Fuses are one of the most basic safety devices in circuits. It is an electrical protector that protects circuits from the effects of overcurrent, thereby avoiding fires, equipment damage, and even destruction.

When the current exceeds the safe level, the fuse will disconnect the circuit as designed to avoid tragedy, but it has been proven to be a low-cost and simple replacement component. This article will cover the types and operations of fuses, as well as tips for selecting the appropriate fuse based on your specifications.

What is a fuse?

A fuse is an electrical protection device that can prevent circuit damage or fire caused by overcurrent. Usually, fuses are made of wires or metal strips that can carry a certain amount of current, but have a lower melting point than other circuit components. Once the current exceeds the design current capacity of the fuse, it will melt, disconnect the circuit, and protect the components from damage.

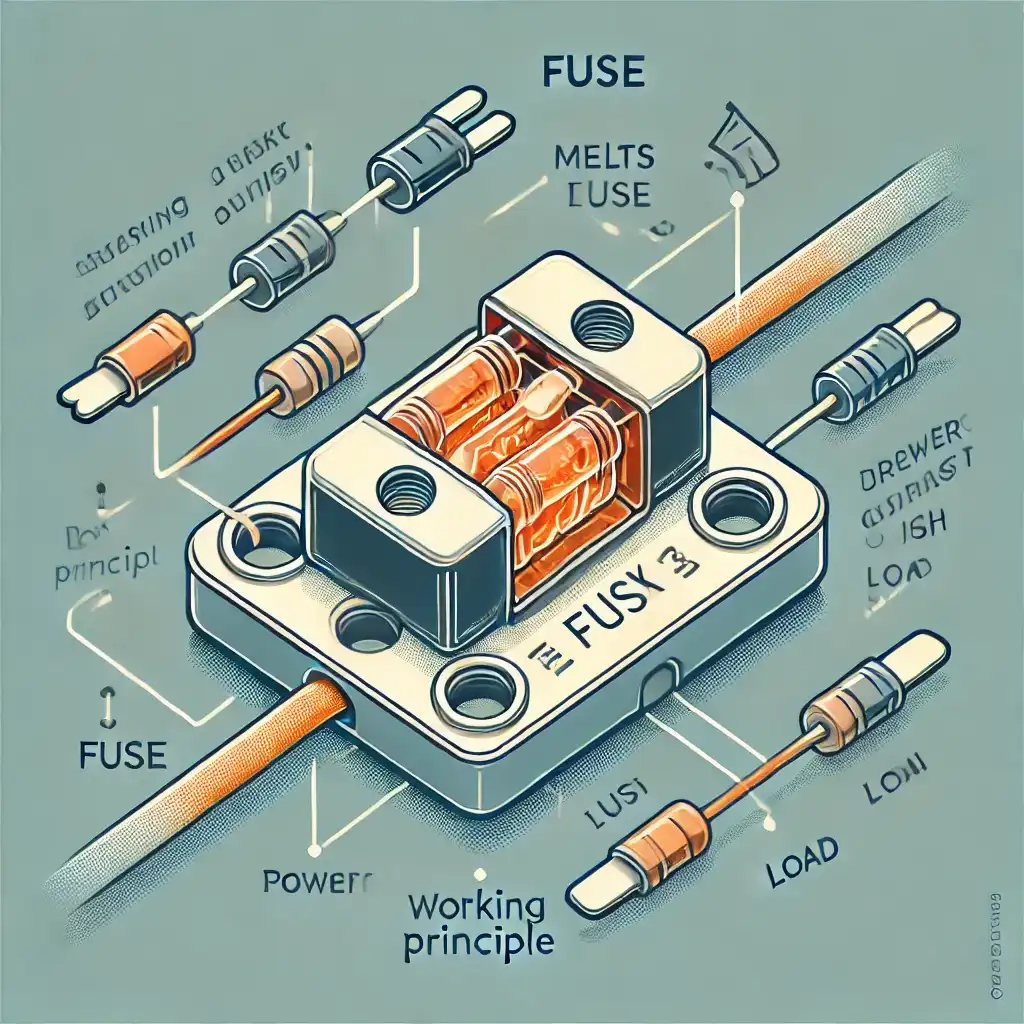

The working principle of fuses

Structure: The fuse is composed of conductive metal strips or wires (zinc, copper, or silver) located within non-conductive materials (ceramic, glass, or plastic).

Normal operation: At a safe current level, the metal strip allows for uninterrupted flow of current.

Overcurrent event: When the current exceeds the rated value of the fuse, the metal will heat up due to resistance loss (Joule heating).

