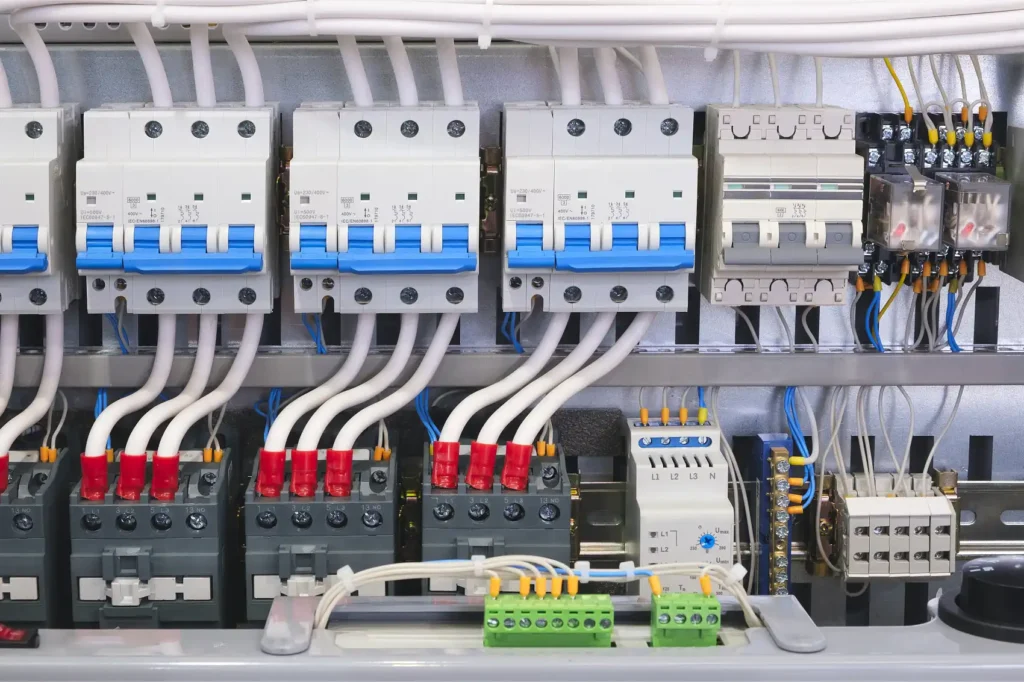

MCCB (molded case circuit breaker) is an essential component of electrical protection systems, which is widely used in industrial, commercial, and domestic power distribution systems.

Among them, which are electronic shaped circuit breakers and thermal magnetic shaped circuit breakers, each has its own working principle, application scenarios, advantages and disadvantages. In this guide, we’ll be discussing the differences between the two types of circuit breakers to help you choose the most suitable one for your needs.

What is a molded case circuit breaker

Molded case circuit breakers (MCCBs) serve as electrical devices that break currents in a circuit when they sense conditions of increased current or short circuits.

Unlike traditional fuses (that are removed and need to be replaced after tripping), molded case circuit breakers can be reset and reused, helping you save on long-term costs and improving reliability. Moulded case circuit breakers can be classified into electronic and thermomagnetic types based on tripping mechanism.

Thermal magnetic molded case circuit breaker

Electronic molded case circuit breaker

Differences in core functions and performance

| Comparison Dimension | Thermal-Magnetic | Electronic |

|---|---|---|

| Protection Function | Overload, short circuit (only twostage protection) | Overload, short circuit, ground fault,undervoltage (four-stage protection) |

| Response Speed | Fast short-circuit response (20-50ms), slow overload response | Faster response for all fault types (within10ms) |

| Accuracy &Stability | Highly affected by temperature,+20% error | +5% error, supports temperaturecompensation |

| ApplicationScenarios | General power distribution, lightingcircuits | Data centers, precision equipmentindustrial automation |

| Maintenance Cost | Low (no programming required,simple structure) | High (requires professional setup) |

Selection suggestion: 5 key factors

1.Priority of Protection Requirements

If only basic overload and short circuit protection are needed, the thermal magnetic type has a higher cost-effectiveness.

Complex scenarios such as motor group control and photovoltaic systems require electronic multi-stage protection and area selective interlocking functions.

2.Environmental adaptability

Thermal magnetic type (with strong mechanical structure anti-interference) is preferred for high temperature or vibration environments.

Electronic devices need to avoid strong electromagnetic interference and have a wider operating temperature range (such as CM1E supporting -40 ℃).

3.Long term cost considerations

The initial cost of the hot magnetic type is low, but it cannot upgrade its functionality.

Although electronic technology requires high initial investment, it can adapt to future needs through software upgrades.

4.Energy Efficiency and Intelligence

Electronic support for energy consumption monitoring and remote control, suitable for smart grids.

Thermomagnetic type is only suitable for traditional distribution networks.

5.Installation and maintenance convenience

Thermal magnetic type is mostly manually operated and easy to maintain.

Electronic systems require the cooperation of electric mechanisms and rely on stable power sources

Market brand recommendation

ONESTO:High cost performance, complete functions, meeting basic industrial and civilian demands, suitable for small and medium-sized enterprises and construction projects.

ABB:High reliability, modularization design, complete intelligent protection function, high short-circuit breaking capacity, suitable for industrial and commercial fields.

Siemens:Compact construction, high durability, precise electronic protection, with communication interface, supporting intelligent management, suitable for industrial automation systems.

schneider:High-end positioning, adopting advanced electronic release technology, intelligent management, stable performance, being used in industrial and high-end buildings widely.

Delixi:Practical and economical, complete basic protection functions, meeting general industrial and commercial demands

Obtain high-quality cost-effective molded case circuit breakers

Suggested purchase type

If the budget is sufficient, electronic circuit breakers are recommended to provide more precise protection and intelligent functions. If the budget is limited or the circuit is simple, thermal magnetic circuit breakers are still a reliable choice.

Purchase advice

Industrial intelligent distribution → electronic

Ordinary commercial building → Thermal magnetic type

Complex load environment → Electronic

Cost sensitive project → Thermal magnetic type

FAQ

Is electronic circuit breaker safer than thermal magnetic circuit breaker?

Electronic circuit breakers have higher precision, but there is no essential difference in basic safety between the two.

Can the tripping parameters of a thermal magnetic circuit breaker be adjusted?

No, the trip value of the thermal magnetic circuit breaker is fixed.

If you want to obtain high-quality molded case circuit breakers with multiple types and specifications, you can contact us