Circuit breakers and miniature circuit breakers serve as essential safety devices, but they differ in size, design, and application. Choosing the correct device directly affects system safety and performance. Engineers often rely on industry data to match device ratings to specific needs.

| Parameter | Details / Market Insights |

|---|---|

| Amperage Ratings | <20 Amps (lighting), 20-40 Amps (outlets), 40-60 Amps (AC units), >100 Amps (industrial) |

| Breaking Capacity | <6 kA (residential), 6-10 kA (industrial), 10-20 kA (specialized) |

| Trip Curve Characteristics | Type B (fast), Type C (balanced), Type D (high inrush), Type K (industrial) |

A well-informed choice of circuit breakers and miniature circuit breakers improves system reliability and supports safer electrical installations.

Key Takeaways

- Circuit breakers handle higher currents and offer advanced features, making them ideal for industrial and large commercial use.

- Miniature circuit breakers (MCBs) are compact, easy to install, and best suited for homes and small businesses.

- Both devices protect circuits from overloads and short circuits, but circuit breakers provide better monitoring and higher breaking capacities.

- MCBs use fixed trip settings, while circuit breakers often have adjustable trip mechanisms for precise protection.

- Choosing the right breaker depends on load size, environment, budget, and compliance with safety standards.

- Regular maintenance and testing keep circuit breakers reliable and extend their lifespan.

- MCBs are cost-effective and reusable, offering simple reset options after trips without replacement.

- Proper selection and installation of breakers ensure safety, reduce downtime, and protect electrical equipment.

Overview

Circuit Breakers

Circuit breakers play a vital role in modern electrical systems. They protect circuits from damage by automatically interrupting the flow of electricity during faults. These devices use advanced safety features to prevent hazards such as fires, shocks, and equipment failure. Modern circuit breakers include overload, short circuit, ground fault, and arc fault protection. Many models also offer remote monitoring and diagnostic features, which help maintenance teams identify issues before they cause downtime.

Note: Regular testing and maintenance of circuit breakers ensure reliable operation and compliance with safety standards like NFPA 70E and NFPA 70B.

The following table highlights key safety features and their functions:

| Safety Feature | Functionality | Key Characteristics |

|---|---|---|

| Overload Protection | Trips breaker when load exceeds safe limits | Thermal trip mechanism |

| Short Circuit Protection | Interrupts electrical flow during short circuits | Magnetic trip mechanism |

| Ground Fault Protection | Detects unintended ground paths | Residual Current Device |

| Arc Fault Protection | Identifies and mitigates arcing faults | Arc Fault Circuit Interrupter |

| Remote Monitoring | Enables remote status monitoring and control | Digital communication interfaces |

Circuit breakers support a wide range of applications, from residential panels to large industrial switchgear. The global market for these devices continues to grow, driven by infrastructure development, stricter safety standards, and new technologies like IoT integration. Major industry players such as ABB, Siemens, and Schneider Electric lead innovation in this field.

Miniature Circuit Breakers

Miniature circuit breakers, or MCBs, are compact devices designed for lower current ratings. They protect household wiring, appliances, and light commercial equipment from overloads and short circuits. MCBs use both thermal and electromagnetic mechanisms to detect faults quickly and accurately. Common ratings include 10A, 16A, and 25A, with voltage ratings of 230V or 415V. Breaking capacities can reach up to 10,000 Amps, making them suitable for most residential and commercial needs.

- MCBs offer several advantages over traditional fuses:

- Reusable after tripping

- Cost-effective

- Easy to reset

- Enhanced reliability and safety

🛡️ MCBs play a critical role in protecting homes and businesses, especially as electrical loads increase with modern appliances.

The market for MCBs shows strong growth, especially in the commercial sector, which leads in revenue expansion. Asia-Pacific holds the largest market share due to rapid industrialization, while North America and Europe follow with steady demand. MCBs come in different types—Type B for residential, Type C for commercial, and Type D for industrial applications—ensuring the right level of protection for each environment.

Circuit breakers and miniature circuit breakers together form the backbone of electrical safety in every sector, adapting to the needs of homes, businesses, and industries worldwide.

