Distribution box manufacturer

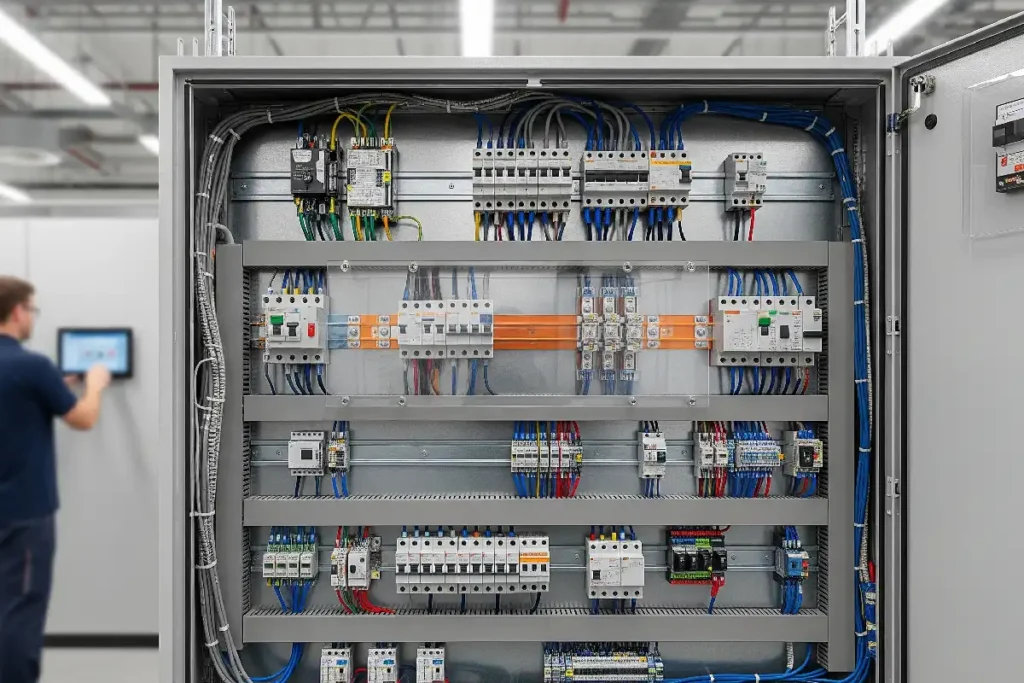

SENTOP, as a leading manufacturer of distribution boxes in the market, not only produces high-quality products with strict processes, but also provides the most competitive prices with its complete supply chain advantages. At the same time, we support OEM manufacturing and personalized customization services to help customers enhance their brand competitiveness and market value.

What are our characteristics

Production technology

Customization and OEM/ODM

High performance-price ratio

Long term partnership

Customizable distribution box

Explore our diverse range of customized distribution boxes, widely used in different scenarios such as residential, commercial, and industrial. We provide comprehensive solutions from basic power distribution and safety protection to integrated intelligent monitoring and efficient management, ensuring that your electrical system remains safe, stable, and efficient during operation, meeting the needs of various complex projects.

Electrical ABS plastic distribution box

OEM circuit breaker distribution box

IP40 waterproof distribution box

Outdoor residential distribution box

High quality steel distribution box control panel

Outdoor sturdy metal distribution box factory wholesale

CE/CB certified waterproof wiring distribution box

Outdoor electrical plastic waterproof shell distribution box

A brief introduction

WHY CHOOSE US

- Industry leading testing: Each distribution box undergoes strict 100% international safety standard testing

- High quality materials: High quality components ensure longer service life and reliable performance

- Engineering Innovation: Our R&D team continuously improves distribution box technology to enhance protection

- Global certification: Our entire distribution box series has obtained IEC, CE, UL, and regional safety certifications

- Comprehensive support: from selection guidance to installation training and after-sales service

Why choose a distribution box?

The reason for choosing a distribution box is that it can provide centralized management and comprehensive protection for the power system. It not only effectively distributes electrical energy, but also ensures electrical safety through components such as circuit breakers and leakage protectors, reducing risks such as short circuits and overloads. High quality distribution boxes also have good sealing and durability, suitable for residential, commercial, and industrial environments, ensuring the stability and efficiency of power supply, and are a key link in building a safe and reliable electrical system.

Robust Safety Design

Our Power Distribution Box features a robust safety design that includes advanced components for high efficacy. It reduces the risk of electrical hazards, ensuring safety at all times.

- High-Quality Circuit Protection

- Sturdy Enclosure Materials

- Fire and Shock Resistance

Efficient Power Management

Designed for efficiency, the Power Distribution Box allows seamless management of power resources while maintaining power stability and reducing waste.

