Picture this: You open a main electrical panel and see a sudden spark. This is called an arcing ground fault. It can get very hot and may cause fires or damage equipment. You often find these dangers in old buildings. These buildings may have missing safety grounds or bad wiring. You need to act fast and be careful to stay safe. Always use Ground Fault Circuit Interrupters and follow electrical rules. Learning these steps helps you stop injuries, protect things, and keep systems working well.

Key Takeaways

- Always wear the right safety gear like insulated gloves, hard hats, and arc-rated clothes to stay safe from electrical dangers.

- Begin ground fault checks by looking closely before using tools. This helps you find hidden problems fast and safely.

- Use the correct electrical testing tools. Follow lockout/tagout steps to make sure power is off before fixing anything.

- Fix broken wires and change bad devices by following electrical codes. This stops shocks, fires, and damage to equipment.

- Do regular checks and tests on grounding systems and GFCI outlets. This helps you avoid expensive problems and keeps systems working well.

Ground Fault Basics

What Is a Ground Fault

You have to know what a ground fault is before fixing it. The National Electrical Code says a ground fault is when electricity goes where it should not. It happens when an ungrounded wire touches something grounded by mistake. This lets electricity find a path to the ground that is not safe. For example, if a wire’s cover breaks, electricity might travel through metal or even a person to reach the ground.

Tip: Always remember that electricity looks for the easiest way to the ground. If it finds a shortcut, it can cause big problems.

Some things that cause ground faults are:

- Old or damaged wires that let electricity leak out.

- Water in places like kitchens, bathrooms, or outside outlets.

- Wrong wiring or missing grounding in the system.

- Circuits with too much power that get too hot and hurt the wire cover.

- Broken appliances that let electricity escape.

Why It Matters

Ground faults are very dangerous and must be taken seriously. When a ground fault happens, equipment can get dangerous voltage on its surface. This can shock anyone who touches it. Wires can get too hot and start fires. Equipment can break, and power can go out suddenly.

- Electric shock: You can get hurt or even die if you touch a live part during a ground fault.

- Fire: Too much electricity can make wires hot and start a fire.

- Equipment damage: Ground faults can break parts and cost a lot to fix.

- System failure: Power can go out and stop work or daily life.

Finding and fixing ground faults quickly keeps you safe and protects your things. Rules say you must use good grounding and safety devices. If you ignore ground faults, you could get hurt, lose property, or get in trouble with the law.

Safety First

PPE Essentials

You always need to wear the right personal protective equipment (PPE) before doing electrical work. The right gear helps keep you safe from shocks, burns, and other injuries. OSHA and NFPA 70E have rules about what you need to wear. Here is a simple guide to the most important PPE for electrical work:

| PPE Type | Description and Use | Notes |

|---|---|---|

| Electrical Hard Hats | These protect your head from shock and things hitting you. | Use Type 1 Class E or Type 2 Class G. |

| Rubber Insulated Gloves | These keep your hands safe from electric shock. | Use Class 0 or higher. Test gloves every day and in a lab every 6 months. |

| Electrical Hazard-Rated Boots | These boots keep your feet safe from electrical dangers. | It is best to wear them for every job. |

| Insulated Tools | These tools stop electricity from going through your hands. | Always use them when working near live parts. |

| Arc-Rated Clothing | This clothing keeps your body safe from arc flash burns. | You must wear it if you are inside the flash protection boundary. |

| Minimum Approach Distance | Stay at least 12 inches away from uninsulated energized parts. | You need gloves before you get close. |

| Additional Equipment | Use fuse pullers, GFCI cords, rubber barriers, and CAT III/IV test meters for extra safety. | These tools help you stay safe during all troubleshooting steps. |

You should also wear safety glasses, face shields, and hearing protection. Always check your PPE for any damage before you use it. Employers must give you time and tools to check your PPE often.

Lockout/Tagout

You must follow lockout/tagout steps every time you fix or check electrical systems. This keeps you safe by making sure no one turns the power back on while you work. Lockout/tagout means you turn off the power, lock the switch, and put a tag with your name and the date. You must make sure the equipment is really off before you start.

Tip: Lockout/tagout stops accidents, keeps you safe from shocks and burns, and helps your team talk clearly. OSHA says you must do these steps to keep everyone safe and lower injuries.

