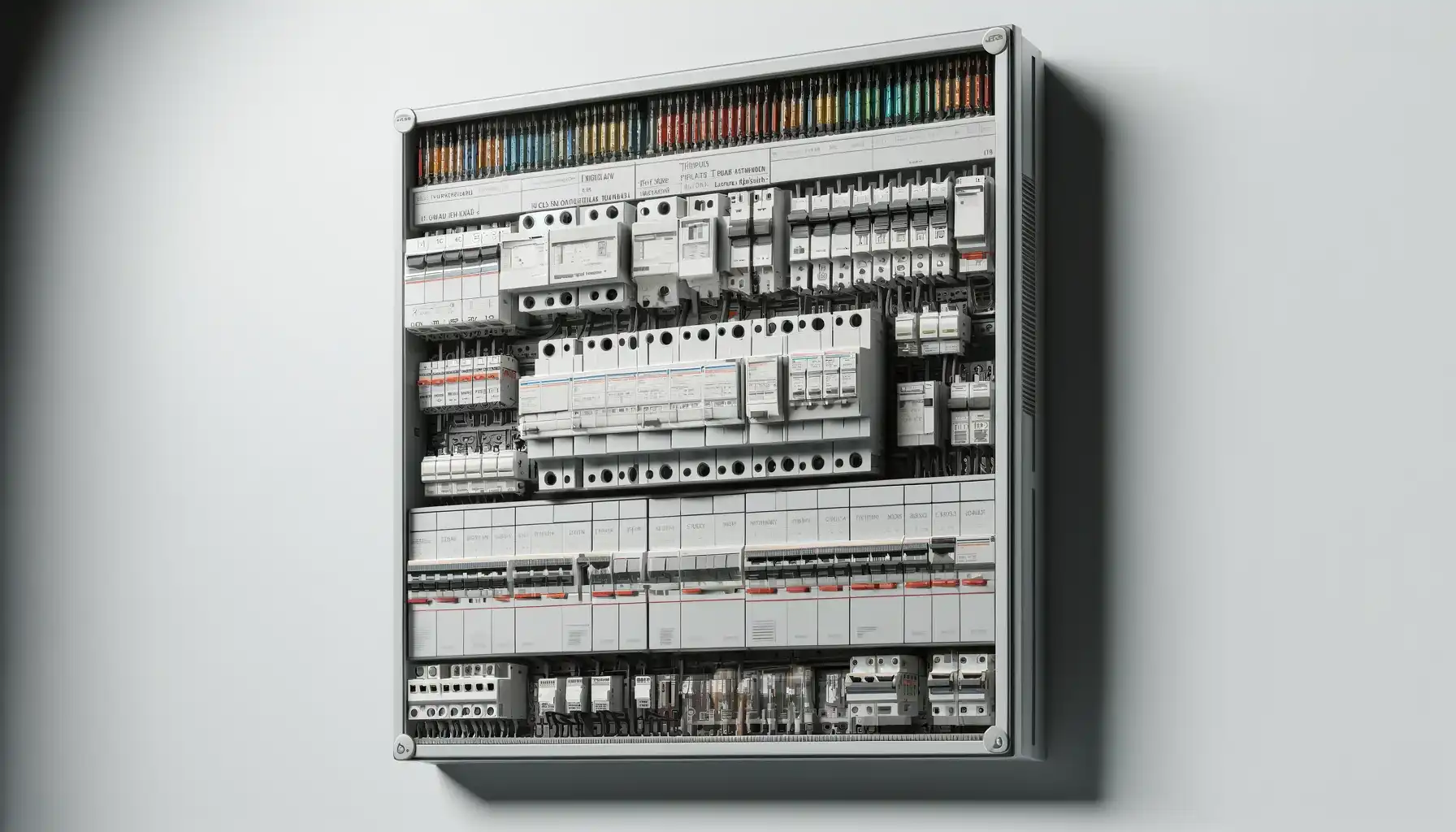

Distribution boards are crucial for safe and effective handling of electricity. Each component in the system contributes to the normal operation of the system and ensures the safety of personnel and equipment.

Due to the continuous increase in energy consumption, more and more people need these accessories.

These components help avoid expensive power outages and ensure people’s safety.

They are very important in places such as data centers where power must be maintained.

With the development of cities and the increase in electricity consumption, these components have now become key to reliable power systems. Through the following article, let us understand the 5 basic components required for each distribution board

Key points

- The main circuit breaker controls the power and ensures maintenance safety.

- Busbars can effectively transmit electricity and are widely used in many industries.

