You will see that PCC Electrical Full Name means power control center panel in electrical engineering. A PCC panel is an electrical panel that controls power for big electrical systems. PCC panels act as main centers that split the main power into smaller circuits. These circuits go to motors, pumps, lights, and HVAC. You use a PCC panel to keep equipment safe from electrical problems and to check power use. In factories or data centers, PCC panels help give safe and neat power to every part of the building.

- Main jobs of a PCC panel include:

- Central power distribution

- Protection from electrical problems

- Features to watch and control power

Key Takeaways

- PCC means Point of Common Coupling or Power Control Center. Both are important in electrical systems.

- PCC panels help control and share power safely in big buildings. These buildings can be factories or data centers.

- The panels have breakers, switches, monitors, and protection devices. These things help keep equipment safe.

- PCC panels help save energy and stop electrical problems. They also make power easy to manage.

- Regular checks and maintenance keep PCC panels working well. This protects people and machines.

PCC Electrical Full Name

What PCC Stands For

You might ask what the pcc electrical full name means in electrical engineering. PCC stands for “Point of Common Coupling.” This is a special place in electrical systems. Here, different networks or customers connect to the utility grid. The PCC is the closest spot to the user where the utility can serve another user. It is often near the utility meter or transformer. The Point of Common Coupling helps check power quality and keep the system steady. People use it to look for harmonics and make sure the power supply is safe and steady.

Sometimes, people use pcc electrical full name to mean “Power Control Center” or “Power Control Center Panel.” In these cases, PCC is the main electrical panel that controls and shares power in big buildings or factories. Long ago, PCC came from the Presidents’ Conference Committee, which made electric streetcars in the early 1900s. Today, you mostly see PCC used for power sharing and control in modern electrical systems.

Tip: When you see “PCC” in electrical engineering, always check what it means. It can mean Point of Common Coupling or Power Control Center, depending on the system.

