You may ask what makes a thermal magnetic circuit breaker different from an electronic circuit breaker. The biggest difference is how each one finds and handles electrical problems. A thermal magnetic circuit breaker uses heat and magnets to find faults. Electronic circuit breakers use sensors and electronics to find problems more exactly. Choosing the right one helps keep your system safe and working well. Think about where you will use it, how much control you want, and what kind of protection is most important.

Key Takeaways

- Thermal magnetic circuit breakers use heat and magnets to find electrical problems. Electronic circuit breakers use sensors and microprocessors to find problems faster and more exactly.

- Electronic circuit breakers act almost right away when there is a fault. They protect sensitive equipment better. Thermal magnetic breakers are slower with overloads but fast with short circuits.

- Thermal magnetic breakers work well in homes and small businesses. They give simple and reliable protection. Electronic breakers are good for factories and big buildings. They have settings you can change and extra safety features.

- Picking the right breaker depends on your system’s voltage, current, speed, adjustability, and where it is used. Electronic breakers give you more control but cost more money.

- Testing and taking care of thermal magnetic breakers keeps them safe and long-lasting. Electronic breakers let you check them from far away and use smart controls to make management easier.

Key Differences

Detection

The main difference is how each breaker finds problems. A thermal magnetic circuit breaker uses two ways to do this. The first way uses a bimetallic strip. If too much current flows, the strip gets hot and bends. When it bends, it trips the breaker. The second way uses an electromagnet. If there is a short circuit, the magnet trips the breaker fast.

Electronic circuit breakers work differently. They use sensors and microprocessors. The sensors check the current very quickly and very well. The microprocessor looks for overloads or short circuits. If it finds a problem, it tells the breaker to trip. Electronic circuit breakers can find problems more exactly.

Tip: Electronic circuit breakers are best if you need fast and exact detection.

Response Time

Each breaker reacts at a different speed. The thermal part of a thermal magnetic circuit breaker is slow. It needs time to heat the bimetallic strip. This slow response stops the breaker from tripping on small spikes. The magnetic part is much faster. It trips right away if there is a short circuit.

Electronic circuit breakers are even faster. The sensors and microprocessors work right away. They can trip the breaker almost instantly for any problem. This quick action helps protect sensitive equipment better.

Here is a simple comparison:

| Breaker Type | Overload Response | Short Circuit Response |

|---|---|---|

| Thermal Magnetic | Slow (thermal) | Fast (magnetic) |

| Electronic | Fast | Fast |

Applications

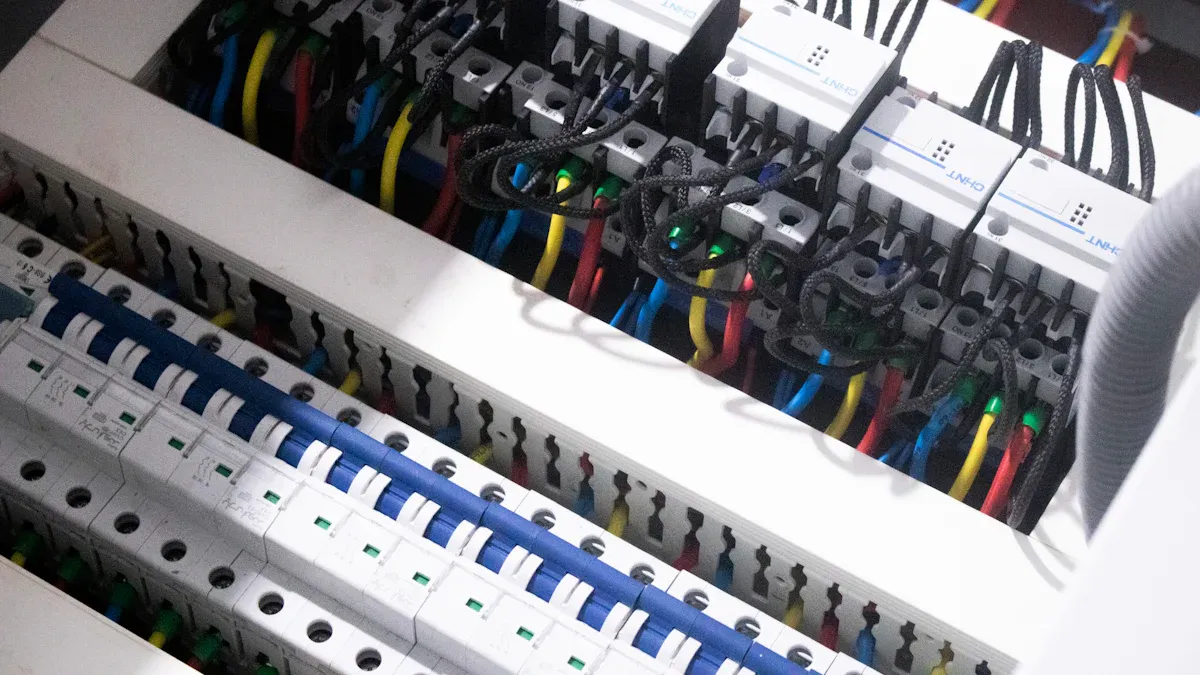

Pick the breaker that fits your needs best. A thermal magnetic circuit breaker is good for homes and small businesses. It works with low voltage and high current. You see it in lighting panels, outlets, and small machines. It gives safe and basic protection.

Electronic circuit breakers are better for places needing more safety. You find them in factories, data centers, and big buildings. They work with medium or high voltage systems. You can change their settings for different jobs. They also have extra features like remote checks and communication.

Note: Choose electronic circuit breakers if you need more settings or better safety.