- The residual current device (RCD) stops electric shock by quickly cutting off the power supply.

- When the current is too high, the fuse will cut off the circuit, thereby preventing overload.

- Surge protective devices (SPDs) protect the system from voltage spikes and damage.

What is a distribution board

The core of a distribution board is a centralized device used to receive electricity and distribute it to various circuits within the building. It can be regarded as a traffic controller for electricity, ensuring the safe and orderly flow of the entire power system. It serves as a centralized point, distributing and directing the electrical energy from the main power source to various circuits, thereby controlling the distribution of power to different areas or appliances.

Distribution boxes typically contain circuit breakers or fuses for each circuit, used for individual control and protection of specific circuits. It plays a crucial role in ensuring safe and efficient distribution of electricity, by interrupting current in the event of a fault to help prevent overload and short circuit.

Main circuit breaker

The purpose of the main circuit breaker

The main circuit breaker is the core of the distribution panel. It controls the current entering the system. Its function is to manage the current and ensure its safety. Without it, handling electricity would become chaotic and dangerous.

Circuit breaker tools are essential tools in both household and industrial fields. It can shut down all power sources during maintenance or emergency situations. For example, when repairing damaged equipment, the main circuit breaker will cut off the power to avoid accidents. The product quality meets safety regulations and reduces the possibility of electrical hazards.

How to protect the system with the main circuit breaker

The main circuit breaker ensures system safety by identifying issues. If the current is too high or a short circuit occurs, it will quickly cut off the power supply. This can protect your equipment and wires from damage.

Circuit breakers are very useful in natural disasters such as earthquakes. They prevent power failures by quickly cutting off faults. In advanced systems such as MMC-HVDC grids, special circuit breakers called DCCBs also play the same role. They quickly cut off faults to ensure the normal operation of the system. The new circuit breaker system can also repair problems faster and maintain system stability.

Installing a good main circuit breaker can protect your power board. It is your first barrier, ensuring the safe and reliable operation of your system.

Busbars

What is the role of busbars in distribution boards

Busbars are crucial for distribution boards. They serve as the primary connectors, transporting current from the main power source to the circuit. The design of the busbar facilitates the smooth flow of current, thereby saving energy and improving system performance.

Bus ducts are widely used in many fields such as factories and green energy systems. For example, in data centers, they can provide stable power and avoid expensive downtime costs. In electric vehicles, they improve efficiency through auxiliary batteries and chargers. The widespread application of bus ducts has made them an indispensable component in many industries.

💡 You know what? In 2022, the global busbar market size will exceed 15 billion US dollars. It is expected that by 2030, the market size will grow to nearly 24 billion US dollars. This indicates an increasing demand for higher quality distribution systems.

Materials used for busbar

The material of the bus duct will affect its working performance and service life. Copper and aluminum are the most popular materials because they have good conductivity. Copper has high strength and rust resistance, making it very suitable for high-power applications. Aluminum is lighter and cheaper, making it ideal for occasions with strict requirements for weight and cost.

Below is a brief comparison of bus duct materials:

| Material | Conductivity | Strength | Performance and Durability |

|---|---|---|---|

| Copper | Excellent | High | Strong, rust-resistant, best for high-power needs. |

| Aluminum | Good | Moderate | Light, affordable, treated to last longer, less durable than copper. |

| Brass | Moderate | High | Strong and durable, but less conductive than copper. |

| Composite Materials | Varies | Varies | Lightweight, improves performance, mixes metals with other materials. |

For your best advice: The appropriate material depends on your system requirements. Copper is most suitable for factories and data centers. Aluminum is highly suitable for green energy systems and electric vehicles. Choosing the right materials can ensure that your power board has good performance and durability.

Residual Current Device (RCD)

Working principle of residual current device

Residual current protection device (RCD) can help you avoid electric shock. They will check the current flow in the circuit. If problems are found, such as leakage, they will quickly cut off the power supply. This quick action can prevent serious injury or even death.

When the current exceeds the set limit (usually 30 mA), RCD will trip. Tests have shown that they must operate between 50% and 100% of the rated current. This ensures that they can quickly identify problems. In the factory, residual current monitoring (RCM) is used in conjunction with RCD. They can detect insulation problems early, which helps to solve them before they cause system failures.

Why is RCD so important for safety

RCD is the key to ensuring the safety of electrical systems. They can protect people and property from electric shock and fire. IEC 60364-6: The 2016 regulations require regular safety inspections. RCM compliant with IEC 62020 can replace traditional insulation testing. This makes the inspection faster, but still very safe.