- Balanced Load Distribution

- Reduced Energy Loss

- Predictive Maintenance Alerts

User-Friendly Access

With user-friendly access points, our Power Distribution Box simplifies monitoring and managing your electrical systems conveniently, ensuring enhanced operational efficiency.

- Easy-to-Access Terminals

- Visual Indicators for Monitoring

- Intuitive Layout

Customizable Configurations

The Power Distribution Box offers customizable configurations tailored to specific needs, providing flexibility for various electrical setups ranging from small to large-scale.

- Scalable Design Options

- Modular Components

- Varied Sizing Choices

Features of Our Power Distribution Box

High safety

The distribution box can effectively protect the circuit, avoid accidents such as short circuit, overload, and electric shock, and ensure electrical safety.

Easy to manage

Centralized power control, easy to control the power supply of different areas or devices, and convenient for maintenance and repair.

Improving power quality

Reasonable distribution design can reduce power loss, achieve optimal distribution, and improve power supply efficiency.

Good protective performance

The distribution box has protective functions such as dust prevention, waterproofing, and anti-corrosion, and can adapt to various environments, especially in industrial environments.

Excellent flexibility

Various switches, circuit breakers, leakage protectors, etc. can be configured as needed to provide power for different environments.

Automation control

The distribution box can adopt an intelligent control system to achieve remote monitoring, automatic alarm, timed switch and other functions, which can improve management efficiency.

Get Your Free Sample!

We provide samples for free, you just need to tell us what you need

Not only manufacturers of distribution boxes

We not only produce high-quality distribution boxes, but also provide diverse customization and value-added services to meet your unique distribution project needs. We focus on quality and innovation, ensuring that every customer can receive tailored solutions, professional technical guidance, and seamless support throughout the entire cooperation process, ensuring the safe and efficient operation of your power system.

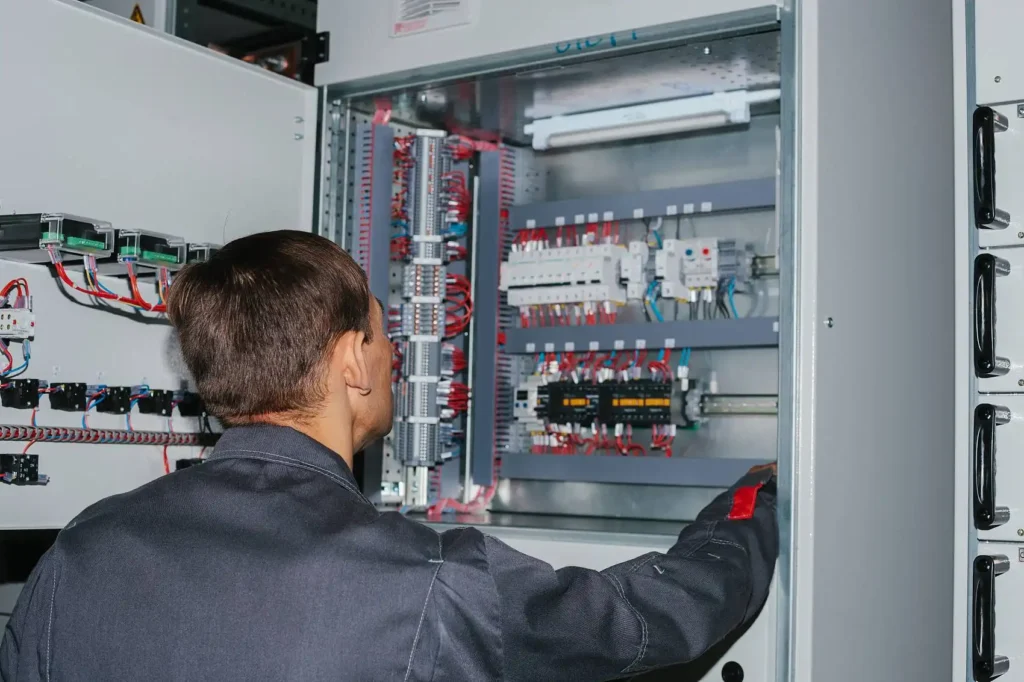

Service Consultation

Whether your distribution box requirements are for basic applications or complex projects, our team can provide professional advice and technical consultation. For high difficulty projects, we provide in-depth engineering support to ensure that you choose the best products and application solutions.

Product Recommendations

Not sure which distribution box is suitable for your system? Our experts will provide free customized advice based on your specific operational and environmental requirements, ensuring that you receive the product that best meets your electrical protection needs.

