What makes a molded case circuit breaker important in electrical systems? The answer is in its parts. Each part has a key job to keep things working and protect circuits from harm. By learning about these parts, you can see how they make systems safer and stop electrical dangers.

Modern MCCBs have new features to work better. For example:

-

Smart breakers with electronic trip units check system health, making it safer.

-

Maintenance switches cut arc energy by clearing breakers faster.

-

Zone selective interlocking shortens arc flashes, clearing faults quicker.

These upgrades show why knowing MCCB parts helps keep systems safe and running well.

Key Takeaways

-

MCCBs keep electrical systems safe by stopping too much current or short circuits. This helps avoid damage and fires.

-

Picking the right MCCB size is very important for safety. It makes sure the breaker can handle your system’s power needs.

-

Taking care of MCCBs, like cleaning and testing them, is needed. This keeps them working well and prevents electrical problems.

-

Learning about MCCB parts, like the trip unit and arc stoppers, shows how they protect your electrical systems.

-

MCCBs can be used in homes, stores, and factories. They are a great choice for keeping modern systems safe.

Overview of Molded Case Circuit Breakers

Purpose and Function of MCCBs

Molded case circuit breakers (MCCBs) are important for keeping electrical systems safe. They stop circuits from getting damaged by overcurrents or short circuits. When something goes wrong, an MCCB stops the current flow. This prevents equipment damage and lowers fire risks. MCCBs are used in homes, businesses, and factories to keep systems safe and reliable.

MCCBs are also very flexible. You can adjust their trip settings to match your circuit’s needs. This makes them useful for many setups, from small homes to big factories.

Importance of Molded Case Circuit Breaker Ratings

Knowing MCCB ratings helps you pick the right one for your system. These ratings show how much current and voltage the breaker can handle safely. For example:

-

MCCBs come in different current ratings, so they fit many uses.

-

They act fast when currents are too high, protecting equipment from harm.

Choosing the right MCCB rating keeps your system safe and working well. It also stops problems caused by using the wrong breaker.

Key Features of MCCBs

MCCBs have special features that make them work better and last longer. Some of these features are:

-

Enhanced Protection: They protect against overloads and short circuits.

-

Higher Breaking Capacity: They handle bigger loads, great for factories.

-

Flexibility in Trip Settings: You can adjust them to fit your needs.

-

Additional Safety Features: Things like trip indicators make them safer.

-

Durability and Reliability: They work well in tough conditions and high heat.

|

Performance Metric |

What It Means |

|---|---|

|

Interrupting Capacity Rating |

Lets MCCBs stop big fault currents safely and reliably. |

|

Adjustable Trip Settings |

Lets you change settings to protect your specific circuit. |

|

Voltage and Frequency Range |

Works with different systems, making them more useful. |

These features make MCCBs a strong choice for protecting electrical systems in many places.

