Surge protectors (SPDs) are essential components in distribution boxes that can protect your electronic devices from immediate voltage surges. Whether in a home or industrial environment, testing the functionality of surge protection devices is key to ensuring that they can provide adequate protection when needed.

Key points

- Checking surge protection devices (SPDs) is crucial for safety and normal operation. Regular testing can detect problems early.

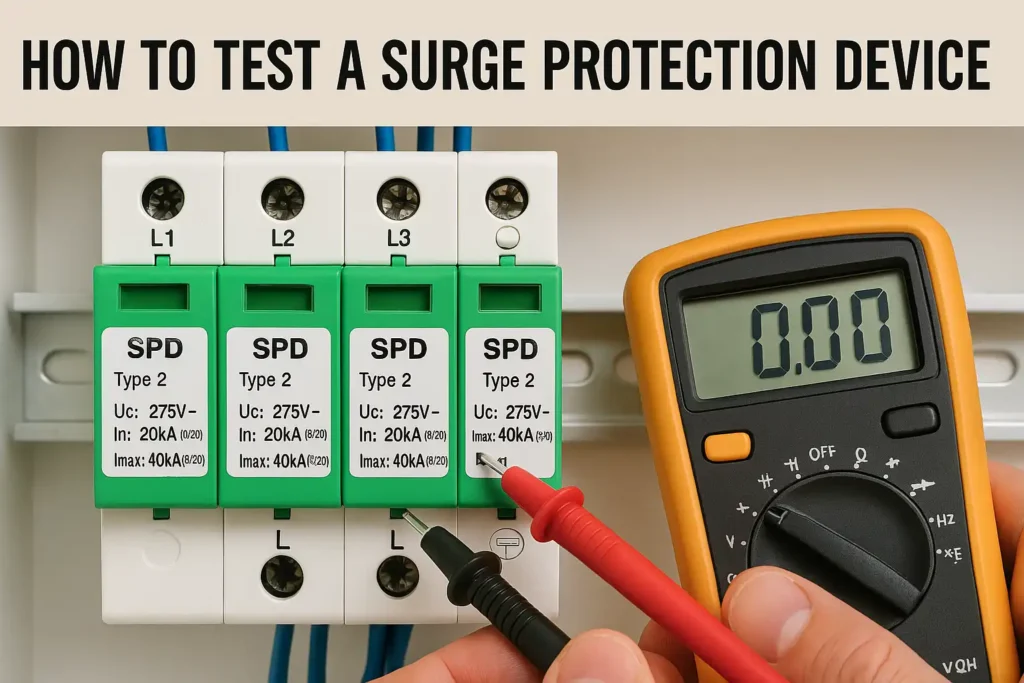

- Use appropriate tools for testing. A multimeter can perform simple checks, but an SPD tester can provide more detailed results.

- Always pay attention to safety. Please turn off the power and wear safety equipment before testing to avoid accidents.

- Record all test results. Keeping records helps monitor SPD status and comply with safety regulations.

- If the surge protector (SPD) is damaged or aged, please replace it. Regular maintenance can ensure the normal operation of your electrical system.

Tools for testing surge protection devices

Use a multimeter for testing

A multimeter is a simple tool for testing SPDs. It can measure voltage, current, and resistance. Before testing, please set the multimeter to the correct mode. Use on-off mode to check SPD components. The buzzing sound indicates normal operation; Silence indicates the presence of a problem. A multimeter is suitable for quick testing, but lacks detailed results.

insulation resistance tester

The insulation tester is used to check the insulation performance of SPD. Poor insulation performance may lead to leakage or malfunction. Connect the tester to SPD and apply voltage. The tester will display the insulation resistance value. A high resistance value indicates good insulation; A low resistance value indicates a problem. Regular testing can ensure the safe and reliable operation of SPD.

Professional SPD tester

A professional SPD tester can provide detailed test results. They will record the time and intensity of surge events. These data help to discover patterns and check performance. Many testers also monitor the health status and lifespan of SPDs. Security features can protect users and devices during testing. Data recording helps track test results. These tools are key to achieving reliable surge protection.

Additional tools for safe and effective testing

To safely test surge protection devices, you will need some additional tools. These tools can improve testing and provide you with a better understanding of SPD performance.

- Surge generator: The surge generator generates voltage spikes to test SPD. They can demonstrate the surge resistance of SPDs in practical situations. Surge generators can also detect weaknesses in the system. Solving these problems can make the system more stable. Engineers use them to reduce risks and optimize power systems.