Logistics Support

If you lack a reliable freight forwarder, we can arrange transportation from the factory to the project site at no additional cost. Our logistics team ensures timely and safe delivery, ensuring that your project proceeds as planned and minimizing downtime and delays.

Installation Support

Do you need installation assistance? Our technical team is always ready to answer your questions and provide practical support. For large-scale projects, we can even dispatch engineers to your site to provide on-site assistance

What are our clients saying

Our customers share their experiences with our Power Distribution Box, highlighting safety, reliability, and performance.

Your trusted electrical equipment supplier

♥Wide selection

♥OEM Quality

♥100% Satisfaction Guarantee

Looking forward to working with you

FAQ

Get answers to common questions about our Power Distribution Box and its features.

What is a Power Distribution Box?

A Power Distribution Box is a critical component that distributes electrical power from a

single source to multiple outlets safely.

How does a Power Distribution Box enhance safety?

It enhances safety by providing circuit protection, ensuring that overloads and short-circuits are managed effectively.

Why choose our Power Distribution Box over others?

Our Power Distribution Box offers superior build quality, customizable options, andcompliance with safety standards.

How do l maintain a Power Distribution Box?

Regular inspections, cleaning, and ensuring proper access are key maintenance practicesfor a Power Distribution Box.

Can the Power Distribution Box be customized?

Yes, our Power Distribution Box can be customized to fit specific requirements andapplications.

What materials are used in the Power Distribution Box?

It is made from high-quality, durable materials that withstand various environmental

conditions.

Is the Power Distribution Box easy to install?

Yes, the Power Distribution Box is designed for easy installation, featuring user-friendlyaccess points.

How do l choose the right Power Distribution Box for my needs?

Consider the load requirements, installation environment, and necessary compliancestandards when selecting a Power Distribution Box.

What standards does the Power Distribution Box comply with?

Our Power Distribution Box complies with industry standards and certifications to ensurereliability and safety.

Our Power Distribution Box complies with industry standards and certifications to ensurereliability and safety.

You can purchase our Power Distribution Box through our website or authorized

distributors.

Understand Power Distribution Box

Table of Contents

What is a distribution box

Distribution box is a very important piece of equipment in the power supply, mainly used for power distribution, control, and protection in order to ensure electrical safety. It is commonly composed of such components as a box, circuit breaker, terminal block, and energy meter, and is used widely in homes, industries, companies, and other places.

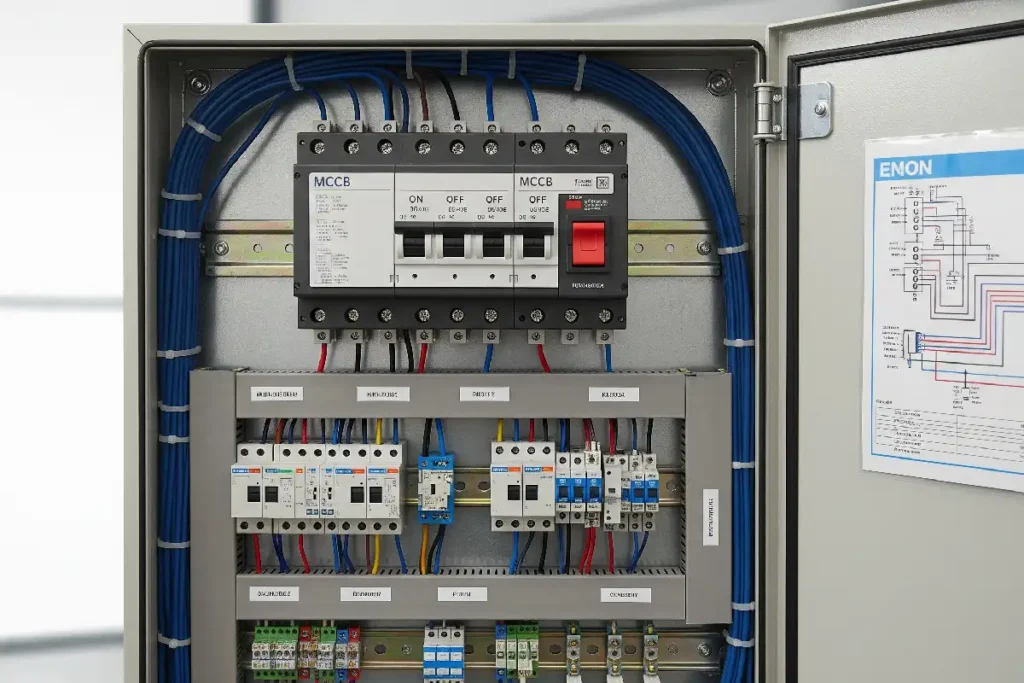

The main components of the distribution box

The distribution box consists of two main parts: the outer shell and electrical components. The shell is usually metal or fire-resistant material, and has functions such as dust prevention, water resistance, and explosion prevention