PCC Panel Definition

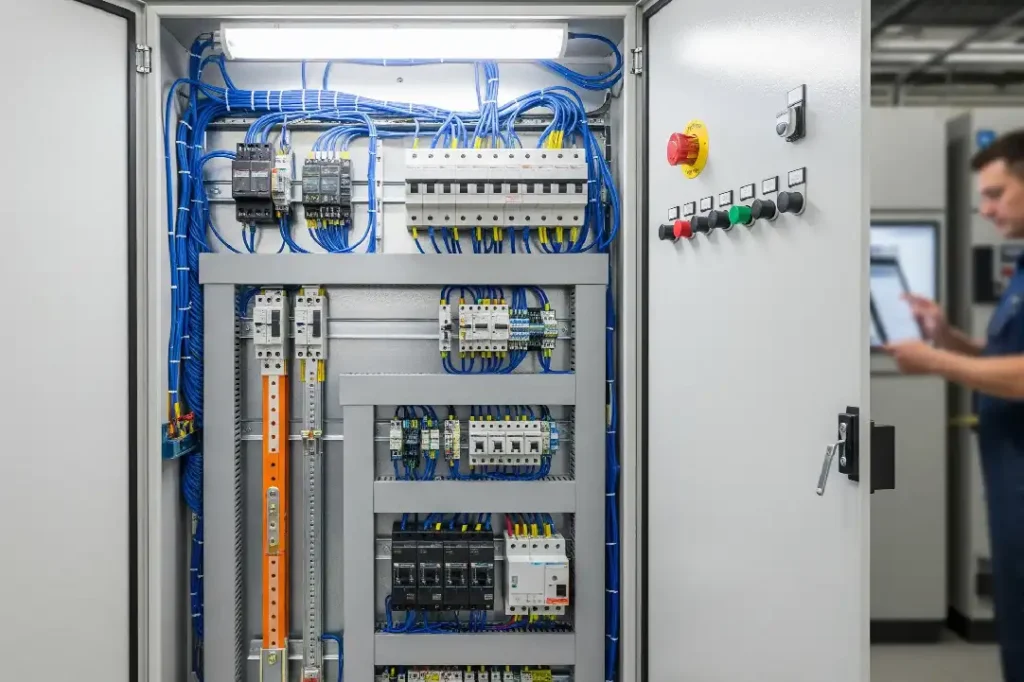

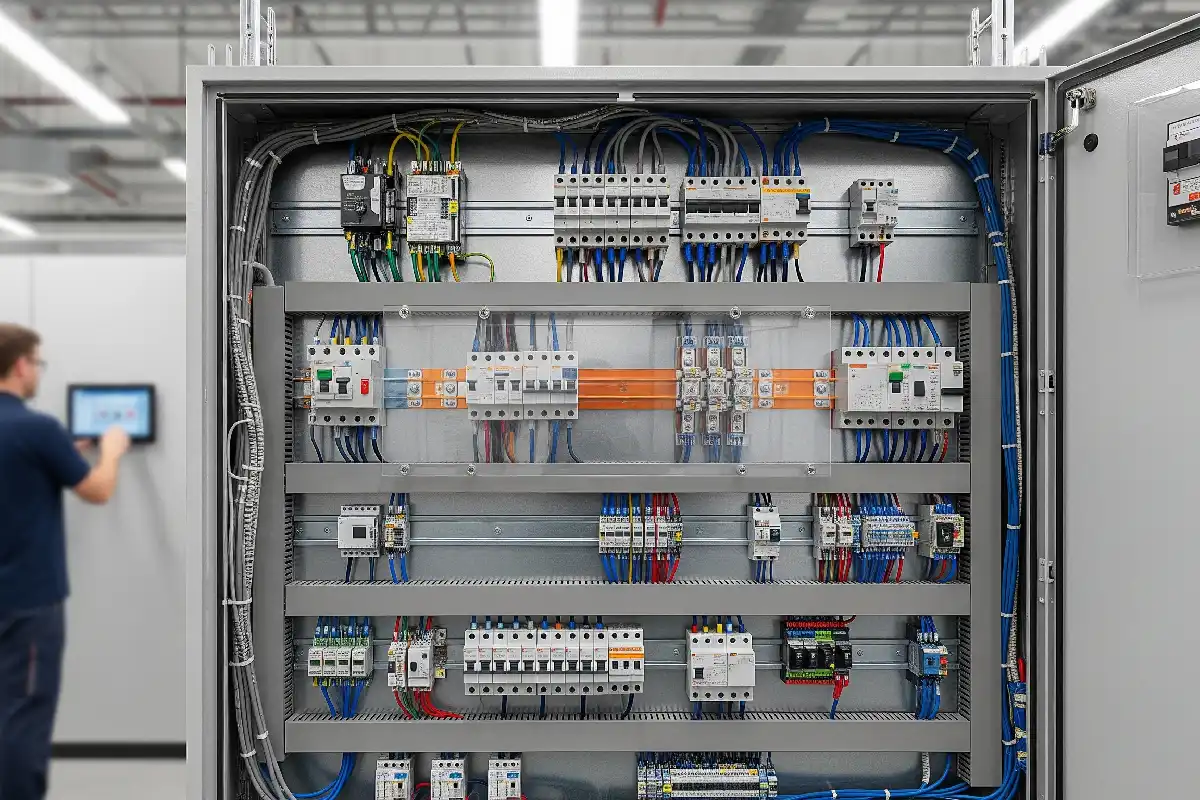

You use a pcc panel to manage and share electrical power in big places like factories or offices. The pcc electrical full name, when talking about panels, means a modular electrical control panel made for safe and easy power sharing. You find these panels in factories, data centers, and big office buildings. A pcc panel is the main hub that controls power to heavy machines, motors, transformers, and other equipment.

Here is a table that shows why a pcc panel is important:

| Aspect | Description |

|---|---|

| Definition | Modular electrical control panels for power sharing and control in big places. |

| Primary Function | Control power supply to heavy machines, motors, transformers, and equipment. |

| Key Features | High rating (up to 6300 A), electrical and mechanical locks, auto-load management, strong build. |

| Components | Feeder breakers, supply breakers, monitors, control devices, switches, protection devices, instruments. |

| Protection Features | Short circuit, overload, earth fault, under voltage protection. |

| Technical Specs | Rated voltage: 415 V, Three-phase, Short circuit rating: up to 70 kA for 1 second, IP ratings (IP54, IP65). |

| Safety and Compliance | Made to follow world standards for safety, reliability, and high fault level handling. |

You see pcc panels built to handle high voltage and current. They have strong protection like circuit breakers and relays. You use these panels to keep equipment safe from electrical problems and to watch power use. PCC panels must follow strict safety rules, like the National Electrical Code and local codes. You find things like good grounding, labeled wires, and enough space for heat inside every pcc panel.