- Clamp meter: A clamp meter can measure current without disassembling the circuit. They are very suitable for real-time system SPD testing. This device will guide you to check the current simply and safely.

- Thermal imaging camera: Overheating may indicate SPD malfunction. Thermal imaging cameras can detect hotspots in devices. This helps you fix the problem before it causes more serious malfunctions.

- Oscilloscope: The oscilloscope displays the waveform of the electric wave. It allows you to instantly see the SPD’s response to power surges. This tool can identify issues that other tools may overlook.

These tools make SPD testing more comprehensive and secure. They provide useful data to ensure the normal operation of your system. Adding them to your daily work ensures a powerful and reliable electrical system.

How to test surge protection devices

Preparation work: Safety inspection and setup

Before testing, please pay attention to safety and settings. Please make sure to check if the power is turned off to avoid electric shock, as this is a guarantee for your own safety. Next, check if the grounding complies with NEC regulations. Good grounding helps surge protectors (SPDs) to function properly. Check the wire size to ensure a secure connection.

Place the surge protector near the equipment it protects. For optimal performance, please use straight and short wires. Ensure that the polarity of the socket is correct and the impedance is low. Please use a grounding tester for testing. Please comply with safety standards such as NEC and UL 1449.

| Code/Standard | Description | Application |

|---|---|---|

| NEC (National Electrical Code) | A standard for the safe installation of electrical wiring and equipment in the United States. | Applies to electrical wiring and equipment in buildings, structures, and premises, including public and private spaces. |

| NESC (National Electrical Safety Code) | A standard for the safety of electric supply and communication lines and equipment. | Applies to the supply and communication lines and equipment, including overhead and underground power lines. |

| IEEE (Institute of Electrical and Electronics Engineers) | A professional association that develops technical standards for a broad range of industries. | Provides standards for the design and installation of surge protection devices and equipment. |

| UL 1449 (Underwriters Laboratories Standard) | A safety standard for surge protective devices. | Applies to surge protective devices for use in low-voltage AC power circuits. |

| IEC (International Electrotechnical Commission) | A global organization that develops and publishes international standards for all electrical, electronic, and related technologies. | Provides standards for the design and installation of surge protection devices and equipment. |

Use a multimeter to measure continuity and voltage

A multimeter can perform basic checks on SPD. To test conductivity, set it to conduction mode. Contact the probe with the SPD terminal. Beeping indicates normal operation; Not emitting a beep indicates a problem. To test the voltage, please switch to voltage mode. Check if the voltage at the SPD terminal is normal.

Test steps:

- Connect the probe to the SPD terminal.

- Use buzzing sound to check continuity.

- Measure voltage to ensure normal functionality.

Test insulation resistance

Insulation testing can check whether the insulation of SPD is firm. Weak insulation may lead to leaks or malfunctions. Measure resistance using an insulation tester. Connect it to SPD and apply voltage. High resistance indicates good insulation; A low resistance indicates a problem.

Regular testing can ensure the reliability and safety of surge protectors. This program can detect issues such as leaks and prevent reverse current flow. This can improve system performance.

Use a professional SPD tester for advanced evaluation

A professional surge protector tester will help you learn more about surge protectors (SPDs). These testers can simulate real surges and test the response of SPDs. They are able to identify issues that basic testers cannot detect.

Firstly, connect the tester to SPD according to the instructions. Choose a testing mode, such as surge simulation or performance check. The tester will send controlled surges and measure the response of the SPD. Check important details such as clamp voltage, response time, and energy absorption. These values can indicate whether SPD is working properly.

Some testers can save data for future viewing. This helps track the long-term performance of SPD. It can also display patterns or recurring issues. Using these testers can usually protect your system from the impact of surges.

