Automatic switch, as an intelligent electrical control device, is widely used in various fields of home, industry, and commerce. It can automatically turn on/off the circuit with environmental changes or according to predefined conditions, thus improving the automation degree of the system and energy utilization efficiency.

In this article, we will describe in detail the operation process of automatic switches so that you can have a better understanding of the working principle and applications of this important device.

Basic concepts of automatic switch

Automatic switch is a device that has the ability to automatically switch circuits based on some conditions such as voltage, current, temperature, etc. It is generally composed of three parts: sensors, control units, and actuators. The automatic switch decides to switch on or off the circuit based on the environmental signal perceived, thereby achieving automatic control of the power equipment.

The core components of automatic switch

Detailed explanation of the workflow of automatic switch

Automatic switches achieve intelligent control of circuits through the collaborative work of sensors, controllers, and actuators. The core process can be divided into four stages: real-time monitoring → logical judgment → action execution → status feedback. The specific process is as follows:

Real time monitoring stage: sensor data collection

The auto switch receives environment or circuit parameters in real time through in-built sensors as the basis of control. Common sensors are:

Current/voltage sensor: to sense circuit overload, short circuit, or voltage anomalies (e.g., sensing the status of the primary and secondary power sources during double power switching)

Photosensor: sensing changes in light through the use of photoresistors to control streetlights or car headlights on/off

Temperature sensor: monitors equipment temperature to prevent overheat faults (e.g., temperature protection within motor protectors)

Human infrared sensor: detects human presence, controls automatic doors or smart light systems. They convert physical signals into electrical signals and pass them to the controller for processing.

Logical judgment stage

At this stage, the controller (such as a microprocessor, DDC controller, or microcontroller) receives sensor signals and makes judgments and decisions based on preset logic

1.Threshold comparison: Compare the detected value with the preset threshold. For example:

In the dual power switch, when the main power voltage is lower than 80% of the rated value, it is judged as a fault and triggers the switching operation.

In overcurrent protection circuits, when the current exceeds the safety threshold, fuse or current limiting measures are activated.

2.Delay processing: In some scenarios, to avoid false triggering, a delay mechanism needs to be introduced. For example:

When switching between dual power sources, a 3-second delay is required to confirm the fault and prevent false judgments caused by instantaneous voltage fluctuations.

The streetlight control system dynamically adjusts the sunrise and sunset times based on latitude and longitude algorithms to avoid frequent on/off operations.

3.Logical operation:

In more complicated systems like smart variable frequency electric actuators, dynamic adjustment is implemented by means of algorithms. For example, with the PID control algorithm for the motor speed control.

Action execution phase

After the controller issues a command, the executing mechanism quickly completes the circuit on/off or state adjustment:

1.Relay action

Electromagnetic relay attracts contacts through coil magnetic field, suitable for high current scenarios (such as dual power switching)

Solid state relay (SSR) uses semiconductor components to achieve contactless switching, with a response speed of milliseconds, suitable for high-frequency operation

2.Motor drive

Automatic doors achieve smooth opening and closing through motor and belt transmission

The intelligent actuator adjusts the motor speed through a frequency converter and precisely controls the valve opening

3.Fuse protection

The overcurrent protection circuit cuts off the fault current through a fast fuse or Hall sensor to protect the safety of the equipment

Status feedback and reset

Fault alarm: Abnormal states are reported through sound and light signals or remote communication modules (such as 4G/Wi Fi), such as backup power supply fault alarms for dual power switches

Automatic reset: After troubleshooting, some systems can automatically recover (such as the overcurrent protection circuit restarting through a self recovery mechanism)

Manual intervention: Support users to manually control through buttons, apps, or remote controls, such as remote operation of smart socket timing switches

Workflow of application scenarios

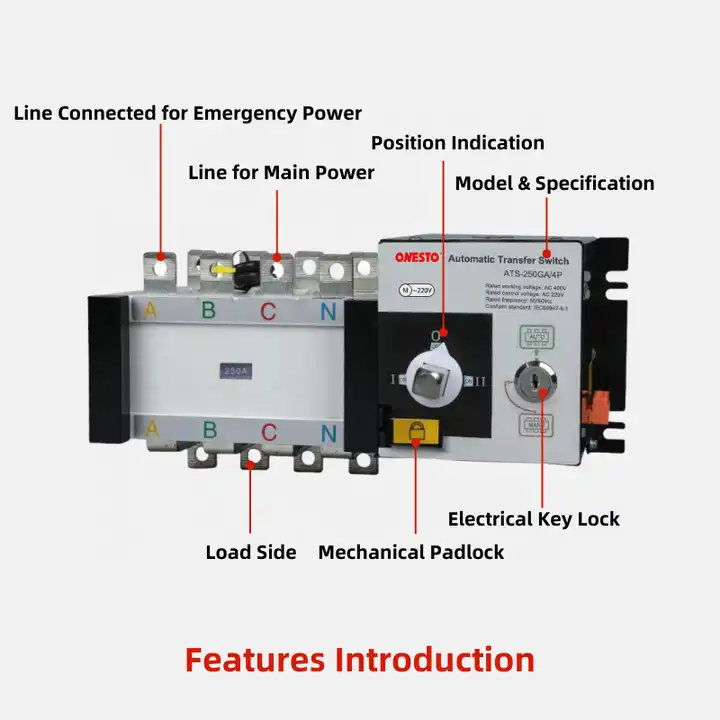

Dual power automatic switching (ATS)

Detecting main power failure → Delay confirmation → Switching to backup power → Automatic switching back after main power restoration

Automatic control of street lamps

Light sensor triggered → latitude and longitude algorithm correction time → relay closed → remote status feedback

motor protection

Current transformer detects overload → microprocessor calculates inverse time curve → relay cuts off power → temperature sensor assists in monitoring

Smart home switch

Infrared/microwave sensor detects human body → microcontroller determines activity duration → relay controls lighting → APP synchronization status

Contact ONESTO

Contact us immediately: Do you have any questions or need customized solutions? Our team is always ready to assist you. Contact us for personalized quotes and expert advice tailored to your specific requirements.

Free Consultation: We provide free consultation to help you understand your choices and choose the best ATS based on your situation.

Here are some information that you may have just been interested in:

How to choose the appropriate type of circuit breaker

Price Guide for Automatic Transfer Switches in 2025

The 10 Best Automatic Conversion Switch Brands of 2025