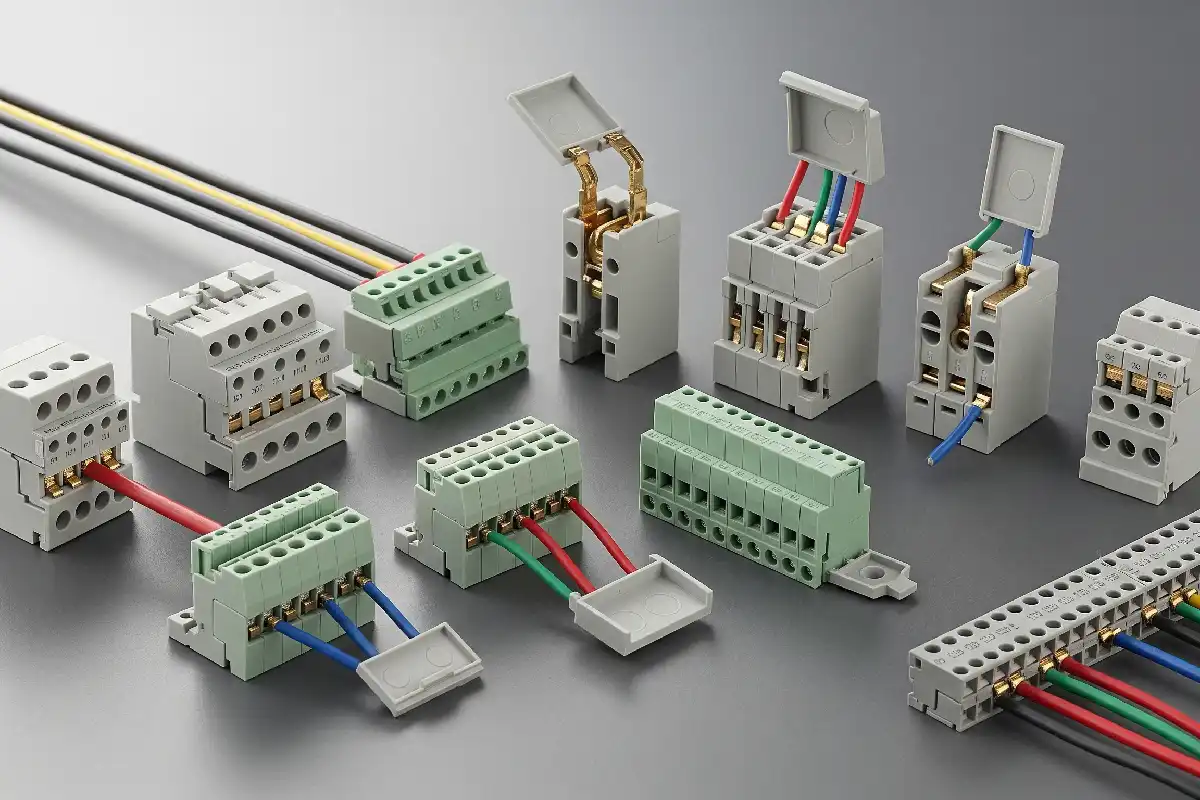

You use terminal blocks to keep your automation systems safe and tidy. These devices help you handle tricky wiring and keep electrical connections safe from harm. Different types have special jobs:

- PCB mount blocks go on circuit boards. They make wire connections neat and easy to fix.

- Barrier strips use screws and plastic walls to hold wires. They work well in setups with lots of power.

- DIN rail blocks fit into panels in factories. They support many ways to connect wires for power.

Key Takeaways

- Terminal blocks help keep automation systems safe and neat. They make it easier to handle wires and protect connections.

- Pick the right terminal block for your job. You can choose screw, spring, push-in, or fused blocks. Each type has its own good points.

- Always look at the electrical ratings before you pick a terminal block. Make sure the current and voltage ratings are higher than what your system needs.

