You keep your home or business safe by regularly testing molded case circuit breakers. Test molded case circuit breakers are essential because broken breakers can cause significant dangers. For example, faulty breakers from one brand were responsible for about 2,800 electrical fires each year in the USA. These fires resulted in injuries, deaths, and millions of dollars in property damage. The table below highlights that some brands fail up to 50% of the time, emphasizing why it is crucial to test molded case circuit breakers regularly.

| Circuit Breaker Brand | Failure Rate / Key Findings |

|---|---|

| Various major brands | Up to 50% failure rate; some do not trip at any current |

| FPE Stab-Lok, UBI | High failure rates and do not trip during tests |

Always use the right tools and follow safety rules when you test molded case circuit breakers to prevent accidents.

Key Takeaways

- Test molded case circuit breakers often to keep your home or business safe from fires and damage.

- Begin by looking closely at the breaker to spot cracks, burn marks, or other damage that might make it stop working.

- Test how the breaker moves by turning it on and off. Make sure it moves easily and resets the right way.

- Use special tools to do electrical tests. Check insulation, contact resistance, and trip functions to get correct results.

- If a breaker does not pass any test, turn off the power right away. Take out the breaker and replace it or ask a professional for help.

Visual Inspection

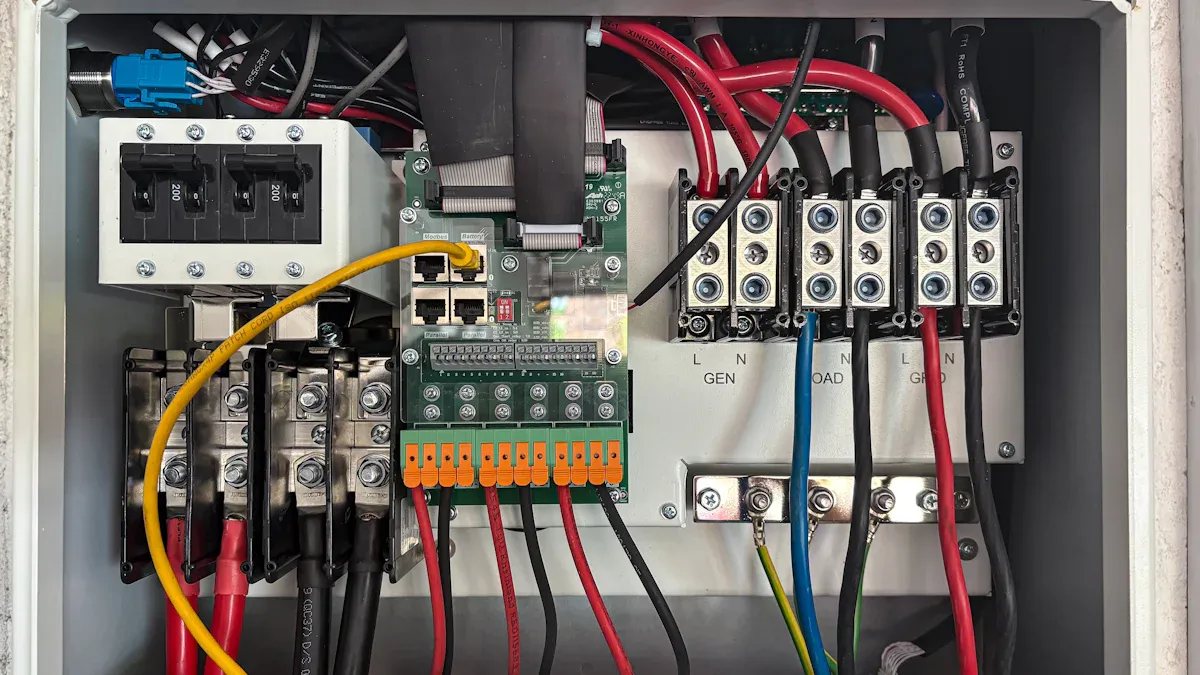

Start by looking at the molded case circuit breaker. This is the first thing you should do. It helps you find problems early. Always turn off the power before you begin. Wear gloves and safety glasses to protect yourself.

