Terminal blocks and cold-pressed terminals have different jobs in wiring. You use terminal blocks to join many wires safely. They help keep wires neat inside machines or control panels. Cold-pressed terminals connect one wire to another part by crimping. Knowing the difference helps you pick the right connector. This keeps things safe and working well. Many industries need these parts for good electrical systems. Places like factories, building sites, and green energy use them a lot. More solar and wind energy means connector choice matters even more.

Key Takeaways

- Terminal blocks join many wires in one spot. They help keep wires neat and safe.

- Cold-pressed terminals make a strong link for one wire. They are good for fast and steady connections.

- Pick terminal blocks if you need to change wires often. They make fixing and changing wires easy.

- Use cold-pressed terminals in small spaces. They are tough and do not rust easily.

- Always look at current and voltage ratings before picking connectors. This keeps things safe and working well.

What They Are

Terminal Blocks

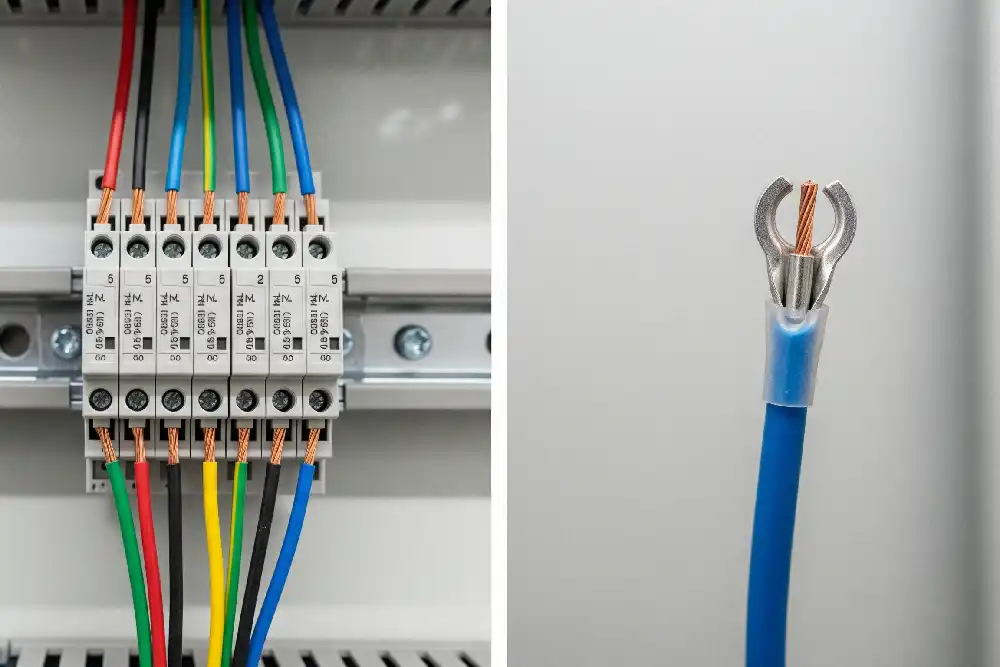

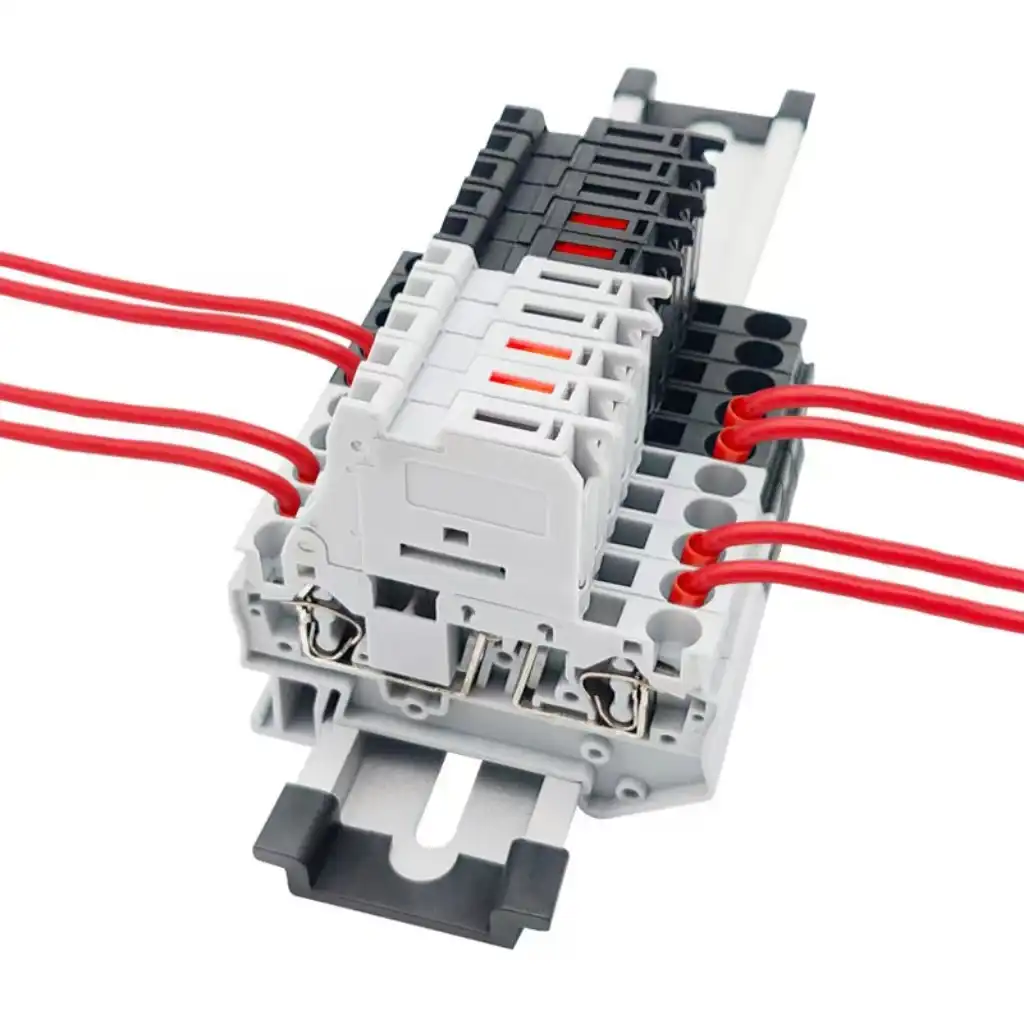

Terminal blocks help you connect many wires in one spot. They keep wires tidy inside machines and control panels. You can change their size by adding or removing parts. Each block has metal inside that holds wires tight. You put wires in and tighten them with screws. This keeps wires safe and stops them from falling out. The outside is often plastic to stop shocks. You see terminal blocks where lots of wires come together, like in factories. You can pick the size and shape you need for your job.

Tip: Terminal blocks are good if you want neat and easy wiring.

