When you purchase terminal blocks, you might overlook five common issues:

- Material compatibility

- Fixation and installation

- Electrical ratings

- Pitch and space

- Accessory and compliance

Missing these factors can lead to poor connections, causing overheating or even violating safety regulations. Loose wires, corrosion, and cramped spaces often result in failures or fire hazards. Pay close attention to these details when you purchase terminal blocks to ensure your electrical system remains safe and functions properly.

Key Takeaways

- Look at the materials in terminal blocks to stop rust and weak links, especially in tough places. – Make sure terminal blocks are tight so wires do not get loose, which can make things too hot or start fires. – Always use terminal blocks with the right power ratings and wire sizes for your system to keep things safe and working well. – Pick the right pitch size and plan space well so your wires fit and do not cause trouble. – Use the right extra parts and check for certifications to stay safe and follow rules.

Material Compatibility

When you pick terminal blocks, look at what materials are used. The housing and contacts are made from different materials. Material compatibility is important for how well your connections last. This matters even more in harsh places.

Dissimilar Metals

Using different metals in terminal blocks can cause trouble. If you connect copper and aluminum, a reaction called galvanic corrosion can happen. This reaction makes the connection weaker and raises electrical resistance. The terminal block might get hot or stop working.

- What happens with incompatible metals?

- Bad electrical contact happens because the metals react.

- The connection can get loose and power may cut out.

- You might see rust, cracks, or broken pieces.

- There is a bigger chance of short circuits and signal loss.

Tip: Always check which metals are in the terminal block and wires.

Corrosion Risks

Corrosion is a big problem, especially outside or in wet places. Water, temperature changes, and chemicals can hurt metal parts. This makes resistance go up and connections get weaker.

- When it gets hot or cold, metals move and make tiny gaps.

- Water and chemicals get in these gaps and start corrosion.

- Corrosion makes oxide layers that block electricity.

- Over time, you might see cracks, loose parts, or total failure.

Here is a table to show which materials fight corrosion best:

| Material | Corrosion Resistance | Common Use Environments |

|---|---|---|

| Copper | Moderate | Indoor, dry |

| Brass | Good | Industrial, moderate humid |

| Stainless Steel | Excellent | Marine, outdoor, chemical |

| Plastic (PA/PC) | Very High | Wet, chemical, outdoor |

Note: Good terminal blocks use tin, silver, or gold coatings. These coatings help stop corrosion and keep connections strong, even in tough places.

Fixation and Installation

When you buy terminal blocks, think about how you will put them in place. It is important to make sure they are fixed tightly. Many people forget about this step. If you do not fix them well, the connections can get loose. Loose connections can cause electrical problems or even be dangerous.

Poor Fixation

Poor fixation means the terminal blocks are not attached tightly. If they are not secure, they can move around. This happens a lot in busy machines or panels. When a terminal block moves, the wires inside can come loose. Loose wires can make resistance go up. This can cause overheating or even start a fire.

- Use strong materials like polyamide or thermoset plastics for long life.

- Put terminal blocks on DIN rails or panels for a steady hold.

- Pick the right wiring method, like screw, push-in, or spring clamp.

- Make sure there are barriers to stop short circuits.

- Find locking parts that keep the block still, even if things shake.

Tip: Always check if the terminal block fits tight and does not move after you put it in.

Vibration Resistance

Vibration is a big problem in places like factories, cars, or big machines. If terminal blocks cannot handle shaking, the connections can wear out fast. Vibration can cause fretting corrosion. It can also make screws or clamps get loose over time. This can lead to cracks, signal loss, or even total failure.

- Use terminal blocks with self-locking parts or spring-loaded contacts to keep wires tight.

- Pick strong materials like hardened steel screws or copper conductors.

- In places with lots of shaking, use ring terminals and good crimping tools so wires do not slip out.

- Support the mounting surface well and do not put all holes in a straight line to stop shaking.

Vibration resistance helps terminal blocks last longer. It also means you will not need to fix them as often. When you buy terminal blocks, always think about how well they can handle movement and stress.

Electrical Ratings

When you look at terminal blocks, electrical ratings are one of the most important things to check. These ratings tell you what the terminal block can handle safely. If you ignore them, you risk damaging your equipment or creating safety hazards.

Voltage and Current Limits

Voltage and current limits show the maximum power a terminal block can carry. If you go over these limits, you can cause overheating, insulation breakdown, or even fire. Terminal blocks must pass electrical tests for current flow and short-circuit current ratings (SCCR). These tests follow standards like NEC and UL. For example, some terminal blocks can handle short-circuit currents up to 100 kA. This helps keep your system safe during faults.

Here is what you need to know about voltage and current ratings:

- The current rating tells you the highest current the block can carry without getting too hot.

- The voltage rating shows the highest voltage the block can handle without breaking down or arcing.

- If you use more current than the rating, the block can melt or fail.