- Think about the future when choosing terminal blocks. Modular and multi-level blocks make upgrades simple and save space.

- Check for safety certifications on terminal blocks. Certified blocks meet industry rules and make your system more reliable.

Terminal Block Types

Screw Terminal Blocks

Screw terminal blocks are common in control panels. You see them in power systems too. These parts let you connect wires easily. You can also disconnect wires fast. You do not need to crimp or solder wires. You only need a screwdriver to attach each wire. The wire touches a metal plate. This way, you get a safe connection. It is also reliable. Screw terminal blocks help you keep equipment organized. They also help with field wiring.

Tip: Screw terminal blocks work for most automation jobs. They fit many wire sizes and types.

Here are some top brands that make screw terminal blocks:

| Manufacturer | Key Differentiators | Connection Technology | Target Applications |

|---|---|---|---|

| Phoenix Contact | German engineering, broad product range | Screw, spring, push-in | Industrial automation, process control |

| WAGO | Spring connection pioneer, tool-free systems | Spring pressure, push-in, cage clamp | Automation, building systems |

| ONESTOP Electrical | Custom solutions, innovative designs | Screw, spring, push-in | Manufacturing, energy, transportation |

| ABB | Hazardous area certifications, global support | Tool-free, snap-in, feed-through | Power, energy, automation |

Spring Terminal Blocks

Spring terminal blocks use springs to hold wires tight. You push the wire in. The spring clamps it in place. This makes installation quick. It also helps you avoid mistakes. Spring terminal blocks come in many sizes. You can use them for small devices. You can use them for big machines too. The spring keeps the wire tight. It works even in tough places. These blocks resist chemicals and water. They last a long time.

- You find spring terminal blocks in cars and planes.

- They are used in telecom and renewable energy systems.

- They also work in smart homes and IoT devices.

Phoenix Contact and Curtis Industries make good spring terminal blocks. Phoenix Contact tests their blocks for strength. Their spring-cage design works well with lots of shaking.

Push-In Terminal Blocks

Push-in terminal blocks let you put wires in without tools. You save time because you do not need screws. These blocks hold wires tight. They do not shake loose. They seal out gas. This helps in places with lots of corrosion. Push-in terminal blocks stay cooler than screw types.

| Feature | Push-in Terminal Blocks | Screw Terminals |

|---|---|---|

| Installation Method | Tool-free insertion, easy handling | Requires tools and specific torque settings |

| Wiring Time | Reduced wiring time | Longer due to tool use |

| Reliability Under Vibration | Superior reliability, vibration-resistant | Dependent on user-applied torque |

| Corrosive Conditions | Guarantees gas-tight connections | May not perform as well under corrosive conditions |

| Temperature Rise | Lower temperature rise than screw connections | Can heat up under load |

You use push-in terminal blocks for sensors and actuators. They fit in small spaces. You can wire many things close together. You can add diodes and LEDs. These blocks work well in modular buildings.

Fused Terminal Blocks

Fused terminal blocks protect circuits from too much current. They have fuses inside. Many have LED lights to show problems. You can find bad circuits fast. You can fix them easily. These blocks keep your equipment safe. They help you avoid long downtime.

- Weidmüller makes strong fused terminal blocks for DIN rails. Their blocks use clamping yoke connections. They have many extra parts. The Klippon® Connect series has SNAP IN systems for easy wiring.

Ground Terminal Blocks

Ground terminal blocks connect wires to earth. You use them to find ground faults. You can disconnect earth in extra circuits. These blocks keep people and machines safe. They make sure earth connections work well.

High-Current Terminal Blocks

High-current terminal blocks carry lots of electricity. You use them when you need 10 amps or more. They do not get too hot. These blocks keep power safe and flowing.

| Current Rating (A) | Description |

|---|---|

| 10A | Maximum current a terminal block can safely carry without overheating. |

Power BusBar Terminal Blocks

Power busbar terminal blocks help you share power with many circuits. You connect several wires to one busbar. This makes power easier to manage in big systems. These blocks handle high currents. They make wiring simple.

