Terminal blocks are usually found in control panels, junction boxes, and distribution boards. Hardware terminal blocks help connect and arrange electrical wires. They are not like software terminals such as Mac Terminal or command line interfaces. Choosing the proper terminal installation location keeps connections safe from water, dust, and shaking. It also makes it easy to fix or check them. Placing terminal blocks in the right spot keeps wires neat and lowers risks. This helps follow electrical rules and ensures the system works well.

Key Takeaways

- Terminal blocks are mostly put in control panels, junction boxes, distribution boards, and machinery enclosures. They help keep electrical wires safe and neat. Picking the right spot keeps wires safe from water, dust, and shaking. This makes fixing things easier and lowers danger. Safety is very important. Use terminal blocks with the right ratings and clear labels. Always follow the rules to stop shorts and shocks. Put terminal blocks where you can reach them easily. Mark wires clearly to help fix problems fast and make changes later. Think about the place and system design. Use moisture-proof blocks in wet spots. Leave extra room for upgrades.

Terminal Installation Location Overview

Terminal blocks help organize and connect electrical circuits. Where you put terminal blocks affects how well the system works. It also affects how easy it is to fix and how safe the wires are. Here are the most common places for terminal blocks in electrical systems.

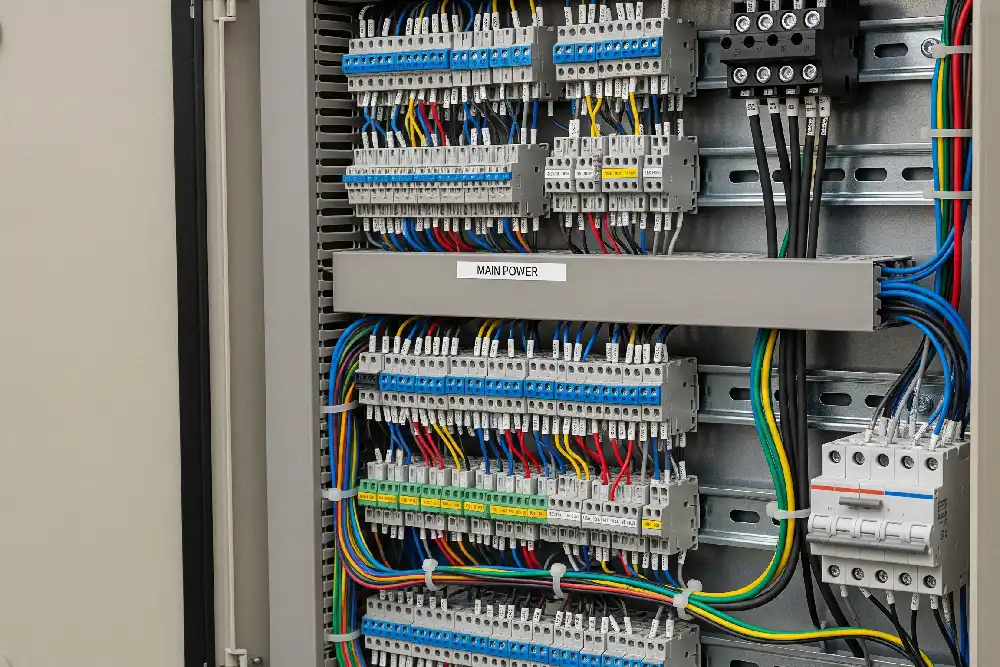

Control Panels

Control panels are the main place for terminal blocks in factories and businesses. Technicians put terminal blocks on DIN rails or right on the panel. DIN rails make wiring easier and save space. Terminal blocks in control panels have modular housings with insulated bodies. This keeps many wires safe. They use different connection types like screw terminals, push-in, and spring-loaded. These features keep wires neat and help with troubleshooting.

Tip: Using different colors and marking tags in control panels helps people find circuits fast and makes fewer mistakes.

Control panels need terminal blocks that follow strict safety rules. UL 508A is one rule for spacing, temperature, and ratings. Good labels and paperwork make sure only trained people work on them.

Junction Boxes

Junction boxes are another common place for terminal blocks in homes and businesses. Terminal blocks in these boxes hold and end wires safely. They help ground and separate parts to stop electrical problems. Putting many circuits in one box saves space and makes work easier.

- Terminal blocks in junction boxes give test points for troubleshooting.

- They make it easy to connect and disconnect wires.

- These boxes let you change wiring later if needed.

Junction boxes must fit the place where they are used. For outside or tough places, boxes with high NEMA or UL ratings keep out dust, water, and hits. Picking the right box keeps wires safe and working.

