You may hear the term MCP in electrical engineering. MCP means Motor Circuit Protector. This device keeps electric motors safe from damage. Damage can happen from too much power or short circuits. People use MCPs in factories and big buildings. MCPs help motors work safely. Learning about MCPs helps you know how to keep electrical systems safe and working well.

Key Takeaways

- MCP means Motor Circuit Protector. It keeps electric motors safe from too much current or short circuits.

- MCPs watch the current and temperature in motor circuits. They shut off power to stop damage before it starts.

- Using MCPs helps save money by stopping expensive motor repairs and lost work time. Spending a little on MCPs can help you save a lot later.

- MCPs are very important in many places, like factories and HVAC systems. They help motors work safely and well.

- When picking an MCP, look at the motor’s details. Choose a device that matches what your system needs.

MCP Definition

What Is an MCP?

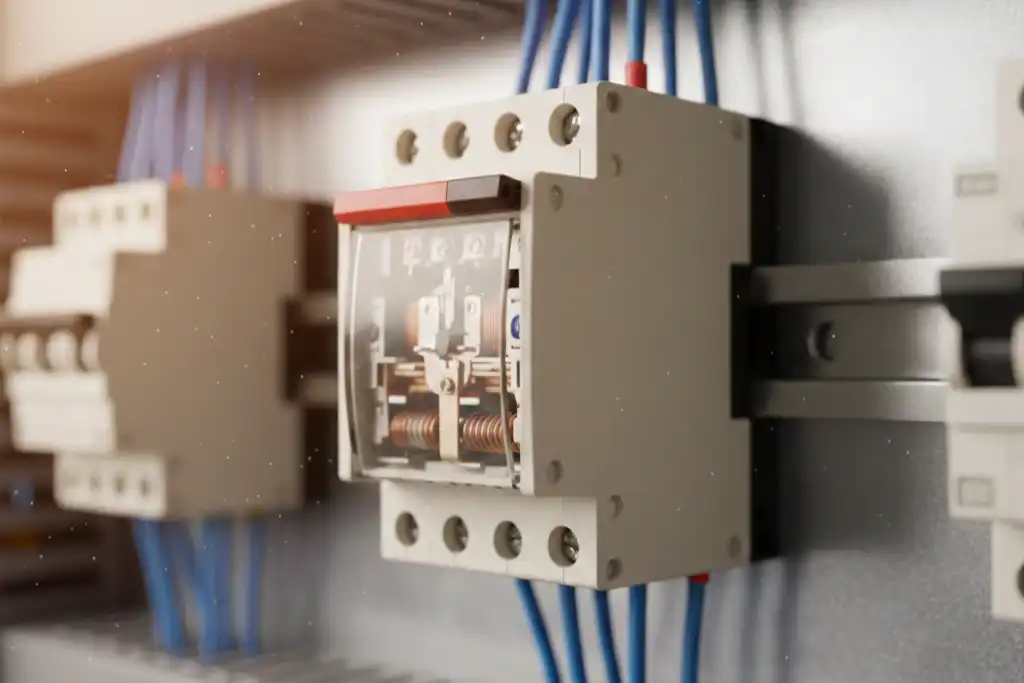

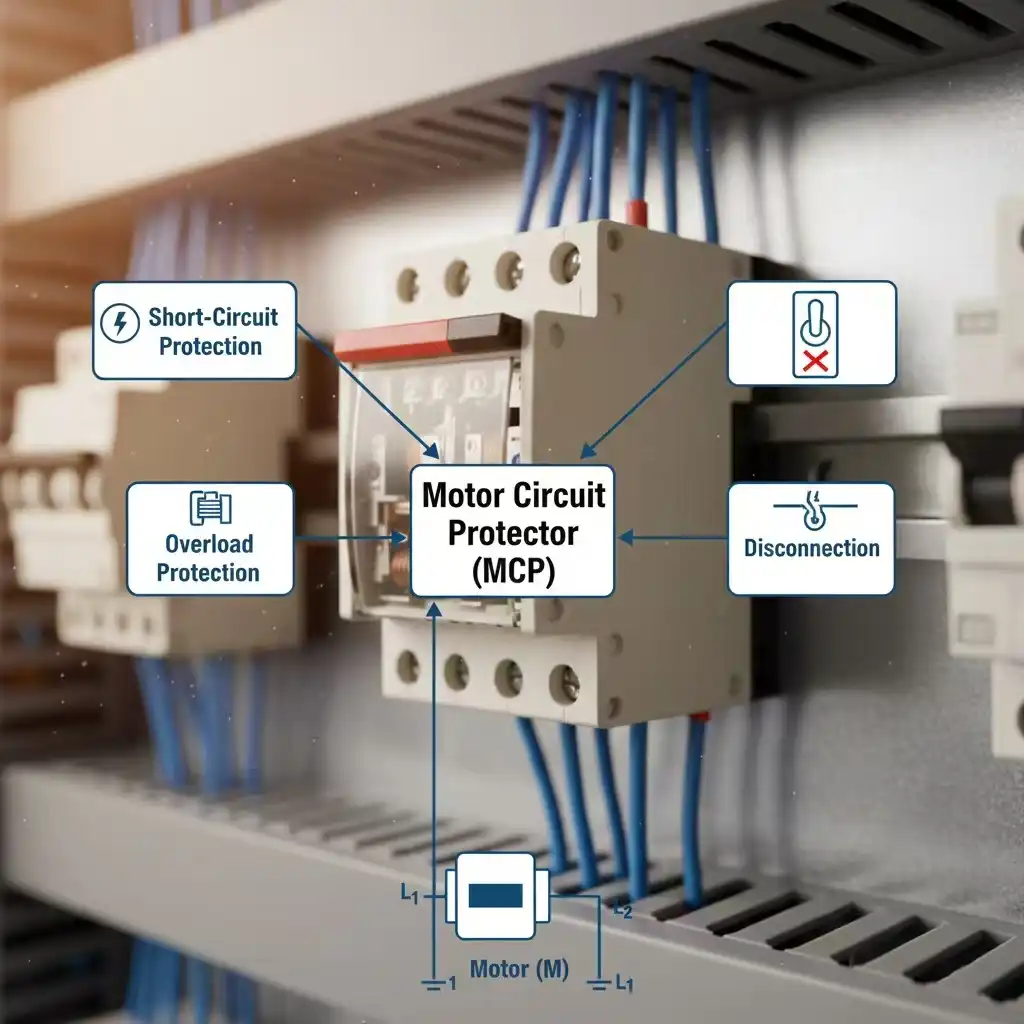

An MCP helps protect electric motors from getting damaged. MCP means Motor Circuit Protector. This device keeps motors safe by stopping too much current or sudden spikes. You can find MCPs in places like factories, schools, and big buildings. MCPs help motors work well and last longer.

Here is a table that shows the main parts and what they do:

| Component | Function |

|---|---|

| Overload Protection | Stops motors from getting too much current and overheating. |

| Short-Circuit Protection | Keeps motors safe from sudden jumps in current caused by faults. |

