A terminal block lets you join wires and keep circuits neat in electrical systems. You use a terminal block to make wiring safer and easier to handle. Terminal blocks help stop problems like overheating, bad wire placement, and loose wires. The table below shows some safety problems you can avoid by picking the right terminal block and using it the right way.

| Safety Issue | How It Happens | What You Can Do |

|---|---|---|

| Overheating | Wrong rating or poor airflow | Use the correct terminal block |

| Poor Wire Insertion | Wires not fully inserted | Insert wires properly |

| Loose Connections | Not tightened enough | Check terminal block regularly |

Knowing what a terminal block does helps you make neat, safe, and strong wiring. You keep your equipment safe and lower risks by learning how terminal blocks work.

Key Takeaways

- Terminal blocks join wires safely. They help keep electrical systems tidy. This makes fixing things easier.

- There are different types of terminal blocks. Some are screw, spring clamp, and push-in types. Each type works for different jobs. They help make wiring faster and safer.

- Picking the right terminal block is important. It should have good insulation and safety labels. This helps stop problems like wires getting too hot or coming loose.

- Modular terminal blocks let you add or take away connections easily. This saves space. It also makes fixing things simple.

- You can put terminal blocks on DIN rails or panels. This keeps wires neat. It also makes repairs faster and safer.

Terminal Block Basics

What Is a Terminal Block

A terminal block is a device that connects wires together. It acts like a bridge for electricity to move safely between wires. Terminal blocks help you keep wires neat and make fixing things easier.

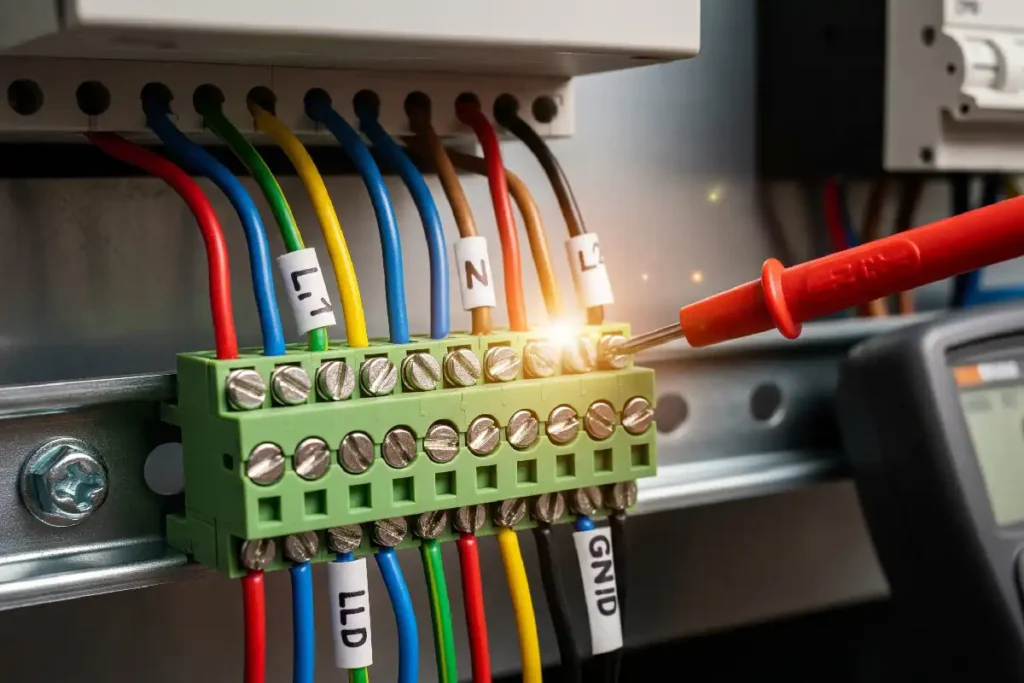

When you look at a terminal block, you see different parts that help make a safe connection:

- Body: This part holds everything together. It is made from strong plastic that does not melt easily.

- Contacts: These metal pieces touch the wires and let electricity pass through.

- Clamps: You use these to hold wires tight. They can be screws or springs.

- Insulators: These stop electricity from leaking or jumping to other places.

- Identification tags: These labels show which wire goes where. They help you fix problems faster.

Some terminal blocks have extra things like wire protectors. These keep wires from getting hurt. Covers help keep you safe from touching wires by accident. The way terminal blocks are built makes it easy to add or change wires.

Tip: Using a terminal block helps you keep wires neat. It also lowers the chance of making mistakes when you install or fix things.

Terminal blocks come in many shapes and sizes. You can pick single-level, double-level, or multi-level types. Some save space by stacking wires on top of each other. This is good for small control panels or tight places.

How Terminal Blocks Work

When you use a terminal block, you connect wires without soldering or crimping. This keeps your wires safe and easy to work with. Here is how you usually connect wires with a terminal block:

1. Get your tools ready. You need a power supply, a terminal block, and a screwdriver. 2. Turn off the power to stay safe. 3. Find the positive and negative terminals on the terminal block. 4. Strip the plastic off the end of each wire. 5. Loosen the screw or clamp on the terminal. 6. Put the bare wire into the right terminal. 7. Tighten the screw or clamp so the wire stays in place. 8. Do this for every wire you want to connect. 9. Check that all wires are tight and no bare wire is showing. 10. Turn the power back on and test your wires.