Power Verification

You must make sure the power is off before you touch any wires or equipment. Use these steps to check if the power is really off:

- Disconnect the load side of the GFCI and all junctions after it.

- Check for neutral-to-ground continuity on each wire segment.

- Find any shorts inside junction boxes or change bad wire segments.

- Use plug-in circuit testers to check wiring connections.

- Make sure grounding and grounded conductors only connect at the main service panel.

You should also look at the wires and use test meters to double-check. Always do these steps before you start repairs.

Ground Fault Identification

Visual Inspection

You should always start by looking closely for problems. This helps you find easy-to-see issues before using any tools. Here are some steps to help you check everything:

- Find the electrical panel. It is a metal box with breakers.

- Turn off the main breaker to stay safe.

- Look at the panel cover. Make sure it is tight and not rusty or burned.

- Check the main breaker. It should have clear labels and look good.

- Look at each breaker or fuse. See if they are labeled, tripped, or blown.

- Check all wiring connections. Wires should be tight and not broken or bare.

- Make sure ground fault protection devices like GFCIs are there and working.

- The panel should be steady and cables should be neat.

- Watch for dangers like bent wires, rust, cuts, burns, or bare live parts.

- Cable ends need the right connectors and must fit the design.

- Look at switches, timers, and fuses. They should not be broken and must be rated for the job.

- All equipment should be mounted well and connections must be tight.

- Cable joints need the right connectors and the panel must be earthed.

- Cable entry points should have tight glands.

- Test the emergency switch. It should stop machines when pressed.

- Use continuity tests to check if switches work right.

Tip: A good visual check can show the ground fault before you need special tools.

Electrical Testing Tools

After looking, you need to use electrical testing tools to find hidden ground faults. Many tools help you do this job safely and well. Here is a table that compares some of the best tools:

| Tool Name | Key Features | Detection Capabilities | User Feedback / Reliability |

|---|---|---|---|

| HD Electric UCT-8/K01 Underground Cable Fault Tester | Tests cables up to 1,500 ft, 8kV DC test voltage, automatic AC detection, clear LED and analog indicators, portable | Finds DC leakage and high-voltage faults, shows GOOD, HIGH LEAKAGE, or FAULT | Reliable, safe, clear readings, praised for field use |

| Fluke Networks IntelliTone Pro 200 | Dual digital/analog tone, SmartTone mode, pair tester, supports many wire types, LED indicators | Traces cables, finds opens, shorts, reversed pairs, reduces noise and false signals | Highly rated, accurate, versatile, some minor build concerns |

You can also use simple plug-in testers, GFCI testers, and advanced AFCI/GFCI circuit testers. These tools help you find arc and ground faults you cannot see. Pick testers with clear lights and smart features for the best results. Always follow safety rules and use the right tool for the job.

Modern insulation resistance monitoring systems give extra safety. These systems watch insulation resistance all the time. They warn you early if resistance drops, so you can fix problems before things break. You can set alarms to match your needs, and the system will warn you before a ground fault gets bad. This keeps your equipment safe and lowers fire risk.

Note: New tools like traveling-wave fault locators, impedance-based testers, and IoT monitors make ground fault finding faster and better. Some systems even use AI to guess faults before they happen.

Section Isolation

If you cannot find the ground fault by looking and testing, you need to split the system into parts. This helps you find the problem step by step. Here is how you do it:

- Preparation: Get all system drawings, cable maps, and history. Gather your tools like insulation testers, multimeters, and cable locators. Make sure the system is off and locked.

- Visual Inspection: Look for damage on cables, especially at joints and bends.

- Segmentation and Isolation: Break the system into smaller parts by disconnecting at key spots. Test each part for insulation resistance.

- Branch Line Testing: Disconnect and test each branch line one at a time to find the bad part.

- Use of Diagnostic Instruments: Use insulation testers to check resistance between wires and ground. Use cable locators and clamp meters to find the exact spot of the fault.

- Safety Precautions: Always keep the system off. Use grounding rods to get rid of stray voltage. Watch for dangers in small spaces.

- Documentation and Collaboration: Write down what you find. Use more than one test if needed. Ask other experts for help if you cannot find the fault.

Alert: Never skip safety steps when splitting the system. Always turn off and lock out the system before testing.

By following these steps, you can find and fix ground faults quickly and safely. Using both looking and testing gives you the best chance to find the problem before it causes trouble.