- Main jobs of a pcc panel:

- Give steady power and stop voltage changes.

- Keep equipment and people safe from electrical dangers.

- Let you control and watch all electrical loads from one place.

- Offer custom solutions for different industries.

- Meet world safety and performance standards.

PCC panels now use smart technology. You see things like automation, IoT, and data analytics. These help you watch power use, plan repairs, and save energy. Some pcc panels use artificial intelligence to study data and find problems before they happen.

You use a pcc panel when you need a strong electrical panel for big jobs. It helps you manage power, protect equipment, and keep your electrical systems working well.

PCC Panel Components

A pcc panel has many important parts. These parts help you control and protect your electrical system. Each part has a special job. They keep power moving safely and working well.

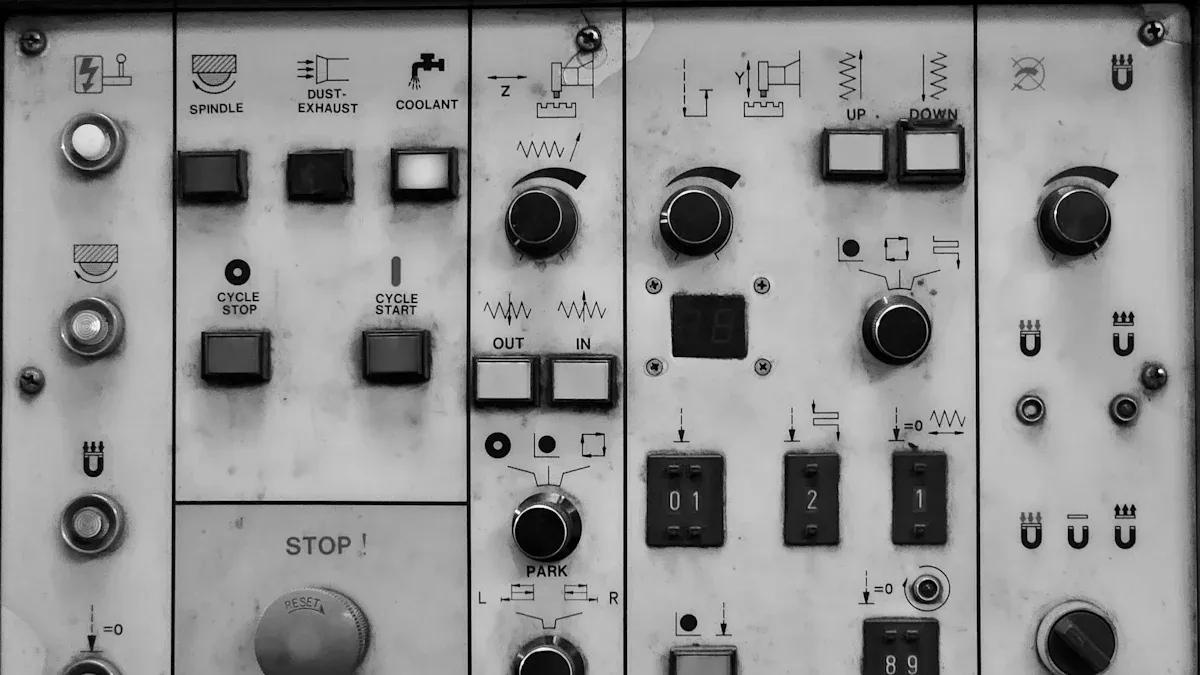

Main Breakers and Switches

You will see different breakers and switches in a pcc panel. Here are some types:

- Single-pole breakers: Used for lights and small outlets. They are usually 15 or 20 amps.

- Double-pole breakers: Used for big machines like stoves or air conditioners. They are 30 to 60 amps or more.

- GFCI breakers: Protect against ground faults. You find them in wet places. They have test and reset buttons.

- AFCI breakers: Help stop electrical fires by finding dangerous arcs. They also have test buttons.

- Combination breakers: Give both GFCI and AFCI protection.

The main breaker controls all the power coming into the pcc panel. It can turn off power to the whole system if needed. Other switches and breakers let you turn off power to certain machines or rooms. These breakers and switches protect against short circuits, overloads, and voltage changes. They help you stop power fast in emergencies and make repairs safer.

Tip: Draw-out type pcc panels let you take out parts for repairs. You do not have to turn off the whole panel.