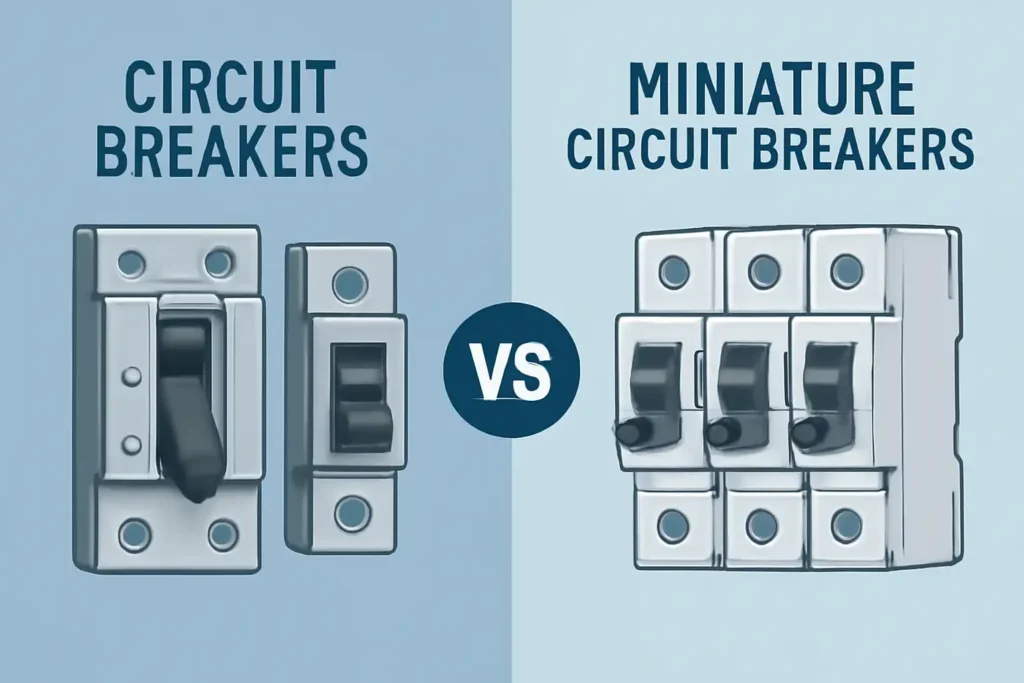

Differences

Size and Design

Physical Size

Miniature circuit breakers (MCBs) feature a compact design. Manufacturers create these devices to fit side by side in standard distribution boards. This compactness saves space, especially in residential and commercial panels. In contrast, industrial circuit breakers, such as molded case circuit breakers (MCCBs), have a much larger footprint. These larger devices accommodate higher current ratings and advanced protection features.

| Feature/Type | Miniature Circuit Breakers (MCBs) | Molded Case Circuit Breakers (MCCBs) | Insulated Case Breakers |

|---|---|---|---|

| Typical Application | Residential, schools, hospitals | Commercial and industrial | Large industrial sites |

| Size and Design | Compact, fixed-trip | Larger, adjustable | Largest, multi-setting |

| Current Ratings | Up to 100A | Up to 2,000+ A | Higher than MCCBs |

| Voltage Ratings | Low voltage systems | Up to 1,000V | Industrial voltages |

| Fault Interruption Capacity | ~10,000A | Up to 200,000A | Very high |

MCBs combine disconnection and overcurrent protection in one small unit, making them ideal for tight spaces.

Construction

MCBs use halogen-free thermoplastics, which are environmentally friendly and recyclable. Their design includes a trip-free mechanism, ensuring the device trips even if someone holds the handle in the ON position during a fault. MCBs also provide high ingress protection (IP20), making them touch-safe for users. Manufacturers design these devices for a long operational lifespan, often up to 10,000 operations.

Larger circuit breakers, such as MCCBs, feature adjustable trip settings and robust enclosures. These devices often come with maintenance features and can be installed in stand-alone enclosures or large switchgear assemblies. Their construction supports higher fault interruption capacities and more complex protection schemes.

Tripping Mechanism

Tripping Relay vs. Tripping Release

Circuit breakers and miniature circuit breakers use different tripping mechanisms to detect and interrupt faults. MCBs rely on a fixed trip mechanism, which cannot be adjusted. This mechanism ensures consistent protection for household and light commercial circuits. Industrial circuit breakers, on the other hand, often use tripping relays with adjustable settings. These relays allow engineers to fine-tune the response to overcurrent and short-circuit events, making them suitable for complex electrical systems.

