Three phase molded case circuit breakers are not the same as single phase ones. They are different in how many poles they have. They also have different wiring and can handle more load. Picking the right breaker keeps equipment safe. It stops expensive problems and keeps people safe. Using the right breaker for the power supply helps things work better.

| Performance Factor | Efficiency Benefit |

|---|---|

| Interrupting Capacity | Stops damage and stops the system from turning off too much. |

| Proper Breaker Sizing | Helps stop overheating and random shut-offs, making things safer and better. |

Key Takeaways

- Single-phase breakers guard circuits with one or two wires. They are good for houses and small offices.

- Three-phase breakers control three or four wires. They can handle more voltage and bigger loads. They are used in factories and big buildings.

- Picking the right breaker size and type keeps things safe. It stops damage and power loss that can cost a lot.

- Three-phase systems work better and save energy. But they cost more to put in than single-phase systems.

- Always use the right breaker for your power supply. Follow safety rules to stop fires or broken equipment.

Molded Case Circuit Breakers

What They Are

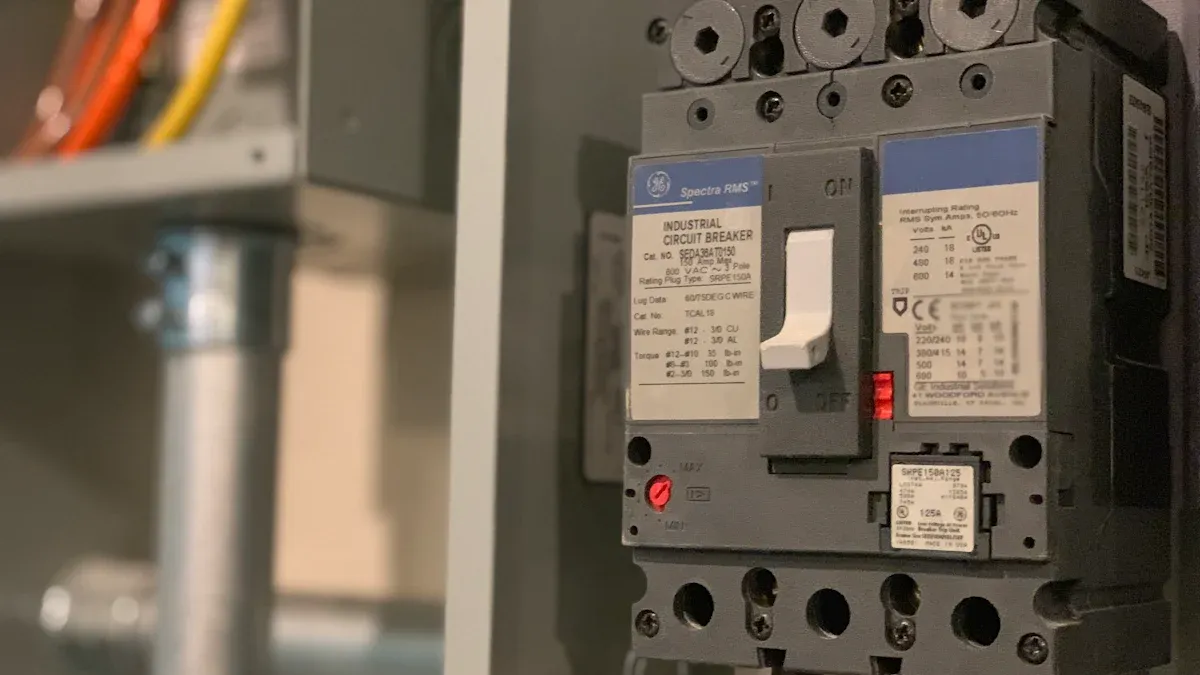

Molded Case Circuit Breakers keep electrical circuits safe from too much current or short circuits. They have a strong case made from special material. This case keeps the inside parts safe and helps stop shocks. Groups like IEEE and UL have rules for Molded Case Circuit Breakers. These rules say what the breakers should do and how strong they must be. The rules also tell how much current and voltage the breakers can handle.