Monitoring and Protection Devices

A pcc panel uses many devices to watch and protect your system. You will see feeder breakers, supply breakers, and special monitors. Control devices help you manage how power moves. Protection devices, like relays and fuses, stop damage from faults or too much power. Instrumentation devices, such as voltmeters and ammeters, show real-time data about your system. These features help you find problems early and keep equipment safe.

Power Distribution Elements

Power distribution elements in a pcc panel make sure every part of your building gets the right power. Here is a table with some key parts and what they do:

| Component | Function | Notes / Details |

|---|---|---|

| Main Breaker | Protects system from overloads and short circuits | Usually rated 100-200A, acts as master switch |

| Bus Bars | Distribute power across outgoing feeders | Made of copper or aluminum |

| Feeder Circuit Breakers | Control and protect individual circuits | Sized for each load |

| Current Transformers (CTs) | Measure current accurately | Work with meters and relays |

| Energy Meter | Monitors power use | Tracks voltage, current, power factor |

| Protection Relays | Disconnect circuits during faults | Includes overload and earth fault protection |

| Indicating Instruments | Show system status | Voltmeter, Ammeter, Frequency Meter |

| Indication Lamps | Display operating status | Red (ON), Green (OFF), Amber (Trip) |

Pcc panels use strong materials and safety features. They can handle high voltage and current. They also have surge protectors and let you work safely during repairs. All these parts work together to give you safe, steady, and efficient power in your building.

PCC in Industry

Industrial and Commercial Uses

PCC panels are found in many big buildings. They work as the main switchboards for power. You use a PCC panel to control and share electricity in places like factories, data centers, malls, offices, and hotels. In a factory, the panel sends power to machines and lights. In a data center, it manages power for servers and cooling. In a mall, the panel controls power for elevators, HVAC, and security. PCC panels are used where many devices need safe and steady power.

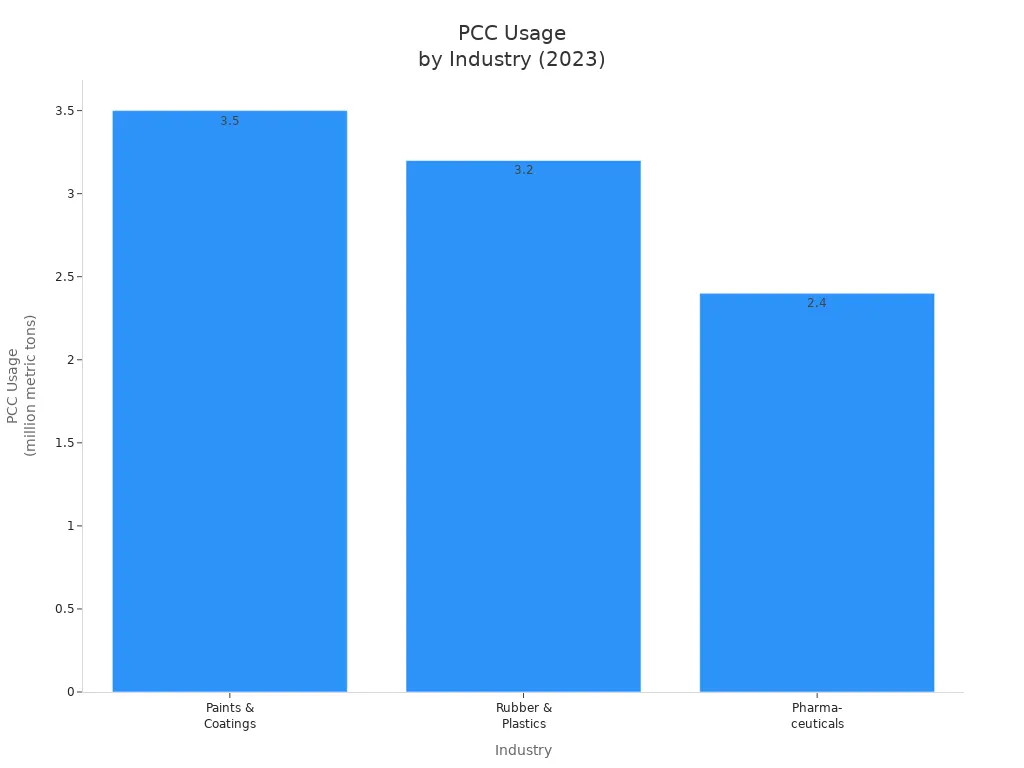

Here is a table that shows how different industries use PCC panels:

