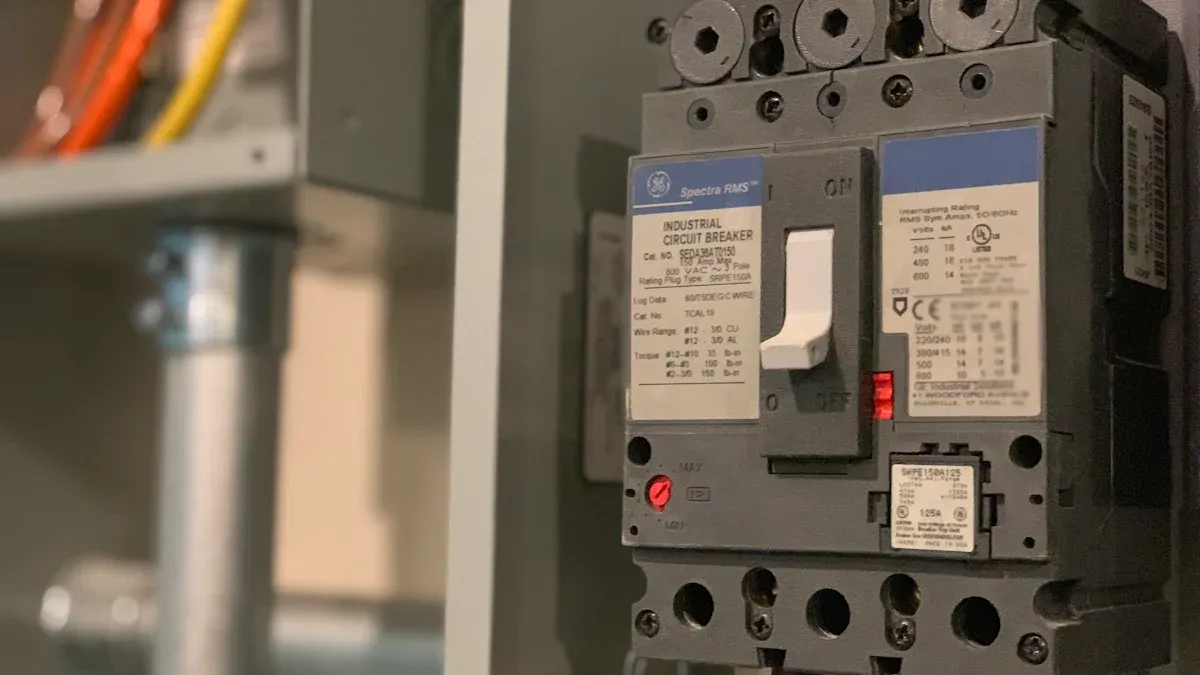

High quality molded case circuit breakers give strong protection in electrical systems. They help stop equipment damage and electrical fires by acting fast when there are problems. A Frost & Sullivan study says these breakers last up to 40% longer than lower-quality ones. Bad circuit protection causes about 25% of electrical failures, so picking better breakers makes things much safer and more reliable. Facility managers like their long-lasting use and lower chance of expensive downtime.

Key Takeaways

- High quality molded case circuit breakers keep electrical systems safe. They stop dangerous currents very fast. This helps lower the chance of fires and damage to equipment. These breakers last a long time because they use strong materials. Regular maintenance also helps them work well. This stops costly problems and keeps things running. They work well in many places, like factories and homes. They meet tough safety rules like UL489 and NRTL certification. Some have special features like adjustable settings and remote monitoring. They are easy to install and make maintenance easier. Buying high quality breakers saves money over time. They lower repair costs and insurance bills. They also help stop expensive problems from happening.

Safety

Protection

High quality molded case circuit breakers keep electrical systems safe. They find and stop dangerous currents very quickly. These breakers use special thermal and magnetic trip units. These units can sense when there is too much current or a short circuit. When something goes wrong, the breaker stops the flow in just milliseconds. This quick action keeps equipment from getting hurt. It also helps machines last longer. Reports show that current-limiting MCCBs lower stress on wires and machines. They do this by cutting off bad currents fast. Some breakers have arc chambers and use magnetic flux to work better with high currents. These things help machines last longer and stop downtime.