| Overload Relays | Watch the motor’s current and turn off power if there is too much. |

| Circuit Breakers | Protect against short circuits; MCBs are for small loads, MCCBs are for bigger ones. |

All these parts work together to keep motors safe.

How MCPs Work

MCPs look for problems in motor circuits. They check the current and temperature in the wires. If the current is too high or the motor gets too hot, the MCP turns off the power. This stops damage before it happens.

- MCPs watch electrical signals like current and temperature.

- They turn off the motor when they find a problem.

- This keeps the motor safe from too much current or short circuits.

You might wonder how quickly an MCP acts. Some protection devices shut off power right away, but they can also trip during normal motor startup. MCPs use both fast and slow actions. They react fast to short circuits with a magnetic part. They wait a little before turning off power during overloads, like an overload relay.

Tip: Pick an MCP for your motor because it reacts quickly to dangerous currents but does not turn off during normal motor startup.

You can count on MCPs to keep your motors safe and working well.

MCP Functions

Overload and Fault Protection

MCPs help keep motors safe from many problems. They protect motors from too much current, phase loss, and other faults. If a motor uses too much current, the coils can get very hot. This can burn out the motor. MCPs stop this by turning off the power before damage happens. If one phase of power fails, the motor can stop or get too hot. MCPs notice phase loss and act fast to protect the motor.