Molded Case Circuit Breakers come in many shapes and sizes. For example, the PowerPact Q can handle up to 250 amps at 240 volts. The PowerPact J can handle up to 400 amps at higher voltages. These breakers use thermal-magnetic or electronic trip units. These units find problems and turn off the circuit fast. Molded Case Circuit Breakers protect against overloads, short circuits, and earth faults. They are very important in commercial and industrial power systems.

Note: Molded Case Circuit Breakers must fit the system’s voltage, current, and use. This helps them work safely and well.

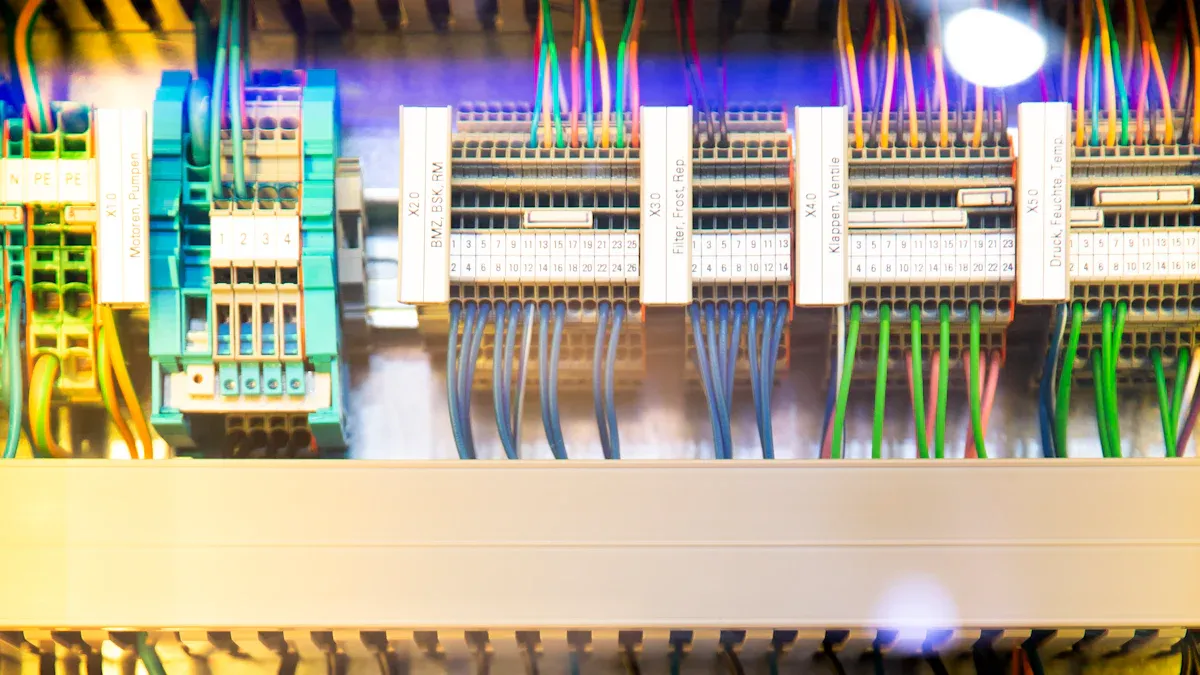

Main Components

Molded Case Circuit Breakers have many parts that help keep electrical systems safe:

- Molded Case (Frame): This part is made from strong materials. It keeps the inside parts safe and stops shocks.

- Operating Mechanism: A handle or lever lets people turn the breaker on or off. It also lets them reset it after it trips.

- Trip Unit: This part finds overloads and short circuits. It uses sensors to trip the breaker and stop the current.

- Arc Extinguishing System: This part puts out electric arcs when the breaker stops a fault.

- Terminals: These connect the breaker to the rest of the circuit.

- Adjustable Trip Settings: People can set these to match what each circuit needs.

- Protection Mechanisms: Thermal protection uses a strip that bends when hot. Magnetic protection uses solenoids to spot quick surges.

- Additional Features: Some breakers have time delays to stop false trips. Some have lights or signs to show when they trip.

All these parts work together to keep circuits safe in many kinds of electrical systems.