Note: Circuit breakers with current-limiting designs can handle fault currents from 10 to 100 kA. They act fast to protect both wiring and machines, making them a reliable choice for many settings.

Fire Risk

High quality molded case circuit breakers also help stop fires and injuries. They are made to meet tough safety rules like UL489. This rule says breakers must pass tests for overloads, strength, and stopping power. Nationally recognized testing labs check these breakers to make sure they are safe. If a breaker has an NRTL label, it means it passed these tests.

- UL489 certification shows the breaker meets important safety rules, like overload trips and lasting a long time.

- The NRTL label means the breaker works safely in real life.

- Bad brands can fail up to 50% of the time. This can cause more fires, injuries, and damage.

- Some brands have caused thousands of fires and millions in damage each year because they did not trip during faults.

High quality molded case circuit breakers from good brands give strong fire and injury protection. They work well and follow safety rules, so they are needed for safe electrical systems.

Reliability

Durability

High quality molded case circuit breakers are made to last a long time. They use strong materials like silver alloys for contacts. These contacts do not wear out fast and keep working well. The breakers also have tough springs and arc chutes. These parts help them work many times without breaking. The High 3P M1 series MCCBs have TUV certification. This means they passed hard tests for safety and strength. These breakers can work in rough places and last longer than normal ones.

A closer look at what affects how long they last:

| Factor/Aspect | Details/Impact on Lifespan |

|---|---|

| Typical Lifespan Range | 15-40 years depending on type, quality, and conditions |

| Failure Rates | 2% annual (years 1-15), 5% (16-25), 12% (>25 years) |

| Material Quality | Better contact materials, stronger springs, robust arc chutes |

| Environmental Factors | High temperature, humidity, dust, chemical exposure reduce life |

| Temperature Effect | Every 10°C increase halves lifespan |

| Maintenance Frequency | Regular maintenance dramatically extends operational life |

Checking and fixing breakers often helps them last longer. Not taking care of them causes about 30% of electrical problems. Testing things like insulation and trips every six months helps them work better. This can make them last about 20% longer. Picking breakers with the right IP rating keeps out dust and water. This can help them work up to 25% longer.

Consistency

Consistency means the breaker works the same way each time. High quality molded case circuit breakers do their job well in many places. They work in factories and offices. Rules like NEMA AB-4 and UL 489 say how these breakers should work. But these rules do not show how they last for many years. Makers use design and tests to prove they are reliable. They do not have data for many decades. Some old breakers may not trip after a long time. Testing them often helps find problems early.

Tip: Doing regular checks and picking the right breaker for the place helps keep protection strong every year.

High Quality Molded Case Circuit Breakers

Efficiency

High quality molded case circuit breakers work well in many places. Their modular design makes them easy to put in and upgrade. These breakers can be used in factories, offices, and homes. Facility managers use them to protect motors and other machines. They also protect generators, welding machines, and capacitor banks. The breakers handle faults and high inrush currents. This helps equipment keep working, even when things get tough.

- MCCBs have adjustable current ratings from 10A to 2500A. This lets them fit many types of machines.

- Their small size lets them fit in tight spots. This is good for modern electrical panels.

- Molded housings keep out dust and water. This helps them last longer.

- You can change trip settings and add features like remote monitoring. This lets you pick the best protection for each job.

- MCCBs work with renewable energy systems like solar PV. They give strong overcurrent and short circuit protection.

Note: Picking the right breaker for the load and place helps you get the best safety and efficiency.

Advanced Features

High quality molded case circuit breakers have special features that make them better than regular ones. Many models use micrologic electronic trip units. These units let you adjust protection and measure energy. They use microprocessors to control how they work. This makes the system more flexible and easy to set up.