Distribution Boards

Distribution boards are the main hubs in big electrical systems. They often use bus bars for high current, but terminal blocks help with smaller circuits. Terminal blocks in these boards send power from one input to many outputs. This keeps wires tidy and lowers mistakes during setup.

Terminal blocks in distribution boards must be strong for good contact and enough current. Clear markings like “N” for neutral and yellow-green for earth help people know what each wire does. The GB4026 standard tells how to mark terminals.

Note: Distribution boards with terminal blocks look neat and make future repairs easier.

Machinery Enclosures

Machinery enclosures are safe places for terminal blocks in factory equipment. These enclosures protect wires from dust, water, and damage. They come in many sizes and shapes for different machines.

| Design Consideration | Description |

|---|---|

| Easy to Install & Maintain | Snap-in or screw-mount designs help quick setup and access. |

| Good Labels & Color Coding | Fewer wiring mistakes and better safety. |

| Handles High Temperatures | Strong materials stand up to heat or cold. |

| Handles Vibration & Shocks | Strong mounts keep wires safe in rough places. |

| Handles Moisture & Chemicals | Waterproof and rust-proof materials protect wires. |

| Right Electrical Specs | Correct ratings and wire setup keep connections safe. |

| Easy to Reach | Technicians can get to terminal blocks for repairs. |

| Works with Accessories | DIN rail and pluggable blocks make changes easy. |

| Follows Safety Rules | Meeting industry rules keeps things reliable. |

Machinery enclosures often use terminal blocks with color pushers, tool-free wiring, and test points. These features help with tricky wiring and keep machines running safely and well.

Installation Factors

When you pick where to put terminal blocks, you need to think about a few things. These things help keep the electrical system safe. They also make it easy to fix and keep working well in different places.

Safety

Safety is the most important thing in any electrical setup. Terminal blocks must keep wires safe and covered. This stops short circuits and loose wires. Many terminal blocks use strong materials like nickel-plated copper. They also use nylon casings to stop rust and handle lots of power. Insulated barriers and clear covers help stop electric shocks. They also make it easier to check the wires. Secure connection types like screw or push-in help stop short circuits. Terminal blocks must follow safety rules and use flame-proof materials in tough places.

- Pick terminal blocks with the right voltage, current, and for the place.

- Turn off power before you install and wear safety gear.

- Label all terminal blocks and wires so you know what they are.

- Check often for loose wires or damage.

Accessibility

Accessibility means how easy it is to reach and fix terminal blocks. The way you set them up—sideways, up and down, or at an angle—changes how much room you need. It also changes how easy it is to fix them. Neat terminal blocks keep wires tidy and apart. This helps you find problems faster. Pluggable terminal blocks let you unplug and plug wires quickly. This makes repairs faster in different places. Using colors and clear labels helps you find the right wires fast.

- Pick wire-entry direction based on space and the place.

- Use pluggable types if you need to fix them often.

- Mark the housings so you can find them easily.

Environment

The place where you put terminal blocks changes how well they work. Wet, dusty, or hot places can be hard on them. In wet areas, use moisture-proof terminal blocks. In oily places, use wires that resist oil. Circuits over 400V need extra covering and clear labels. Keep high and low voltage wires apart with special dividers. The control cabinet should keep out dust and heat, especially in tough places.

- Use moisture-proof terminals in wet places.

- Keep high and low voltage wires apart with clear labels.

- Leave empty terminals between positive and negative wires.

System Design

System design helps you choose and place terminal blocks. Easy-to-use features and extras can save time when you install them. The type of connection depends on what people like and the place. Grouping power parts and using splitters changes where you put them. Clear labels help you keep track and fix things. Good spacing and grounding keep things safe. Places for terminal blocks should be easy to test and fix, even if things change.

- Leave at least 20% extra space for future changes.

- Pick terminal blocks with the right protection for outside or hot places.

- Use colors and labels to make fixing easier.

Terminal Installation in Practice

Industrial

Factories and plants use terminal blocks for hard wiring jobs. Workers put terminal blocks on DIN rails inside control panels. DIN rails help keep wires neat and make changes simple. Screw-down terminal blocks, like ones from Weidmuller or Phoenix Contact, are used a lot. Spring-loaded terminal blocks are better in places that shake a lot. They do not get loose over time. Workers label wires with snap-on markers or heat shrink tubes. Ferrules keep connections tight when many wires share one terminal. Extra wires are put in cables to make repairs faster.

- DIN rails help keep wires neat.

- Different types like screw-in, spring-cage, push-in, and IDC are used.

- Spring-cage and push-in types stay tight in shaky places.

