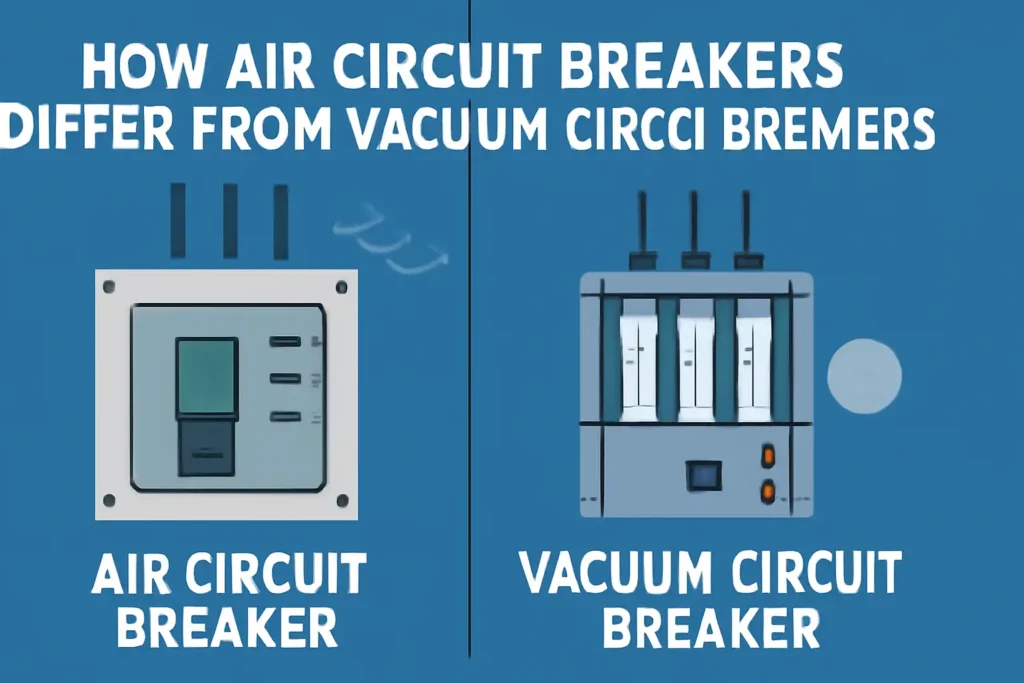

Air circuit breakers and vacuum circuit breakers stop electrical problems in different ways. Engineers pick one based on how much care it needs, how safe it is, and where it will be used. For example, vacuum circuit breakers are good in places with dust or lots of water in the air. They also do not need much fixing. Air circuit breakers need to be checked and cleaned more often. Picking the right breaker can save money on repairs and make electrical systems safer.

Key Takeaways

- Air circuit breakers are best for low-voltage systems. They need regular check-ups to work safely and well.

- Vacuum circuit breakers use a sealed vacuum to stop arcs fast. This makes them safer and easier to care for in medium-voltage systems.

- You should pick the right breaker based on voltage, care needs, safety, cost, and where it will be used.

- Vacuum circuit breakers last longer and save money over time. They cost more at first. Air circuit breakers cost less at first but need more care.

- Both breakers keep electrical systems safe. Picking the right one makes things safer, cuts down on stops, and fits your system’s needs.

Air Circuit Breakers

Definition

Air circuit breakers, or ACBs, keep electrical systems safe from too much current or short circuits. IEC 60947-2 says these breakers work in power systems up to 1000 volts AC and 1500 volts DC. They can handle small and large currents, from just a few amps to over 6300 amps. Engineers put them in main switchboards, mostly in factories and power plants. Many ACBs have special features like electronic trip units. These let people measure, control, and talk to the breaker. These features help workers watch and manage big electrical systems safely.

