Main contacts in circuit breakers carry the normal load current, while circuit breaker contacts known as arcing contacts handle strong electrical arcs during switching. Both types of circuit breaker contacts work together to safely stop current and protect equipment. Studies show the condition of circuit breaker contacts significantly affects their performance. Utilities use special tools like dynamic resistance measurements to check the health of circuit breaker contacts and prevent unexpected outages.

Key Takeaways

- Main contacts move normal current safely. They use soft copper alloys. This keeps resistance low and stops overheating.

- Arcing contacts deal with the electrical arc during switching. They use hard metals like tungsten. This protects main contacts from getting damaged.

- Main and arcing contacts work together in a set order. They stop current fast. This keeps circuit breakers safe and reliable.

- Checking and testing contacts often helps stop failures. It lowers outages and makes circuit breakers last longer.

- Using the right materials and designs for contacts makes things safer. It cuts down on wear and keeps people and equipment safe.

Circuit Breaker Contacts

Types of Contacts

Circuit breaker contacts are important for electrical safety. There are two main types: main contacts and arcing contacts. Each type has its own job and uses different materials.

- Main contacts, also called primary contacts, carry the normal current. They need to handle high power and not get too hot. They should not wear out quickly. Engineers use copper for these contacts because it conducts electricity well. The shape and material help them work safely and efficiently.

- Arcing contacts deal with the arc made when the breaker opens or closes. These contacts use strong materials like tungsten or molybdenum. These metals can take a lot of heat and stress from the arc. They do not conduct electricity as well as copper.

Note: Main contacts work with de-ion plates. These plates help cool and split the arc, so it goes out faster.

Modern circuit breaker contacts use copper alloys like copper-bismuth or copper-chromium. These materials stop the contacts from getting too hot and help them last longer.

| Voltage Level | Common Types | Typical Applications |

|---|---|---|

| Low Voltage | Miniature Circuit Breakers (MCBs), Molded Case Circuit Breakers (MCCBs) | Homes, offices, light industry |

| Medium Voltage | Vacuum Circuit Breakers, Air Circuit Breakers | Factories, substations, power distribution |

| High Voltage | Gas Circuit Breakers (SF6), Oil Circuit Breakers | Power transmission networks |

Contact Operation Sequence

The way circuit breaker contacts work keeps switching safe and reliable. This order protects the main contacts from arc damage and keeps the system working.

- When opening:

- The main contacts open first. This stops the current.

- The arcing contacts open next. They take the arc and protect the main contacts.

- When closing:

- The arcing contacts touch first. They handle any arc that starts.

- The main contacts close after and carry the current.

Main contacts use softer alloys for low resistance and better current flow. Arcing contacts use harder alloys like tungsten or silver to fight arc damage. Some arcing contacts have an arcing horn. This helps move the arc to the arc chute, where it can be put out safely.

Circuit breaker contacts often wipe against each other when closing. This action cleans the contacts and makes them work better. The whole process is fast, usually less than 120 milliseconds for high-voltage breakers.