Melting (melting): The melting of a metal strip creates a gap that disconnects the circuit.

Isolation: The circuit remains open until the fuse is manually replaced.

Summarize:Now, when current flows through the fuse, the value of the current passing through the fuse is directly proportional to the value of the resistance of the metal material in the fuse. If the circuit current is too high, the heated metal sheet will also melt, thus interrupting the circuit. Typically, the speed of the melting process does depend on the size and duration of the current. Hence the precise computation of fuses melting characteristics is a must in the designing in order to quickly react to overloading position.

Different types of fuses

1.Tubular fuse

Hollow cylindrical devices are known as tubular fuses, they are commonly used in industrial and high-power applications. They are categorized based on their architecture and voltage management:

Glass tube fuse:

- It has a transparent glass tube, and the end caps are metal with visible fuse internals.

- Application: Low voltage circuitry for electronics and small household appliances, etc.

Ceramic fuse:

- This high voltage environment is implemented by first filling the ceramic body with sand to suppress electric arcs.

- Sample: Widely applied in industrial equipment and solar inverters, AC voltage up to 600V.

2.Plug in fuse (car)

Most modern vehicles now use blade fuses, and for good reason — they’re small and easy to remove when blown.

Structure:

- Clear plastic cover allows to check the visual condition of the fuses.

- Show the rated current value by color: (20a — yellow, 10a — red)

Application:

- Vehicle: Protect electronic devices like headlights, electronic control units and infotainment systems.

- Common use in cars, truck and motorcycles.

Main features:

- Durability: vibration- and temperature-tolerant (−40 ° C up to 125 ° C).

- Utilizing standard (ATO/ATC), mini and micro size designs for standardization, ensuring compatibility.

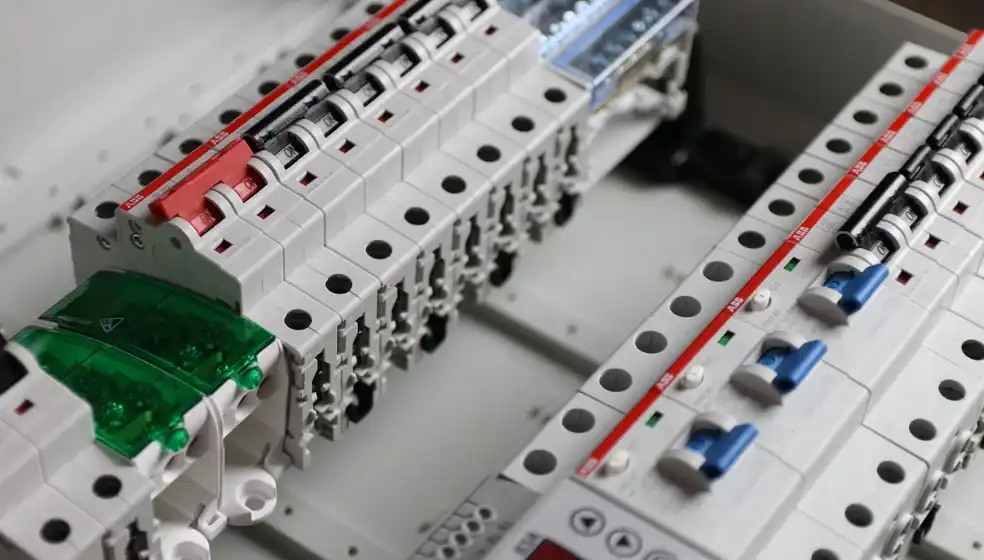

3.High Rupturing Capacity (HRC) fuse

High interrupting capacity (HRC) fuses are specifically designed for more demanding industrial applications that have either higher voltages or severe fault currents, making typical fuses incapable to sustain the stress.

Structure:

- Ceramic body: strengthened with substances like alumina for enduring high-voltage arcs.

- Arc extinguishing filler: The fuse includes a sand (or boric acid or other) filling that rapidly cools and extinguishes the arc.

- Parts such as silver or copper: fuse chains—calibrated with extreme precision—that melt in a predictable manner when overloaded.

Application:

- Industrial motor protection: protects manufacturing plant motors from short circuits.

- APPLICATIONS:Switchgear, transformers for fault currents up to 100kA.

- Renewable energy system: shields the solar cell arrays and wind turbines from the harshness of the grid side surges.

Main features:

- Suitable for ultra high breaking capacity: Breaking current greater than 100kA without breaking.

- Normally: Operate continuously: Allow temporary overload when the motor starts; avoid continuous faults.