Cold-Pressed Terminals

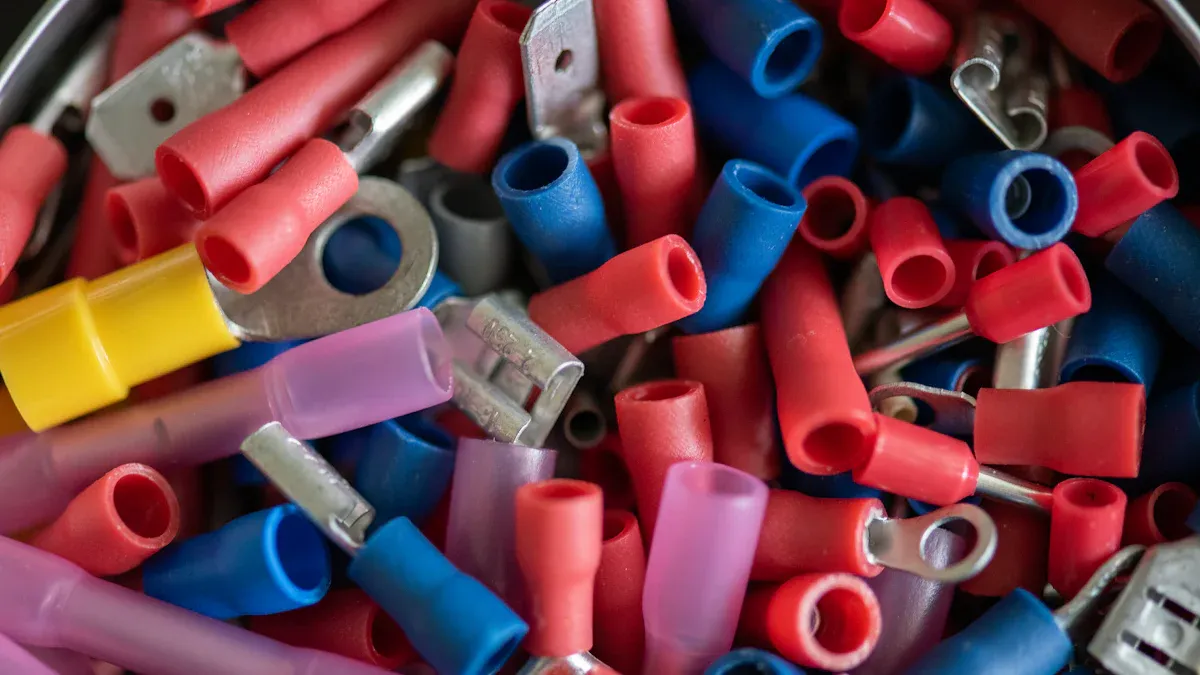

Cold-pressed terminals join one wire to a part, like a switch. You use pliers to squeeze the metal onto the wire. This makes a strong hold without using heat. Cold-pressed terminals have many shapes, like pins and blades. They often have covers to stop electric shock. They are made from brass or copper, which carry electricity well.

Here is a table that lists some common cold-pressed terminals and what they are made of:

| Terminal Type | Conductor Cross-section | American Wire Gauge | Maximum Current | Material |

|---|---|---|---|---|

| Insulated Receptacle Disconnects | 0.5-1.5mm² | 22-16 | 10A | Brass |

| Insulated Pin Terminals | 0.5-1.5mm² | 22-16 | 19A | N/A |

| Insulated Blade Terminals | 0.5-1.5mm² | 22-16 | 19A | Copper |

| Insulated Male Connectors | 0.5-1.5mm² | 22-18 | 10A | N/A |

| Non-Insulated Cord End Terminals | N/A | N/A | N/A | Copper tube |

Terminal blocks and cold-pressed terminals do different jobs in wiring. You pick cold-pressed terminals when you want a fast and safe way to connect one wire.

Structure and Connection

Physical Design

When you look at terminal blocks, you see a modular design. You can add or remove blocks to fit your needs. This design lets you arrange many blocks in a row or create separate groups. You get more flexibility when you build or change electrical panels. If you need to add new parts or fit automation equipment into a standard box, you can adjust the layout easily. Terminal blocks often support a wide range of wire sizes. For example, the ST2 series push-in terminal blocks work with wires from 0.25mm² to 16mm².

Cold-pressed terminals have a different focus. Each terminal connects to a single wire. You find them in many shapes, such as pins or blades. They do not connect multiple wires together in one spot. Instead, you use them when you want a fast and strong link for one wire. The design is simple and compact, which makes them easy to fit in tight spaces.

Note: Terminal blocks and cold-pressed terminals both help you make safe connections, but their designs suit different jobs.

Installation Methods

You need different tools for each type. When you install terminal blocks, you usually use a wire stripper to remove insulation from the wire. Then, you use a screwdriver to tighten the wire into the block. Sometimes, you might use pliers, but this is optional.

- Tools for terminal blocks:

- Wire stripper

- Screwdriver

- Pliers (optional)

For cold-pressed terminals, you use special crimping tools. These tools match the size and type of terminal. Some brands make tools for certain jobs, like solar work or aviation plugs. You place the wire in the terminal and squeeze it with the tool to make a tight connection.