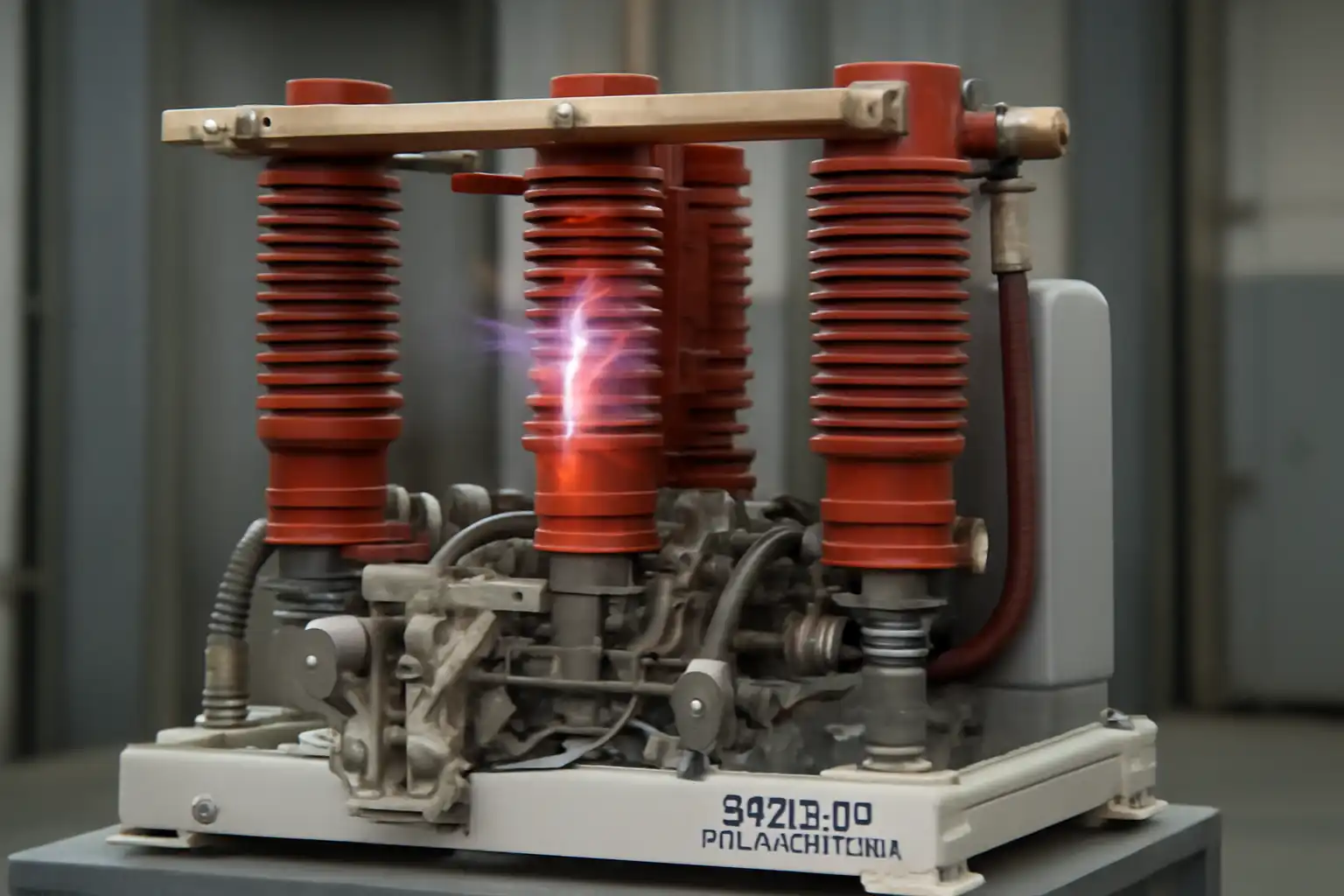

Working Principle

An air circuit breaker stops electricity when it finds a problem. When it opens, an electric arc appears between the contacts. The breaker has steel plates called arc chutes that break the arc into smaller pieces. The arc makes a magnetic field that pushes it to the plates. As the arc splits, each part gets a higher voltage. When the total voltage is more than the supply voltage, the arc goes out. The breaker uses the natural zero crossing of AC, which happens every 10 milliseconds, to help stop the arc. Some breakers use magnetic coils to make arc quenching faster and better.