Terminal blocks use different ways to hold wires, like screws, springs, or push-in clamps. Each way keeps the wire tight and stops problems. You can take wires out or put them back in easily when you need to fix things.

Terminal blocks have many good points compared to other ways of connecting wires:

- You save time because you only strip the wire and tighten a screw.

- You keep wires neat, which helps you find problems faster.

- You make things safer by stopping loose wires and shocks.

- You can add or remove wires quickly, so your system is flexible.

- You spend less money because terminal blocks last a long time.

Using terminal blocks is smart if you want a safe and neat electrical system. You can use them in control panels, machines, lights, and more. Their simple design and easy setup make them great for everyone.

Note: Always follow the instructions from the maker. Check your wires to stop problems like overheating or loose wires.

Terminal Block Characteristics

Insulation and Safety

When you pick a terminal block, check its insulation and safety. Insulation keeps electricity inside the terminal block. It stops electricity from jumping to other wires or metal. This helps stop short circuits and electric shocks. Manufacturers use special materials for insulation. Each material has its own strengths and uses.

| Insulation Material | Dielectric Strength (kV/mm) | Key Characteristics |

|---|---|---|

| Polyamide (PA66) | 25 | Modified thermoplastic, improved fire protection, high continuous operating temperature |

| Glass-fibre reinforced PA (PAGF) | 30 | Excellent dimensional stability, halogen-free flame retardant |

| Polycarbonate (PC) | >30 | High dimensional stability, high electrical insulation, suitable for closely spaced potentials |

| Technical ceramics | >10 | High mechanical strength, heat resistant, water repellent, high chemical stability |

| Germin KrG (duroplast) | 10 | Flame-retardant, high dimensional stability, low water absorption, suitable for harsh environments |

| Epoxy resin (EP) | 160 | Extremely high dielectric strength, heat resistant, radiation resistant, used in nuclear plants |

You should also look for safety certifications. Many terminal blocks have marks like UL, CE, CSA, and ROHS. These marks show the terminal block meets safety rules. For example, a UL mark means it is safe for control panels and machines. Certifications help you trust the product and lower accident risks.

| Certification / Standard | Description |

|---|---|

| UL (Underwriters Laboratories) | Certification ensuring compliance with strict safety standards, recognized globally, with accredited laboratories performing recognized tests. |

| CE (Conformité Européenne) | European conformity marking indicating compliance with EU safety, health, and environmental requirements. |

| CSA (Canadian Standards Association) | Certification for compliance with Canadian safety standards. |

| ROHS (Restriction of Hazardous Substances) | Certification ensuring restriction of hazardous materials in electrical components. |

| IEC 60947-1 | International standard covering general rules for low-voltage switchgear and controlgear. |

| IEC 60947-7-1 | Standard for terminal blocks for copper conductors. |

| IEC 60947-7-2 | Standard for protective conductor terminal blocks. |

| IEC 60947-7-3 | Standard for fuse terminal blocks, including safety requirements. |

Tip: Always check for these marks when buying a terminal block. They help keep your wiring safe and working well.

Modularity and Flexibility

Modularity is a key terminal block characteristic. A modular terminal block lets you add or remove connections easily. You can build your system step by step. Only add what you need. This saves money and space in your panel.

- You can grow your system as you need more connections.

- Modularity makes fixing or upgrading one part simple.

- You can fit many connections in a small space.

- Maintenance is easy because you can disconnect wires fast.

Most terminal blocks use modular designs like screw clamp, push-in, and spring clamp. These types let you install or remove wires quickly. This saves time during setup and repairs. Some special terminal blocks also have modularity and extra safety for complex systems.

Modular terminal blocks help keep your wiring neat and safe. You get a system that can change as your needs grow.

Terminal Block Types

Screw Terminal Blocks

A screw-in terminal block uses a screw to hold the wire. You put the wire in, then turn the screw to keep it tight. This gives a strong and steady connection. You often find screw-in terminal blocks in factories and control panels. They are also used in power systems. These terminal blocks can handle more power and higher voltage. That makes them good for tough jobs. Screw-in terminal blocks work with many wire sizes. After you put them in, you do not need to check them much. But they are bigger and take longer to set up than other types.

| Parameter | Value |

|---|---|

| Voltage rating | 250 V (UL/IEC) |

| Current rating | 16 A (UL), 24 A (IEC) |

| Wire gauge | 22-14 AWG |

| Pitch | 5 mm |

Tip: Pick a screw-in terminal block if you want a strong and lasting connection for circuits that use a lot of power.

Spring Clamp Terminal Blocks

A spring-cage terminal block uses a spring to grip the wire. You push the wire in, and the spring holds it tight. This keeps the wire safe, even if things shake or move. You do not have to tighten anything again. Spring clamp terminal blocks are used in trains, ships, and factories. These terminal blocks are fast to put in and work well where there is a lot of shaking.

