The main difference between a terminal block and a busbar is what they do. A terminal block connects single wires in a safe way. A busbar spreads high currents to many circuits. This difference is very important in modern electrical setups. Using the wrong part or method can cause overheating. It can also make things less reliable or even start fires. Electricians need to know that busbars need careful connections for heavy loads. Terminal blocks have set ratings for safer and neater wiring.

Key Takeaways

- Terminal blocks join and arrange single wires safely. They make circuits simple to repair and change.

- Busbars move large amounts of electricity to many circuits. They save space and handle lots of power.

- Picking the right part depends on current, voltage, wire size, space, and safety needs.

- Terminal blocks are flexible and simple to take care of. Busbars give strong and steady power to circuits.

- Using the right steps and safety rules stops overheating and loose wires. It also helps avoid expensive errors.

Definitions

Terminal Block

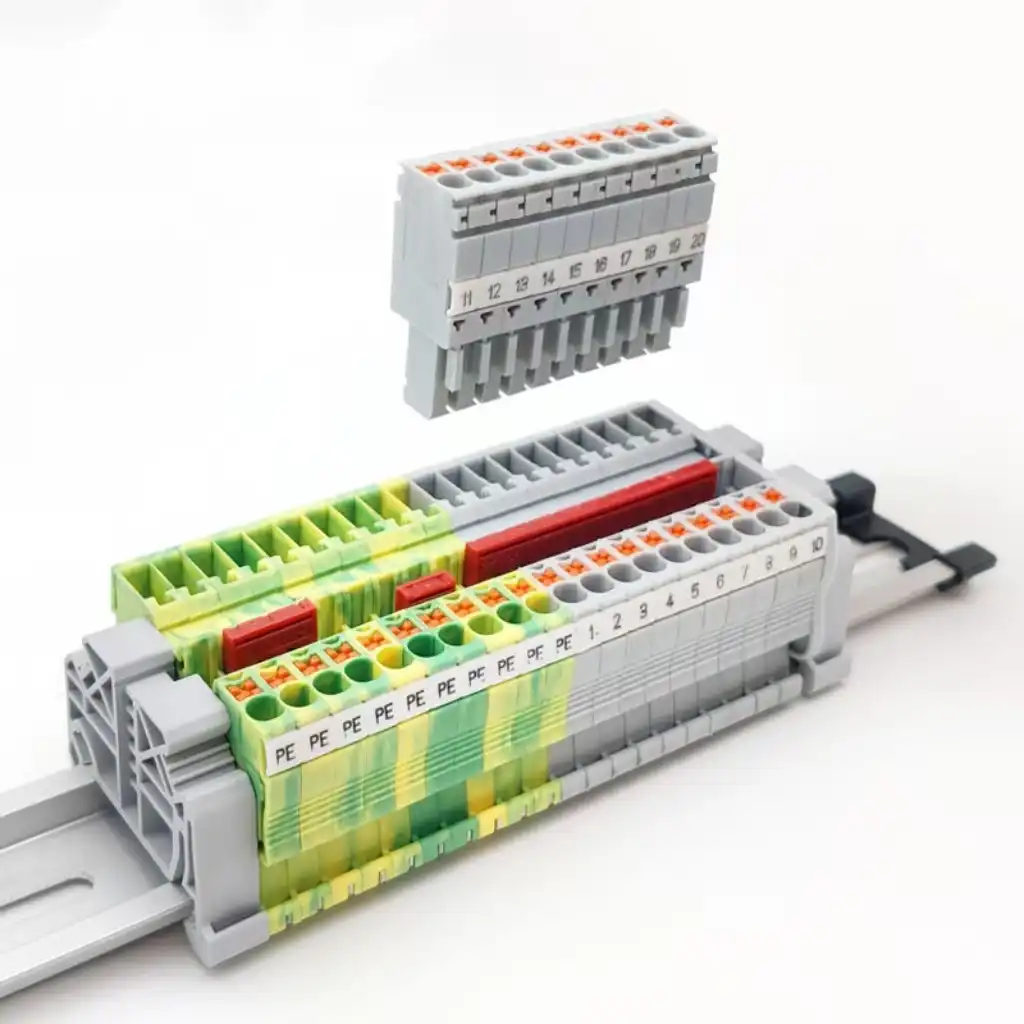

A terminal block helps connect and organize wires. International codes like CSA C22.2 No 158 and UL 1059 explain what a terminal block is. It is a group of wiring terminals and blocks that hold them. Electricians use terminal blocks to join copper and aluminum wires safely. These devices can handle up to 1500 volts. They also work with wire sizes up to 2000 kcmil. Terminal blocks keep wires tidy. They also make it easier to manage circuits in control panels and automation systems.