Main Contacts

Function

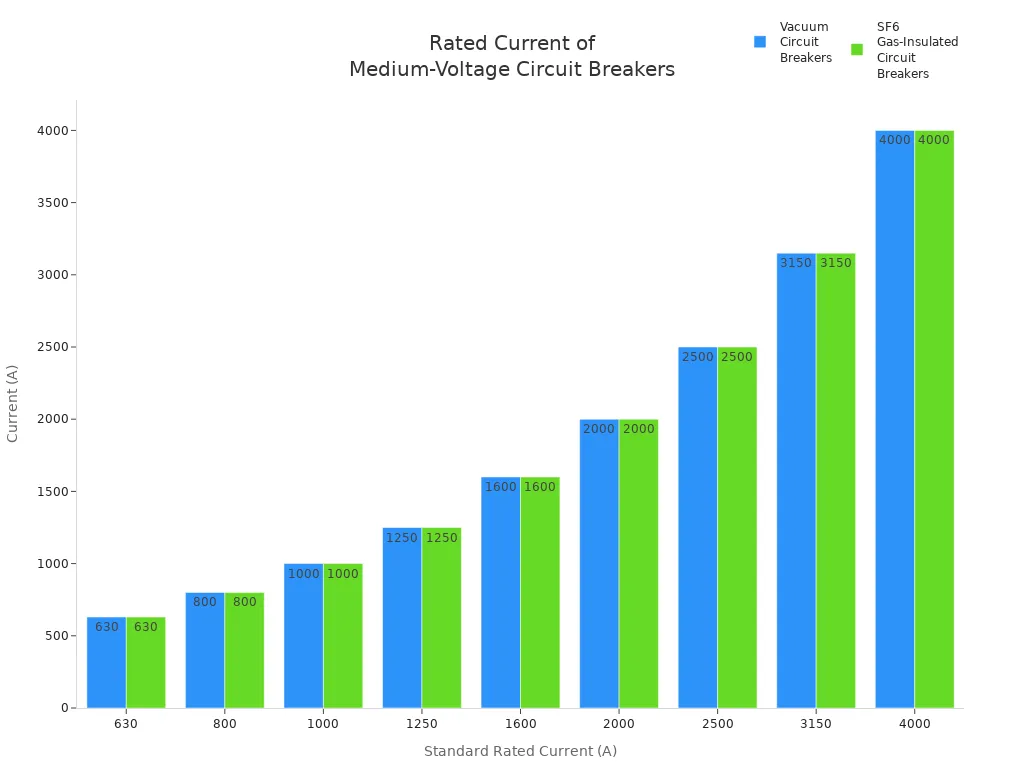

Main contacts are very important in circuit breakers. They let normal current flow when the breaker is closed. These contacts must handle large amounts of electricity. They should not get too hot or wear out fast. In medium-voltage circuit breakers, main contacts can work with up to 3000 or 4000 amperes. The table below shows how much current different circuit breakers can handle:

| Circuit Breaker Type | Typical Operating Current (A) | Standard Rated Current Values (A) |

|---|---|---|

| Vacuum Circuit Breakers | Up to 3000 | 630, 800, 1000, 1250, 1600, 2000, 2500, 3150, 4000 |

| SF6 Gas-Insulated Circuit Breakers | Up to 4000 | 630, 800, 1000, 1250, 1600, 2000, 2500, 3150, 4000 |

Materials

Main contacts are made from copper or copper alloys. These materials let electricity move easily. This keeps resistance low. Engineers treat the surfaces of main contacts to help them work better. They might use chemicals or special coatings. This keeps the contacts clean and smooth. It also helps lower the voltage drop at the contact point. Low resistance is important for good performance.

Role in Normal Operation

Main contacts need to keep resistance low during normal use. This stops the breaker from wasting energy or getting too hot. Groups like NETA have rules for how much resistance can change between phases. People test main contacts often to watch resistance and find problems early. Some main contact problems are false tripping, not opening or closing, and damage while working. The table below shows these problems and how often they happen:

| Failure Mode | Approximate Frequency |

|---|---|

| Circuit breaker opens when it should not (false tripping) | Highest occurrence (~42%) |

| Failure to open or close when required | Significant (~32%) |

| Failure while opening | Moderate (~9%) |

| Damage during successful opening | (~7%) |

| Failure to close when required | (~5%) |

Checking and testing circuit breaker contacts often helps stop failures and keeps electrical systems safe.

Arcing Contacts

Function

Arcing contacts are very important in circuit breakers. When the breaker opens, an electric arc forms between them. Their main job is to stop the current safely. They do this by controlling and putting out the arc. In low-voltage breakers, the contacts move apart fast and far. This makes the arc last a short time. Medium-voltage breakers use special ways to handle stronger arcs. They might use arc chutes, vacuum interrupters, or oil baths. These designs help arcing contacts deal with arc energy. They also protect the breaker from getting damaged. Arcing contacts must carry current and control the arc. This helps the breaker work safely and last longer.

Arcing contacts use different ways to control the arc. They might stretch the arc, break it into small pieces, or blow it away. Arc chutes, vacuum interrupters, and magnetic coils help with this.