Internally, it consists of the following main components:

Circuit breaker: e.g. air switch, leakage protection switch, dual power automatic transfer switch, which is responsible for overload, short circuit and leakage protection

Surge Protection Device (SPD): three-stage protection mechanism that is designed to safeguard against voltage surges or lightning strikes

Electricity meter: mechanical or electronic, used for measuring electrical energy

Ammeter/voltmeter: detects circuit parameters and has to be connected in parallel or series

Auxiliary equipment: such as relays, contactors, intelligent monitoring modules, etc

Classification of distribution boxes

Surface mounted: attached directly to the wall for ease, suitable for home or office spaces

Concealed installation: Fitted into the wall for fitting, beautiful but hard to service, usually utilized in settings with high decorating requirements

Wall mounted: Attached on the wall, suitable for scenarios with not a lot of space

Floor standing: Attached on the ground or base, often utilized in industrial environments

The core function of the distribution box

Energy distribution: Divide the main circuit electrical energy into various branches to feed the needs of various equipment

Circuit protection: Rapid interruption of overcurrent, short circuit, and leakage through circuit breakers to prevent equipment damage and fire

Monitoring and control: Real-time display of voltage, current, and other parameters, some high-end models with remote intelligent monitoring

Emergency Switching: The dual power automatic transfer switch can switch to the backup power supply smoothly when the main power fails

Installation of distribution box

Fixed method

Box and component installation

Distribution box wiring

Wiring process

The inlet and outlet of the wire should be sealed with fireproof adhesive or fireproof partitions, and the wire harness should be fixed neatly with a bending radius of ≥ 2 times the diameter of the wire harness

Mother busbar connection: Copper busbar bending requires special tools to avoid cracks; Apply neutral Vaseline to the connection between the busbar and the equipment to prevent oxidation

How to choose a suitable distribution box

Selection of key technical parameters

Brand selection

SENTOP, Chint, Delixi, and others offer high cost-effectiveness, comply with international standards, and provide comprehensive after-sales service

Schneider, Siemens, ABB are suitable for high-end demand, but their prices are relatively high

Price factor

The influencing factors on the price of distribution boxes primarily include material, brand, and protection level. Materials used for distribution boxes are usually separated into stainless steel and plastic types. The former is durable and possesses good durability for outdoor or bad environments, and the latter is light, suitable for indoor or those environments with less stringent requirements against corrosion. Based on the different environments for application, you can freely use appropriate materials.

Brand-wise, the performance, quality, and price of distribution boxes of different brands differ tremendously. For example, ABB、 Siemens and other popular global brands are premium brands with high product quality, suitable for events demanding high standards of automation circuits, but at relatively higher prices. If you have limited funds, you can choose ONESTO brand distribution boxes, which offer high quality but are cost-effective and economical.

In addition, the level of protection is another important factor to affect the cost of distribution boxes. According to your own demand, you may choose distribution boxes with different protection levels such as explosion-proof, dustproof, waterproof, etc. to ensure the equipment is operated safely and stably under specific conditions.

Distribution box faults and their handling methods

1. Overload and short circuit faults

Performance: The circuit breaker trips frequently, the temperature of the box rises abnormally, and the insulation layer of the wire is burnt.

solve:

Reduce the load and ensure that the total current does not exceed the rated value of the distribution box;

Use a megohmmeter to detect short circuit points, repair or replace damaged circuits

2. Leakage tripping

Performance: The leakage protector frequently operates, and the equipment casing is electrified.

solve:

Check if the N and PE wires are connected to the dedicated terminal block, ensuring that the grounding resistance is ≤ 4 Ω;

Use splash proof leakage protection in humid environments (operating current ≤ 15mA)

3. Circuit breaker malfunction

Closing failure: may be due to poor button contact, burnt fuse, or damaged electromagnet.

Replace the closing button or fuse core, and check if the control circuit voltage is normal

4. Component aging and poor contact

Symptoms: Blackening of sockets, oxidation of terminals, and overheating of wire joints.

solve:

Replace the blackened socket to prevent excessive resistance from causing a fire;

Tighten loose wiring terminals, use copper wires and install arc separators to prevent arc short circuits

5. Abnormal voltage

Performance: The voltmeter displays too high or too low, and the equipment runs unstably.

solve:

Adjust the transformer tap or capacitor compensation capacity;

Check if the secondary circuit connection of the current transformer is reliable