Thermal and Magnetic Elements

Both MCBs and larger circuit breakers use thermal and magnetic elements for protection. The thermal element, usually a bimetallic strip, responds to prolonged overcurrents by bending and triggering the trip. The magnetic element reacts instantly to high current surges, such as those caused by short circuits.

| Aspect | Category/Range | Typical Application/Notes |

|---|---|---|

| Tripping Mechanism | Thermal | Bimetallic strip, protects against prolonged overcurrent |

| Magnetic | Electromagnetic force, trips instantly on short circuits | |

| Thermal-Magnetic | Combines both protections, versatile for various settings |

MCBs typically use a thermal-magnetic trip unit, which provides reliable protection for most residential and commercial applications. Industrial circuit breakers may offer more advanced or adjustable trip units to match specific load requirements.

Poles and Configuration

Number of Poles

MCBs usually come in single-pole or double-pole configurations. These options suit the needs of low-voltage domestic or light-industrial circuits. In contrast, industrial circuit breakers, such as MCCBs, often feature three or four poles. This design supports large three-phase loads and complex distribution systems.

| Feature | Miniature Circuit Breaker (MCB) | Moulded-Case Circuit Breaker (MCCB) |

|---|---|---|

| Typical Application | Low-voltage domestic/light-industrial | Large three-phase loads, motor starting |

| Pole Arrangement | Usually single-phase, single-pole | Three-phase, multi-pole |

| Current Ratings | Up to 100A | 100 to 2500A |

Application of Poles

Single-pole MCBs protect individual circuits, such as lighting or outlets. Double-pole versions can disconnect both live and neutral wires, increasing safety. Three-pole and four-pole circuit breakers handle three-phase power, which is common in industrial settings. These configurations allow for the protection of motors, large equipment, and entire distribution panels.

Engineers select the number of poles based on the type of load and the electrical system’s complexity.

Circuit breakers and miniature circuit breakers offer a range of pole configurations to match the demands of residential, commercial, and industrial environments.

Current and Breaking Capacity

Current Ratings

Current ratings define the maximum continuous current a device can handle without tripping. Miniature circuit breakers (MCBs) typically support ratings from 6A to 100A, making them suitable for residential and light commercial circuits. Larger circuit breakers, such as molded case circuit breakers (MCCBs), offer much higher ratings, often up to 2,500A or more. Engineers select the appropriate rating based on the expected load and the type of installation.

Testing laboratories like KEMA, CESI, and CERDA conduct rigorous type tests to verify current ratings. These tests include temperature rise, mechanical endurance, and power testing. Compliance with international standards such as IEC and IEEE ensures that both circuit breakers and miniature circuit breakers perform reliably under rated conditions.

Breaking Capacity

Breaking capacity measures the highest fault current a device can safely interrupt. MCBs usually have breaking capacities between 6kA and 10kA, which covers most residential and small commercial needs. Industrial circuit breakers can interrupt much higher currents, sometimes exceeding 200kA, to protect large equipment and distribution systems.

Manufacturers test breaking capacity using short-circuit and withstand tests in accredited labs. These tests confirm that the device can safely disconnect high fault currents without damage. Adherence to standards like IEC and GOST guarantees safety and performance in real-world conditions.

| Device Type | Typical Current Rating | Typical Breaking Capacity |

|---|---|---|

| MCB | 6A – 100A | 6kA – 10kA |

| MCCB | 100A – 2,500A+ | 25kA – 200kA+ |

Proper selection of current rating and breaking capacity prevents equipment damage and electrical hazards.

Application Areas

Residential

The residential sector relies heavily on MCBs for circuit protection. These devices prevent electrical fires and faults in homes, apartments, and small buildings. Market studies show that residential applications account for the largest share of global circuit breaker sales. Factors such as urbanization, population growth, and advanced home electrical systems drive this trend. In North America, low voltage circuit breakers dominate residential installations, supporting lighting, outlets, and appliance circuits.