Repair Techniques

Wiring Repair

Start by fixing any bad or broken wiring. First, turn off the power and make sure it is safe. Take out wires that are burned, frayed, or rusty. Use wire strippers to cut back to clean copper. Pick the right size and type of wire for the job. Make sure your connections are tight and use approved connectors like lugs or crimps. Do not use tape or wire nuts for repairs with lots of current. Check that ground and neutral wires are not mixed up. Put all wires neatly in junction boxes and label them. After you finish, test the circuit for continuity and insulation resistance before turning the power back on.

Tip: If connections are loose or not done right, you can get voltage drops, ground loops, or another ground fault. Always check and tighten every connection.

Device Replacement

If you find a bad outlet or device, pick the right one to replace it. The National Electrical Code has rules for this. Use the table below to help you choose:

| Replacement Scenario | Allowed Replacement Device(s) | Marking Requirements | Equipment Grounding Conductor Requirement |

|---|---|---|---|

| Non-grounding type receptacle replacement without equipment grounding conductor | Another non-grounding type receptacle | N/A | Not required |

| Replacement with GFCI receptacle | GFCI receptacle marked “No Equipment Ground” | Must be marked “No Equipment Ground” | Must NOT connect grounding conductor from GFCI receptacle to any outlet |

| Replacement with grounding-type receptacle | Grounding-type receptacle supplied through GFCI | Must be marked “GFCI Protected” and “No Equipment Ground” | Must NOT connect grounding conductor between grounding-type receptacles |

- Do not put a new, unprotected outlet where GFCI protection is needed.

- Always use a GFCI device in these places, even if there is no ground wire.

- Label all GFCI-protected outlets the right way.

- Never connect the equipment-grounding conductor to outlets if it is not needed.

Grounding Fixes

Keep the grounding system in good shape to stop future ground faults. Connect all metal parts that do not carry current together. This gives a safe path for fault currents and helps safety devices work fast. Follow these steps for best results:

- Add materials that hold water or conduct electricity to soil with high resistance.

- Test ground resistance often and write down the results.

- Check grounding wires and connectors for rust or damage.

- Clean and tighten all grounding connections.

- Watch for things that might change the grounding.

- Add more electrodes if you need to upgrade grounding.

- Use materials that do not rust for all connections.

- Teach your team how to check and test grounding.

Note: Always write down your repairs and tests. Keep a log with dates, what you did, and the results. Use maintenance software if you can to track changes and make your process better.

Testing and Prevention

Post-Repair Checks

When you finish repairs, you need to make sure the system is safe. You also need to check that the ground fault is fixed. Follow these steps to check your work:

- Turn off the circuit you worked on. This stops new problems during testing.

- Use an ohmmeter to check resistance between neutral and ground. The number should be at least 1 megohm.

- Take out the neutral disconnect link for a short time. Do the resistance test again.

- Put current into the phase and neutral wires. This checks if the current transformers and relays work right.

- Make sure the sensor is set up right. Put in current at certain levels and watch how the relay acts.

- Do timing tests by putting in double the pickup current. Check if the trip times match the maker’s rules.

- Test the ground-fault system with less control voltage, about 55% of normal. See if the relay and breaker still work.

- Write down all your test results. Make sure you follow the code and the maker’s rules before turning the power back on.

Tip: Always check insulation resistance again after repairs. If the resistance is low, look for water or broken insulation before you reconnect.

Preventive Maintenance

You can stop most ground faults by doing regular maintenance. Checking and testing often helps you find problems early. This saves money and keeps things working. Here are important steps for good preventive maintenance:

- Look at cords, cables, outlets, and switches for damage or heat marks.

- Keep electrical panels clean and make sure connections are tight.

- Test all GFCI outlets often to make sure they work.

- Change old insulation and broken parts right away.

- Clean and oil motors and moving parts.

- Check grounding wires for rust or if they are loose.

- Keep good records of all maintenance and repairs.

- Have a professional check your system every year.

- Work with managers and contractors to keep everything safe.