Single Phase Molded Case Circuit Breakers

Operation

Single phase molded case circuit breakers keep circuits safe. They find and stop bad currents. These breakers use two main trip methods. The thermal trip has a strip that bends when hot. This happens if too much current flows. When it bends, the breaker opens. The electromagnetic trip works fast for short circuits. It uses a coil to make a magnetic field. This trips the breaker right away. When the breaker opens, an arc appears. The arc extinguishing system puts out the arc. This stops damage and fire risks.

Performance numbers show how well these breakers work. The rated operating short-circuit breaking capacity (Ics) tells how many times the breaker can stop a short circuit and still work. The rated ultimate short-circuit breaking capacity (Icu) is the most current the breaker can stop once. After that, it might not work again. Arcing distance is also important. It makes sure there is enough space to stop faults when the arc is put out.

Features

Single phase molded case circuit breakers have many features. These help them fit different needs. Many breakers let you change trip settings. This lets you pick the right protection for each circuit. You can open or close the breaker by hand. You can also reset it after it trips. Some breakers have lights or windows. These show if the breaker is on or off.

The table below shows some popular single-phase breaker series and their features:

| Circuit Breaker Series | Current Range | Voltage Ratings | Key Features |

|---|---|---|---|

| LEGA (Hydraulic-Magnetic) | 1–50 A | 120–415 VAC, 80 VDC | Low-profile, reliable |

| BRSCB-40 (Thermal) | 20,000–40,000 A | 500 VAC | Surge arrester, visual alarm |

| D2R (Hydraulic-Magnetic) | 0.5–100 A | N/A | Multiple mounting options |

| TeSys GB2 (Thermal-Magnetic) | 3.3–108 A | 250 VAC | Flexible industrial protection |

| 41225C (Magnetic) | 2–63 A | 230–400 VAC | B, C tripping curves |

These features help breakers work well in many places.

Applications

Single phase molded case circuit breakers are used in homes and businesses. They protect lights, outlets, and small machines. Data shows MCCBs are used more than miniature circuit breakers worldwide. The 76A–250A group is the most common. Most single-phase MCCBs are used in homes, businesses, and power systems. They are also used in trains and factories.

Here is a real example from a hospital. A fault happened on a 20-amp single-phase branch circuit. The breaker tripped and stopped more damage. But the ground-fault settings were wrong. Both normal and emergency power went out. The hospital checked the system and fixed the settings. They also upgraded the system. This made things safer and more reliable. This story shows why correct settings and use of single-phase breakers matter, especially in important places.

Picking and setting single phase molded case circuit breakers the right way keeps systems safe, reliable, and up to code.

Three Phase Molded Case Circuit Breaker

How It Works

A three phase molded case circuit breaker keeps three-wire power systems safe. It checks each phase for too much current or short circuits. If it finds a problem, it shuts off all three wires at once. This helps stop fires and keeps machines from breaking. Before putting it in, workers check the size and clean the contacts. They make sure it fits in the switchgear. They test the trip unit by making fake problems to see if it works fast. Workers also do regular tests like checking resistance and insulation. These tests help the breaker stay safe and work well. Timing tests make sure the breaker opens and closes at the right time. This stops arcing and keeps voltage steady.

Key Features

Three phase molded case circuit breakers have many helpful features:

- They measure current for the whole line, not just one wire.

- You can change trip settings to protect different loads.

- The breaker can stop very high fault currents, up to 50,000 amps, and can be reset after a problem.

- Arc systems put out electric arcs fast to keep people safe.

- They follow rules like IEC 60947-2 for good performance.

- These breakers last a long time and do not need much care.

People need to keep loads balanced on all wires. If loads are not balanced, the breaker might trip too soon. Watching the system and working with other breakers helps stop problems.