There are many types of terminal blocks. Some common ones are barrier strips, IEC PCB mount, feed-through, and edge connectors. Each type has its own job. Barrier strips keep wire ends apart. Feed-through blocks connect wires straight across. The way wires are held in place is different too. Some use screws. Others use spring cages, push-in designs, or insulation displacement. Electricians pick the right type for the job and the wire they have.

| Classification Category | Terminal Block Types | Description / Typical Use Cases |

|---|---|---|

| Connection Style | Barrier Strips, IEC PCB Mount, Feed-Through, Edge Connectors | Barrier strips keep wires apart; IEC PCB mount connects wires to boards; Feed-through joins wires; Edge connectors fit PCB edges without solder. |

| Wire Securing Method | Screw Terminals, Spring-Cage Connection, Push-In, IDC | Screw terminals use screws to hold wires; spring-cage uses springs for fast connection; push-in lets you insert wires without tools; IDC uses insulation displacement for many wires at once. |

| Application Function | Ground, Fuse, Thermocouple, Power Distribution, Molded Case Circuit Breaker, Pluggable Wire-to-Housing | Ground blocks connect to ground; fuse blocks stop too much current; thermocouple blocks avoid voltage mistakes; power distribution blocks handle big currents; MCCB blocks make things safer; pluggable blocks let you connect and disconnect fast. |

Tip: Terminal blocks help with fixing problems and making changes. You can work on one wire without messing up the rest.

Busbar

A busbar is a solid metal bar that sends power to many circuits. Codes like IEC 61439 and the National Electrical Code (NEC) say busbars are bars made of copper or aluminum. Busbars split power into different circuits. They are used in switchgear, distribution boards, and battery banks. Busbars are made to carry high currents, sometimes thousands of amperes.

There are different kinds of busbars. Solid busbars are strong and carry lots of current. Laminated busbars cut down on electrical noise and work better in high-frequency systems. Flexible busbars use thin copper strips or braided wires. They can bend and handle shaking or movement. Insulated busbars have a coating for safety and a smaller size. The type you pick depends on how much current you need, how much space you have, and safety needs.

| Busbar Type | Typical Materials | Key Features and Applications |

|---|---|---|

| Solid Busbars | Copper, Aluminium | Carry lots of current, strong, used in switchgear and panels. |

| Laminated Busbars | Copper, Aluminium (layered) | Lower electrical noise, work well in high-frequency jobs. |

| Flexible Busbars | Thin copper strips, braided conductors | Can bend, handle shaking, and heat changes. |

| Insulated Busbars | Copper or Aluminium with insulating coating | Safer, smaller, used in many ways. |

Note: Busbars must be the right size and protected. This stops overheating and keeps things safe when using high currents.

Key Differences

Terminal blocks and busbars do different jobs in electrical setups. Terminal blocks help organize and end single wires. This makes circuits easy to change and fix. Busbars send high currents to many circuits. They give one spot for power to spread out.

| Feature/Aspect | Terminal Blocks | Busbars |

|---|---|---|

| Primary Function | End single wires and organize circuits | Spread high current by joining many connections |

| Current Handling | Low to medium current (up to about 100-200A per pole) | High to very high current (hundreds to thousands of amperes) |

| Structure | Modular, insulated connectors with separate clamping | Solid metal bar (copper/aluminum) with bolted spots |

| Insulation | Built-in insulation for each connection point | Usually uses air gaps or outside insulators |

| Space Efficiency | Good for many small wires, can be packed tightly | Small for big power cables, saves space |

| Flexibility | Easy to change and fix circuits | Not as easy to change; takes more work |

| Typical Use Cases | Control panels, automation, sensor wiring | Switchgear, distribution boards, battery banks |

| Cost | Cheaper per connection, can add more | Costs more at first but good for big currents |

| Maintenance | Easy to work on and change wires | Must turn off big sections to work on it |

Terminal blocks are best for organizing and handling single circuits with medium current. Busbars are great for sending lots of power and saving space. Electricians must pick the right part based on how much current is needed, space, and if they need to make changes later.