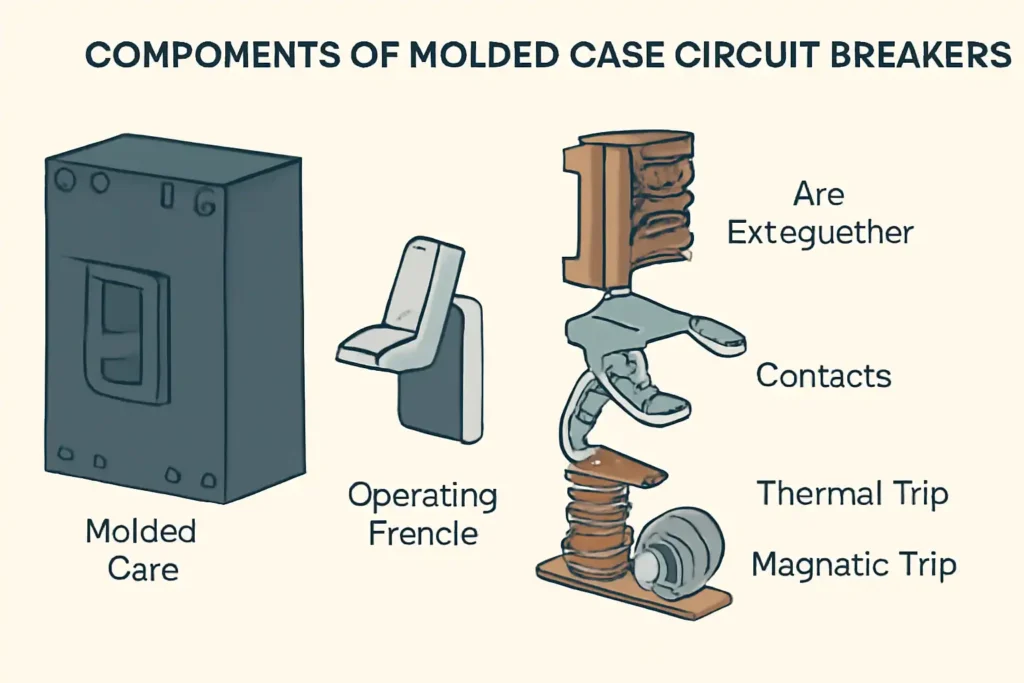

Components of Molded Case Circuit Breakers

Molded Case and Its Protective Role

The molded case is the MCCB’s outer cover. It protects the inside parts from damage. It is made from strong materials like thermoset plastic or thermoplastic. These materials can handle heat and impacts, keeping the MCCB working in tough conditions.

The molded case also helps with safety. It stops people from touching live parts, lowering shock risks. Its design keeps the inside parts safe and insulated for reliable use.

Tip: Look for a strong and well-made molded case when picking an MCCB. A good case improves safety and lasts longer.

Operating Mechanism and Its Functionality

The operating mechanism is the MCCB’s main part. It opens and closes the breaker’s contacts. When you turn the MCCB on or off, this mechanism moves fast. It uses stored energy to work quickly and smoothly.

It also works automatically during problems. If the current gets too high, the mechanism activates the trip unit. This disconnects the circuit to stop damage and keep things safe.

This mechanism is built to be dependable. It works well in normal times and reacts fast during faults. This quick action is key to protecting your system.

Contacts and Their Role in Current Flow

Contacts let electricity pass through the MCCB. They have fixed and moving parts. When the MCCB is on, the contacts close, letting electricity flow. When it trips, the contacts open, stopping the current.

Good contacts are important for MCCB performance. Strong contacts last longer and stay connected under heavy use. They also lower resistance, helping electricity flow better.

Contacts are key for safety. During a fault, they open fast to stop dangerous currents. This protects equipment and lowers fire risks.

Note: Keep contacts clean and in good shape. Dirty or worn contacts can cause problems and make the MCCB less safe.