| Industry | PCC Usage (million metric tons, 2023) | Key Applications and Benefits |

|---|---|---|

| Paper | Largest share (part of 69 million total GCC & PCC) | Used in newsprint, coated papers, packaging board; improves cost efficiency, opacity, and surface quality. |

| Paints & Coatings | 3.5 | Enhances gloss, durability, and dispersion in decorative and industrial paints. |

| Rubber & Plastics | 3.2 | Improves physical strength, tear resistance, and extrusion properties in elastomers and thermoplastics. |

| Pharmaceuticals | 2.4 | Used as filler, antacid base, and nutritional supplement in oral dosage forms. |

PCC panels help send power to many floors and rooms. They keep the power steady and stop problems. You can control lights, HVAC, elevators, and more from one place.

Benefits and Importance

PCC panels give many good things in big buildings. You get to control and watch power from one spot. They have safety features like circuit breakers and protection from ground faults, overloads, and short circuits. These features help stop electrical dangers.

You can find and fix problems fast, so you lose less time. PCC panels make power better by stopping surges and voltage changes. You save energy by using power only where needed. You can watch and control systems from far away. PCC panels are easy to change or add to because of their design.

Here are some main benefits of PCC panels:

- Control and share power for all systems.

- Strong safety with good protection.

- Work well even in tough places.

- Can handle faults and heat for safe power.

- Watch and control power in real time.

- Save space and money.

Tip: You can change PCC panels to fit your building and connect them to smart systems for better control.

PCC panels help your building work well. They protect equipment, save energy, and make sure every part gets the right power.

PCC vs MCC Panel

Key Differences

There are big differences between a PCC panel and an MCC panel. A PCC panel gives out the main power in a building. It works with high voltage and current. It sends electricity to many areas. An MCC panel is for controlling electric motors. MCC panels work at lower voltage, up to 415V. They help start, stop, and protect motors.

MCC panels have motor starters, overload relays, and variable frequency drives. These parts help you control motors safely. PCC panels use circuit breakers, transformers, and busbars to share power. MCC panels get power from PCC panels. Then, they send it to motors. You see MCC panels in places with lots of motors, like factories or water plants. PCC panels give power to MCC panels and other machines.

Here is a table that shows how each panel is different:

| Aspect | MCC Panel (Motor Control Center) | PCC Panel (Power Control Center) |

|---|---|---|

| Primary Function | Controls and protects electric motors | Distributes electrical power across the facility |

| Voltage Level | Operates at lower voltage (≤415V) | Handles higher voltage and current levels |

| Key Components | Motor starters, overload relays, VFDs | Transformers, circuit breakers, busbars, power meters |

| Focus | Localized motor management and protection | Overall power distribution and energy monitoring |

| Design Emphasis | Control elements for motor operation and protection | Components for stepping down and distributing power |

| Relationship | Receives power from PCC panels | Supplies power to MCC and other panels |

| Typical Applications | Manufacturing plants, water treatment, HVAC systems | Power plants, large factories, commercial buildings |

Note: MCC panels are made for motor control. PCC panels are for power sharing and management.

Selection Considerations

You need to think about your needs before picking a panel. MCC panels are best for controlling motors. You use them in places with many motors, like car factories. MCC panels have motor starters, soft starters, and interlocks. They work with low and medium voltage motors.

PCC panels are better for sharing power to big machines. You use them for things like transformers, generators, and MCC panels. PCC panels watch, protect, and switch many devices. They can handle very high current, up to 6300A.

Here are some things to think about:

- Type of load: Pick MCC panels for motors, PCC panels for power sharing.

- Voltage levels: MCC panels work with low and medium voltage. PCC panels handle higher voltage and current.

- Protection needs: MCC panels protect motors. PCC panels protect feeders and big machines.

- System complexity: PCC panels are good for big, complex systems. MCC panels are good for managing many motors.

- Installation location: Put PCC panels near the power source. Put MCC panels close to the motors.

