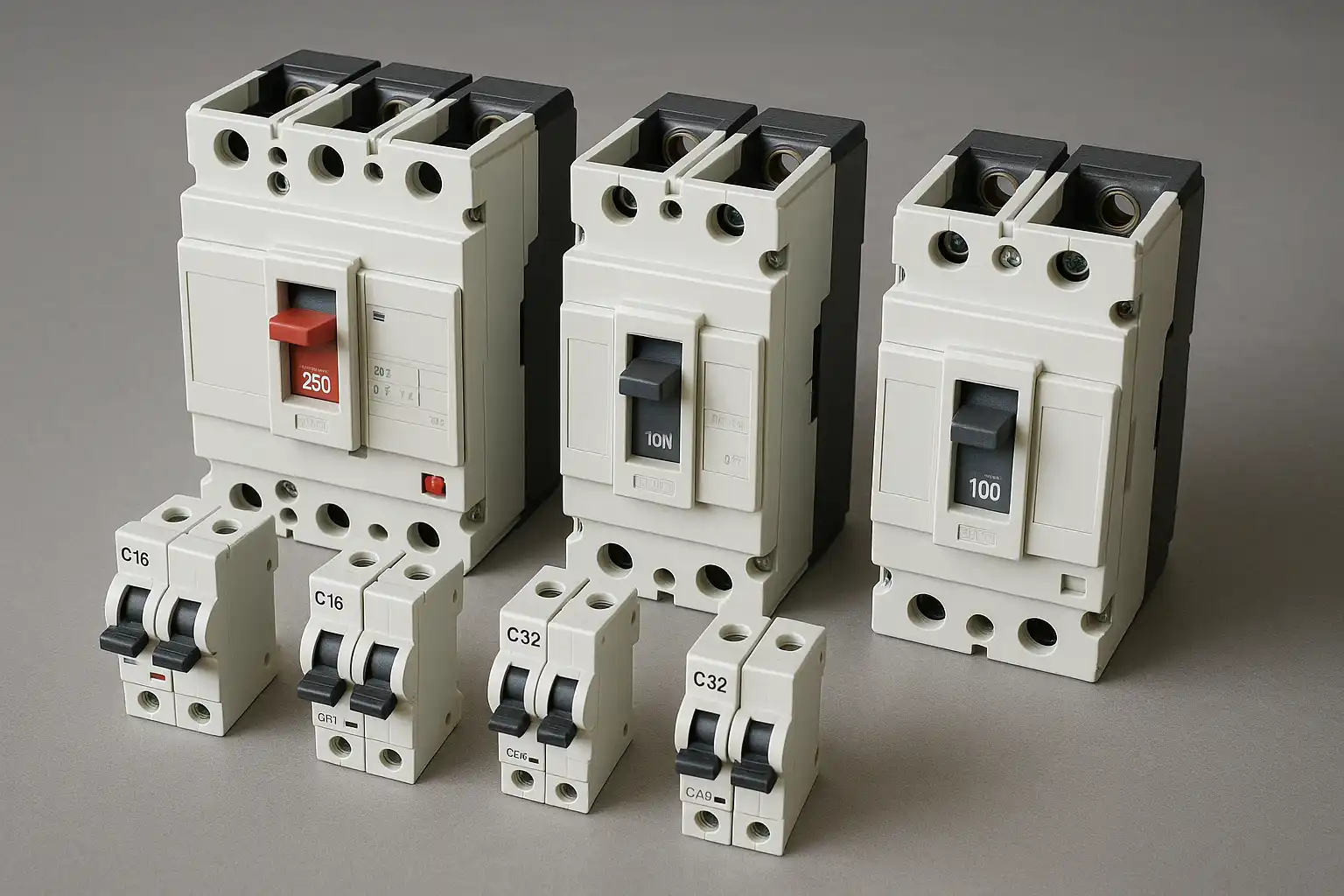

MCCBs and MCBs are different in size and design. These differences decide where and how they are used.