Multi-Level Terminal Blocks

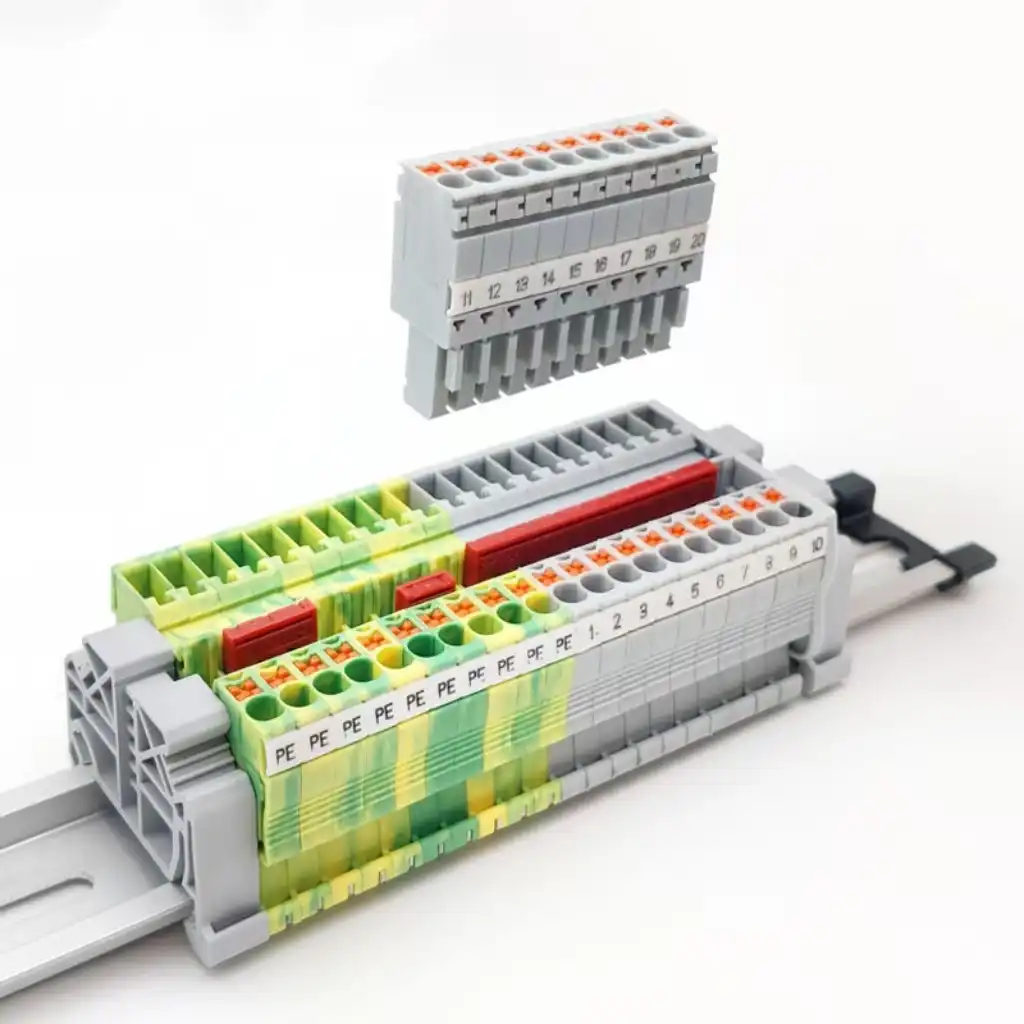

Multi-level terminal blocks save space in panels. You stack wires on different levels. You fit more wires in less space. These blocks make installation fast. They help you fix problems quickly. For example, a three-level block holds six wires in 5.1mm. This saves up to 66% space compared to single-level blocks.