Commercial

Commercial buildings, including offices, schools, and hospitals, use both MCBs and larger circuit breakers. These environments require reliable protection for lighting, HVAC systems, elevators, and sensitive equipment. Surveys indicate that medium voltage circuit breakers are increasingly deployed in commercial settings to ensure uninterrupted power and support renewable energy integration. Smart building technologies and grid modernization further boost demand for advanced circuit protection.

Industrial

Industrial facilities depend on high-capacity circuit breakers to protect heavy machinery, motors, and complex distribution networks. The need for uninterrupted power supply and integration of renewable energy projects drives the adoption of medium and high voltage circuit breakers in factories and plants. Asia Pacific leads in industrial deployment due to rapid industrialization, while North America and Europe focus on grid upgrades and energy efficiency. Usage surveys highlight the growing demand for low voltage circuit breakers in small-to-medium industrial units, especially where safety and reliability are critical.

Circuit breakers and miniature circuit breakers adapt to the unique requirements of each sector, ensuring safety and operational continuity.

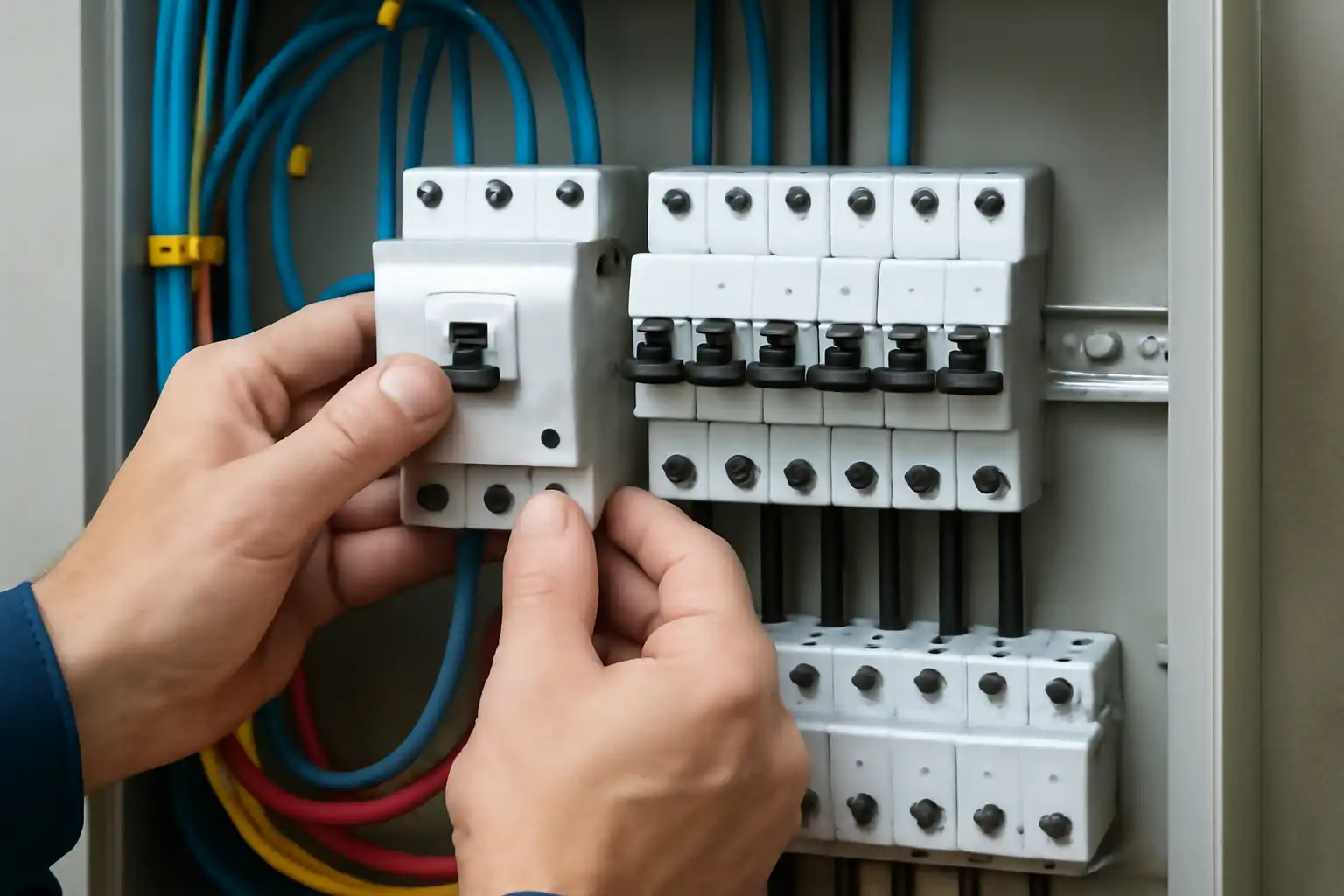

Installation and Maintenance

Installation

Proper installation ensures reliable operation and long service life. Electricians mount MCBs on DIN rails inside distribution boards, making them easy to install and replace. Larger circuit breakers may require bolted connections and custom enclosures. Installers must follow manufacturer guidelines and local electrical codes to guarantee safety and compliance.

Maintenance

Regular maintenance extends the lifespan of circuit protection devices and reduces the risk of failure. Technicians perform several key tests:

- Contact Resistance Test: Measures resistance across closed contacts to detect wear or contamination.

- Visual Inspection and Mechanical Measurement: Checks for erosion, pitting, and wear depth; recommends replacement if limits are exceeded.

- Dynamic Resistance Measurement (DRM): Records resistance during contact movement to identify uneven wear.

- Timing Test: Measures the speed of contact operation; delays may indicate mechanical issues.

- Contact Alignment Test: Assesses contact positioning; misalignment requires correction.

These tests provide quantifiable data on device condition and reliability. Maintenance records help forecast future needs and predict potential failures. While direct upkeep costs vary, regular testing and inspection minimize downtime and support safe operation.

Routine maintenance and adherence to testing protocols ensure that circuit breakers and miniature circuit breakers deliver consistent protection.

Cost and Availability

Price