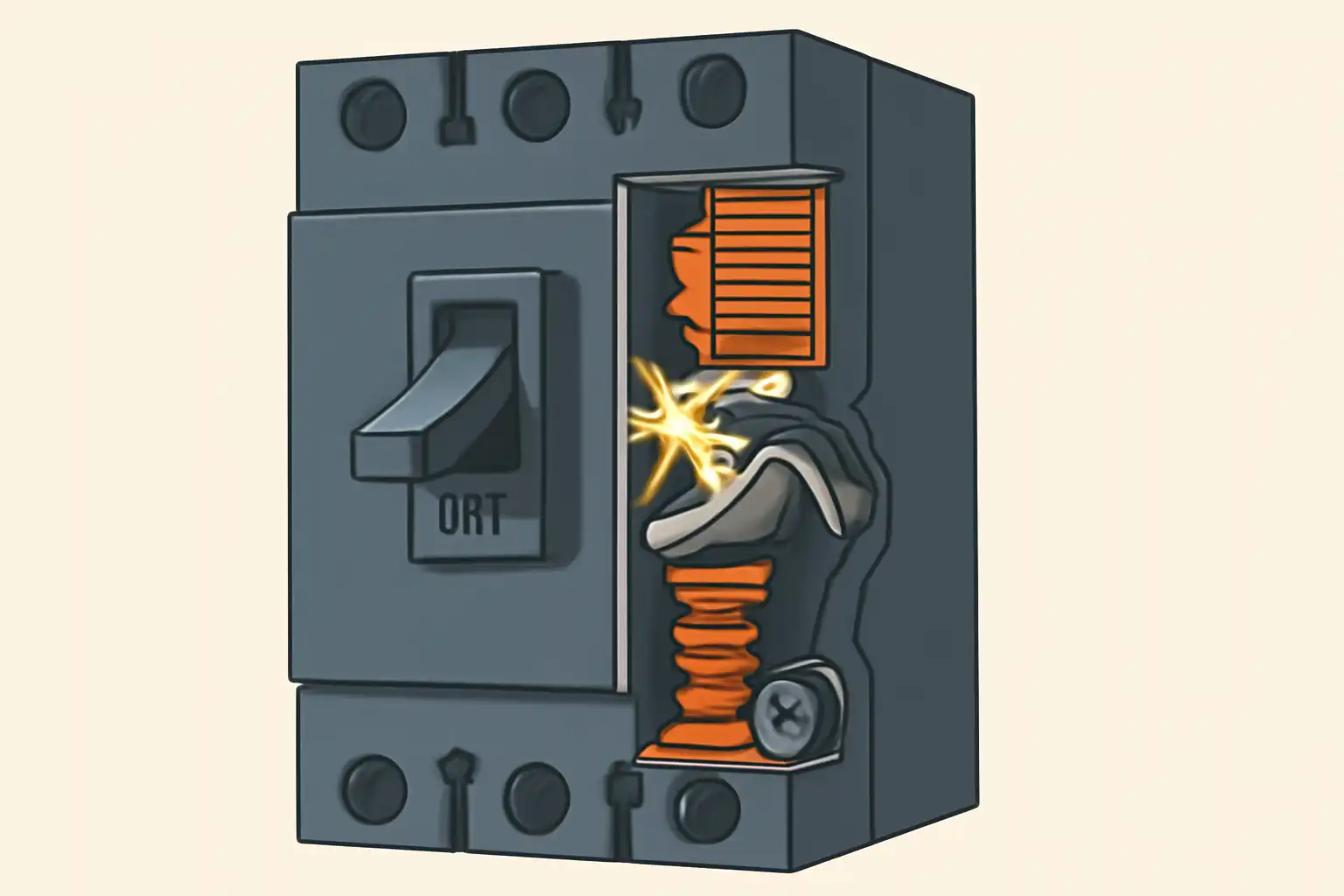

Arc Extinguishers and Arc Quenching

Arc extinguishers are very important in molded case circuit breakers. When a problem like a short-circuit happens, an electric arc forms as the contacts pull apart. This arc creates a lot of heat, which can harm the MCCB’s parts and nearby equipment. Arc extinguishers stop this arc quickly, keeping the breaker safe and working well.

The process of stopping the arc involves these steps:

-

Arc Formation: When contacts open, hot plasma forms from the electric spark.

-

Arc Extinguishing: Arc chutes stretch and cool the arc, breaking it into smaller parts. This cooling stops the arc and reduces heat damage.

-

Materials Impact: The plasma can wear out insulating materials and damage contacts. It may also leave conductive dust, which affects how the MCCB works over time.

|

Mechanism |

What Happens |

|---|---|

|

Arc Formation |

A spark between contacts creates hot plasma. |

|

Arc Extinguishing |

Arc chutes stretch and cool the arc, stopping it fast. |

|

Materials Impact |

Plasma wears out parts and leaves dust that can cause issues. |

Modern MCCBs use better designs to improve arc quenching. For example, air in the arc chutes helps cool and split the arc. Springs help the contacts separate quickly when the circuit breaks. These features make MCCBs more reliable and reduce damage during problems.

Tip: Check arc chutes and contacts often for damage or wear. Good maintenance keeps arc extinguishers working well and helps your MCCB last longer.