- Triple-level blocks keep wiring neat.

- Their small size helps you keep panels tidy and easy to fix.

DIN Rail Terminal Blocks

DIN rail terminal blocks snap onto DIN rails. You install them fast. You can wire many things in one cabinet. These blocks hold wires tight. They work with modular designs. You can cut them into smaller pieces. They still work well. Some handle up to 600 volts and 65 amps. They fit wire sizes from #6 to #26 AWG.

- DIN rail terminal blocks work with many communication modules.

- They make wire ends safe and upgrades easy.

Note: Picking the right terminal block helps you build safe automation systems. Brands like Phoenix Contact and WAGO have many choices for your needs.

Features

Reliability

You want your automation system to work well every day. Reliable terminal blocks help you do this. They use strong materials that fight heat and vibration. These materials also stop corrosion. Your connections stay safe in tough places. Many terminal blocks have insulation barriers. These barriers stop short circuits. They keep your wiring safe. You can find blocks in many shapes and sizes. This helps you pick what you need.

| Feature | Description |

|---|---|

| Ease of installation | Quick-connect terminals and modular systems for scalability. |

| Safety | Insulation barriers and secure connections to prevent short circuits. |

| Durability | High-quality materials that resist heat, vibration, and corrosion. |

| Customization | Various configurations for specific voltage, current, and mounting needs. |

Installation

You save time with tool-less terminal blocks. Push-in connection technology lets you insert wires fast. You do not need a screwdriver or other tools. This method is much faster than screw types. Many machine builders use push-in blocks now. They make wiring easier and help you make fewer mistakes. You spend less time on each wire. This helps when you have lots of wires to install.

Tip: Tool-less terminal blocks help you finish projects faster and with fewer errors.

Wire Compatibility

You need to match the wire size and type to the terminal block. Most blocks fit many wire sizes. Some accept both solid and stranded wires. Always check the current and voltage ratings. This stops overheating and damage. Look at the pitch, or space between each pole. Make sure your wires fit well. You also want the wire entry to match your panel layout. This makes wiring easy.

- Check current rating

- Check voltage rating

- Match wire size and type

- Choose the right pole count

Safety

Safety is important in every automation project. Terminal blocks protect you and your equipment. They use insulation barriers to stop accidental contact. Secure connections keep wires from coming loose. Many blocks meet strict safety standards. Some blocks have LED indicators to show problems fast. You can trust these features to keep your system safe and running.