Price plays a significant role when selecting between different types of circuit protection devices. Miniature circuit breakers (MCBs) usually cost less than larger industrial circuit breakers. Manufacturers design MCBs for mass production, which keeps their prices low. Most residential and small commercial projects use MCBs because of their affordability.

Larger circuit breakers, such as molded case circuit breakers (MCCBs) and insulated case circuit breakers, have higher prices. These devices offer advanced features, higher current ratings, and greater breaking capacities. The cost reflects the complexity of their construction and the materials used. Industrial projects often require these breakers to meet strict safety and performance standards.

The following table compares typical price ranges:

| Device Type | Typical Price Range (USD) | Common Application |

|---|---|---|

| MCB | $5 – $50 | Homes, small businesses |

| MCCB | $50 – $500+ | Factories, large offices |

| Insulated Case CB | $500 – $2,000+ | Heavy industry, utilities |

💡 Tip: Buyers should consider not only the initial price but also the long-term value, including reliability and maintenance costs.

Market Access

Market access determines how easily buyers can obtain the right circuit protection devices for their needs. MCBs are widely available at electrical supply stores, online retailers, and through local distributors. Their popularity in residential and commercial sectors ensures a steady supply and quick delivery times.

Larger circuit breakers, such as MCCBs and insulated case breakers, may require special ordering. These devices often come with custom specifications, so lead times can be longer. Industrial buyers usually work with authorized distributors or directly with manufacturers to ensure they receive certified products.

Global brands like ABB, Siemens, and Schneider Electric maintain strong distribution networks. These companies provide technical support, product training, and after-sales service. Local suppliers also play a key role, especially in emerging markets where demand for reliable circuit protection continues to grow.

📦 Note: Easy market access helps reduce project delays and ensures that replacement parts are always available when needed.

Circuit Breakers and Miniature Circuit Breakers: Pros and Cons

Circuit Breakers

Advantages

- Circuit breakers provide strong protection against overloads, short circuits, and ground faults. This helps reduce fire risks and keeps people safe.

- Many models offer advanced features, such as arc-fault detection and ground-fault protection, which further improve safety.

- Smart circuit breakers allow for remote monitoring and energy management. These features help building managers track power use and spot problems early.

- Industrial circuit breakers support high current ratings and can handle large electrical loads. This makes them ideal for factories and commercial buildings.

- Circuit breakers are reusable. After a trip, users can reset them instead of replacing them, which saves money over time.