Applications

Air circuit breakers do many important jobs in today’s electrical systems.

- Factories use ACBs to protect medium-voltage systems from too much current or faults.

- Offices and data centers use ACBs for safe and steady power.

- Plants and factories use ACBs to stop electricity during problems and keep equipment safe.

- In high-voltage systems, air blast circuit breakers stop arcs from big electrical energy and help prevent blackouts.

Tip: ACBs have settings you can change, so they work well in places that need strong and flexible protection.

Vacuum Circuit Breakers

Definition

Vacuum circuit breakers, or VCBs, use a sealed vacuum to stop electricity when there is a problem. The vacuum puts out the arc when the breaker opens. Engineers use VCBs in medium-voltage systems from 1,000 volts up to 38,000 volts. The vacuum keeps the contacts clean and stops them from rusting. This design helps VCBs last longer and work well in tough places.

Working Principle

A vacuum circuit breaker stops current by pulling apart two contacts inside a vacuum chamber. When the contacts move away, an electric arc forms between them. The vacuum has almost no air or gas, so the arc cannot last long. The arc goes away fast because the vacuum does not let it stay. The breaker uses special contact materials to help the arc go out even faster and reduce damage. This all happens in just a few milliseconds, so VCBs are very quick and dependable.

Note: The vacuum chamber stays closed for the whole life of the breaker. This means the breaker does not need much care.

Applications

Vacuum circuit breakers work best where medium-voltage systems need strong and steady protection.

- Power stations use VCBs to protect transformers and switchgear.

- Factories pick VCBs for machines that need steady power and fast fault clearing.

- Commercial buildings use VCBs in main panels to keep people and equipment safe.

- Mines and chemical plants like VCBs because they work well in dusty or wet places.

| Application Area | Why Use VCBs? |

|---|---|

| Power Stations | Fast arc quenching, reliability |

| Factories | Low maintenance, long life |

| Commercial Buildings | Safe operation, compact size |

| Mines/Chemical Plants | Withstand harsh conditions |

Tip: VCBs do not let out harmful gases or need lots of cleaning, so they are good for places with strict safety rules.

Air Circuit Breakers and Vacuum Circuit Breakers: Key Differences

Arc Quenching

Air circuit breakers and vacuum circuit breakers stop arcs in different ways. Air circuit breakers use air to put out the arc. When the contacts open, an arc forms in the air. Arc chutes break the arc into smaller parts and cool it down. This makes it easier to stop the arc. But air takes longer to become a good insulator again, so the process is slower.

Vacuum circuit breakers use a sealed vacuum chamber. When the contacts pull apart, the arc forms from metal vapor. The vacuum does not let the arc last long. The arc goes out almost right away. The vacuum quickly becomes a good insulator again. This makes vacuum circuit breakers faster and more dependable for stopping arcs.

| Aspect | Air Circuit Breaker (ACB) | Vacuum Circuit Breaker (VCB) |

|---|---|---|

| Arc Quenching Medium | Air | Vacuum |

| Arc Chutes | Needed to split and cool the arc | Not needed |

| Dielectric Recovery | Slow, due to ionized air | Fast, due to vacuum |

| Arc Extinction Speed | Slower | Almost instant |

| Internal Structure | More complex | Simpler |

Tip: If the arc stops faster, the breaker and equipment get less damage.

Voltage Range

Air circuit breakers and vacuum circuit breakers work best at different voltages.

- Air circuit breakers use air to stop arcs and are best for low-voltage systems, usually below 11 kV.

- Vacuum circuit breakers use a vacuum, which gives better insulation. They work well in medium-voltage systems, from 11 kV to 33 kV, and sometimes higher.

- Vacuum circuit breakers are common in power stations and factories with medium-voltage needs.

- Air circuit breakers are often found in commercial buildings and smaller industrial setups.

Note: Picking the right breaker for the voltage keeps the system safe and working well.

Performance

How well a breaker works depends on how fast it can stop faults. Air circuit breakers handle high currents in low-voltage places. They take longer to stop arcs because air cools slowly. This can wear out the contacts faster.