Trip Unit and Overload Protection

The trip unit is one of the most important parts of a molded case circuit breaker. It watches the current in the circuit and turns off the breaker if something goes wrong, like an overload or short-circuit. This automatic action protects your system and keeps it safe.

There are two main kinds of trip units:

-

Thermal-Magnetic Trip Units: These use a metal strip to find overloads and a coil to react to short-circuits.

-

Electronic Trip Units: These advanced units use sensors and small computers for accurate protection. They also let you adjust settings to fit your system’s needs.

Overload protection is a key job of the trip unit. If the current stays too high for too long, the trip unit shuts off the circuit. This stops overheating and lowers fire risks.

Note: Pick an MCCB with the right ratings for your system. Correct ratings help the trip unit work well without causing unnecessary shutdowns.

Modern MCCBs also have trip indicators. These show why a fault happened, making it easier to fix problems. This saves time and keeps your system running smoothly.

Callout: Set the trip unit to match your circuit’s needs. This gives the best protection and avoids unnecessary trips.

Molded Case Circuit Breaker Applications

Molded case circuit breakers (MCCBs) are very important in many areas. They keep electrical systems safe and reliable. MCCBs handle high currents and stop overloads, making them useful in homes, businesses, and factories.

Industrial Applications of MCCBs

Factories and industries need MCCBs to protect machines and systems. They guard motors, generators, and feeders from high currents and short circuits. For example, MCCBs stop motors from overheating, which can save money and prevent damage.

MCCBs are also flexible for industries. You can adjust their settings to protect specific machines. This helps equipment work better and stay safe.

Tip: Check MCCBs often in factories to avoid sudden problems.

Commercial Applications of MCCBs

In businesses, MCCBs protect power systems and keep electricity flowing. They are used in malls, offices, and hospitals where power is very important.

Modern MCCBs have smart features like remote checks and problem alerts. These help find issues early, making systems safer and reducing downtime. Following maintenance rules keeps MCCBs working well and avoids failures.

Callout: More businesses now use MCCBs because safety is a big need.

Residential Applications of MCCBs

MCCBs are also great for homes. They stop overloads and short circuits, keeping your home’s power system safe. Unlike regular breakers, MCCBs are good for high-power items like generators and big appliances.

As cities grow and people use more electricity, homes need better power systems. MCCBs give strong protection, making them a top choice for modern homes.

Note: Check your MCCB regularly to keep your home safe and protected.

How Components Help Molded Case Circuit Breaker Applications

Each part of an MCCB has an important job. Together, they make MCCBs work well in many uses. MCCBs protect motors, generators, and feeders in high-current systems.

The molded case keeps the MCCB strong and safe. It protects the inside parts from damage and stops shocks. This makes MCCBs dependable, even in tough places. Terminals link wires to the MCCB. They stop heat buildup, keeping power flowing safely.

The operating mechanism opens and closes the circuit. You can use it by hand or let it work automatically during problems. It acts fast to lower risks in high-current systems. The trip unit is like the MCCB’s brain. It finds overloads and short circuits, turning off the circuit to keep equipment safe. It works well for motors and generators.

The arc chamber stops electric arcs during faults. It stretches and cools the arc, stopping harm to the MCCB and nearby items. This is very useful for things like welding machines, where arcs happen often.

MCCBs are great tools for many jobs. They handle high currents well, making them perfect for protecting motors and feeders in factories and businesses. All parts work together to keep systems safe and running smoothly.

Tip: Clean terminals and check the arc chamber often. This helps MCCBs last longer and work their best.

Maintenance and Testing of MCCBs

Why Regular Maintenance is Important

Taking care of MCCBs keeps them safe and reliable. Regular checks help find problems early, stopping bigger issues later. This also ensures MCCBs protect against electrical faults as they should. Without proper care, MCCBs might fail when needed most, risking your system and safety.