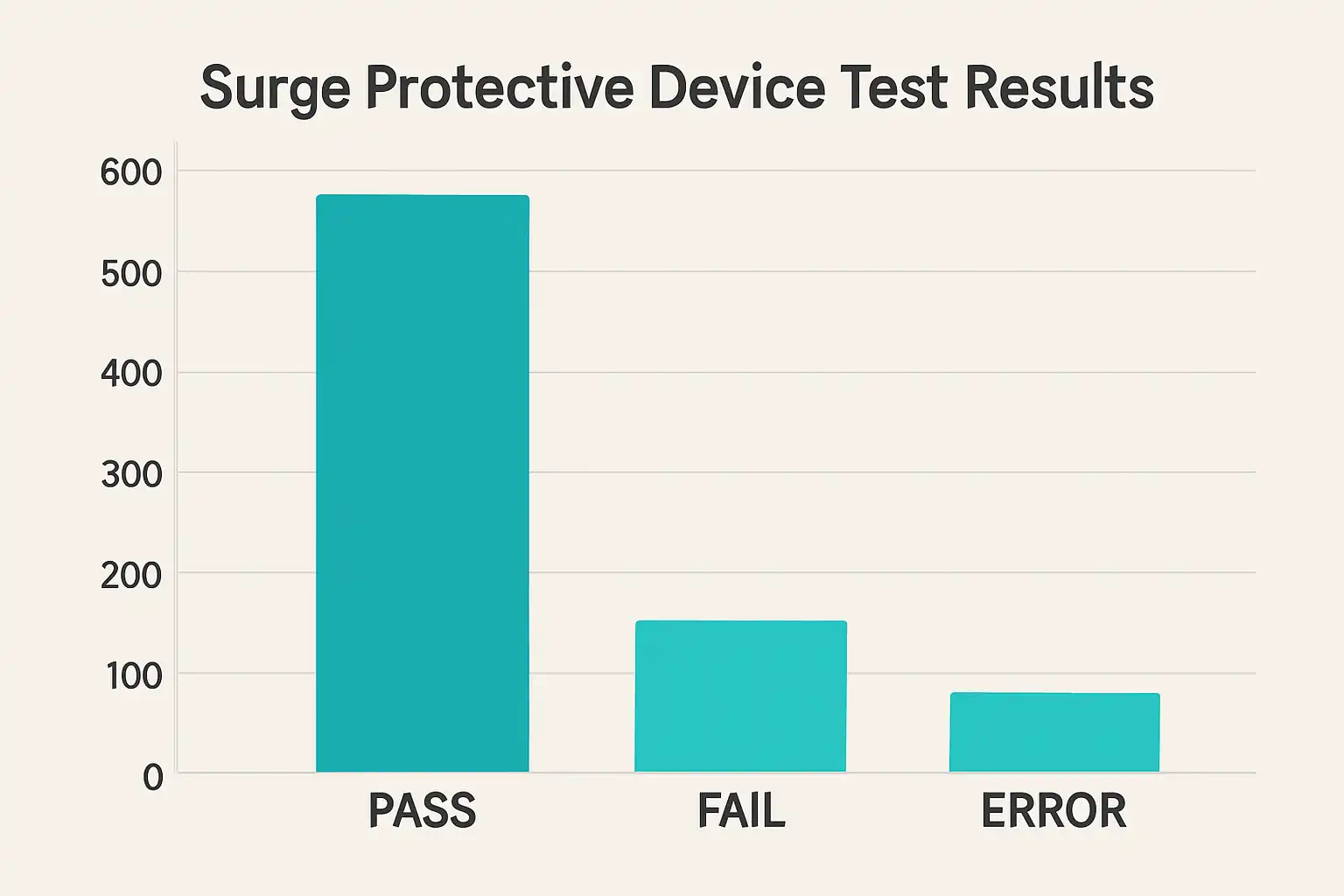

Record and analyze test results

The data recording after the testing process is also very important. Recording helps you monitor the health status of SPD and plan future testing. Please record the date, time, and type of testing, and indicate the tools used and the SPD type tested.

Here is the table I made for your reference:

| Test Parameter | Measured Value | Acceptable Range |

|---|---|---|

| Clamping Voltage | 400V | 330V - 450V |

| Response Time | 1 ns | ≤ 2 ns |

| Insulation Resistance | 100 MΩ | ≥ 50 MΩ |

Monitor data and check for any abnormalities. If there are any abnormalities, please investigate the cause. This may be caused by wear, incorrect settings, or replacement of SPD.

By monitoring and inspecting the results, you can also maintain the integrity of the surge protection system and troubleshoot as soon as possible.

Understand the test results

Signals of success and failure in test results

In the testing process of surge protectors (SPDs), it is necessary to understand what are the important indicators of success or failure. Some SPDs are equipped with indicator lights to display their status. The product works normally when the green light is on. The red light on or off indicates equipment malfunction or replacement.

During the testing period, check if there is any visible damage to the SPD. Minor dents or cracks are acceptable as long as they do not affect its functionality. For SPDs with a protection level of IP20 or higher, please use a 5N force test finger. If no live parts are touched, the SPD test is qualified. During the testing period, SPD should not explode, generate sparks, or cause harm to personnel or equipment.