Applications

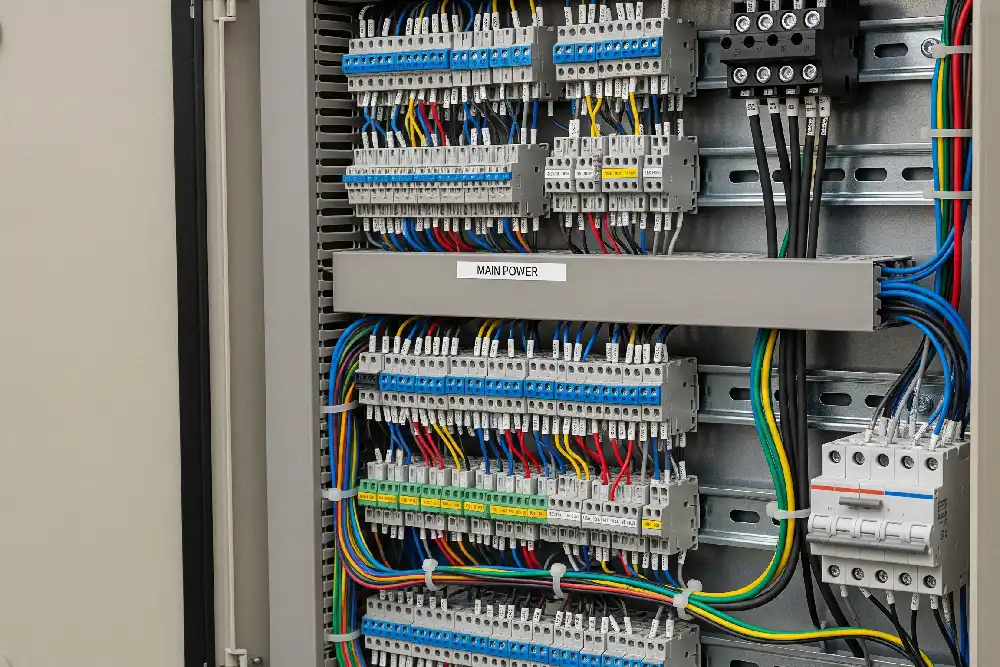

Control Panels

Control panels use many types of terminal blocks. Multi-level blocks help connect sensors and actuators. They fit in small spaces. You save space and can upgrade later. Disconnect blocks let you separate wires fast. You use a lever or switch to do this. This makes fixing things easier and quicker. I/O blocks and sensor blocks link devices to controllers. You use them for three or four-wire devices like proximity sensors. Power distribution blocks send power from one source to many places. They keep your panel neat and safe.

- Multi-level blocks save space and help you add more.

- Disconnect blocks make fixing things easier.

- I/O and sensor blocks connect devices to controllers.

- Power distribution blocks keep wires neat and safe.

Tip: Neat control panels help you find problems fast.

Power Distribution

Power terminal blocks hold many wires together. This keeps connections safe and strong. Power distribution blocks send electricity from one place to many others. You see these blocks in factories with machines. They link control systems, sensors, and actuators. Smart power blocks watch circuits and warn about problems. These features help you stop downtime and support new tech like IoT and Industry 4.0.

- Hold many wires for safe connections.

- Make wiring simple and neat.

- Send power to many places in factories.

- Watch circuits to fix problems before they happen.

Signal Wiring

Terminal blocks help organize signals from sensors and actuators. They help you manage lots of wires in cabinets. When you add more sensors, you get different electrical levels. Fusing and disconnect options keep things safe. Color-coded pushers help you avoid mistakes. These features help you install and fix things faster.

Note: Good signal wiring keeps your system working well and easy to fix.

Field Devices

You use terminal blocks to connect field devices to marshalling cabinets. This is common in process control systems. You get a simple and strong connection. It is easy to manage. Many engineers like this way better than remote I/O or Fieldbus. It keeps things neat. Some blocks, like Klippon® Connect W2C and W2T, shield cables and help test signals.

- Connect signals from field devices.

- Use strong systems for good performance.

- Shield cables and test signals with special blocks.

Selecting a Terminal Block

Choosing the right terminal block helps you build a safe and reliable automation system. You need to look at several important factors before you decide.

Electrical Ratings

You must check the electrical ratings first. These ratings keep your system safe from overheating and damage.

- Pick a block with a current rating at least 150% higher than your maximum expected current.

- Make sure the voltage rating is above your system voltage. This protects against surges.

- Count the number of circuits you need. This tells you how many poles your block should have.

- Look at the pitch, which is the space between each pole. The pitch affects how your wiring fits in the panel.

- Choose the wire entry orientation that matches your design. You can pick horizontal, vertical, or 45° entry.

Tip: Always check the ratings on the product label before you buy.

Wire Size

You need to match the wire size to the block.

- Check the wire gauge range in the specifications.

- Make sure the block fits both solid and stranded wires if your project needs them.

- Pick a block that handles the wire type you use most.

Environment

Your installation environment changes what block you need.

- Use PCB mount blocks for small circuit boards.

- Pick barrier strips for high current and voltage jobs.

- Choose DIN rail blocks for industrial panels and power distribution.

Note: The right block lasts longer in tough places like factories or outdoor setups.

Space

Space in your panel matters.

- Multi-level blocks save room by stacking wires.

- Compact designs fit tight spaces.