Typical Uses

Three phase molded case circuit breakers are used in many places. They protect power plants, solar and wind systems, and big factories. In power networks, they help send electricity safely to homes and businesses. The table below shows where these breakers are used and why they matter:

| Application Segment | Description | Key Insights |

|---|---|---|

| Power Generation | Used in thermal, hydro, and renewable plants to protect equipment. | Demand grows with modernization and renewable projects. |

| Renewable Energy | Manage wind and solar networks, protect against faults. | Essential for safe grid integration. |

| Power Distribution | Main protection in distribution networks. | Needed for urbanization and industrial growth. |

| Industrial | Used in manufacturing and processing plants. | Linked to global expansion and smart manufacturing. |

| Commercial & Residential | Manage high loads in offices, schools, and homes. | Demand rises with smart home trends and upgrades. |

The world market for these breakers was $10.64 billion in 2024. It may grow to $17.22 billion by 2032. Asia Pacific is growing fastest because of new factories and buildings. New smart breakers with sensors help save energy and make things safer.

Key Differences

Poles and Wiring

Single-phase and three-phase circuit breakers are different in how many poles they have and how they are wired. Single-phase breakers usually have one or two poles. A single-pole breaker only controls the live wire. A double-pole breaker controls both the live and neutral wires. These breakers are good for homes and small businesses. These places do not need a lot of power, and the wiring is simple.

Three-phase circuit breakers control three or four wires. A three-pole breaker shuts off all three live wires at the same time. A four-pole breaker also shuts off the neutral wire. This is important in places like hospitals and data centers. These places need more power and have strict safety rules. This setup is used in big buildings and factories.

| Breaker Type | Poles Controlled | Typical Voltage | Typical Application | Isolation Level | Compliance Context |

|---|---|---|---|---|---|

| 1P (Single Pole) | 1 (Live wire only) | ~230 V single-phase | Lighting, small appliances | Partial isolation | Basic residential standards |

| 2P (Double Pole) | 2 (Live and Neutral) | ~240 V single-phase | High-power appliances | Full isolation | Enhanced residential/commercial safety standards |

| 3P (Three Pole) | 3 (Three phases) | ~400 V three-phase | Industrial motors, transformers | Full phase isolation | Industrial standards for three-phase systems |

| 4P (Four Pole) | 4 (Three phases + Neutral) | ~400 V three-phase + neutral | Data centers, hospitals | Full isolation including neutral | Strict safety standards |

Rules like IEC 60898-1 tell how many poles and what wiring to use. These rules help stop electrical problems and keep things safe.

Power and Voltage

Single-phase circuit breakers work with lower voltages, like 120V or 230V. They handle smaller loads. These breakers are used in homes and small offices. Most big appliances in these places do not need more than 15kW. The wiring is easy, with just a live and a neutral wire.

Three phase molded case circuit breaker units work with higher voltages, often 400V or more. They can handle much bigger loads, from 50kW up to 500kW or more. These breakers use three or four wires. This lets them send more power without using too much current in each wire. This helps stop wires from getting too hot and keeps the system steady.

| Parameter | Single-Phase Circuit Breaker | Three-Phase Circuit Breaker |

|---|---|---|

| Typical Voltage | 230V at 40A (9.2kW) | 400V at 100A per phase (69kW total) |

| Power Calculation Formula | P = V × I × PF | P = √3 × V × I × PF |

| Efficiency | ~75% | ~90% |

| Line Loss Reduction | Baseline | 25–30% less line losses |

| Wiring Requirements | 2 wires (live + neutral) | 3 or 4 wires (3 live + neutral) |

| Load Capacity | Up to 15kW with 63A breakers | 50kW to 500kW+ with 250A+ breakers |

Three phase molded case circuit breaker systems use a special formula to find power: P = √3 × V × I × PF. This formula shows why they can give more power with the same current. This makes the system work better for big machines and long wires.

Efficiency and Cost

Three-phase systems are more efficient than single-phase systems. They split the load between three wires. This lowers the current in each wire. Less current means less heat and smaller wires. Three-phase circuit breakers can be up to 90% efficient. Single-phase breakers are usually about 75% efficient.

It costs more to put in a three-phase system at first. The wiring is harder, and the breakers cost more. But, the better efficiency and higher power can save money later. This is true for factories and big buildings. Single-phase systems are cheaper to put in and take care of. But, they cannot handle big or growing power needs.

⚡ Tip: If a business wants to grow, it is smart to get a three phase molded case circuit breaker system. This can stop expensive changes later.

Safety

Safety is very important when picking a circuit breaker. Single-phase breakers protect homes and small offices from too much current and short circuits. They turn off the circuit fast to stop fires and damage.