Materials

Arcing contacts need special materials to handle high heat and arc damage. The table below shows some common materials and what they do:

| Material Type | Typical Compositions | Key Properties |

|---|---|---|

| Silver-Tungsten (Ag-W) | Silver with tungsten | Resists arc damage, takes heat well, costs more |

| Silver-Tungsten Carbide (Ag-WC) | Silver with tungsten carbide | Keeps steady resistance, is hard, can weld under high current |

| Silver-Graphite (Ag-C) | Silver with graphite | Resists welding, does not resist arc damage as well |

| Copper-Tungsten (Cu-W) | Copper with tungsten | Handles arc damage well, used in oil or gas |

Tungsten is a strong metal that melts at high heat. This slows down arc damage. Graphite helps stop welding but does not fight arc damage as well. The material choice depends on the breaker and where it is used.

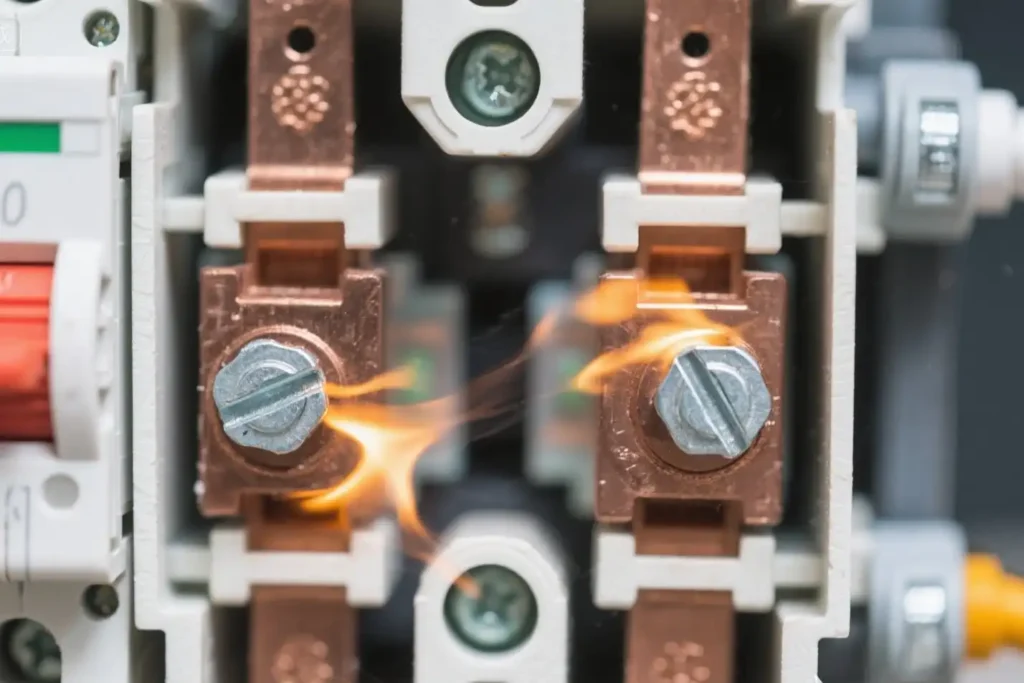

Arc Handling

Arcing contacts must deal with a lot of arc energy. This is true in high-voltage circuit breakers. The arc energy can be very high in a short time. This strong energy can wear out the contacts and change their shape. Some breakers use vacuum chambers to help. The vacuum makes the arc go away faster. This helps the contacts last longer. Copper-chromium alloys also help by fighting heat and damage. Sensors can check how much the contacts have worn down. This lets workers fix or change them before they break.

- In air-break circuit breakers, arcing contacts may need new parts every few months.

- In vacuum contactors, arcing contacts can last a long time with little care.

Checking arcing contacts often and using the right materials helps stop damage and keeps circuit breakers safe.