- Tools for cold-pressed terminals:

- AMP guillotine style tools

- Rennsteig crimpers

- Molex pin & socket tools

- Hollingsworth tools for heat shrink splices

- Anderson Power Pole tools

- Daniels aeronautical tools

- PM Hand Tools for crimp/solder

You choose the right tool based on the terminal and the job. This helps you make safe and reliable connections every time.

Functions and Uses

Typical Applications

Terminal blocks are used in many places. They help keep wires safe and neat. You see them in machines, cars, and medical tools. Here is a table that shows where terminal blocks are used:

| Application Area | Description |

|---|---|

| Industrial Equipment | Connects wires in machinery and equipment. |

| Power Supply Components | Handles higher-current input and output connections. |

| Instrumentation Components | Used in devices that need precise electrical connections. |

| 5G and Wireless Equipment | Supports advanced communication technologies. |

| Aerospace | Provides reliable connections in aircraft systems. |

| Automation & Control | Important for control systems in factories. |

| Automotive | Used in vehicles for many electrical tasks. |

| Medical Technologies | Ensures safe connections in medical devices. |

| Oil & Gas / Marine | Used in energy extraction and marine equipment. |

Cold-pressed terminals are also used in many areas. You use them to connect one wire fast and safely. Some places you find them are:

- Appliances

- Automotive wiring

- Data centers

- Defense and military equipment

- Energy solutions

- Industrial machinery

Tip: Use terminal blocks for big wiring jobs. Use cold-pressed terminals for quick, single-wire work.

Connection Types

Terminal blocks and cold-pressed terminals work in different ways. Terminal blocks join many wires together. You can use them for high or low voltage. Some types handle strong currents and high voltages. For example, the UK-16N terminal block can carry 101 amps at 800 volts.

| Model | Rated Current (A) | Rated Voltage (V) |

|---|---|---|

| UK-1.5N | 17.5 | 660 |

| UK-2.5B | 32 | 800 |

| UK-3N | 32 | 800 |

| UK-5N | 41 | 800 |

| UK-6N | 57 | 800 |

| UK-10N | 76 | 800 |

| UK-16N | 101 | 800 |

Cold-pressed terminals connect just one wire at a time. They can also handle strong currents. For example, the BV22 model can carry 115 amps. You pick the terminal by wire size and current needed.

| Model | Maximum Current (A) |

|---|---|

| BV1.5 | 19 |

| BV2 | 27 |

| BV5.5 | 48 |

| BV8 | 62 |

| BV14 | 88 |

| BV22 | 115 |

Both types are important in electrical systems. You choose based on how many wires and how much power you need.

Terminal blocks and cold-pressed terminals: Key Differences

Comparison Table

The table below shows how terminal blocks and cold-pressed terminals are different. It lets you see their features next to each other.

| Feature | Terminal Blocks | Cold-Pressed Terminals |

|---|---|---|

| Main Use | Connects many wires in one spot | Connects one wire to a device or another wire |

| Electrical Conductivity | Made for low-resistance connections | Better conductivity from cold forming |

| Reliability | Depends on how it is made and installed | More reliable because of strong structure |

| Resistance to Current Flow | Has moderate resistance | Lower resistance, smooth surface |

| Durability | Normal durability | Lasts longer and resists bending |

| Connection Type | Uses screws or clamps | Cold-welded by crimping |

| Maintenance | Easy to check and change wires | Harder to fix or change after crimping |

| Corrosion Resistance | Can rust if not protected | Resists rust well |

| Safety Standards | IEC 60947-7-1/-2/-3, UL 1059, EN 45545-2, UL 94 | UL 94, EN 60695-11-10, ASTM E 162, ASTM E 662 |

| Typical Applications | Used in control panels, machines, automation | Used in cars, appliances, data centers |

Note: Both terminal blocks and cold-pressed terminals follow strict safety rules. Terminal blocks meet IEC 60947-7-1/-2/-3, which checks strength and safety. Cold-pressed terminals meet fire and smoke safety rules, like UL 94 and ASTM E 162.

Pros and Cons

It is important to know the good and bad sides of each type. This helps you choose the best connector for your needs.

Terminal Blocks

Pros:

- Lets you connect many wires together.

- Simple to put in and swap wires.

- Saves money for big wiring jobs.

