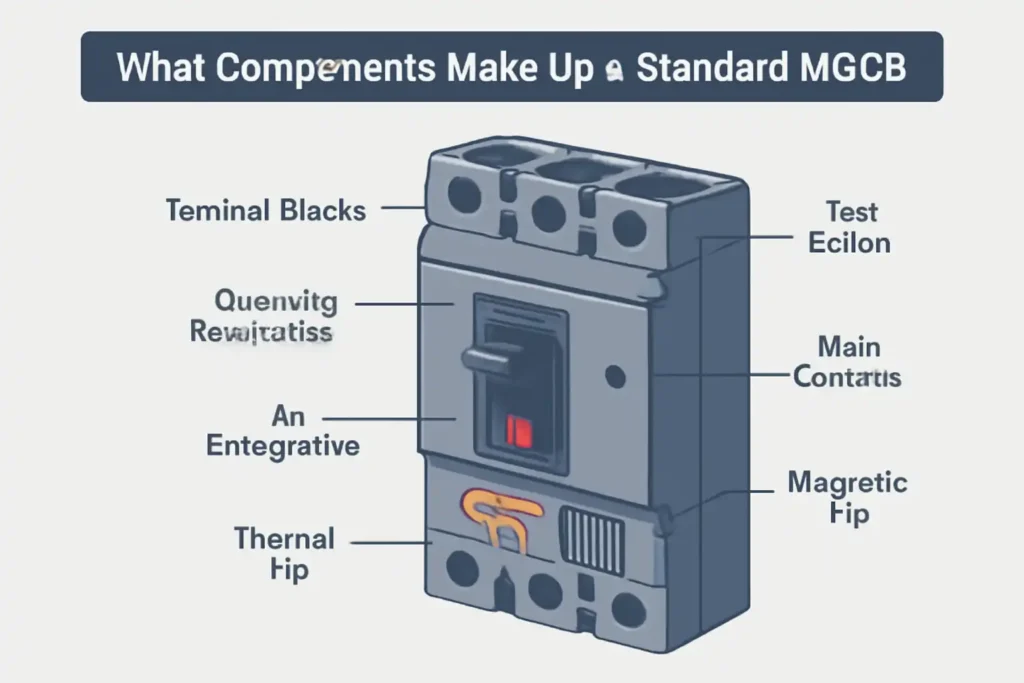

A standard molded case circuit breaker has many important parts. Contacts let electricity flow and can stop it. The thermal trip element finds when there is too much current. The magnetic trip element acts fast if there is a short circuit. The molded case keeps the inside safe and covered. The operating mechanism opens or closes the circuit. Arc extinguishers get rid of dangerous arcs safely. Each part helps stop damage to equipment. They also help lower the risk of electrical danger.

| Component/Aspect | Statistic/Standard | Safety Significance |

|---|---|---|

| Fault Interruption Capacity | Interrupts thousands of amperes in milliseconds | Prevents overload and short circuit damage |

| Human Safety Threshold | 100 mA can cause severe harm | Breaker trips quickly to prevent injury |

| Reliability in Large Sites | 0.57% replacement rate in 850+ MCCBs | Ensures high durability and reliability |

Knowing about these parts helps people spot problems. Some brands can fail up to 50% of the time during faults. This can make fires more likely and make things less safe.

Key Takeaways

- A molded case circuit breaker has important parts. These include contacts, thermal and magnetic trip elements, a strong case, an operating mechanism, and arc extinguishers. All these parts work together to keep electrical systems safe.

- The thermal trip element protects from too much current. It senses heat and opens the circuit. The magnetic trip element stops short circuits fast. It uses magnetic force to do this.

- The molded case keeps the inside parts safe from dust and water. It also protects them from damage. This helps the breaker last longer. It can handle tough conditions safely.

- Automatic breakers react quickly to problems. They can connect to remote systems. This makes things safer and saves money in big buildings and factories.

- Adjustable trip settings help change how the breaker works. Clear indicators make it easy to see problems early. This keeps systems working well and safe.

Standard Molded Case Circuit Breaker Components

Contacts

Contacts are the main path for electricity inside the standard molded case circuit breaker. They connect or disconnect the circuit when the breaker works. Good materials like copper or silver alloys help contacts last longer. These materials also let electricity flow better. Over time, contacts can get old or move out of place. This can cause the breaker to fail. Regular tests check for problems like weak pressure or sparks. These tests make sure contacts work right and keep the breaker safe. Contacts are very important for stopping electricity during faults. They help protect equipment and people from harm.

Tip: Check contacts every year with special sound and discharge tests. This helps find early signs of wear and lowers the chance of sudden failures.