Main vs. Arcing Contacts

Differences

Main and arcing contacts are not the same. They look different and do different jobs in a circuit breaker. Main contacts carry normal current. They use softer metals with more silver. This helps electricity move easily. Arcing contacts use harder metals like tungsten, cadmium, and zinc. These metals can take the heat and stress from arcs. The table below shows how they are different:

| Aspect | Main Contacts | Arcing Contacts |

|---|---|---|

| Material | Softer alloys with higher silver content | Harder silver alloys with cadmium, tungsten, and zinc |

| Function | Carry main load current with low resistance | Withstand and control the electrical arc during separation |

| Operation | Larger size, lower resistance, open/close after arcing contacts | Open/close first to draw and transfer the arc away from main contacts |

| Design Feature | Simpler construction | Shaped surfaces for wiping motion; may have a “horn” for arc transfer |

| Purpose | Conduct current efficiently | Protect main contacts from arc damage by handling the arc |

Main contacts are made to carry current safely. Arcing contacts are made to protect main contacts from arc damage.

How They Work Together

Main and arcing contacts must work together. This teamwork keeps the system safe during normal times and faults. Here is what happens during a short-circuit:

1. The breaker finds a high fault current and opens fast. 2. Main contacts start to open and stop the current. 3. When main contacts move apart, arcing contacts take over. 4. Arcing contacts handle the arc and keep main contacts safe. 5. The breaker closest to the problem clears it first. This stops other breakers from tripping.

Good teamwork between main and arcing contacts helps clear faults fast. This keeps the power on and stops extra outages.

Timing is very important. Groups like IEC and ANSI make rules for how long contacts stay closed and how fast they open. These rules help contacts work together and break current safely.

Importance for Safety

Electrical safety depends on main and arcing contacts working right. If they do not work together, the breaker may not stop current in time. This can cause big arc flashes, damage, or even hurt people. Arc erosion and stress can wear out contacts. This makes resistance go up and the breaker work worse.

Checking and fixing contacts is very important. Experts say to check main and arcing contacts after a set number of uses or years. For example:

- Check after 10 short-circuit uses.

- Check after 2000 electrical uses.

- Check every 12 years for some high-voltage breakers.

Arcing contacts wear out faster because they face more heat and stress. They need to be replaced more often, which costs more. New materials like special composites and lead-free silver alloys help contacts last longer. Some companies use smart tools and IoT to make contacts better.

The environment also matters. Humidity can cause rust. Dust can make things overheat or short out. Special coatings and sealed boxes help keep contacts clean and working well.

When main and arcing contacts work as they should, circuit breakers keep people, equipment, and the power grid safe.

Main and arcing contacts are both very important in circuit breakers. Main contacts let normal current flow. Arcing contacts keep main contacts safe by taking care of the arc when switching happens.

- Arc contacts take in heat and stress. This keeps main contacts from wearing out too soon.

- Checking and testing contacts often helps systems work well. People check things like resistance and if the contacts line up right.

- Good designs, like using slots in contacts, help control arcs. This also helps contacts last longer.

Circuit breaker contacts are made with care. This helps protect people and equipment every day.

FAQ

What happens if arcing contacts wear out?

If arcing contacts wear out, they cannot stop arc energy. This can hurt the main contacts. The circuit breaker might not protect the system. Checking them often helps stop this problem.

Why do main contacts use copper?

Copper lets electricity move easily. Main contacts need low resistance to work safely. Copper also keeps the contacts cool when used.

How often should technicians inspect circuit breaker contacts?

Experts say to check contacts after a certain number of uses. For example, after 10 short-circuit events or every 12 years for high-voltage breakers. Regular checks help find problems early.

Can a circuit breaker work without arcing contacts?

A circuit breaker without arcing contacts will not last long. Main contacts would get arc damage right away. This makes them wear out faster and can be unsafe.

What signs show contact problems in a circuit breaker?

Signs are higher resistance, overheating, or worn spots. The breaker might trip for no reason or not open or close. Technicians use special tools to test and find these problems.

The following information may be of interest to you

How to Distinguish Between Industrial and Residential Circuit Breakers?

Understanding a and b Contacts in Circuit Breakers

How to choose wires for your 220V 15 ampere circuit breaker

How ACB Work Inside: Components and Their Purposes

What size of wire is suitable for a 30 ampere circuit breaker

Circuit-Breaker-Contacts-scaled-e1753615688212.webp)