- Compliance: Make sure your panels follow rules like IEC 61439, UL 508A, and NFPA 79.

| Factor | PCC Panel (Power Control Center) | MCC Panel (Motor Control Center) |

|---|---|---|

| Primary Use | Distributing and controlling power to subcircuits and heavy equipment | Controlling low to medium voltage three-phase motors |

| Voltage Range | Handles high current ratings up to 6300A | Low voltage: 208V to 600V; Medium voltage: 2300V to 15000V |

| Design Features | Multiple panels with breakers, busbars for high fault tolerance | Motor starters, interlocking, vacuum contactors |

| Typical Applications | Overall power distribution in industrial systems | Industries with many motors |

| Protection & Control | Monitors, protects, and switches multiple devices | Motor-specific protection against overloads and short circuits |

| Operational Complexity | Suitable for complex systems requiring centralized control | Optimized for motor management and control |

| Installation Location | Close to power source | Near motors or motor loads |

Tip: Check and maintain both PCC and MCC panels often. This keeps them safe and working well.

PCC Panel Maintenance

Common Issues

When you work with a pcc panel, you may face some common problems. Knowing what to look for helps you keep your system safe and working well. Here are some issues you might find:

- Loose connections can cause overheating or sparks.

- Dust and dirt build-up can block airflow and lead to overheating.

- Worn-out breakers or switches may not trip during a fault.

- Corroded terminals can stop power from flowing smoothly.

- Overloaded circuits can trip breakers often.

- Faulty wiring can cause short circuits or fires.

- Old labels make it hard to find the right circuit.

You should check your pcc panel often. Look for signs of damage, heat, or strange smells. If you see flickering lights or hear buzzing, you may have a problem. MCC panels can also have similar issues, especially if you use them with many motors. When you use both pcc and mcc panels, always check for signs of wear or damage.

Safety and Upkeep

You must follow strict safety steps when you maintain a pcc panel. Here is what you should do:

- Turn off the main breaker before you start any work.

- Use insulated tools like voltage testers and rubber-handled pliers.

- Wear personal protective equipment such as helmets, safety shoes, goggles, and gloves.

- Never touch live wires or terminals.

- Watch for water or flammable materials near the panel.

- Follow all safety rules and standards.

- Do regular preventive maintenance to catch problems early.

- Inspect your pcc panel to make sure it meets safety codes.

Tip: Always label wires and devices clearly. This makes future repairs safer and faster.

Here is a table of best practices for pcc panel maintenance:

| Category | Recommended Safety Practices |

|---|---|

| General Practices | Keep enough space for heat to escape. Use the right size wire trays. Label everything for easy checks. |

| Electrical | Ground the panel well. Use extra breakers and fuses. Keep sensitive wires away from high-power parts. |

| Wiring | Use CAD tools for neat wiring. Run wires straight, not diagonal. Leave extra wire for changes. |

You should also check mcc panels often. MCC panels control motors, so they need regular checks for loose wires, worn starters, or overheating. If you use both pcc and mcc panels, keep a schedule for inspections. This helps you avoid big problems and keeps your building safe.

Knowing what PCC means in electrical engineering helps you keep power safe. Here is a simple summary:

| Aspect | Key Point |

|---|---|

| What is PCC? | The Point of Common Coupling links networks and controls power flow. |

| Why it matters | Learning about PCC helps you make things safer and save energy. |

- You keep your building safe by following safety rules. Use the right wires and label panels clearly.

- Checking panels often and picking smart ones helps stop accidents and keeps things working.

- If you know about PCC panels, your power stays steady and reliable for a long time.

Always pick, care for, and use PCC panels carefully to keep people and equipment safe.

FAQ

What is the main job of a PCC panel?

A PCC panel controls and shares electrical power in large buildings. You use it to keep equipment safe and to manage power for machines, lights, and other systems.

What makes a PCC panel different from an MCC panel?

A PCC panel manages power for the whole building. An MCC panel controls only electric motors. You use a PCC panel for power sharing and an MCC panel for motor control.

What safety features do you find in a PCC panel?

You find circuit breakers, overload protection, earth fault protection, and clear labels. These features help you stop electrical problems and keep people and equipment safe.

What should you check during PCC panel maintenance?

You should look for loose wires, dust, worn breakers, and signs of heat or damage. Regular checks help you find problems early and keep your system working well.

What standards must a PCC panel follow?

A PCC panel must meet safety codes like the National Electrical Code (NEC), IEC 61439, and local rules. These standards help you make sure the panel is safe and reliable.

See also

Which circuit breakers are used in the Motor Control Center

How to Match the Type of MCB to Your Electrical Load

What Is the Full Name of MCCB in Electrical Engineering

What Is the Full Name of RCD in Electrical Systems

Electric motor circuit breaker selection and usage