Thermal Trip Element

The thermal trip element keeps wires safe from too much current. It senses heat when there is an overload. A bimetallic strip bends when it gets hot and opens the circuit. This stops wires and devices from getting too hot. Makers test the thermal trip element by heating the breaker. They measure how fast it reacts. Trip and function tests make sure it works in real faults. Cleaning and checking the thermal element often keeps it working well. The thermal trip element helps the standard molded case circuit breaker stop overloads. This prevents damage and fire.

Magnetic Trip Element

The magnetic trip element protects against short circuits very fast. When a big surge of current happens, a coil makes a strong magnetic field. This field pulls a lever and trips the breaker right away. The magnetic trip element acts in just milliseconds. This stops bad damage to wires and equipment. Its design makes it accurate and stops it from tripping for no reason. It stays reliable because it uses magnetic force, not moving parts that wear out. This part is needed for quick action in big buildings and factories.

Molded Case

The molded case is the tough outside shell of the standard molded case circuit breaker. It is made from strong stuff like glass polyester or thermoset resin. This gives it strength and keeps electricity inside. The molded case keeps dust, water, and bumps away from the inside parts. It also helps cool the breaker when it is working. High interrupting ratings mean the molded case can handle big faults without breaking. This makes sure the breaker stays safe and works well even in hard places.

- The molded case helps the breaker last longer by protecting its parts.

- Its strong build lets the breaker handle tough jobs without failing.

Operating Mechanism

The operating mechanism makes the breaker open or close the circuit. It has levers, springs, and links that move the contacts. This happens when someone flips the switch or a trip element works. The mechanism must move fast and smooth to be safe. Tests like timing and resistance checks show if the mechanism is healthy. Power companies use these tests to find slow trips or worn parts. Most big breaker failures come from problems with the mechanism. Checking and fixing it often keeps it working well.

Arc Extinguishers

Arc extinguishers stop dangerous electric arcs when contacts open. Arcs can make heat, damage, or even fires if not stopped. Arc extinguishers use copper or silver alloys to cool and break the arc fast. Some breakers use special gases or vacuum chambers to stop arcs better. By making the arc last less time, these parts protect the breaker and other equipment. Arc extinguishers are key for safety and stopping damage during circuit breaks.

- Arc extinguishers lower the risk of fire and injury by stopping arcs.

- Their design helps the standard molded case circuit breaker stay safe and reliable.

How the Components Work

Overload Protection

Overload protection uses a thermal trip element to watch for too much current. When too much current flows, the bimetallic strip gets hot and bends. This bending opens the contacts and stops the current. It keeps wires and devices from getting too hot. Records from the field show overload protection works well for a long time. Experts use special tools to see how often breakers trip and how long they last. Lab tests check how fast the breaker trips when current is too high. These tests follow strict rules like the IEC-60898-1 standard. This rule says the breaker must trip within one hour if current is just above normal. Careful testing and real-world data show overload protection helps stop fires and damage.

Short Circuit Protection

Short circuit protection works fast to stop dangerous surges. The magnetic trip element senses a sudden spike and trips the breaker in milliseconds. This quick action keeps wires and equipment safe. Engineers use software to study fault currents and set up breakers right. These studies help stop arc flashes and other dangers. Reports show that if a breaker is not sized right, it may not trip. This can cause damage and downtime. After good studies and changes, the right breaker stops faults and keeps things safe. Research shows advanced protection can find short circuits in just 4 milliseconds. This blocks damage before it starts.

Manual and Automatic Operation

Circuit breakers can work by hand or by themselves. Manual breakers need a person to move a handle to open or close the circuit. These are best for lower voltages. Automatic breakers use electrical signals to trip without help. This lets them act fast during faults. Automatic breakers have many good points:

- They respond faster and stop faults in milliseconds.

- They watch circuits all the time and catch problems right away.

- Smart technology lets automatic breakers connect to remote systems for better control.

- They save money over time by lowering labor and equipment damage.

Automatic breakers are great for big buildings and factories where safety and speed are important.

Arc Interruption

Arc interruption is a main job for any circuit breaker. When contacts open, an electric arc forms. Arc extinguishers inside cool and split the arc to stop it safely. Tests show the shape of contacts and how the arc moves can change the damage inside. For example, spiral-type contacts spread out the arc. This helps stop deep damage in one spot. Special designs, like transverse magnetic field contacts, move the arc around to spread out heat. These features help the breaker last longer and keep working safely.

Additional Features

Trip Settings

Trip settings let people change how a circuit breaker works. These settings help the breaker fit what the system needs. There are different adjustable trip features:

- Continuous Amps: People can set the breaker to trip at 20% to 100% of its rated current. This stops the breaker from tripping too soon and keeps equipment safe.