Features

Terminal Block Features

Terminal blocks help organize wires in electrical panels. They keep wires safe and neat. These parts make sure each wire connects well. Many things affect how terminal blocks work in different places:

- Connection Methods:

- Screw clamp, spring clamp, and push-in terminals work in different ways.

- Screw clamps need you to tighten them with tools. They do okay with shaking.

- Spring clamps stay tight even if things shake. They are faster to put together with special tools.

- Push-in terminals let you put wires in quickly. You do not need tools if you use ferrules. They are good for lots of wires.

- Screw clamp, spring clamp, and push-in terminals work in different ways.

- Environmental Resistance:

- Terminal blocks can handle hot and cold, wet and dry, shaking, dust, and chemicals.

- Some types have high IP ratings and hold wires tight even if things move.

- Safety and Compliance:

- Insulation barriers keep wires apart. This stops short circuits.

- Grounding and certifications like UL and IEC make them safe for factories.

- Installation and Space Efficiency:

- Multi-level blocks save space up and down. You can mount them on DIN rails or screw them down.

- You can set them up sideways, straight, or at an angle to make them easy to reach.

- Material Durability:

- The outside uses PA66, polycarbonate, or ceramics. These materials resist fire, are strong, and do not break down with chemicals.

- Metal parts like screws and clamps use copper alloys with coatings. This makes them strong and stops rust.

- Application Suitability:

- Terminal blocks work well in tough places. They are used in control systems, telecom racks, and automation panels. Their strong connections and modular design help in these jobs.

Note: Terminal blocks must fit the wire size and type. Their current rating should be higher than what the system needs. This stops overheating.

| Feature / Criteria | Screw Clamp | Spring Clamp | Push-In |

|---|---|---|---|

| Vibration Resistance | Okay; may loosen over time | Very good; stays tight | Very good; holds tight with ferrules |

| Assembly Speed / Labor | Slow; you tighten by hand | Fast; use tools, no torque check | Fastest; just push in, saves time |

| Required Tools | Screwdriver needed | Flathead or special tool | No tools if wire has ferrule |

| Conductor Preparation | No prep needed | No prep needed | Ferrule helps wires fit better |

| Wire Density | Okay; screws need space | Good; fits more wires | Best; fits lots of wires close |

| Material Type | Key Properties Affecting Durability | Impact on Durability and Use Cases |

|---|---|---|

| Polyamide (PA66) | Handles heat, resists fire, low smoke, no halogen | Safer in fires, works in hot places, good for trains and factories |

| Glass-fibre reinforced PA | Stays the same shape, very strong, no halogen flame | Very tough, good for end brackets and strong parts |

| Polycarbonate (PC) | Keeps shape, insulates well, no halogen flame | Good for big or close terminal blocks, strong and safe |

| Duroplasts (Epoxy resin) | Keeps shape, resists fire and chemicals, very safe | Used in rough places like ships and nuclear plants |

| Technical Ceramics | Handles heat, repels water, resists sparks, very strong | Best for places with lots of heat and wear |

Busbar Features

Busbars move lots of electricity to many circuits. What they are made of and how they look changes how well they work and how safe they are.

- Material Selection:

- Copper is great for carrying electricity and does not rust easily.

- Aluminum is lighter and cheaper but needs to be bigger to carry the same current as copper.

- Shape and Geometry:

- Flat, U, T, L, laminated, flexible, and round shapes change how well busbars work.

- Laminated and flexible busbars lower electrical noise and can bend or move.

- Current-Carrying Capacity:

- Busbars can carry very high currents. They work for jobs that need hundreds or thousands of amperes.

- Insulation and Safety:

- Coatings or mounts keep people from touching busbars by accident.

- Strong safety features stop short circuits, overloads, and arc faults.

- Design Flexibility and Space Efficiency:

- Busbars can be shaped to fit panels. This saves space and makes them easy to install.

- Their small size helps use space well.

- Maintenance and Reliability:

- All connections are in one place, so fixing problems is easier.

- They give steady power and help machines run without stopping.

Tip: Copper busbars lose less electricity and work better. Aluminum busbars are lighter and cheaper for big jobs.