Motors also need protection from ground faults, jammed motors, and load problems. MCPs look for these issues and react quickly. Changes in voltage can hurt motors, but MCPs help them run well. Here are the main problems MCPs help with:

- Current overload

- Phase loss

- Ground faults

- Stalled or jammed motors

- Load imbalances

- Voltage changes

Note: MCPs do not just stop one problem. They protect motors from many different faults in busy electrical systems.

Applications in Motor Circuits

You can find MCPs in many places where motors work hard. Factories use MCPs to keep motors in packaging and material handling safe. Food and drink plants use MCPs to protect machines. Big buildings need MCPs for heating, cooling, and moving air.

Here is a table that shows where MCPs are used most:

| Industrial Sector |

|---|

| Packaging Equipment |

| Food and Beverage |

| Material Handling |

| Processing Industries |

| HVAC Equipment |

MCPs are used in places with many motors and in motor control centers. Electric motors help run many jobs in these places. They help with heating, cooling, and moving things. MCPs make sure motors stay safe and keep working.

- Electric motors run many machines in factories.

- Motors help with heating and cooling in big buildings.

- Ventilation systems use motors to move air.

- Cooling and refrigeration need motors to work safely.

Tip: When you pick an MCP, think about the kind of motor and what it does. Choose a device that fits your system’s needs.

MCP vs. Other Devices

MCP vs. MCCB

You may wonder how MCPs and MCCBs are different. Both keep electrical circuits safe, but they do not work the same way. MCCBs protect against short circuits and overloads. They can be used for many electrical loads, not just motors. MCPs are made to protect motors. They act fast when there is a problem that can hurt a motor.

Molded Case Circuit Breakers (MCCBs) stop short circuits and overloads. Motor Circuit Protectors (MCPs) do not have overload trip features. MCPs are used with other devices for thermal protection. The IT circuit breaker, called MCP, gives short-circuit protection. It needs extra devices for overload protection.

Here is a table that shows how MCPs and MCCBs are not the same:

| Feature | Motor Circuit Protector (MCP) | Molded Case Circuit Breaker (MCCB) |

|---|---|---|

| Motor-Specific Protection | High (tailored trip curves) | Low (general purpose) |

| Sensitivity to Motor Faults | High (instantaneous fault detection) | Medium |

| Thermal Overload Monitoring | Advanced (motor-specific) | Limited |

| Selective Coordination | Better (adaptive profiles) | Moderate |

| Application Focus | Motor protection in MCCs | Broader electrical protection |

MCP vs. Standard Breakers

Standard circuit breakers are used in homes and small buildings. They stop electricity if there is a short circuit or overload. These breakers do not have special features for motors. If you use a standard breaker for a motor, it may turn off during normal startup. It may not protect the motor from special problems.

You might see names like MCC or MCP as Motor Control Panel. These names sound alike, but they are not the same. Always check the full name and what the device does before you pick one.

Tip: Pick the right device for your job. Use an MCP for motors. Use an MCCB for general circuits. Use a standard breaker for simple loads.

MCP and Motor Safety

Risks Prevented by MCPs

Motors can have many problems in electrical systems. They might get too hot or use too much current. Sometimes, motors can burn out. MCP helps stop these problems. This device looks for trouble and acts quickly. MCP protects your motor from high fault currents. It also stops short circuits and overheating. MCP keeps wires safe by stopping dangerous currents early.

Here are some risks MCP helps prevent:

- Overload (too much current)

- Underload (not enough load)

- Phase loss (missing power phase)

- Locked rotor (motor cannot turn)

- Short circuit

- Leakage current

- Phase imbalance

- Overheating

- Overvoltage

- Undervoltage

- Grounding faults

- Power anomalies

- Winding insulation failure

- Bearing wear

- Rotor eccentricity

- Winding aging

MCP protects against many problems. It does not just stop one fault. MCP helps motors last longer and work safely.

Real-World Benefits

Using MCP saves you money and trouble. Motors are expensive to fix or replace. If a motor breaks, you lose time and money. MCP helps you avoid these losses. You pay a little for maintenance. You save much more by stopping big failures.