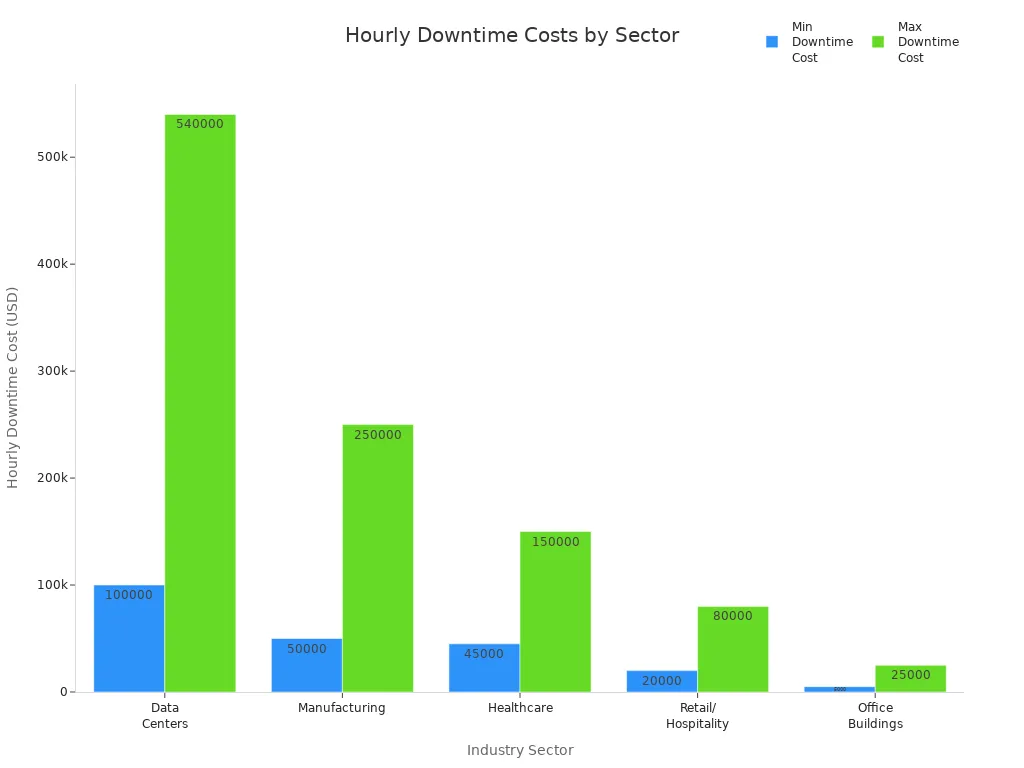

Doing regular maintenance saves money and stops failures. Places that do this save 12-18% and have fewer problems than those that only fix things when they break.

| Maintenance Type | Statistical Evidence | Impact on Failures and Costs |

|---|---|---|

| Preventive Maintenance | 12% to 18% cost savings compared to reactive maintenance | Decreases number of failures, reduces downtime |

| Reactive Maintenance | Failure rate is three times higher than preventive | Higher costs and increased risk of incidents |

A good preventive maintenance plan keeps your equipment safe, saves money, and protects your electrical system from ground faults.

You can keep your electrical systems safe if you follow a simple checklist. First, look for any damage or things that look too hot. Next, test the insulation and see if breakers work right. Then, check GFCI outlets and make sure the grounding system is good. Write down everything you find and fix.

Doing regular checks and maintenance follows NEC, OSHA, and UL rules. Keep learning about new codes and tools with training. Make safety part of your daily routine. Always wear PPE, talk about safety, and go over emergency plans with your team. Take time to check and test things before problems happen.

FAQ

What is the fastest way to find a ground fault?

You can start with a visual inspection. Look for burned wires or damaged insulation. Use a GFCI tester or a multimeter to check for faults. Isolate sections of the circuit to narrow down the problem area.

Can you repair a ground fault without turning off the power?

Never try to repair a ground fault with the power on. Always turn off and lock out the circuit first. This keeps you safe from shock and injury.

How often should you test GFCI outlets?

Test GFCI outlets every month. Press the “Test” button, then the “Reset” button. If the outlet does not trip or reset, replace it right away.

What tools do you need for ground fault troubleshooting?

- Insulated screwdriver

- Multimeter

- GFCI tester

- Wire strippers

- Insulation resistance tester

These tools help you find and fix ground faults safely and quickly.

The following information may be of interest to you

What You Need to Know About Ground Fault Causes

Grounding protection and surge protection stop surprise shocks

What should I do if the circuit is overloaded?

What Causes Circuit Breaker Overheating and How to Prevent It

Comparison between residual current device and GFCI