Signs of Damage

Check the breaker for cracks, dents, or burn marks. These can mean the breaker is damaged or has a problem. Use a flashlight to help you see better. Look for:

- Cracks or dents on the outside

- Burn marks or dark spots near the ends

- Rust or green spots on metal parts

- Plastic that looks melted or smells burnt

These issues can make the breaker stop working or cause a fire. The table below lists common damage and why it matters:

| Damage Indicator | Description and Cause | Why It Matters |

|---|---|---|

| Cracks and Dents | Hit or squeezed too hard | Makes breaker weak, might break |

| Burn Marks | Too much electricity or heat | Shows it had a problem, could burn |

| Corrosion | Water or bad connection | Can stop breaker from working |

| Discoloration | Got too hot or too much power | Warns you about bigger problems |

| Melted Insulation | Got very hot | Must be replaced right away |

Overheating and Wear

Look for signs that the breaker got too hot. If you see melted parts, dark spots, or smell burning, it means too much power went through. Heat can hurt the inside and make it less safe. If you notice these things, change the breaker soon.

Installation Issues

Breakers can fail if not put in right. Check for loose screws, parts that do not line up, or wires that do not fit. Watch out for:

- Breakers that turn off a lot for no reason

- Strange buzzing or humming noises

- Breakers that will not turn back on

- Lights that blink or power that goes out

Always follow the maker’s directions and make sure the breaker fits your panel. The NFPA 70B says to check breakers every year. Regular checks help you find problems early. This keeps your electrical system safe and working well.

Mechanical Operation Test

Testing the mechanical operation of a circuit breaker helps you make sure it works as it should. This step checks if the breaker moves smoothly and resets correctly. Always turn off the power and wear safety gear before you touch any breaker. Safety rules and standards, like IEC 60364-6, require you to test molded case circuit breakers regularly. About one-third of adjustable breakers stay at factory settings, which can cause problems. You help prevent accidents by following proper testing steps.

Manual Cycling

Manual cycling means you turn the breaker on and off several times by hand. This test shows if the switch moves easily and does not stick. You should feel a firm click each time you move the handle. If the handle feels loose or hard to move, the breaker may have a problem.

- Turn the breaker off, then on, at least three times.

- Listen for any strange sounds, like grinding or squeaking.

- Watch for smooth movement and a clear snap into each position.

| Test Type | What You Do | What to Look For |

|---|---|---|

| Manual Cycling | Flip breaker on/off by hand | Smooth, firm movement |

| Mechanical Test | Repeat open/close cycles | No sticking or failure |

Routine cycling helps you spot issues early. If the breaker does not move well, replace it right away.

Reset Function

The reset function lets you restore power after the breaker trips. You test this by first turning the breaker off, then back on. Some breakers have a button for resetting. Make sure the breaker stays in the “on” position after you reset it. If it trips again right away, there may be a fault in the circuit or the breaker itself.

Many breakers, like those in the S800 series, offer manual and automatic reset options. These breakers meet strict standards, such as IEC/EN 60947-2, and have features like overload warnings and built-in safety devices. You may also find breakers with adjustable current settings and extra contacts for alarms.

Tip: Always check the breaker’s manual for the right way to reset it. If you cannot reset the breaker, or if it trips again, call a professional.

By following these steps, you make sure your breaker works safely and reliably. Regular mechanical tests are a key part of how you test molded case circuit breakers.