- Works well for most electrical needs.

Cons:

- Can rust if not covered well.

- Screws can get loose if not tightened.

- Needs more space in small places.

Cold-Pressed Terminals

Pros:

- Makes a strong, cold-welded connection.

- Has lower resistance and better flow of electricity.

- Very tough and resists rust.

- Handles tough places and stops cable aging.

- Helps cables last longer.

Cons:

- Needs special tools to crimp.

- Hard to fix or change after crimping.

- Only connects one wire at a time.

Tip: Pick terminal blocks if you want easy repairs and flexible wiring. Use cold-pressed terminals for strong, lasting connections in hard conditions.

How to Choose

Selection Tips

When you pick connectors for your project, you need to look at several important factors. Each factor helps you make sure your wiring is safe and works well. Here is a table that shows what you should check:

| Factor | Description |

|---|---|

| Current Rating | Prevents overheating and failure; must match your system’s needs. |

| Voltage Rating | Avoids dielectric breakdown; always check even if not a main concern. |

| Wire Size | Must fit the terminal for a solid connection and good performance. |

| Wire Entry Orientation | Affects how easy it is to install and reach the wires. |

| Pitch | Controls the space between terminals; important for fitting in tight spots. |

| Pole Count | Decides how many wires you can connect; match this to your project’s needs. |

You should always match the current and voltage ratings to your system. Pick the right wire size for the terminal. Check the wire entry orientation so you can install wires easily. Pitch matters if you have limited space. Pole count tells you how many connections you can make.

Tip: For high-vibration places, use spring-cage (push-in) terminal blocks. They install quickly and hold wires tight, even when things shake.

If you work with cars or trucks, make sure your cold-pressed terminals match the wire and connector. Choose terminals based on the wire’s diameter. Try to get surface contact, not just point contact, for better reliability. If you handle RF signals, think about impedance matching to stop signal loss.

When to Use Each

You need to know what each connector does best. Terminal blocks and cold-pressed terminals work in different ways.

- Use terminal blocks when you want to connect many wires in one place. They help you keep wiring neat and make changes easy.

- Pick cold-pressed terminals when you need a strong, single-wire connection. They work well in cars, appliances, and places where you want a fast, solid link.

If you need to fix or change wires often, terminal blocks make the job simple. If you want a connection that lasts a long time and resists rust, cold-pressed terminals are a good choice.

Remember: Always check your project’s needs before you choose. The right connector keeps your system safe and reliable.

Terminal blocks and cold-pressed terminals do different jobs in wiring. Terminal blocks connect lots of wires together. Cold-pressed terminals are good for one wire at a time. If you know these differences, you can pick the right connector. When you choose, keep these things in mind:

- Good materials make connectors last longer and work better.

- Safety rules from around the world help keep things safe.

- How well the supplier checks their products matters for reliability.

Use this checklist before you decide: make sure the connector fits your wire, look at safety rules, and check if the supplier does good quality checks.

FAQ

What is the main job of a terminal block?

A terminal block lets you connect several wires in one place. You use it to keep wiring neat and safe inside machines or panels. It helps you organize and manage many connections easily.

What tools do you need for cold-pressed terminals?

You need a wire stripper and a crimping tool. The crimping tool matches the size and type of terminal. This helps you make a strong and safe connection every time.

What makes cold-pressed terminals different from soldered connections?

Cold-pressed terminals use pressure to join the wire and terminal. You do not need heat or solder. This method gives you a strong, reliable connection that resists rust and lasts longer.

What should you check before choosing a connector?

Always check the current and voltage ratings. Make sure the connector fits your wire size. Look for safety standards. Good quality checks from the supplier help you get reliable parts.

What are common mistakes when using terminal blocks?

- You might not tighten the screws enough.

- You could use the wrong wire size.

- You may forget to check for rust or damage.

- You might not follow safety rules.

See also

Why Choose Customized Terminal Blocks for Unique Electrical Needs

Top 7 Terminal Block Brands Every Engineer Should Consider

Quick Guide to Common Terminal Blocks in Industrial Automation

How to Pick the Ideal Terminal Block for Your Project