- Compared to fuses, circuit breakers offer better long-term value and reliability.

💡 Smart circuit breakers can reduce energy usage by up to 30%, making them a good choice for energy-conscious facilities.

Disadvantages

- Circuit breakers often cost more than fuses or basic protection devices. The price increases with advanced features like smart monitoring.

- Some smart circuit breakers depend on internet connections for remote features. This can create problems if the network goes down.

- Installation and setup for advanced models can be complex. Electricians may need special training.

- Cybersecurity concerns may arise with smart breakers, as remote access could expose systems to risks.

- Regular testing and calibration are needed to keep circuit breakers working well, especially in high-voltage or industrial settings.

Miniature Circuit Breakers

Advantages

- Miniature circuit breakers (MCBs) have a compact design, making them easy to install in small spaces like home panels.

- MCBs respond quickly to electrical faults, providing fast protection for household circuits.

- Their simple structure leads to high reliability and a low failure rate. Most issues come from installation errors, not the device itself.

- Maintenance is straightforward. Users can easily reset MCBs after a trip, and routine checks are simple.

- MCBs come in many types and ratings, so they fit a wide range of residential and light commercial needs.

- Modular and scalable designs allow for easy upgrades and changes.

🏠 MCBs help homeowners and electricians meet safety codes while keeping installation and maintenance costs low.

Disadvantages

- MCBs have limited current and breaking capacity. They may not suit heavy industrial or high-voltage applications.

- Price differences can be significant, especially for high-performance or specialty models.

- MCBs are less effective in direct current (DC) circuits because of arc extinguishing challenges.

- Some advanced electronic MCBs rely on manufacturer support and software, which can make repairs harder.

- Periodic testing is needed to ensure continued protection, adding to the maintenance workload.

Selection

Factors

Load Requirements

Selecting the right protection device starts with understanding the load. The rated voltage and current of the breaker must match or exceed the circuit’s needs. Engineers check the maximum expected current and choose a breaker with an ampere rating that fits. If the breaker’s rating is too low, it may trip too often. If it is too high, it may not protect the circuit. Breaking capacity must also meet or exceed the highest possible short-circuit current in the system. For motor circuits, the breaker should have a long-delay setting that matches the motor’s rated current. Instantaneous trip points should fall within 8 to 15 times the motor’s rating to avoid nuisance trips.

Environment

Environmental conditions play a major role in device selection. Factors such as temperature, humidity, vibration, and altitude can affect performance. For example, high temperatures may cause thermal MCBs to trip earlier than expected. In these cases, magnetic MCBs or breakers with temperature compensation work better. Installers should also consider the enclosure’s IP rating to protect against dust and moisture. In harsh environments, derating tables help adjust the breaker’s current rating for safe operation.

Budget

Budget influences the choice between basic and advanced models. MCBs usually cost less and suit most homes and small businesses. Larger breakers with higher ratings and extra features cost more. Buyers should consider not only the purchase price but also long-term costs like maintenance and replacement. Reputable brands may cost more upfront but offer better reliability and support.

Safety Standards

Compliance with safety standards ensures reliable protection. Residential installations should use breakers certified to IEC 60898-1. Industrial settings require devices that meet IEC 60947-2. Certifications such as CE, UL, or CCC show that the product meets strict safety rules. Installers must also follow local codes and regulations to ensure safe and legal installations.

Tips

- Match the breaker’s current rating and breaking capacity to the circuit’s needs.

- Choose the right trip curve (B, C, D, K, or Z) for the type of load, such as lighting, motors, or sensitive electronics.

- Select the correct number of poles for single-phase or three-phase systems.

- Check the IP rating and consider derating for high temperatures or harsh environments.

- Prefer well-known brands for better quality, warranty, and spare parts.

- Understand breaker symbols and markings to avoid installation errors.

- Always verify compliance with international and local standards.

🛡️ Careful selection based on these factors helps ensure safety, reliability, and cost-effectiveness for any electrical installation.