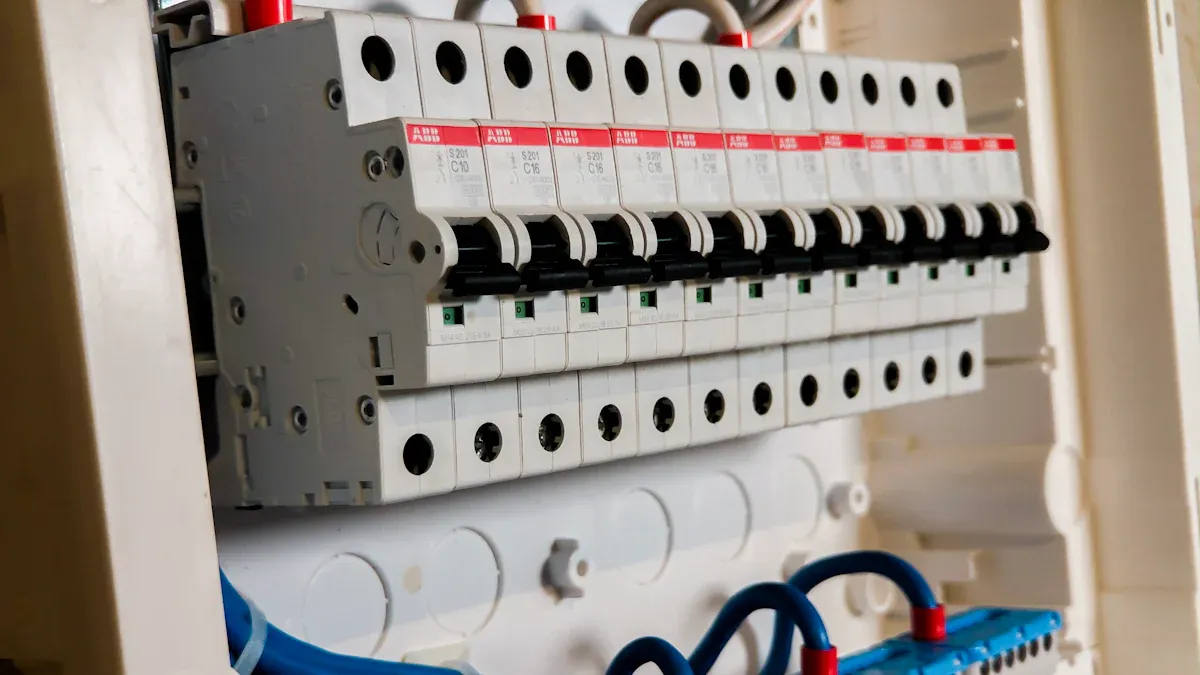

MCBs are small and light. Their compact size works well in homes or small industries with limited space. You can easily place them in small panels or boards. Their simple design helps them fit into smaller circuits without trouble.

MCCBs, however, are bigger and stronger. They are built to handle higher currents, so they need a tougher design. Though smaller than air circuit breakers (ACBs), MCCBs are about three to four times larger than MCBs. This size allows MCCBs to have adjustable settings and extra safety features, making them great for factories and businesses.

Here’s a quick comparison of their size and use:

|

Type |

Size Comparison |

Application Context |

|---|---|---|

|

MCCB |

About three to four times smaller than ACB |

Best for high current needs in industries |

|

Smaller than MCCB |

Perfect for homes and small industries |

The designs of MCCBs and MCBs match their uses. MCBs are simple with fixed settings, making them easy to use. MCCBs have a more advanced design with adjustable settings, letting you change them for different circuits.

Tip: Use an MCB for small circuits at home. For bigger circuits in factories, an MCCB is better.

Advantages and Limitations of MCCB and MCB

Advantages of MCCB

MCCBs are very useful in industries needing strong circuit protection. Their closed design keeps dust, water, and dirt out. This makes them last longer and work well in tough conditions. MCCBs are also dependable. They protect against too much current, short circuits, and ground faults with little upkeep.