- Always check the manufacturer’s guidelines for safe operation.

- In industrial places, terminal blocks often need higher ratings than in homes. For example, some industrial blocks handle up to 25 A at 480 Vac.

- Standards like UL 1059 and IEC 60947-7-1 set the rules for these ratings.

Note: Exceeding these ratings can cause overheating, arcing, and even fires. Always choose a terminal block with ratings higher than your system’s needs.

Wire Size Match

Wire size is another key factor. Terminal blocks are made for certain wire gauges. If you use the wrong size, you can get loose connections or poor contact. This can lead to heat buildup and even fire.

- Terminal blocks fit specific wire gauge ranges for a secure connection.

- Wires that are too thin may slip out, causing loose connections.

- Wires that are too thick may not fit well, leading to high resistance and heat.

- The type of wire—solid, stranded, or flexible—also matters for a good grip.

- Using the right wire size helps keep the current and voltage within safe limits.

| Wire Gauge | Fits Terminal Block | Risk if Mismatched |

|---|---|---|

| Too Thin | No | Loose, slips out, sparks |

| Correct | Yes | Safe, secure connection |

| Too Thick | No | Poor contact, overheating |

Always match the wire size to the terminal block’s rating. This keeps your connections safe and reliable.

Pitch and Space

When you pick terminal blocks, pitch and space are very important. Pitch means the distance from one terminal’s center to the next. Space is about how much room you have in your panel or device. If you ignore these, you might have trouble fitting parts or wiring safely.

Pitch Size Mismatch

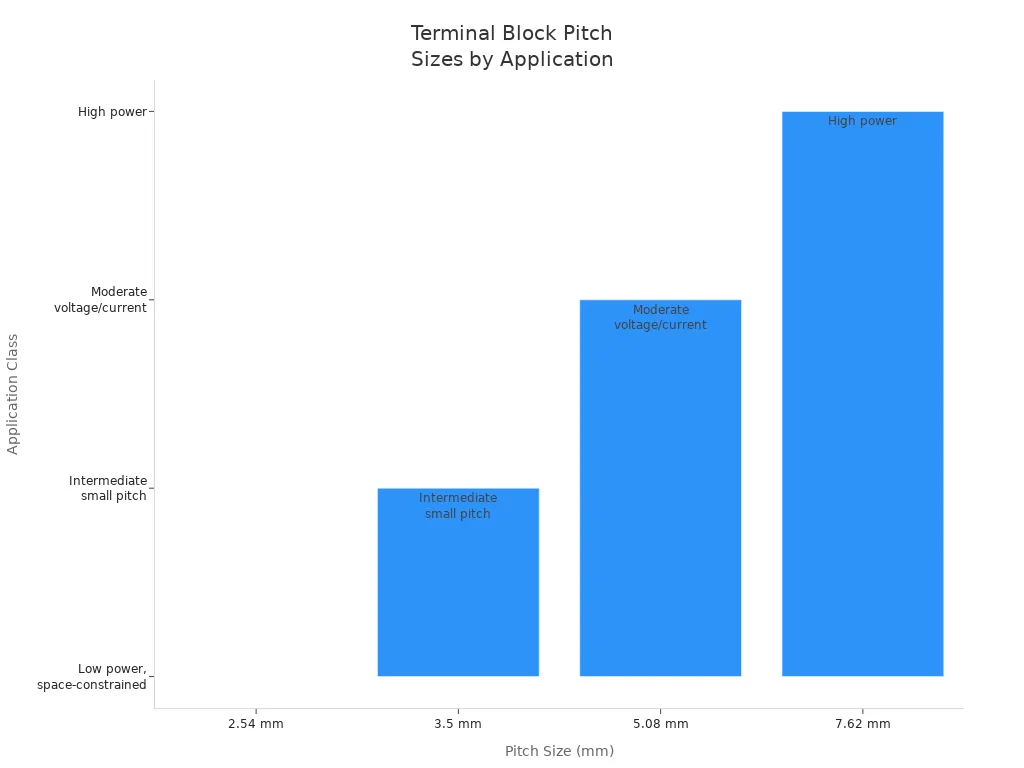

Pitch size mismatch happens if the pitch does not fit your design. Small pitch lets you put more connections in a small spot. But it can make wiring harder and lower the current the block can take. Large pitch gives more room for wires and can handle more current. But it takes up more space.

Some companies, like Phoenix Contact, make pitch sizes from 2.5 mm to 20 mm. Bigger pitch sizes usually mean higher voltage and current. For example, 2.54 mm pitch is good for small, low-power jobs. A 7.62 mm pitch works for bigger, high-power jobs. There is no strict rule, but bigger pitch means more power.

| Pitch Size (mm) | Typical Application Voltage/Current Class | Description |

|---|---|---|

| 2.54 | Low power, space-constrained applications | Small pitch lets you fit many connections but handles less current |

| 3.5 | N/A | Medium pitch, not as common, used in some small designs |

| 5.08 | Moderate voltage/current applications | Good middle size, used in home and car electronics |

| 7.62 | High power applications | Big wires for more current, used in factories and power systems |

Tip: Always check the pitch size before you choose a terminal block. This helps you avoid wiring problems and keeps your system safe.