Discovering signs of SPD damage or malfunction

Surge protectors will wear out over time, especially after receiving multiple surges. Regular inspections can help detect early damage or malfunctions. Check for cracks, rust, or burnt parts. Strange noises, sparks, or odors also indicate the presence of a problem. If the system runs poorly or trips frequently, the SPD may not function properly.

Be careful: SPD requires regular maintenance. Check once a month. Check for discoloration, heating, or burning odor. If these issues are found, please replace the SPD immediately.

Choose to repair or replace SPD

It is crucial for safety to determine whether the SPD should be replaced or repaired. For example, minor issues such as loose wires or minor cracks should be repaired. When the SPD has been significantly damaged, such as component burnout or performance degradation, it should be replaced. Additionally, SPDs should also be replaced when they have attained their service life or have survived several surges.

Maintenance steps

- Search for visible damage or abnormal conditions.

- Use a multimeter or SPD tester to test SPD.

- Match the results with manufacturer rules or industry standards.

By regularly checking, you can ensure that the surge protection system is safe and functioning properly.

Troubleshooting and Maintenance of Surge Protective Devices (SPDs)

Common problems and their causes

SPD may experience issues, leading to a decrease in its performance. Understanding these issues can help you quickly fix them. The following table lists common problems and their causes:

| Issue | Cause |

|---|---|

| Misaligned Disk Column | Disks may move during transport or setup, causing small discharges. |

| Weak Spring Pressure | Low pressure makes disks shift, leading to discharges. |

| Too Much Mechanical Stress | High stress damages seals and inside parts. |

| Weak Dielectric Strength | Poor strength leads to tracking or flashovers during surges. |

| Moisture Inside | Water entering the SPD lowers its performance and causes failure. |

| Outside Flashover | Short arresters may flash over, causing harm. |

| Too Many Partial Discharges | Repeated discharges wear out internal parts, causing failure. |

Tip: Regularly check SPD to detect these issues early and avoid major repairs. If you want to replace the SPD, you can choose ONESTO brand, which offers you a discounted price and provides a 2-year quality warranty service

Steps to address issues identified during testing

If any issues are found during SPD testing, please follow the steps below to fix them:

- Check for physical damage: Check for cracks, rust, or burns. Replace severely damaged surge protectors (SPDs).

- Repair loose wires: Check all wires and terminals. Tighten all loose wires.

- Clean internal parts: use dry cloth or air spray to remove dust or dirt.

- Replace damaged components: Replace damaged disks, springs, or seals with new ones.

- Addressing moisture issues: Drying SPD and improving its sealing to block water.

- Retest: After the repair, test the SPD to ensure its proper functioning.

Methods for long-term maintenance of SPD

Good maintenance can ensure the long-term good operation of SPD. The following table lists some practical tips and their benefits:

| Maintenance Method | Result | Failure Frequency |

|---|---|---|

| For most SPDs, only minimal maintenance is required | Saves time and maintains maintainability | Rare |

| Replacing high-risk SPDs | By focusing on equipment that may fail, risks can be avoided | As needed |

| Testing failed SPDs | Identify the cause of unexpected issues to prevent future occurrences | When failures occur |

To maintain the SPD in good condition:

- Plan regular inspections: Check monthly for any damage, water or loose wires.

- Replace the old SPD: Replace the SPD with one that is close to its service life to avoid sudden problems.

- Keep maintenance records: Write down all inspections, repairs, and replacements.

Conclusion

Functional testing of surge protectors is extremely crucial, and regular inspection and replacement can ensure that your equipment at all times receives the best protection. With the proper technique of testing and maintenance, you can simply avoid power surge damage and ensure long-term protection for your electronic devices.

FAQ

What shall I do if the indicator light on the surge protection device goes out?

In case the indicator light on the surge protection device goes out, it may be an indication that the device has lost its protective ability. You should replace the device immediately to safeguard your equipment.

Do surge protection devices need to be replaced after a certain period?

Yes, surge protection devices do have a lifespan. Even though it seems to be working properly, its protective function will also be weakened after a few surge events, so it needs to be replaced in due time.

How to check whether the grounding of the surge protection device is normal?

You can use a multimeter to measure the grounding resistance of the surge protection device to test if its grounding resistance meets the regulations. If the grounding resistance exceeds the regulations, it may have an impact on the protection effect of the equipment.

The following information may be of interest to you

How does SPD deal with strong surge voltage?

How to Test Surge Protection Devices for Optimal Performance

What You Need to Know About Surge Protection Device Lifespan