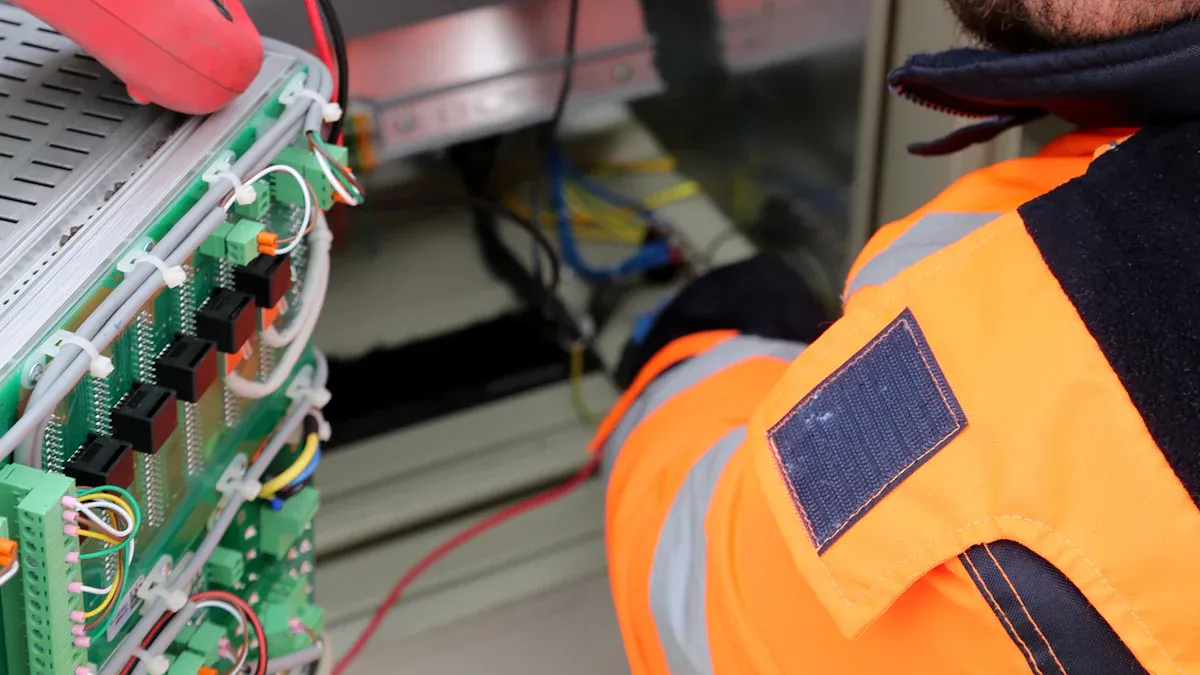

Test Molded Case Circuit Breakers Electrically

Electrical testing is the best way to check if a breaker works. You need special tools for these tests. These tools measure insulation, contact resistance, and trip functions. These tests help you find problems you cannot see. Always follow safety rules before you start. Turn off the power and wear gloves and safety glasses. Use lockout/tagout steps to keep everyone safe.

Insulation Resistance Test

First, check the insulation resistance. This test shows if the insulation stops electricity from leaking. You use a megohmmeter, also called a “megger,” for this. Set the voltage based on the breaker’s rating. Most low-voltage breakers use 500 V DC or 1000 V DC.

Follow these steps:

- Take the breaker out of all circuits.

- Put the megger leads on the breaker’s terminals.

- Turn on the test voltage for one minute.

- Look at the resistance value.

A good breaker should have high resistance. For low-voltage circuits, you want at least 0.5 megaohms (MΩ). For circuits up to 1 kV, you want 1.0 MΩ. If the number is lower, the insulation may be bad. Temperature and humidity can change the results. Check the room before you test. Always take out sensitive electronics before you test molded case circuit breakers.

| Equipment Type | Test Voltage (DC) | Minimum Insulation Resistance |

|---|---|---|

| Circuit Breaker Main Circuit | Voltage-dependent | 2 MΩ/kV |

| Low Voltage Circuits | 500 V DC | 0.5 MΩ |

| Up to 1 kV Circuits | 1000 V DC | 1.0 MΩ |

Tip: Test between each terminal and ground, and between all terminals. If you see low resistance, change the breaker.

Contact Resistance Test

Next, check the contact resistance. This test shows if the contacts let electricity flow well. High resistance means the contacts are dirty or worn. You use a digital low resistance ohmmeter (DLRO) for this.

How to do it:

- Make sure the breaker is off and safe.

- Attach the DLRO leads to both ends of the breaker.

- Turn on the DLRO and read the number.

Good breakers have very low resistance, less than 100 micro-ohms (μΩ). If the number is higher, the contacts may be bad. Contact resistance depends on the material and how clean the contacts are. Experts use special testers to check small changes. If you test molded case circuit breakers and see high resistance, replace them.

- Special testers check contact resistance with different force.

- Dirt, rust, and wear can make resistance go up.

- FEM simulations help experts set up good tests.

- Dynamic contact resistance tests give more data for high-voltage breakers.