4. Specialized fuses

Specialized fuses are suitable for niche applications that cannot be met by standard designs. These include disposable thermal fuses and resettable devices for dynamic protection.

Thermal fuses and self recovering fuses

Thermal fuse

Structure:

Thermistor alloy particles enclosed in ceramic or plastic shells.

Design to melt at a specific temperature (e.g. 72 ° C to 240 ° C).

Application:

Overheating protection for coffee machines, hair dryers, and power tools.

The HVAC system can prevent compressor damage due to overheating.

Main features: disposable use; After activation, it needs to be replaced.

Self healing fuse (PTC)

Structure:

Polymer based positive temperature coefficient (PTC) materials.

When the current exceeds the threshold, the resistance will increase sharply.

Application:

Overcurrent protection in USB ports, battery packs, and LED drivers.

Automotive electronic devices that require automatic recovery after troubleshooting.

Main feature: Automatically reset when the temperature is normal.

Main specifications of fuses

From the perspective of safety and performance, understanding the technical data of fuses is very important. Here are several basic parameters to consider when choosing a fuse.

rated voltage

The rated voltage determines how much voltage can be applied to the fuse to keep arcing and insulation faults within a safe range. This specification consists of two categories:

- AC Voltage: Designed specifically for household appliances and other AC power systems (common rated values include 125V AC or 250V AC).

- DC voltage: suitable for DC applications such as automobiles and solar systems (rated voltage range from 12V DC to 1000V DC).

- Low breaking capacity (1-10kA): this is for residential circuits and small household appliances.

- A higher breaking capacity (10-200kA): These are used in applications that require them, such as industrial machinery, power grids, and renewable energy systems.

Application areas of fuses

Fuses are ubiquitous in electrical systems, providing targeted protection for residential, automotive, industrial, and consumer applications. They serve as fault insurance devices to prevent catastrophic failures caused by overcurrent. The following are common situations where fuses are essential:

3. Electronic products

Miniature fuses which are typically placed inside electronic equipment are handy for safeguarding circuit boards and other components from damage. For example, cellular phones, television, computers, etc. typically employ miniature fuses for handling current overload and short circuit situations.

4. Automotive Circuit

Fuses are also used in newer cars to protect electrical circuits and prevent ruining sensitive circuit components when the current is too high. Most vehicle circuits are equipped with a number of fuses that will shut down specific circuits when they are malfunctioning.

How to choose the appropriate fuse

Choosing the appropriate fuse requires balancing technical specifications, application requirements, and environmental conditions. Please follow the following steps to ensure optimal protection and reliability.

Step 1: Determine circuit parameters

First, assess the basic electrical characteristics of the circuit:

- Operational voltage: Match the fuse’s rated AC/DC voltage with the highest voltage of the circuit.

- Normal current: it measures the constant current within a normal use.

- Surge current: Identify temporary spikes (e.g., motor start-up or capacitor charging).

- Fault current: Estimated worst-case short-circuit current the fuse must interrupt.

Step 2: Match the fuse type according to the application

Customize fuse types according to your system requirements:

Quick melting fuse:

- Used for sensitive electronic devices that require immediate protection (LED drivers, microcontrollers).

Slow melting fuse:

- Very suitable for motors, transformers, and power supplies with temporary surges.

Resettable PTC fuse:

- Deploy in battery packs or USB ports that cannot be manually replaced.

Step 3: Consider environmental factors

- Temperature: High ambient temperatures may require a reduction of the current carrying ability of the fuse (e.g. 20% at 50 ° C).

- Vibration: Automotive or industrial use requires blade fuses or shock resistant designs.

- Humidity: Choose sealed fuses in outdoor or marine use.

- Size too big: The 30A fuse in the 10A circuit cannot interrupt moderate overloading.

- Ignoring power spikes: Applying quick fuses to inductive loads will cause repetitive failure.

- Mixed AC/DC: 250V AC fuses may create dangerous arcs in 48V DC solar installations.

Summarize

Fuses incorporated in electrical circuits are simple yet important safety elements that can protect electrical circuits against the risks of overloading and short circuits.

Understanding different classes of fuses and their application helps us make proper protective devices to ensure prolonged safety and sound operation of electric equipment. After going through the introduction in this article, we know more about the working principle, selection guideline, and normal applications of fuses.

FAQ

Here are some information that you may have just been interested in:

What is the difference between a circuit breaker and a fuse?

What Fuse Size Is Best for a 200W Solar Panel

How do fuse holders protect electrical equipment?