Comparison Table

| Aspect / Feature | Terminal Blocks | Busbars |

|---|---|---|

| Connection Type | Ends each wire; easy to add more | Sends power to many circuits from one spot |

| Current Capacity | Handles low to medium current | Handles very high current |

| Material | Body made of PA66, PC, ceramics; copper contacts | Made of copper, aluminum, or copper alloys |

| Space Efficiency | Good for lots of wires; saves space | Small size for big power jobs |

| Installation Flexibility | Easy to change and add circuits | Not easy to change after setup; can add more later |

| Safety Features | Barriers, grounding, certifications | Coatings and strong protection against problems |

| Durability | Lasts long with good materials; resists shaking, chemicals, heat | Lasts long with copper or aluminum; resists rust and damage |

| Cost | Costs less at first; good for small jobs | Costs more at first; saves money for big jobs |

| Scalability | Easy to add or change circuits | Can add more circuits; not easy to change one |

| Maintenance | Easy to fix or change one wire | Fixing needs to shut down big parts sometimes |

| Application Suitability | Used in control panels, automation, telecom, factories | Used in switchgear, boards, battery banks, big power systems |

⚡ Terminal blocks are great for changing and fixing things. Busbars are best for moving lots of power and saving space.

Applications

Terminal Block Uses

Terminal blocks are important in many electrical systems today. Factories use them to connect sensors and relays. They also link programmable logic controllers, called PLCs. Big machines like tractors and bulldozers need terminal blocks for safe wiring. Cars and trucks use them to join switch panels and outputs. In control panels, workers put DIN rail terminal blocks to organize wires. Circuit boards often have PCB mount terminal blocks for wire connections. Barrier strips help wires stay safe in places that shake or have high voltage. These examples show terminal blocks keep wires neat, safe, and easy to fix.

- Industrial control panels

- Automation systems in factories

- Heavy machinery and vehicles

- Electronic circuit boards

- Power distribution in enclosures

Tip: Terminal blocks make fixing problems and changing circuits fast. They are great where you need things to work well and change easily.

Busbar Uses

Busbars help move lots of electricity in big buildings. Switchgear and panelboards use busbars to send power quickly. Substations and transformers need busbars to move current safely. Data centers use busbars for small, strong power setups. Solar farms and wind turbines use busbars to join many power sources. Motor control centers and battery banks also use busbars. Big factories like food plants and chip makers use busbars instead of cables. This helps lower heat and stops voltage loss.

- Switchgear and panelboards

- Substations and transformers

- Data centers and IT racks

- Solar and wind power installations

- Battery banks and energy storage

Note: Busbars move power well and safely in places that need lots of current and little downtime.

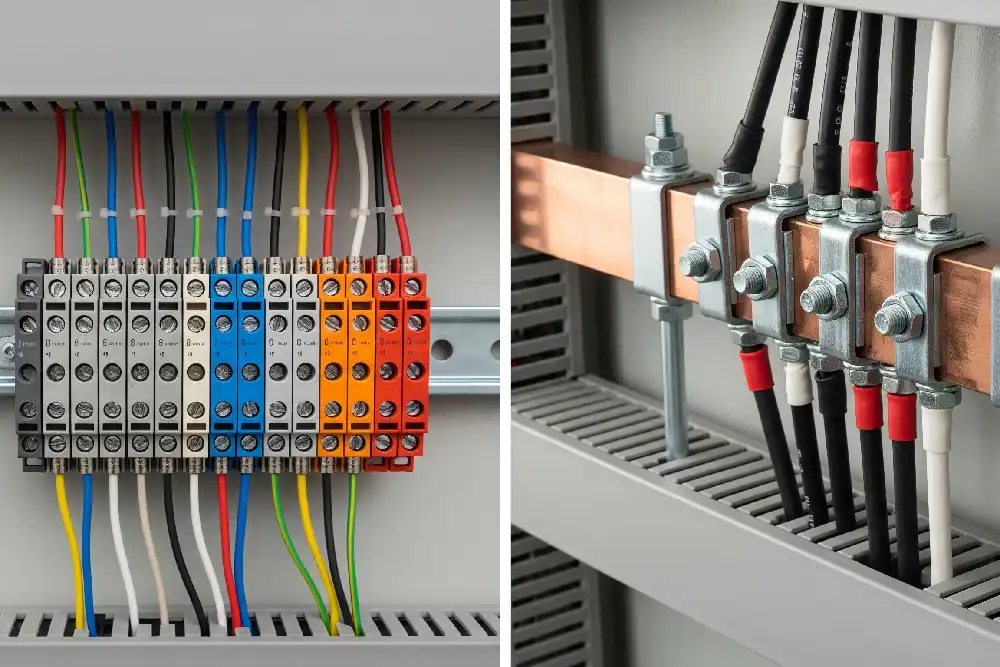

Visual Identification

Workers can tell terminal blocks and busbars apart by how they look. Terminal blocks have separate parts made of tinned copper. Plastic ridges keep each wire in its own spot. This makes it easy to see each circuit. Color codes help workers find DC, AC, and ground wires fast. Busbars are solid metal bars, usually copper or aluminum. They gather many wires to spread out power. Busbars use color codes for phases, not for each wire.