- Pluggable and tab connectors make changes quick.

- Ferrules and strong labels help keep things safe.

Tip: Picking the right terminal block for the job stops loose wires and keeps machines working.

Residential

In houses, terminal blocks are in junction boxes and distribution boards. US building codes say each junction box must show its size in cubic inches. This helps electricians follow rules for safe wire splicing. Many terminal block boxes do not meet these rules. So, electricians use standard junction boxes with approved connectors like Wago. Some boxes have bus-type terminals, but these are not safe if they join neutral and ground wires. Checking and fixing these boxes is important, but people often forget.

- Junction boxes must show their size.

- Only approved connectors can go in standard boxes.

- Bus-type terminals joining neutral and ground are not safe.

- Checking and fixing boxes helps stop problems.

Commercial

Offices and stores use terminal blocks in control panels, lights, and distribution boards. Placement must follow strict rules for safety and how well things work. Installers match wire size to the job and strip wires to the right length. They control screw tightness to stop damage. Terminal housings need to be flame-proof and have color codes to stop mistakes. In wet places, waterproof terminals keep out water. Three-phase circuits need clear markings to avoid mix-ups. Installers plan so terminals are easy to reach for repairs.

- Terminal blocks must meet safety and work rules.

- Installers use color codes and keyways to stop mistakes.

- Waterproof terminals go in kitchens and bathrooms.

- Clear markings help with three-phase wires.

Note: Good planning and labels in offices and stores keep electrical systems safe and easy to fix.

Software Terminal Locations

Software terminals let people use computers with text commands. These are not the same as hardware terminal blocks. People use the mac terminal or command line to control computers. They also use them to run programs or manage files. Where you find each terminal app depends on the operating system.

mac Terminal

The mac terminal is an app on every Mac computer. You can find it in the Applications folder, inside Utilities. The mac terminal lets you type commands to control your Mac. It comes with macOS, so you do not need to install it. The mac terminal works with many command line tools. People use it to run scripts, install apps, and check settings. You can use the mac terminal for system or user level installs. Many students and developers use the mac terminal for coding and learning.

Note: The mac terminal is not a real device. It is a software tool that lets you use text to talk to your computer.

Command Line Paths

The command line is a tool on Windows, Linux, and macOS. Each system has its own command line app. On Windows, it is called Command Prompt or PowerShell. You can find it by searching “cmd” or “PowerShell” in the Start menu. Some programs let you add command line tools with a windows installer. On Linux, the command line is called terminal or shell. You can open it from the menu or by pressing special keys. On macOS, you use the mac terminal for the command line. The command line lets you run programs, move files, and change settings. Some tools install for everyone (system level), others just for one person (user level). The command line is a software tool, not a hardware part like terminal blocks.

| Operating System | Terminal Application Name | Typical Path or Access Method |

|---|---|---|

| macOS | mac terminal | Applications > Utilities > Terminal |

| Windows | Command Prompt, PowerShell | Start Menu > Search “cmd” or “PowerShell” |

| Linux | Terminal, Shell | Applications Menu or Ctrl+Alt+T |

People use the command line to control computers, but it is always a software app, not a real device.

Terminal blocks are found in control panels, junction boxes, distribution boards, and machinery enclosures. Putting them in the right spot keeps things safe and helps everything work well. Here are some important tips:

- Put terminal blocks in places that are dry, clean, and steady.

- Pick blocks that match the current and voltage needed.

- Make sure wires are tight and check them often.

- Think about hardware and software when you plan for repairs and how things run.

Planning ahead and installing terminal blocks the right way stops problems and helps electrical systems last a long time.

FAQ

What is a terminal block used for?

A terminal block joins electrical wires together. It helps keep circuits safe and simple to handle. Electricians use terminal blocks in many electrical systems.

What types of terminal blocks exist?

There are different types of terminal blocks. Some common ones are screw-in, spring-cage, push-in, and pluggable. Each type works best for certain wiring jobs and places.

What should people check before installing a terminal block?

People need to check the voltage and current ratings first. They should also look at the place, like if it is wet or hot. Labels and wire sizes are important for safety.

Tip: Always turn off the power before you work with terminal blocks.

What makes a good location for a terminal block?

A good spot is dry, clean, and easy to get to. The place should keep wires safe from harm. Putting terminal blocks in the right spot helps with repairs and keeps things safe.

See also

How many wires can be connected to one terminal block

What Is a Terminal Block and How Does It Work

What You Should Know About Terminal Blocks and Their Other Names

How many types of wiring terminals are there?

How to Safely Attach Wiring Terminals to Terminal Blocks in 2025