Here is a table that shows how much you can save:

| Cost of Preventive Maintenance | Potential Savings from Prevented Failures |

|---|---|

| $500 | $20,000 |

| $300-$600/year per motor | $10,000-$50,000+ per unplanned failure |

| $95,000/year savings | N/A |

A small cost for MCP protects your motors and your money. Your machines keep working. You do not need expensive repairs. MCP helps you feel calm and keeps your business strong.

Tip: Check your motors often and use the right protection. This keeps motors safe and costs low. 😊

Practical Use of MCPs

Selection Tips

When you pick a motor circuit protector, look at a few things. First, check the ratings. The current and voltage ratings must match your motor. You also need to check breaking capacity and trip features. There are different types of protectors. Some are thermal-magnetic, electronic, or hydraulic-magnetic. Each type has special features. Some models let you change trip settings or watch them from far away. Extra features like ground-fault protection make things safer.

Here is a table to help you compare:

| Factor | Description |

|---|---|

| MPCB Ratings | Includes current rating, voltage rating, breaking capacity, and trip characteristics. |

| Type of MPCB | Thermal-Magnetic, Electronic, and Hydraulic-Magnetic types have unique features. |

| Additional Features | Adjustable trip settings, remote monitoring, and ground-fault protection improve safety and control. |

You also need to pick the right size. Use the motor’s horsepower and full load amps to choose. The table below shows some common ratings:

| Motor HP | Full Load Amps | Switch or Fuse Clip Rating (With Overload Relays) |

|---|---|---|

| 1/6 | 4.4 | 5 |

| 1/4 | 5.8 | 7 |

| 1/3 | 7.2 | 9 |

| 1/2 | 9.8 | 12 |

| 3/4 | 13.8 | 17 1/2 |

| 1 | 16.0 | 20 |

| 1 1/2 | 20.0 | 25 |

Tip: Always look at the National Electrical Code (NEC) and UL tables before you choose. Pick a protector that lets you change settings after you put it in.

Global Adoption

You can find motor circuit protectors in many places. Factories and buildings around the world use them. The market for these devices is getting bigger. Experts think the global market will reach $6.7 billion by 2025. Motor circuit breakers are the biggest part, but MCP is growing fast. The MCP market could go from $1.8 billion in 2025 to $3.5 billion by 2035.

Many countries use these protectors in their industries. The Asia Pacific region uses them the most. China, Japan, India, and South Korea have the highest use. China is a leader in making things. Japan and South Korea focus on high-tech jobs. India is growing fast with new factories and digital tools.

Note: As more countries build factories and use more machines, the need for motor circuit protectors will keep going up.

You have learned that MCP keeps motors safe from problems. It stops overloads, short circuits, and other faults. The table below lists what MCP does:

| Key Function | Description |

|---|---|

| Overload Protection | Stops motors from getting too hot |

| Short-Circuit Protection | Cuts off power if there is a fault |

| Easy Installation | Simple to set up for motor use |

| Reliability | Handles high starting currents without trouble |

| Cost Reduction | Helps save money by stopping motor damage |

Using MCP makes your system work better and break down less. Pick the right protection to keep motors safe and your machines working well.

FAQ

What does MCP stand for in electrical engineering?

MCP means Motor Circuit Protector. It helps keep motors safe. It stops damage from too much current or short circuits.

Can you use an MCP for any type of motor?

You can use an MCP for many motors. Factories, schools, and buildings use MCPs. Always check the motor’s size and power first.

How is an MCP different from a regular circuit breaker?

An MCP has special trip settings for motors. Regular breakers might turn off during motor startup. MCPs act fast when there is a fault but let motors start.

Do MCPs need extra devices for full protection?

Yes, you need overload relays with MCPs. MCPs stop short circuits. Overload relays help with overheating and long-term problems.

See also

Which circuit breakers are used in the Motor Control Center

How to Choose MCCB for Protecting Large Motors in Factories

How to Match the Type of MCB to Your Electrical Load

Electric motor circuit breaker selection and usage

Common Scenarios for Using ACB in Power Distribution