Vacuum circuit breakers work in medium-voltage systems. They stop faults quickly because the vacuum puts out the arc almost right away. This means the contacts last longer and there is less downtime. Vacuum circuit breakers can also stop bigger faults in their voltage range.

| Circuit Breaker Type | Voltage Range | Interrupting Capacity |

|---|---|---|

| Air Circuit Breaker | Low-voltage | Low to medium |

| Vacuum Circuit Breaker | Medium-voltage | Medium to high |

Vacuum circuit breakers work better in medium-voltage systems. Air circuit breakers are strong and flexible for low-voltage, high-current jobs.

Maintenance

Maintenance is a big difference between air circuit breakers and vacuum circuit breakers. Air circuit breakers need more checks and cleaning. Their arc chutes, air pressure parts, and seals need regular care, especially in dusty or wet places. Most factories check air circuit breakers at least twice a year.

Vacuum circuit breakers need less care. Their sealed vacuum interrupter keeps out dust and water. Workers only need to check the moving parts and test the vacuum every few years. This means less downtime and lower costs over time.

Both types need care to stay safe, but vacuum circuit breakers save time and money because they need less service.

Safety

Safety is very important when picking between air circuit breakers and vacuum circuit breakers. Air circuit breakers are riskier because they stop arcs more slowly. This can make longer arcs and more heat, which might hurt equipment or people if not handled right. They also need more care, which can lead to mistakes.

Vacuum circuit breakers are safer because they stop arcs almost right away. Their sealed design keeps out dust and water. Problems are rare, but a leak in the vacuum can cause trouble. Regular checks help stop this. Overall, vacuum circuit breakers keep people and equipment safer.

| Aspect | Air Circuit Breaker (ACB) | Vacuum Circuit Breaker (VCB) |

|---|---|---|

| Arc Extinction Speed | Slower | Almost instant |

| Maintenance Needs | Frequent | Minimal |

| Safety Risks | Higher, due to longer arcs and upkeep | Lower, due to fast arc extinction |

| Lifespan | Shorter | Longer |

Cost

Cost is also important. Air circuit breakers cost less to buy at first. But they need more care and may not last as long, so costs can go up later.

Vacuum circuit breakers cost more at first. Their sealed design and longer life mean less care and fewer replacements. Over many years, vacuum circuit breakers often save money, especially where downtime is costly.

Picking between air circuit breakers and vacuum circuit breakers depends on your budget, how often you can do maintenance, and how long you want the system to last.

Pros and Cons

Air Circuit Breakers

Air circuit breakers have many good points for different electrical systems. They give strong protection in homes, businesses, and factories. These breakers work best for low-voltage jobs under 1000 volts. Many engineers pick them because they are simple, tough, and save money. Their design makes it easy to add new parts or make changes later. New air circuit breakers use smart tools like IoT and AI. These tools help workers watch the system and fix problems before they get big. This stops long power outages. Air circuit breakers also follow strict safety rules and help save energy.

Main advantages of air circuit breakers:

- Simple and robust design

- Cost-effective for budget-conscious projects

- Quick fault detection and clearing

- Flexible and scalable for future needs

- Enhanced safety features, like arc fault detection

- Support for smart monitoring and remote maintenance

Tip: Air circuit breakers are important in green energy systems and modern power networks.

But air circuit breakers also have some problems. Sometimes, air leaks out and this can hurt how well they work. The air compressor needs its own care, which means more work. Some breakers are sensitive and need to be checked often.

Common disadvantages:

- Air leakage problems

- Extra maintenance for air compressors

- Sensitivity to environmental changes

Vacuum Circuit Breakers

Vacuum circuit breakers are known for being safe and lasting a long time. They use a vacuum to stop arcs fast, so the contacts do not wear out quickly. These breakers do not use bad chemicals, so they are better for the earth. Many power plants and factories like vacuum circuit breakers because they do not need much care and work well in tough places. They act fast to protect equipment and keep the power steady.