- Spring clamp terminal blocks do not get loose from shaking.

- You can put them in fast and do not need tools.

- They need less checking than screw-in terminal blocks.

Push-In Terminal Blocks

A push-in terminal block lets you connect wires by pushing them in. The spring inside holds the wire against the metal part. You do not need screws or tools for most wires. This way is quick, safe, and keeps air out. Push-in terminal blocks can save you half the time it takes to install compared to screw-in types. You use them in control panels and small devices where space and speed are important.

IDC Terminal Blocks

IDC terminal blocks use insulation displacement connection. You do not have to strip the wire first. You push the wire in, and a metal blade cuts the cover to touch the wire. This gives a fast and safe connection. IDC terminal blocks are used a lot in phone systems and places with lots of wires. You see them in telecom gear, I/O modules, and sensor wires.

Specialized Terminal Blocks

Some terminal blocks have special parts for certain jobs. A barrier terminal block has small walls between each terminal. This keeps wires apart and neat. It makes things safer and helps stop short circuits. You find barrier terminal blocks in power and control panels. Deadfront terminal blocks hide live parts inside plastic. This keeps you from touching them by mistake. These are important for safety in high-voltage places.

| Terminal Block Type | Amp Rating (A) | Voltage Rating (V) |

|---|---|---|

| Barrier | 5 – 90 | 150 – 600 |

| Deadfront | 50 – 85 | 600 |

Military and space systems use special terminal blocks. These can be high-voltage, multi-level, or made just for them. These terminal blocks must meet strict rules for safety and work well.

Note: Always pick the right terminal block for your job. The right terminal block keeps your wires safe, neat, and easy to fix.

Mounting and Applications for Terminal Blocks

DIN Rail Mounting

You often see terminal blocks on a DIN rail in control panels. A DIN rail is a metal bar that holds many terminal blocks in a line. This helps you keep wires neat and saves space. You can snap each terminal block onto the rail fast. Most of the time, you do not need special tools.

Here are some main benefits of DIN rail mounting:

- You can add or take away terminal blocks as needed.

- Your panel stays neat and does not take up much space.

- You save time because it is quick to set up.

- You can use different types of terminal blocks for many jobs.

- Terminal blocks on DIN rails can handle shaking and heat.

Tip: DIN rail mounting makes fixing things easy. You can put labels on each terminal block to help you find problems fast.

Panel Mounting

Panel mounting is another way to put in a terminal block. You screw the terminal block onto a flat surface. This makes the connection strong and steady. You use panel mounting where there is a lot of shaking or when you want it to stay in place.

Panel mount terminal blocks are simple to put in and fix. You can reach each terminal block fast for repairs or upgrades. Many terminal blocks have colors and clear labels. These help you avoid mistakes and work faster.

Other ways to mount terminal blocks are PCB mounting, chassis mounting, and free-floating mounting. Each way works best for different jobs, like small electronics or big machines.

Common Uses

You use terminal blocks in many places. In homes, terminal blocks are in distribution boxes. They help you join wires safely and keep things tidy. In offices and stores, terminal blocks keep control panel wires organized. Inspectors like these setups because they follow safety rules.

In factories, terminal blocks link machines and sensors. You can test power easily with terminal blocks. DIN rail terminal blocks are common in factories because they keep wires neat and easy to find.

| Setting | Typical Use for Terminal Block |

|---|---|

| Residential | Splicing wires in distribution boxes |

| Commercial | Organizing control panel wiring |

| Industrial | Connecting machines and sensors |

Note: Always pick a terminal block that fits your wire size, voltage, and where you use it. This keeps your wires safe and easy to fix.

A terminal block lets you connect wires in a safe way. It helps keep your wires neat and tidy. There are different types like screw, spring clamp, and push-in. Each type works best for certain jobs. When picking a terminal block, check for color codes and strong connections. Easy-to-read labels are also important.

- Terminal blocks cover wires so you do not touch them. This helps stop electrical accidents from happening.

- You can change wires fast and see which wire is which. They work well and do not break easily.

- Terminal blocks last a long time and are easy to take care of. This saves money and makes fixing things simple.

Knowing how a terminal block works helps you make safer and better electrical systems.

FAQ

What does a terminal block do in an electrical circuit?

A terminal block lets you join two or more wires. You use it to make safe, organized connections. It helps you keep circuits neat and easy to fix.

What types of wires can you connect with a terminal block?

You can connect solid, stranded, or flexible wires. Most terminal blocks work with copper wires. Always check the wire size and type before you connect.

What makes a terminal block different from a wire nut?

A terminal block gives you a fixed spot to connect wires. You can add or remove wires easily. A wire nut twists wires together but does not offer the same neatness or labeling.

What should you check before choosing a terminal block?

You should check the voltage rating, current rating, wire size, and safety certifications. Pick a terminal block that matches your project needs and keeps your wiring safe.

See also

What Is DIN Electrical Terminology and Why Does It Matter

How to determine if the charger has surge protection function

Spring energy storage in a circuit breaker

How to Install a Three-Phase Surge Protection Device Step by Step

How to Safely Connect RCBOs in Your Electrical Distribution Panel