- Dual-break rotating contacts lower peak fault currents. This protects machines and lets the breaker stop bigger problems.

- Snap-in terminal designs let you switch between busbar and lug connections fast.

- You can mount them in different ways, like with rear connections or plug-in bases. This makes them easy to install.

- Built-in communication features let you check and control them from far away. This can save money on running costs.

- QR codes and windows let you see technical data and breaker status fast. This makes fixing and checking them easier.

These new features help high quality molded case circuit breakers work well in many ways. They give strong protection and can be set up to fit any place. Their advanced features help keep things safe, reliable, and efficient.

Cost Savings

Lower Maintenance

High quality molded case circuit breakers help save on repairs. They are built strong and use good parts. This means they break less often. Facility teams do not spend as much fixing them. The materials last a long time, so contacts and springs do not wear out fast. Checking these breakers is easier because they do not get damaged or rusty much. If something does break, you can swap out parts quickly. This helps keep downtime short and stops big work delays.

A system that gets checked often is less likely to fail suddenly. Cheap breakers need more checks and repairs. These extra visits cost more over time. High quality molded case circuit breakers help keep repair costs steady and easy to plan.

Long-Term Value

Buying high quality molded case circuit breakers is a smart choice for the future. They cost about $2,500 to put in at first. But you save more money as time goes on. Each year, you pay about $1,000 for upkeep. This is less than with cheap breakers. Bad breakers can fail up to 20% of the time. Each time one fails, it can cost $150,000 to fix and replace things.

| Cost Factor | Details / Figures |

|---|---|

| Initial Installation Cost | About $2,500 |

| Annual Maintenance Cost | About $1,000 (more with cheap ones) |

| Failure Rate | 15-20% for cheap installations |

| Failure Incident Cost | About $150,000 each time |

| Insurance Premium Impact | Up to 10% higher from claims |

| 5-Year Total Cost of Ownership | $35,000 to $180,000 |

Getting pros to install certified breakers can lower insurance costs by 15%. It also keeps equipment warranties safe and makes the system work better. In five years, the total cost can be between $35,000 and $180,000. Picking high quality molded case circuit breakers helps stop big failures and keeps costs down for a long time.

Tip: Getting certified installers and doing regular checks helps you save money and keeps things safe.

High quality molded case circuit breakers keep things safe and save money. They stop fires and help avoid expensive shutdowns. Facility managers like them because they last long and have smart features. When picking circuit protection, people should think about:

- Keeping people and equipment safe

- Making sure things work well everywhere

- Spending less money in the future

Picking the right breaker helps electrical systems stay safe and work well.

ONESTOP provides high-quality molded case circuit breaker solutions

FAQ

What makes a molded case circuit breaker high quality?

High quality MCCBs are made with strong parts. They have special trip units that work well. These breakers go through hard safety tests. They last longer than regular ones. They also protect machines better.

What features help MCCBs prevent electrical fires?

MCCBs have trip units that act fast. They use arc chambers to stop bad currents. These breakers meet safety rules like UL489. This helps lower the chance of fires.

What applications use high quality MCCBs?

Factories, offices, and homes use these MCCBs. They protect motors and generators. They also work with renewable energy systems. Facility managers pick them because they work well.

What maintenance do high quality MCCBs need?

Teams check MCCBs often to keep them working. They look at insulation and test trip parts. They also clean the contacts. Good care helps breakers last longer.

What advanced options do modern MCCBs offer?

Many MCCBs have electronic trip units. Some let you watch them from far away. You can change their settings. Some have QR codes for fast info. These things make them safer and easier to use.

The following information may be of interest to you

What You Need to Know About How Molded Case Circuit Breakers Work

What Situations Call for the Use of a Molded Case Circuit Breaker

Exploring the Components of Molded Case Circuit Breakers

MCB and MCCB Compared Which Circuit Breaker Is Right for You

Intelligent MCCB circuit breaker