Another big benefit is handling sudden high currents. This is important for machines like motors that need extra power when starting. MCCBs can handle these power surges without shutting off, keeping machines running smoothly.

|

Advantage |

Description |

|---|---|

|

Durability |

Closed design keeps MCCBs safe from dust and water, lasting longer. |

|

Dependability |

Protects from overcurrent, short circuits, and ground faults with little upkeep. |

|

High Inrush Current Handling |

Manages sudden high currents, great for machines like motors. |

Tip: Use MCCBs for factories needing strong and adjustable circuit protection.

Advantages of MCB

MCBs work great for homes and small businesses. They are small, easy to set up, and need little care. Their main job is to stop overloads and short circuits. This keeps the electrical system and people safe.

MCBs are becoming more popular. In 2022, the AC MCB market was worth $2.2 billion. By 2032, it may grow to $3.8 billion, increasing by 5.5% yearly. This shows how much they are used in homes for safe and affordable circuit protection.

Note: MCBs are best for protecting home circuits safely and cheaply.

Limitations of MCCB

MCCBs have some downsides. They are big, so they don’t fit in small spaces. They also cost more than MCBs, which can be a problem for tight budgets. Plus, MCCBs are harder to install and fix. You need trained workers, which can raise costs over time.

Reminder: MCCBs are strong but may not fit small spaces or budgets.

Limitations of MCB

MCBs work well for homes but have some downsides. These should be considered before using them for circuit protection.

-

Limited Current Capacity

MCBs can only handle small currents, usually between 6A and 63A. This makes them unsuitable for circuits needing higher currents. For factories or heavy electrical loads, MCBs won’t provide enough protection. -

Fixed Settings

MCBs have fixed trip settings that cannot be changed. This means they can’t adjust to circuits with changing electrical needs. This lack of flexibility can be a problem for some systems. -

Lower Breaking Capacity

MCBs can only handle fault currents up to 15kA. They may fail during severe short circuits, which could damage your electrical system. This makes them less reliable for high fault currents. -

Not Suitable for Industrial Use

MCBs are made for homes and small businesses, not factories. They don’t have the strength or features needed for industrial systems. For example, they can’t handle high inrush currents or protect against ground faults.

Note: For circuits with high currents or complex systems, use an MCCB. It offers better safety and reliability.

Knowing these limits helps you pick the right breaker. Always check your circuit’s needs before choosing an MCB.

Choosing Between MCCB and MCB

Factors to Consider

When picking between MCCB and MCB, think about key factors. These help ensure the breaker fits your circuit’s needs. Each factor affects safety, efficiency, and reliability.

-

Current Ratings

The breaker should handle the current without tripping too often. For higher currents, MCCBs are better because they have adjustable settings and higher capacity. -

Interrupting Capacity

The breaker must stop fault currents safely without damage. MCCBs can handle bigger fault currents, making them great for factories. -

Physical Design

Look at the size and type of breaker. MCBs are small and fit in home panels. MCCBs are stronger and work well in industries. Fixed types are easy to install, while withdrawable ones are easier to maintain. -

System Coordination

Breakers should work well with other devices to isolate faults. MCCBs have adjustable settings, which help in complex systems. -

Added Features

Check if you need extra parts like switches or shunt trips. MCCBs typically include multiple functional configurations to meet special application requirements -

Breaking Capacity

Choose a breaker that can handle fault currents in your system. MCCBs are better here, as they can manage higher fault levels. -

Number of Poles

Match the poles to your circuit. Single-pole MCBs are common in homes. Three- or four-pole MCCBs are used in industries.

|

Description |

|

|---|---|

|

Current Ratings |

Ensure the breaker handles the load without frequent trips. |

|

Interrupting Capacity |

The breaker must safely stop fault currents without damage. |

|

Physical Design |

Pick fixed or withdrawable types based on space and maintenance. |

|

System Coordination |

Ensure breakers work well with other devices to isolate faults. |

|

Added Features |

Check for extra parts like switches or shunt trips if needed. |

|

Trip Settings |

Adjustable settings allow changes for specific circuit needs. |

|

Breaking Capacity |

Choose a breaker that handles fault currents in your system. |

|

Number of Poles |

Match poles to the circuit for proper protection. |

Tip: Use MCBs for homes. For factories, MCCBs offer more flexibility and power.