- Terminal blocks: Separate parts, plastic walls, one wire per spot, lots of color codes

- Busbars: One solid metal bar, no separate parts, phase color codes

Tip: If you see plastic walls and single wire slots, it is a terminal block. If you see one solid metal bar, it is a busbar.

Choosing the Right Option

Selection Factors

Picking the right part for an electrical setup takes careful thought. Experts look at electrical details first. The voltage and current ratings must be higher than what the circuit needs. This helps keep things safe. Wire details are important too. The terminal size should fit the wire’s thickness. The wire and terminal materials, like copper or aluminum, need to match. This stops rust and keeps connections strong. The place where you install the part matters. Heat, wetness, and chemicals can make parts wear out faster. Installers pick materials and coatings that last in tough places. How you put the part in also matters. Screw, spring, and plug-in types each have their own good points. Some save space, some are faster, and some are easier to use. Price is important too. The best choice works well and fits the budget.

Checklist for Decision-Making:

- Check voltage and current ratings

- Make sure wire size and material match

- Look at how well it handles heat and wetness

- Pick the type that fits the space and is easy to install

- Think about cost and how well it works

Tip: Always check the maker’s instructions and local rules before you choose.

Common Mistakes

Making mistakes when picking or installing parts can make things unsafe. Not matching wire type and thickness can cause weak connections. This may make things stop working sometimes. Forgetting about heat, wetness, shaking, or chemicals can make parts break early. Not leaving enough space makes wires crowded and hard to fix. Ignoring safety rules and needed labels can break laws and slow down work. Picking parts with low voltage or current ratings can make them get too hot or even start fires. Not thinking about what the job needs can make things work badly or not last long. If you do not label wires or keep things neat, fixing problems gets harder.

Frequent Errors: 1. Wires are loose or not tight enough 2. Screws are too tight and hurt the wire 3. Wire size is wrong and makes weak connections 4. Wires are stripped wrong and do not touch well 5. Terminals are not lined up and cause problems 6. Not enough insulation between terminals can cause shorts 7. Shaking or movement makes connections loose over time 8. Dust, water, or chemicals can hurt how parts work 9. No labels make it hard to know what goes where 10. Not testing after setup means you might miss problems

⚠️ Prevention: Follow the maker’s steps, use the right tools, and check things often to stop these problems.

Picking terminal blocks or busbars depends on a few main things. The current and voltage ratings should be higher than what the system needs. Pole count, pitch, and wire fit matter for how you set it up. The way wires go in should match the design.

Choosing the right part keeps things safe and working well for a long time. Installers need to think about the place, rules, and how the system will work. For more details, check IEC 61439, UL 891, and DIN EN 60204-1. These guides help with design and installation.

FAQ

What is the main purpose of a terminal block?

A terminal block helps connect single wires together. It keeps wires neat and safe. Electricians use them to make wiring easy to handle.

What makes a busbar different from regular wiring?

A busbar is a thick metal bar for power. It sends lots of electricity to many circuits. Busbars can carry more current than normal wires. They also help save space in power systems.

What materials are most common for terminal blocks and busbars?

Terminal blocks use polyamide or polycarbonate for insulation. Their contacts are made from copper alloys. Busbars are made from copper or aluminum. These materials are strong and handle heat well.

What should someone check before choosing between a terminal block and a busbar?

They should look at how much current and voltage is needed. Wire size and space for installation matter too. Safety rules are important. The best choice depends on what the system needs and future repairs.

What are common signs of a problem with terminal blocks or busbars?

Loose wires, too much heat, or color changes are warning signs. Damage you can see is also a problem. Checking these parts often helps keep things safe.

See also

5 basic components required for each distribution board

What You Should Know About Terminal Blocks and Their Other Names

How many wires can be connected to one terminal block

8 Best Terminal Block Manufacturers for Reliable Electrical Connections

What Is a Terminal Block and How Does It Work