Key advantages of vacuum circuit breakers:

- Superior arc extinction for less wear and longer life

- High safety with low risk of fire or explosion

- No greenhouse gases or harmful chemicals

- Minimal maintenance needs

- Fast fault isolation for grid stability

- Strong insulation for high-voltage use

- Cost-effective over time due to long lifespan

Note: Vacuum circuit breakers help smart grids and green energy, which supports today’s energy goals.

Some people think the higher first cost is a problem. But the lower care needs and longer life often make up for this in the end.

| Feature | Air Circuit Breaker | Vacuum Circuit Breaker |

|---|---|---|

| Initial Cost | Lower | Higher |

| Maintenance Needs | Frequent | Minimal |

| Environmental Impact | Moderate | Low |

| Lifespan | Shorter | Longer |

Air circuit breakers and vacuum circuit breakers both have special strengths. The best one to use depends on what the electrical system needs.

Choosing the Right Breaker

Selection Factors

Picking the right circuit breaker depends on a few big things. One important thing is voltage level. Air circuit breakers work best in low-voltage places, like office buildings or motor control centers. Vacuum circuit breakers are better for medium-voltage spots, such as substations or big factories.

How much care the breaker needs is also important. Air circuit breakers have more parts and need to be checked often. This is extra true if there is a lot of dust or wet air. Dust and water can make the parts wear out or rust. Vacuum circuit breakers are sealed tight, so dust and water cannot get in. This means they last longer and do not need much fixing.

Cost is another thing to think about. Air circuit breakers are cheaper to buy at first. But they might need more repairs and cost more later. Vacuum circuit breakers cost more when you buy them. They save money over time because they last longer and need less work.

Safety for the environment matters too. Air circuit breakers can let out gases and might cause fires. Vacuum circuit breakers do not let out bad gases. They are safer and less likely to catch fire or explode. They also work well in tough places.

How much space you have can change your choice. Air circuit breakers are bigger and need more room. Vacuum circuit breakers are smaller and fit better in tight spaces.

| Key Factor | Air Circuit Breakers (ACBs) | Vacuum Circuit Breakers (VCBs) |

|---|---|---|

| Voltage Level | Low voltage systems | Medium voltage systems |

| Maintenance | Frequent, more complex | Minimal, simple |

| Environmental Impact | Releases gases, fire risk | No harmful gases, safer |

| Size and Space | Larger, needs more space | Compact, space-saving |

| Cost | Lower initial, higher upkeep | Higher initial, lower upkeep |

| Suitability | Commercial, industrial low voltage | Substations, medium voltage, harsh environments |

Tip: Think about future upgrades. Vacuum circuit breakers are easier to use with new technology.

Air circuit breakers and vacuum circuit breakers do not do the same job. Air circuit breakers are good for low voltage systems. Vacuum circuit breakers work with medium voltage and need less care. Picking the right breaker depends on voltage, how much power is used, and where it will be.

Checklist for selection:

- Make sure the breaker voltage and current fit the system

- See if the breaker works with the panel and brand

- Think about how much care the breaker will need

- Ask a licensed electrician for help with hard setups

Picking the right breaker keeps electrical systems safe and working well.

FAQ

What is the main job of a circuit breaker?

A circuit breaker keeps electrical systems safe. It stops electricity if there is a problem. This helps stop fires, damage to equipment, and injuries.

Can air circuit breakers and vacuum circuit breakers be used in the same place?

Engineers do not put both types in one panel. Air circuit breakers are for low voltage. Vacuum circuit breakers are for medium voltage. Each one is made for a different job.

How often should someone check a vacuum circuit breaker?

Most vacuum circuit breakers only need a simple check every few years. Their sealed design keeps out dust and water. This means they need less care than air circuit breakers.

Are vacuum circuit breakers safer than air circuit breakers?

Vacuum circuit breakers stop arcs faster and have a sealed chamber. This makes them safer in tough or dangerous places. They also lower the risk of fire or explosion.

The following information may be of interest to you

What is the highest rated circuit breaker?

Application and advantages of air circuit breakers

Comprehensive guide for wiring methods of air circuit breakers