Here’s why maintenance matters:

|

Key Point |

What It Means |

|---|---|

|

Testing makes sure MCCBs work right, avoiding electrical dangers. |

|

|

Risk Reduction |

Verifies settings to prevent damage and lower fire risks. |

|

System Integrity |

Keeps the whole system safe and avoids costly breakdowns. |

Maintaining MCCBs helps them last longer and work better. This is especially true for systems with powerful machines like motors, where overload protection is key.

Tip: Check and clean MCCBs often to keep them working well.

How to Test MCCB Parts

Testing MCCBs is an important part of their care. It checks if parts like the trip unit and contacts are working properly. Following standard tests helps find any weak spots in the MCCB.

Here are some common tests to do:

|

Test Type |

What It Checks |

|---|---|

|

Measures insulation between parts. Failing this test shows poor protection. |

|

|

Contact Resistance |

Checks how well contacts carry electricity. Results are compared to the maker’s guidelines. |

|

Tripping Test |

Tests how the MCCB reacts to too much current. Simulates problems to check thermal and magnetic safety features. |

These tests confirm the MCCB can handle overloads and short circuits. For example, the tripping test ensures the trip unit works fast during faults, protecting your system.

Note: Always follow the maker’s instructions when testing MCCBs. This ensures correct results and avoids extra wear on parts.

Common Problems and Fixes

Even with regular care, MCCBs can have problems over time. Knowing common issues helps you fix them quickly and keep things running smoothly.

Here are some frequent MCCB problems:

-

Some MCCBs don’t trip as they should, even at 135% of their rated current.

-

Certain brands have high failure rates, with some reaching 50%.

-

Poor testing standards can lead to unreliable performance under stress.

Past data also shows recurring issues:

-

Many MCCBs had similar failures between 1980 and 2000.

-

Current testing methods may not fully ensure reliability, needing better approaches.

To fix these problems:

-

Check the trip unit often to ensure it reacts to overloads and faults.

-

Clean and tighten contacts to keep electricity flowing properly.

-

Replace worn or broken parts quickly to avoid bigger issues.

Callout: If your MCCB trips too often or acts strangely, get a professional to inspect it.

By staying on top of maintenance, you can reduce downtime and ensure MCCBs keep your system safe and reliable.

Knowing the parts of molded case circuit breakers shows their importance. Each part, like the case and trip unit, works together. They stop overloads, control arcs, and keep electricity flowing safely. This makes them vital for homes, businesses, and factories.

Taking care of them is very important. Without regular checks, they might not work during problems. This could cause fires or damage equipment. Maintenance keeps them safe and working well, helping your system stay dependable.

Tip: Check and test your circuit breakers often to keep them working their best.

FAQ

What makes MCCBs different from regular circuit breakers?

MCCBs manage higher currents and have adjustable trip settings. They also include advanced features like arc extinguishers and electronic trip units. These make them ideal for factories and businesses.

Tip: Choose MCCBs for systems needing more power and flexibility.

How do you pick the right MCCB for your setup?

Check your system’s current and voltage needs. Match these with the MCCB’s ratings. Look for features like adjustable settings and arc extinguishers for extra safety.

Note: If you are unsure about the correct rating, you can visit our directory or consult us. Provide solutions

How often should MCCBs be checked?

Inspect MCCBs every 6 to 12 months. Clean the contacts, test the trip unit, and check the arc extinguishers. Regular care keeps them safe and working longer.

Callout: Skipping maintenance can cause failures during electrical problems.

Can MCCBs be used in homes?

Yes, MCCBs are great for houses with big appliances or generators. They offer better safety than regular breakers, especially for modern homes with higher power needs.

Emoji Tip: 🏠 MCCBs are a great choice for safe home power systems.

What are signs of a bad MCCB?

Frequent tripping, overheating, or visible damage are warning signs. If the MCCB doesn’t trip during problems, replace it quickly.

Alert: Replace broken MCCBs right away to prevent electrical dangers.

The following information may be of interest to you

Intelligent MCCB circuit breaker

The difference between MCCB and MCB

Key factors to consider when choosing a molded case circuit breaker

Application-of-molded-case-circuit-breakers.webp)