Note: Always check your numbers with the maker’s limits. High contact resistance can make the breaker overheat and fail.

Trip Test (Thermal and Magnetic)

The trip test checks if the breaker trips when it should. You test both the thermal and magnetic trip functions. Use a primary injection tester for this. This tool sends a set current through the breaker.

Steps for a trip test:

- Connect the tester to the breaker.

- Set the current to the breaker’s rated value for thermal trip.

- Raise the current to test the magnetic trip.

- Watch the breaker and write down the trip time.

Thermal tests check if the breaker trips after too much power for a while. The breaker should not get hotter than 40°C for currents below 800A, or 50°C for higher currents. Magnetic tests check if the breaker trips right away during a short circuit. Compare your results to the breaker’s specs.

- PME-500-TR testers check trip and close times, contact resistance, and motion.

- Raptor systems do primary current injection for trip tests.

- SMC-12 systems are used for routine and quality control tests.

- Always test in steady conditions and compare to the maker’s data.

If the breaker does not trip as it should, it is not safe. Take it out and replace it. Testing helps keep your electrical system safe and working well.

| Evidence Type | Description | Source / Reference |

|---|---|---|

| Industry Standards | IEEE C37 series, UL 489, UL 67, NEMA AB 4 – recognized standards governing circuit breaker design and testing | IEEE, UL, NEMA official publications and standards documents |

| Statistical Studies | Research on reliability, failure rates, and testing procedures of molded case circuit breakers | Studies by Braun (1972), Steel (1970, 1972), Lindquist et al. (2008), Natti et al. (2004) |

| Independent Testing | Failure analyses and functional test data linked to fire loss statistics | Wright-Malta Corp. for U.S. Consumer Product Safety Commission; Aronstein & Lowry (2011) |

| Monitoring Agencies | Role of UL and ETL in overseeing testing and certification processes | UL and ETL regulatory services and monitoring reports |

| Empirical Evidence | Statistical failure rates showing variability among manufacturers and implications for safety | Aronstein’s research on defective breakers and failure rates, including private communications (2017) |

| Industry Observations | Observations on testing procedure changes and their impact on breaker quality | Expert opinions and documented test results indicating reliability concerns and manufacturer differences |

Always follow industry standards like UL 489, IEEE C37, and NEMA AB 4 when you test molded case circuit breakers. These rules help you make sure your tests are correct and your results are good.

If a Breaker Fails a Test

Immediate Actions

If a breaker does not pass a test, you must act fast. First, turn off the power to the breaker. This keeps everyone safe from shocks or fire. Take the breaker out so no one can use it by mistake. Put lockout/tagout tags on it to show it is not safe. Never try to reset or use a breaker that failed a test.