Space Constraints

Space constraints are a big problem in panels and devices. Terminal blocks can use a lot of space, especially if you need many connections. Small pitch blocks save space but can be hard to wire. Large pitch blocks are easier to use but need more room.

- Small pitch lets you fit more connections but is harder to handle.

- Large pitch is easier to wire but uses more space.

- The way wires go into the block changes how much space you need.

- Modular and stackable terminal blocks help you organize wires and save space.

- IEC terminal blocks are smaller and let you fit more connections in a small area.

You need to balance space, how easy it is to use, and safety. Picking the right pitch and layout helps you use your panel space well without making wiring too hard.

Accessory and Compliance

When you buy terminal blocks, you need to think about more than just the block. Accessories and compliance are important for safety and following the rules. These things help your setup work well and meet industry standards.

Accessory Selection

What accessories do you need for your terminal block? Accessories help you connect, test, and protect wires. Each one has a special job. The right accessory depends on where and how you use it.

| Accessory Category | Description and Function |

|---|---|

| Plug-in Bridges | Share power between blocks with the same size. |

| Potential Bridges | Connect different levels in multi-level terminal blocks. |

| Bridge Bars | Let you test safely with bars and sliders. |

| Short-circuit Plugs | Make quick connections for testing or fixing. |

| Test Plugs/Adapters | Make it easy to test and fix circuits. |

| Marking Materials | Help you label terminals and stop wiring mistakes. |

| Pick-off Plugs | Add extra contacts with a latch that holds tight. |

| Function Plugs | Split signals, add fuses, or link parts together. |

| Safety Accessories | Give covers, warning signs, and sleeves for safety. |

You should pick accessories that fit your wire size and current needs. Always check if the accessory matches your terminal block and keeps things safe.

Tip: Pick accessories that make your system safer and easier to fix.

Standards and Certification

What rules and certificates should you look for? Terminal blocks must follow strict rules for safety and quality. Certifications like UL, CSA, and ISO show a product meets these rules. You will also see standards such as UL 1059, CSA C22.2 No. 158, and IEC 60947-7. These rules cover safety, how well it works, and how to install it.

- DIN VDE 0100-520 says you need covers for conductor connections.

- DIN VDE 0100-718 and VdS 2033 need special blocks for disconnecting neutral wires in risky places.

- ATEX and IECEx certifications are needed for dangerous or explosive areas.

Check the label or datasheet for these marks before you buy terminal blocks.

Purchase Terminal Blocks for Compliance

What does compliance mean for your project? Compliance means your terminal blocks are safe for your job. Medical devices need blocks that can handle water, chemicals, and shaking. Factories need strong blocks for tough places. Both must meet UL and IEC rules, but medical blocks have even stricter rules for patient safety.

When you buy terminal blocks, always make sure they have the right certificates for your job. This keeps your system safe and helps you avoid big problems.

When you buy terminal blocks, look out for five main problems. These are material compatibility, fixation and installation, electrical ratings, pitch and space, and accessory compliance. These issues can make your system unsafe. They can also cause weak connections and cost you more money later.

You should check the ratings and look for any damage. Think about where you will use the terminal blocks.

Ask experts for advice so you follow the rules and pick the right parts. If you only care about price, you might have to pay for repairs later. Choose carefully to keep your system working well and safe.

If you are looking for high-quality wiring terminals, welcome to browse our complete product line.

FAQ

What is the main purpose of a terminal block?

A terminal block lets you join two or more wires. It keeps wires neat and makes sure connections stay safe. You can also test, fix, or change circuits more easily with it.

What should you check before buying a terminal block?

Check the material, electrical ratings, pitch size, and what accessories you need. Always look for the right certifications for your project. This helps you stay safe and avoid wiring mistakes.

What happens if you use the wrong wire size in a terminal block?

Using the wrong wire size can make connections loose or too hot. Wires that are too thin might fall out. Wires that are too thick may not fit and can cause problems.

What accessories can improve terminal block safety?

Marking materials, covers, and test plugs help keep wiring safe and tidy. These tools also help you spot and fix problems faster.

What certifications should you look for on terminal blocks?

Look for UL, CSA, or IEC marks on terminal blocks. These marks show the product is safe and good quality. Always check for these marks before you buy.

See also

Why Choose Customized Terminal Blocks for Unique Electrical Needs

What Causes Terminal Failure in Electrical Terminal Blocks

How many wires can be connected to one terminal block

How to Pick the Ideal Terminal Block for Your Project

Features and Functions of DIN Rail Mount Terminal Blocks Explained