Comparison Table

Choosing between a circuit breaker and a miniature circuit breaker (MCB) often depends on several technical and practical factors. The following table highlights the most important differences. This comparison helps readers quickly identify which device best fits their needs.

| Feature / Parameter | Circuit Breaker (CB) | Miniature Circuit Breaker (MCB) |

|---|---|---|

| Physical Size | Large, bulky | Compact, space-saving |

| Current Rating | 100A to 2,500A+ | 6A to 100A |

| Breaking Capacity | Up to 200kA+ | 6kA to 10kA |

| Trip Mechanism | Adjustable (thermal, magnetic, electronic) | Fixed (thermal-magnetic) |

| Number of Poles | 1 to 4 (often 3 or 4 for industry) | 1 or 2 (sometimes 3 or 4) |

| Application Area | Industrial, commercial, utility | Residential, light commercial |

| Installation | Panel-mounted, custom enclosures | DIN rail, standard distribution box |

| Maintenance | Requires regular testing, skilled labor | Minimal, easy reset |

| Price Range | $50 – $2,000+ | $5 – $50 |

| Market Availability | Specialized suppliers, longer lead times | Widely available, quick delivery |

| Standards | IEC 60947-2, UL 489 | IEC 60898-1, UL 1077 |

| Reset Method | Manual or remote | Manual reset |

| Lifespan (Operations) | 10,000 – 20,000+ | Up to 10,000 |

| Advanced Features | Arc fault, ground fault, smart monitoring | Basic protection |

Tip:

For home or small office use, MCBs offer a simple and cost-effective solution. For factories or large buildings, circuit breakers provide higher protection and flexibility.

Key Takeaways

- Circuit breakers handle higher currents and offer more advanced features. They suit heavy-duty and industrial environments.

- MCBs fit best in homes and small businesses. Their compact size and easy installation make them popular for everyday use.

- Both devices protect against overloads and short circuits. However, only circuit breakers support advanced monitoring and higher breaking capacities.

Summary List:

- Circuit breakers: High capacity, adjustable, industrial use, higher cost.

- MCBs: Compact, fixed settings, residential use, affordable.

🛡️ Always match the device to the application. Proper selection ensures safety, reliability, and compliance with electrical standards.

Circuit breakers and miniature circuit breakers differ in size, current rating, and application. Choosing the right device protects equipment, reduces downtime, and lowers long-term costs. Facilities that use circuit breakers with proper maintenance can extend equipment life by over 10 years and prevent most failures. The table below shows how circuit breakers offer better safety and lower operating costs than fuses. For a quick overview, readers can review the comparison table above.

| Factor | Circuit Breakers | Fuses |

|---|---|---|

| Operating Cost | Lower | Higher |

| Downtime | Minimal | Extended |

| Safety | Improved | Higher risk |

FAQ

What is the main purpose of a circuit breaker?

A circuit breaker protects electrical circuits from damage. It stops the flow of electricity when it detects a fault, such as an overload or short circuit. This action helps prevent fires and equipment failures.

Can you reset a miniature circuit breaker after it trips?

Yes, users can reset a miniature circuit breaker (MCB) by switching it back to the ON position. The device does not need replacement after tripping, unlike a fuse.

How do you choose between an MCB and a regular circuit breaker?

Engineers select an MCB for low current, residential, or light commercial use. They choose a regular circuit breaker for higher currents or industrial settings. The decision depends on current rating, breaking capacity, and application area.

Do circuit breakers require regular maintenance?

Yes. Technicians perform routine tests and inspections on circuit breakers. These checks ensure reliable operation and help identify wear or damage before problems occur.

Are MCBs suitable for industrial applications?

MCBs work best in homes and small businesses. Industrial sites usually need larger circuit breakers with higher current ratings and advanced features.

What does “breaking capacity” mean?

Breaking capacity shows the highest fault current a device can safely interrupt. A higher breaking capacity means the device can handle stronger electrical faults without failing.

Can you use an MCB for direct current (DC) circuits?

Most MCBs are designed for alternating current (AC) circuits. Some special models can protect DC circuits, but users must check the manufacturer’s specifications before installation.

🛡️ Tip: Always follow local electrical codes and manufacturer guidelines when selecting and installing circuit protection devices.

The following information may be of interest to you

The difference between AC MCB and DC MCB

Comprehensive analysis of miniature circuit breakers

The difference between MCCB and MCB

How to Distinguish Between Industrial and Residential Circuit Breakers?

KC6-KU-3-pole-circuit-breaker.webp)