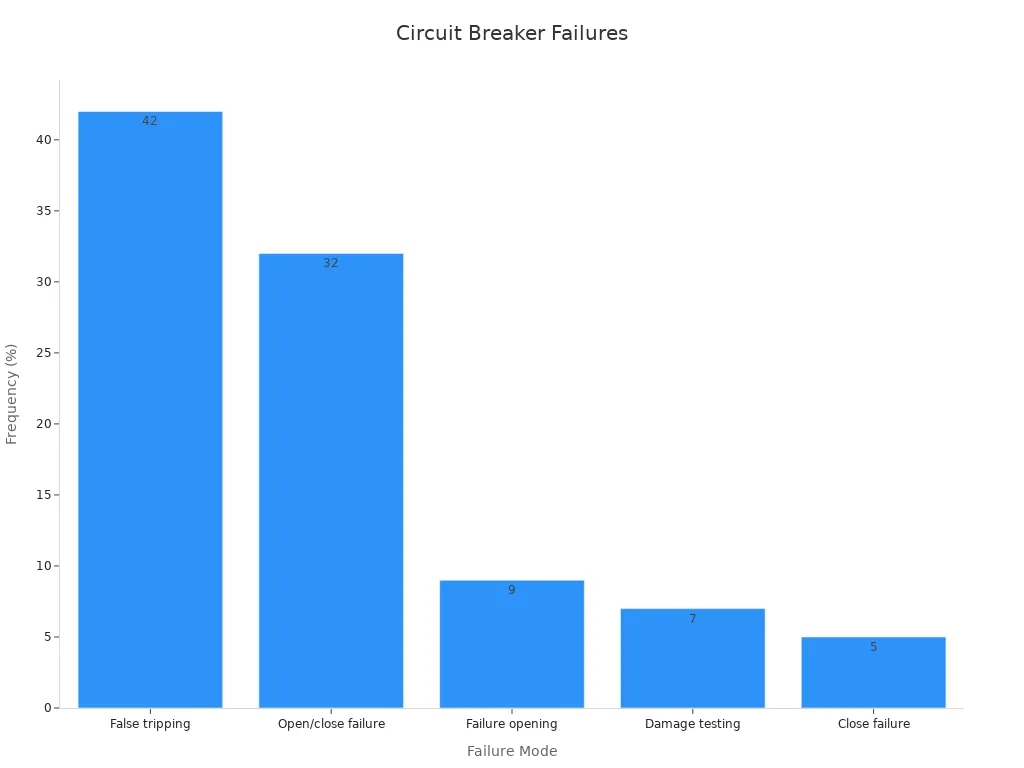

Here is a table that shows the most common ways breakers fail and how often:

| Failure Mode | Approximate Frequency |

|---|---|

| False tripping (opened when it should not) | Highest (~42%) |

| Failure to open or close properly | Moderate (~32%) |

| Failure while opening | Lower (~9%) |

| Damage during operation or testing | Minor (~7% combined) |

| Failure to close when required | Low (~5%) |

You can see that false tripping happens the most. Problems with opening or closing are also common. These issues can make you lose power or even cause a fire.

Replacement or Service

After you take out the breaker, decide what to do next. Most of the time, you should put in a new breaker. New breakers are safer and work better. If your breaker is special or costs a lot, you can send it to a repair shop. Always use the right parts for your panel and follow the maker’s rules.

You need to test molded case circuit breakers after you fix or replace them. This makes sure the breaker works the right way. Testing often helps you find problems early and keeps your system safe.

Consult a Professional

Sometimes, you may not know why the breaker failed. If this happens, call an electrician or engineer. Experts can find hidden problems, like bad wires or design mistakes. For example, a refinery in Montana had a big explosion because of a bypassed switch. After experts helped, the refinery used new breaker technology. This stopped more accidents and kept workers safe.

Professionals use special tools and ways to test molded case circuit breakers and make your system better. They can also tell you about upgrades that protect your equipment and stop problems. If you are not sure, always ask an expert for help.

You can keep your electrical system safe by doing three steps. First, look at the breaker for any damage. Next, check if it moves and works right. Last, test it with special tools to see if it works well. Doing these tests often helps you find problems early. This can stop big repairs and keep people safe.

- Checking breakers often makes them last longer and work better.

- If you skip tests, you might have fires or get shocked. You could even break the law.

- Testing also helps save energy and follow safety rules.

Safety is always most important. If you see a problem or feel worried, call an expert. Make testing a habit so you feel safe and follow the rules.

FAQ

How often should you test molded case circuit breakers?

You should test molded case circuit breakers at least once a year. If you use them in harsh environments or critical systems, test them more often. Regular testing helps you catch problems early and keeps your electrical system safe.

What tools do you need to test a circuit breaker?

You need a flashlight, screwdriver, megohmmeter (megger), and a digital low resistance ohmmeter (DLRO). For trip tests, use a primary injection tester. Always wear safety gloves and glasses.

Tip: Check your breaker’s manual for any special tool requirements.

Can you test a breaker without removing it from the panel?

You can do a visual inspection and manual cycling without removing the breaker. For insulation and contact resistance tests, you must remove the breaker from the circuit. This keeps you safe and gives you accurate results.

What should you do if a breaker trips during testing?

If a breaker trips, stop the test and check for faults in the circuit. Remove the breaker and inspect it for damage.

- Replace the breaker if you find any issues.

- Call a professional if you feel unsure.

The following information may be of interest to you

Common fault diagnosis guide for miniature circuit breakers

Intelligent MCCB circuit breaker

Why Won’t My Circuit Breaker Reset and What Can I Do?

Molded case circuit breaker 125 ampere 4P