Practical Scenarios

Real-life examples can help you decide between MCCB and MCB. Here are some situations:

-

Residential Applications

For homes, MCBs are the best choice. They are small, affordable, and handle lower currents. For example, to protect lights or small devices, an MCB rated 6A to 63A works well. -

Industrial Applications

Factories need MCCBs. They manage high currents from big machines and have adjustable settings. For instance, motors needing high starting power run smoothly with an MCCB. -

High Fault Current Environments

In places with high fault currents, MCCBs are a must. They handle severe short circuits safely. For example, in a factory with heavy loads, MCCBs manage fault currents over 50kA. -

Critical Systems Requiring Maintenance

If quick repairs are needed, use MCCBs with withdrawable designs. These are easy to replace, keeping critical systems running. -

Environmental Considerations

The location matters. MCBs work indoors in clean spaces. MCCBs are better for dusty or humid areas. For example, enclosed MCCBs prevent leaks and hazards in tough conditions.

|

Description |

|

|---|---|

|

Short-Circuit Calculation |

Find fault current (Ik) using IEC 60909-0:2016. |

|

Selectivity Requirement |

Check if delayed tripping is needed; ACB works best. |

|

Maintenance & Continuity |

Use draw-out ACB for quick repairs in critical systems. |

|

Performance Margin |

If Ik exceeds MCCB’s Icu/Ics, use ACB. |

|

Environmental Factors |

Adjust for high temperatures using IEC 60890:2014. |

|

Smart Features |

Check if monitoring or remote control is needed. |

Note: Always check your circuit’s current, fault levels, and environment before choosing a breaker.

Picking between MCCB and MCB depends on what you need. MCCBs manage higher currents and can be adjusted, making them great for factories. MCBs are smaller with fixed settings, perfect for homes.

To keep systems safe and working well, think about key factors like load type, current rating, and fault handling. The table below explains these important points:

|

Factor |

Why It Matters |

|---|---|

|

Load Type |

Different devices need specific breakers for proper safety and function. |

|

Rated Current |

Breakers must match the current to avoid tripping or weak protection. |

|

Breaking Capacity |

Breakers must handle fault currents safely, above expected levels. |

|

Installation Method |

Choose breakers that suit the environment for safety and durability. |

Takeaway: Use MCCBs for factories or high-power needs. For homes or small setups, MCBs are safe and affordable.

FAQ

What is the main difference between MCCB and MCB?

MCCBs handle higher currents, up to 1600A, for factories. MCBs manage lower currents, from 6A to 63A, for homes.

What does “breaking capacity” mean in MCCB and MCB?

Breaking capacity is the highest fault current a breaker stops safely. MCCBs handle up to 50kA, great for industries. MCBs manage up to 15kA, perfect for homes.

What are the adjustable features in MCCBs?

MCCBs let you change trip settings for overcurrent and short circuits. This helps protect circuits with changing loads in factories. MCBs have fixed trip settings.

What type of circuit breaker should you use for a factory?

Factories need MCCBs for high currents, adjustable settings, and strong breaking capacity. These features protect machines and complex systems.

What makes MCBs suitable for residential use?

MCBs are small, affordable, and easy to set up. They stop overloads and short circuits, keeping home devices and people safe. Fixed settings make them simple to use.

Tip: Pick a breaker based on your system’s current and safety needs.

The following information may be of interest to you

Intelligent MCCB circuit breaker

The difference between AC MCB and DC MCB

Key factors to consider when choosing a molded case circuit breaker