Thermal Magnetic Circuit Breaker

How It Works

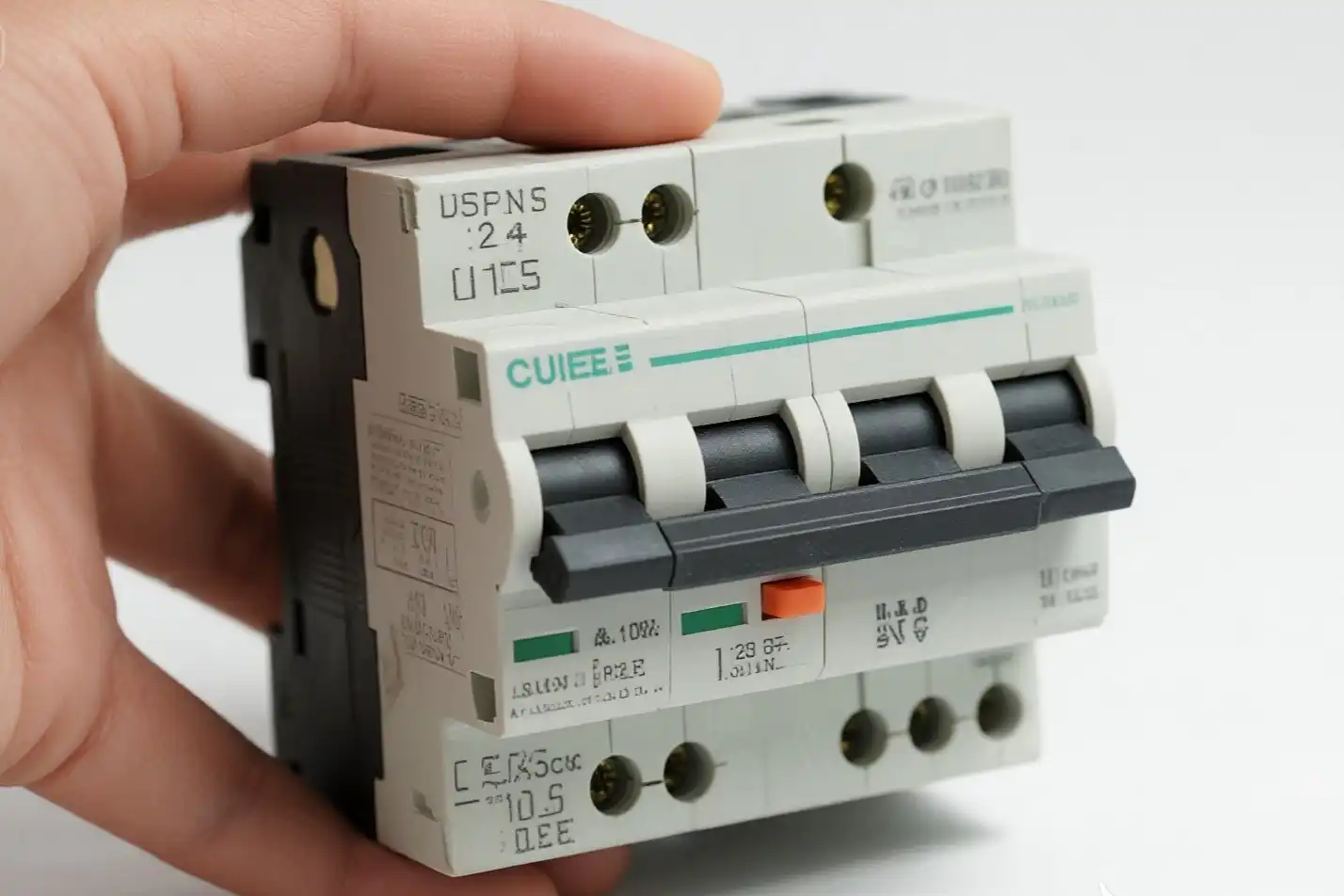

A thermal magnetic circuit breaker keeps your electrical system safe in two ways. The first way uses a bimetallic strip. When too much current goes through, the strip gets hot and bends. This bending makes the breaker turn off the power. The second way uses an electromagnet. If there is a short circuit, the magnet trips the breaker very fast. This means you are safe from both slow overloads and quick faults.

Features

You can find thermal magnetic circuit breakers in many places. They are used in homes, offices, and factories. These breakers must follow safety rules like the UL 489 standard. This rule helps make sure they work safely and well. Many breakers can stop large fault currents. You can pick from different ways to mount them, like plug-in, bolt-on, or draw-out. Some newer models let you change the magnetic trip setting or add ground-fault protection.

Here is a table that lists main features and uses:

| Category | Details |

|---|---|

| Industry Benchmark | UL 489 standard for safety and performance |

| Key Features | High interrupting capacity, durability, flexible mounting, advanced trip units |

| Common Applications | Homes, hospitals, high-rise buildings, agriculture, municipal systems, hotels, data centers |

| Performance Statistics | Long-term durability, low maintenance, advanced monitoring |

| Installation & Maintenance | Proper torque, regular inspection, periodic testing, maintenance logs |

Tip: Check and test your thermal magnetic circuit breaker often. This helps it last longer and stay safe.

Pros and Cons

Thermal magnetic circuit breakers have many good points:

- They are very reliable and safe.

- The design is simple and easy to take care of.

- They meet most electrical codes and rules.

But there are also some downsides:

- You cannot adjust them as much as electronic breakers.

- The thermal part reacts slower to overloads.

A thermal magnetic circuit breaker gives you safety, strength, and a good price. You can use it for most homes and businesses.

Electronic Circuit Breaker

How It Works

Electronic circuit breakers use new technology to keep your system safe. They have semiconductor sensors and microprocessors inside. The sensors check the current all the time. If the current gets too high, the microprocessor tells the breaker to trip. This happens very quickly. You get quick and exact protection from overloads and short circuits. The system can also find arc faults. Arc faults are sparks that can start fires.

Features

Electronic circuit breakers have many helpful features. You can change the settings for different loads. This lets you set the breaker for what you need. The breaker finds problems exactly and reacts fast. Some models let you watch and control them from far away. You can link them to building management systems for better control.

Here is a table with some main features and how they work:

| Feature Category | Numerical Assessment (Precision) | Qualitative Assessment (Communication & Features) |

|---|---|---|

| Trip Command Response Time | Less than 2.5 milliseconds | Uses power electronics and software for fast, accurate interruption |

| Arc Fault Detection Time | Detects arc within 1.5 milliseconds | Advanced algorithms and sensors provide reliable arc detection |

| Arc Fault Mitigation Time | Less than 4 milliseconds | Modular design allows expanded detection and communication between modules |

| Sensor Types | N/A | Uses bare-fiber and lens-type sensors for light detection |

| Communication Capabilities | N/A | Integrated communication helps with fault location and maintenance |

| System Modularity | N/A | Scalable modules link multiple breakers for wider protection |

Tip: Pick electronic circuit breakers if you want fast, exact, and remote protection.