- Check the pitch and pole count to make sure everything fits.

| Space-Saving Feature | Benefit |

|---|---|

| Multi-level design | More wires, less space |

| Compact pitch | Fits small panels |

Maintenance

Easy maintenance saves you time and trouble.

- Pick blocks with spring-cage or push-in designs for quick wiring changes.

- Look for blocks that let you disconnect wires fast.

- Choose blocks with clear labels and LED indicators to spot problems quickly.

- Make sure the block can handle dust, heat, and vibration if your system runs in harsh conditions.

Tip: Easy-to-maintain blocks help you fix issues faster and keep your system running.

Quick Tips

Matching Needs

Pick terminal blocks that fit your project. First, check if the wire gauge matches. This stops wires from getting loose or too hot. Look at the current and voltage ratings. These numbers tell you if the block can handle your power. Safety features are important. Choose blocks with insulation barriers and strong locks. These keep you and your equipment safe.

Here is a simple table to help you match features to your needs:

| Feature | Importance |

|---|---|

| Wire Gauge Compatibility | Makes sure wires stay tight and do not overheat. |

| Current and Voltage Ratings | Shows if the block can handle your power needs. |

| Safety Features | Keeps people and machines safe from electrical dangers. |

Tip: Always read the product label for ratings and safety marks before you install.

Future Expansion

You might want to add more devices later. Pick terminal blocks that make upgrades easy. Multi-level and modular blocks save space and let you add wires. Push-in and spring-cage designs make rewiring simple. You can take out and put in wires without tools. This saves time when you grow your system.

- Modular blocks let you add more poles.

- Multi-level designs fit more wires in small panels.

- Tool-less connections make upgrades faster.

Note: Planning for future growth keeps your automation system flexible.

Standards

Use terminal blocks that meet industry standards. UL, IEC, and CSA marks mean the block passed safety tests. These standards help you avoid problems during inspections. They also keep your system safe from electrical dangers. Always look for certification marks on the product and box.

- UL and IEC standards cover safety and performance.

- CSA marks show the block is good for North America.

- Certified blocks work better in tough places.

✅ Using certified terminal blocks helps you build a safer and more reliable automation system.

You can choose from many terminal block types for your automation work. Each type has special features for safety, saving space, and easy setup. Picking the right terminal block helps your system stay safe and work well.

Remember: Choosing the right one stops problems and keeps your equipment safe.

Quick Checklist for Selection:

- Check current and voltage ratings

- Match wire size and type

- Think about space in your panel

- Look for safety certifications

- Plan for future expansion

Do you want to purchase wiring terminals? ONESTOP Electrical provides you with professional customized solutions.

FAQ

What is a terminal block used for?

A terminal block helps you connect wires safely. It keeps circuits neat in machines and control panels. Terminal blocks hold wires tight. They make fixing things easier.

How do you choose the right terminal block?

You need to check wire size, current, and voltage. Look for safety marks on the block. Pick one that fits your panel and project.

Tip: Always read the label before you buy.

Can you reuse terminal blocks?

You can use many terminal blocks again if they look good. Check for cracks or damage before you reuse them. Some blocks, like push-in types, make rewiring simple.

What is the difference between screw and push-in terminal blocks?

| Feature | Screw Terminal Block | Push-In Terminal Block |

|---|---|---|

| Tools Needed | Yes | No |

| Wiring Speed | Slower | Faster |

| Vibration Safe | Good | Excellent |

Do terminal blocks improve safety?

Terminal blocks help protect you from electric shocks. They stop wires from touching each other. Many blocks have insulation barriers and meet safety rules.

✅ Certified terminal blocks help you build safer systems.

See also

How to Pick the Ideal Terminal Block for Your Project

Top Distribution Box Manufacturers Compared for 2025

Top 7 Terminal Block Brands Every Engineer Should Consider

Why Choose Customized Terminal Blocks for Unique Electrical Needs