- Long Time Delay: This setting lets the breaker wait before it trips. It helps stop shutdowns if there is only a short overload.

- Short Time Pick Up: This feature lets the breaker trip only for certain faults. It clears problems farther down the line but does not turn off the main breaker.

- Short Time Delay: People can make the breaker wait before it trips for short faults. This helps the breaker work well with other protection devices.

- Ground Fault Pick Up: This setting changes how much the breaker reacts to ground faults. It helps stop trips that are not needed.

Utilities like PG&E, SCE, and SDG&E use these trip settings to make things safer and more reliable. This is very important in places where fires can happen.

Indicators

Indicators show what is happening with the circuit breaker. These features help workers know if the breaker is open, closed, or has tripped. Some common indicators are:

- Mechanical Flags: These show if the breaker is on, off, or tripped.

- LED Lights: These lights give quick feedback, even in dark or crowded places.

- Digital Displays: Some breakers have screens that show trip history, load, or fault types.

Tip: Check indicator lights and flags often. This helps find problems early and keeps systems safe.

Certifications

Certifications show that a circuit breaker meets safety and performance rules. Groups like UL, NFPA, and IEEE make these rules. Certified breakers go through hard tests for fire, shock, and other risks. For example, UL Listing means the breaker passed safety and reliability tests. NFPA 70B and ANSI/NETA MTS give rules for testing and care. IEEE 1458-2017 gives advice for picking and testing breakers in factories.

| Feature | Performance and Safety Role | Key Characteristics |

|---|---|---|

| Overload Protection | Stops overheating and fires by tripping when load is too high | Thermal trip mechanism, adjustable trip settings |

| Short Circuit Protection | Stops high fault currents fast to protect equipment | Magnetic trip mechanism, high interrupting capacity |

| Ground Fault Protection | Finds ground faults to stop shocks and equipment damage | Residual Current Device (RCD), sensitive detection |

| Arc Fault Protection | Finds dangerous arcs to stop electrical fires | Arc Fault Circuit Interrupter (AFCI), advanced sensing technology |

| Under Voltage Protection | Trips breaker when voltage is too low to protect equipment | Voltage sensing mechanism, adjustable thresholds |

| Overvoltage Protection | Trips breaker on voltage spikes to protect equipment | Surge Protection Devices (SPDs), transient voltage suppression |

| Remote Monitoring & Control | Makes things safer and easier by letting people check and control breakers from far away | Digital communication interfaces, remote trip and reset capabilities |

| Mechanical Interlocks | Stops unsafe breaker moves by making sure things happen in order | Key interlocks, locking mechanisms |

| Dual Rating | Keeps things safe under different electrical conditions | AC/DC ratings, temperature compensation |

| Diagnostic & Testing | Lets people check breaker health and test it often | Self-diagnostic capabilities, built-in test functions |

These certifications and features help circuit breakers keep people, equipment, and property safe in many places.

A standard molded case circuit breaker has many main parts. These parts are contacts, thermal trip element, magnetic trip element, molded case, operating mechanism, and arc extinguishers. Each part helps keep people and electrical systems safe.

- Technicians who know about these parts can work on breakers safely.

- Picking the right breaker means knowing what each part does.

Knowing these parts helps stop accidents and keeps systems working well.

FAQ

What does a molded case circuit breaker protect against?

A molded case circuit breaker keeps electrical systems safe from problems. It protects against overloads, short circuits, and dangerous arcs. The breaker stops the flow of current if it finds something unsafe. This helps stop fires, keeps equipment from breaking, and lowers the chance of getting hurt by electricity.

What materials make up the contacts in a molded case circuit breaker?

Manufacturers use copper or silver alloys to make the contacts. These metals let electricity move easily and do not wear out fast. Strong contacts help the breaker work well for a long time.

What indicates a circuit breaker has tripped?

Mechanical flags or indicator lights show when a breaker trips. Some breakers have digital displays too. These features help workers find problems fast and turn the power back on safely.

What is the purpose of the molded case?

The molded case covers and protects the inside parts. It keeps out dust, water, and bumps. The case also stops people from touching live parts by accident.

What certifications should a molded case circuit breaker have?

A good breaker should have certifications from groups like UL, NFPA, or IEEE. These marks show the breaker is safe and works well.

The following information may be of interest to you

Electronic vs Thermal Magnetic Molded Case Circuit Breaker

Adjustable MCCB Thermal Control Modular Circuit Breaker

Comprehensive analysis of miniature circuit breakers

What You Need to Know About How Molded Case Circuit Breakers Work