Pros and Cons

Electronic circuit breakers are flexible and give strong protection. You can use them for many jobs. The fast action helps keep sensitive devices safe. You also get lots of details about your system. This helps you take care of it.

But these breakers cost more than regular ones. The design is harder, so you might need an expert to set them up. Studies show electronic breakers have more features and flexibility. But they also cost more and need careful planning. Think about these things before you choose a breaker.

Note: Electronic circuit breakers are best where you need high accuracy, quick action, and smart checks.

Choosing

Factors

When picking a circuit breaker, you should think about a few things. Each thing helps you choose what works best for you.

- Speed: Decide how quickly you want the breaker to work. Electronic circuit breakers trip almost right away. A thermal magnetic circuit breaker can be slower when there is too much current.

- Accuracy: Electronic models protect your system more exactly. They use sensors and microprocessors to find problems.

- Adjustability: Some breakers let you change how they work. Type A adjustable breakers let you set many things after you buy them. Type B adjustable breakers are set once and cannot be changed later.

- Environment: Look at how hot or cold the place will be. Thermal magnetic circuit breakers work best up to 40°C and have special labels for this. Electronic breakers do not change when it gets hotter or colder.

- Voltage and Current: Check how much voltage and current your system uses. Residential breakers (IEC 60898-1) work up to 125A and 25kA. Industrial breakers (IEC 60947-2) can handle much bigger numbers.

Note: Always look at the labels on the breaker for ratings and settings.

Use Cases

You can pick a breaker type for each common job.

| Application | Best Breaker Type | Why Use It? |

|---|---|---|

| Home or Apartment | Thermal magnetic circuit breaker | Simple, safe, and meets most home needs |

| Factory or Data Center | Electronic circuit breaker | Fast, adjustable, and protects equipment |

| Outdoor or Hot Area | Electronic circuit breaker | Not affected by temperature changes |

| High Current System | Electronic circuit breaker | Handles large loads and advanced protection |

Decision Guide

Here is a checklist to help you choose:

- What voltage and current does your system have?

- Do you need the breaker to be fast and exact?

- Will you need to change the settings often?

- Is the breaker for a house or a factory?

- Will the breaker be in a hot place?

If you say “yes” to speed, accuracy, or adjustability, pick an electronic circuit breaker. If you want something simple and reliable for your home, choose a thermal magnetic circuit breaker.

Now you understand how each breaker is different. A thermal magnetic circuit breaker is simple and works well for homes and small businesses. Electronic circuit breakers are quick, exact, and can be changed for special systems. Always pick the breaker that fits your needs. Use this checklist:

- Look at your voltage and current.

- Choose how much control you need.

- Think about where you will use it.

If the job is hard, ask an expert for help.

FAQ

What is the main job of a circuit breaker?

A circuit breaker keeps your electrical system safe. It turns off the power if there is a problem. This helps stop fires and keeps your devices from breaking.

What makes a thermal magnetic circuit breaker different from an electronic one?

A thermal magnetic breaker uses heat and magnets to spot problems. An electronic breaker uses sensors and a microprocessor to find issues. Electronic types work faster and protect more exactly.

What should you check before choosing a circuit breaker?

You need to look at your system’s voltage and current. Think about if you want fast action, settings you can change, or remote control. Always check the label for ratings.

What happens if you use the wrong type of breaker?

You might not get good protection or your stuff could get damaged. The wrong breaker might not turn off when it should. This could cause fires or break your equipment.

What extra features do electronic circuit breakers offer?

Electronic circuit breakers can let you watch them from far away. You can change their settings and they find problems better. Some can connect to building systems for easier control.

The following information may be of interest to you

Electronic vs Thermal Magnetic Molded Case Circuit Breaker

Detailed explanation of the workflow of automatic switch

Difference between electromagnetic and electronic RCCB

Breaking Down the Three Types of Circuit Protection for Beginners