Three phase molded case circuit breaker units give even more safety in places with lots of power. They turn off all three wires at once. This stops dangerous voltage problems. Four-pole breakers also turn off the neutral wire. This is needed in places where safety is very important. Rules like IEC 60898-1 say these features are needed to lower the risk of electrical problems.

Using the wrong breaker can cause big trouble. A single-phase breaker in a three-phase system might not turn off all wires. Some wires could stay live and be dangerous. A three-phase breaker in a single-phase system might not work right. This could break equipment or start a fire.

🚨 Alert: Always use the right breaker for the power supply and job. The wrong breaker can break equipment, cause blackouts, or hurt people.

Choosing the Right Breaker

Selection Factors

Picking the right molded case circuit breaker keeps equipment safe. It also makes sure things work safely. You need to think about many things before choosing. The table below shows the most important things to check:

| Selection Criteria | Description |

|---|---|

| Current Rating | Make sure it matches or is higher than the circuit’s current. |

| Breaking Capacity | The breaker must stop the biggest fault current. |

| Trip Characteristics | Pick thermal-magnetic or electronic trip units for your needs. |

| Adjustable Trip Settings | Set the trip point to match what your system needs. |

| Voltage Rating | Check if it works with your system’s voltage. |

| Number of Poles | Choose based on if you have single-phase or three-phase. |

| Size and Physical Dimensions | Make sure it fits in your panel or equipment. |

| Environmental Conditions | Think about heat, wetness, and dust. |

| Accessories | Add things like extra contacts or shunt trips if needed. |

| Standards and Certifications | Make sure it meets safety and quality rules. |

Engineers also look at selectivity and coordination. They use guides and software from the maker. This helps the main breaker and other breakers work together. It makes the system more reliable. It also keeps power on during faults. For example, a Three phase molded case circuit breaker with adjustable settings protects big factories.

Mistakes to Avoid

Many projects have trouble because the wrong breaker is picked. Some common mistakes are:

- Mixing up breaker symbols, so the wrong breaker is used.

- Not using the maker’s tables, which can make breakers fail during faults.

- Forgetting about things like heat or dust, which can cause false trips or damage.

- Not matching the breaker’s interrupting power to the system’s fault level, which is unsafe.

- Not doing careful studies, which can make breakers trip at the wrong time and cause outages.

⚠️ Always check technical data, coordination, and the environment. This stops expensive mistakes and keeps people safe.

Three phase molded case circuit breaker units work with higher voltages. They also handle bigger loads than single phase breakers. Each type has its own wiring and number of poles. This helps them fit different power needs. When picking a breaker, check the current rating and trip type. Also look at how it mounts and what rules it must follow. Do not pick a breaker that is too big for the job. Always match the breaker to the system’s voltage and load. Picking carefully keeps equipment safe and stops expensive problems.

FAQ

What is the main difference between single-phase and three-phase molded case circuit breakers?

Single-phase breakers protect circuits with one or two wires. Three-phase breakers protect circuits with three or four wires. Three-phase breakers handle higher voltages and larger loads. They work best in factories and big buildings.

Can a single-phase breaker be used in a three-phase system?

No. A single-phase breaker cannot protect all wires in a three-phase system. This creates safety risks. Always use a breaker that matches the system type.

How do you choose the correct number of poles for a circuit breaker?

Check the power supply. Use one or two poles for single-phase systems. Use three or four poles for three-phase systems. The number of poles must match the number of wires needing protection.

Why do three-phase breakers cost more than single-phase breakers?

Three-phase breakers have more parts and higher ratings. They protect larger systems and handle more current. The extra features and safety standards increase the cost.

What happens if the wrong breaker type is installed?

Using the wrong breaker can cause equipment damage, fire, or power loss. It may also break safety rules. Always select a breaker that fits the system and load.

The following information may be of interest to you

Single Phase vs Three Phase Electricity: Which is Best for You?

Choosing Between Single-Phase and Three-Phase Solar Inverters

Selection guide for three-phase automatic transfer switch

What You Need to Know About Three-Phase Solar Inverters

Solution-for-molded-case-circuit-breakers.webp)