In the factory, RCM can provide additional assistance. They can detect the continuously rising residual current early. Early repair of these issues can avoid costly downtime. This also improves the reliability of the distribution board. Adding RCD and RCM can make homes and workplaces safer and more comfortable.

⚡ Tip: Test your residual current device (RCD) frequently to ensure they are functioning properly. Press the test button to check if they are ready to protect you.

Fuse

How to prevent electrical overload with fuses

Fuses are crucial for ensuring the safety of electrical systems. When the current is too high, the fuse will cut off the circuit. A small wire inside the fuse will melt when the current is too high. This phenomenon is called “blown fuse“, which can cut off the current, prevent fire or overheating.

Different fuses can meet different needs. Quick fuses can quickly melt in sudden surges, making them ideal for protecting precision equipment. A slow fuse can be blown in a short surge. For example, machines in factories use slow fuses when starting a surge. Choosing the appropriate fuse can ensure the safe and reliable operation of the system.

What is the difference between fuses and circuit breakers

Fuses and circuit breakers are both used to protect electrical systems, but their working principles are different. The fuse can only be used once. After melting, it must be replaced. The circuit breaker can be reset and reused after tripping. This makes them easier to use frequently.

Fuses are simpler and more cost-effective. They are very suitable for small systems or situations that require cost savings. Circuit breakers are more suitable for large systems, such as distribution boards. They reset quickly and have stronger processing capabilities. Some even have advanced features such as remote control.

Understanding these differences can help you choose the right product. Fuses and circuit breakers are both key to ensuring safety and reliability.

Surge Protection Device (SPD)

Protect the system from voltage surges

Surge protectors (SPDs) can protect your system from sudden voltage surges. These surges may be caused by lightning strikes, power outages, or equipment failures. If there is no SPD, surges may damage electronic devices, cause work to stop, and even trigger fires.

SPD provides protection by releasing additional voltage from the device. Engineers use surge generators to simulate voltage spikes to test SPDs. This test aims to check whether SPD can handle surges well. It can also identify weak links in the system, providing better protection. These tests ensure that SPDs comply with standards and are able to cope with different surge levels.

SPDs with rated currents ranging from 100.1 to 200 kA can provide strong protection in factories and offices. They can protect expensive equipment and ensure smooth system operation. Installing SPD helps to avoid expensive repairs and delays caused by surges.

Why use surge protection devices

There are many benefits to installing SPDs on power distribution boards. Firstly, they can prevent electrical surges from damaging your equipment. This can extend the service life of the equipment and reduce maintenance costs. Secondly, SPD can improve system reliability and ensure the normal operation of hospitals and other places.

Modern systems are becoming more complex, and the demand for surge protectors (SPDs) is also increasing. These devices help manage connected systems and maintain power stability. The new SPD design has better performance and is easier to obtain, resulting in a larger number of users.

SPD can also prevent lightning related surges. As people gradually realize its value, more and more households and businesses are starting to install SPD. Using SPD can protect your property safety, reduce risks, and ensure the normal operation of your system.

⚡ Tip: Regularly check your SPD to ensure they are still functioning properly.

Summarize

The five parts of a distribution board – main circuit breaker, busbar, residual current device, fuse, and surge protector – are crucial for safe and effective management of electricity. Each part has its own special function to protect your system and ensure smooth power flow.

Understanding these components can help you better set up and maintain them. Whether it’s fixing problems or improving systems, understanding their functions can ensure that everything runs safely and reliably.

Regularly inspect these components to ensure their proper functioning and avoid any issues.

FAQ

What is the function of the distribution board?

Distribution boards can safely manage and share electricity. It can prevent issues such as overload, short circuit, and voltage spikes, ensuring that power flows smoothly to all connected devices.

How often should you check the power distribution board?

Check the parts every 6 to 12 months. Regular inspections can detect damages or problems early. This ensures that your system runs safely and reliably.

Can circuit breakers replace fuses?

Yes, you can replace the fuse with a circuit breaker. Circuit breakers are reusable and easy to reset after tripping. Please ensure that the new component meets the security requirements of your system.

Why do we need surge protection devices?

Surge protectors can prevent voltage spikes caused by lightning strikes or surges. They can protect electronic devices, reduce maintenance costs, and improve system reliability.

Which material is most suitable for busbars in strong systems?

Copper is the preferred choice for high-power systems. It has good conductivity, high strength, and long service life. It also has anti rust properties, making it very suitable for factories and data centers.

The information below may be of interest to you

How to choose the size of the distribution board

How a Distribution Board Works and Why It Matters

Residual Current Circuit Breaker (RCD) and Leakage Protection