Molded case circuit breakers are not built the same as insulated case circuit breakers. They have different designs and work in different ways. Each type has special features that help keep electricity safe and systems working well. Picking the right breaker keeps equipment safe and stops dangers. Electricians and engineers need to know these differences to choose the best one for a job.

Key Takeaways

- MCCBs have a hard plastic cover. They work well in homes and small shops. ICCBs have stronger, heat-proof covers. They are used in big buildings and factories.

- MCCBs can handle up to 2500 amperes of current. ICCBs can handle more current, up to 5000 amperes. ICCBs also have better safety features.

- You can reset MCCBs easily, but you cannot fix them inside. ICCBs can be fixed without turning off the whole system.

- You must pick the right breaker for the job. Think about current, voltage, place, and safety needs. This keeps systems safe and working well.

- Many new breakers let you check them from far away. This helps find problems early. It also saves energy and money.

Key differences

Overview

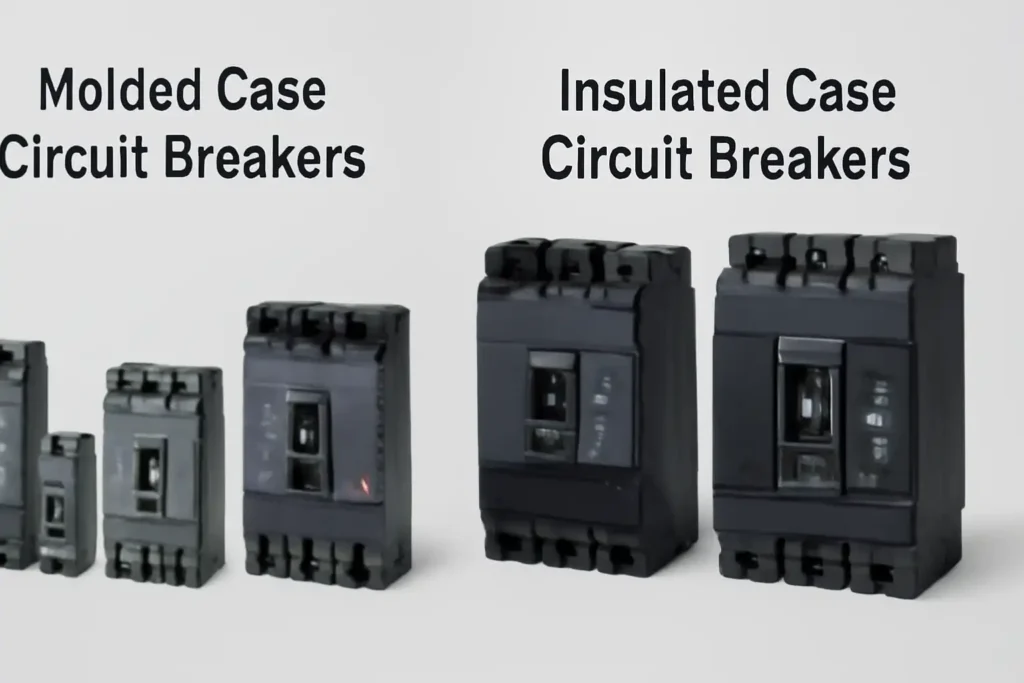

Molded case circuit breakers and insulated case circuit breakers do similar jobs. But they are different in a few big ways. Their build, how they work, and where they are used make them unique. Engineers and electricians pick one based on what the system needs. Molded case circuit breakers have a tough outside made from molded insulation. This makes them strong and not too expensive. Insulated case circuit breakers use a solid, heat-proof cover. This gives more safety in hard places.

Some studies used the Design for Six Sigma (DFSS) method to make molded case circuit breakers better. DFSS has steps like Define, Measure, Analyze, Design, and Verify. These steps help make changes using facts and data. These changes show how MCCBs work differently from ICCBs.

Main distinctions

MCCBs and ICCBs are not the same in how they are built, how much current they handle, and where they are used. The table below shows these main differences:

| Aspect | Molded Case Circuit Breaker (MCCB) | Insulated Case Circuit Breaker (ICCB) |

|---|---|---|

| Current Capacity | 15 to 2500 amperes | 800 to 5000 amperes |

| Construction | Molded insulating material casing, rugged and cost-effective | Solid, heat-resistant insulation for enhanced safety |

| Typical Applications | Residential and light industrial settings | Large commercial buildings, data centers, industrial environments |

| Performance Focus | General protection, managing overcurrents and short circuits | High-load environments, adjustable trip settings for precise protection |

| Safety Features | Standard insulation and protection | Enhanced arc flash risk reduction and improved safety |

Tip: Always think about the current rating and where the breaker will be used. MCCBs are good for homes and small businesses. ICCBs are better for big places that need more safety.

Molded case circuit breakers meet IEC 60947-2 rules. These rules are for low-voltage switchgear in factories. They need to handle high voltages, so MCCBs can work in tough places. ICCBs have better insulation and safety. They are used where there are big loads and strict safety needs.

Molded case circuit breakers

Definition

Molded case circuit breakers stop circuits from getting damaged. They do this when there is too much electricity or a short circuit. The inside parts are covered by a strong, molded material. This makes the breaker small and tough. Engineers use these breakers to stop the flow of electricity if something goes wrong. They help stop fires and keep equipment safe in many places.

Construction

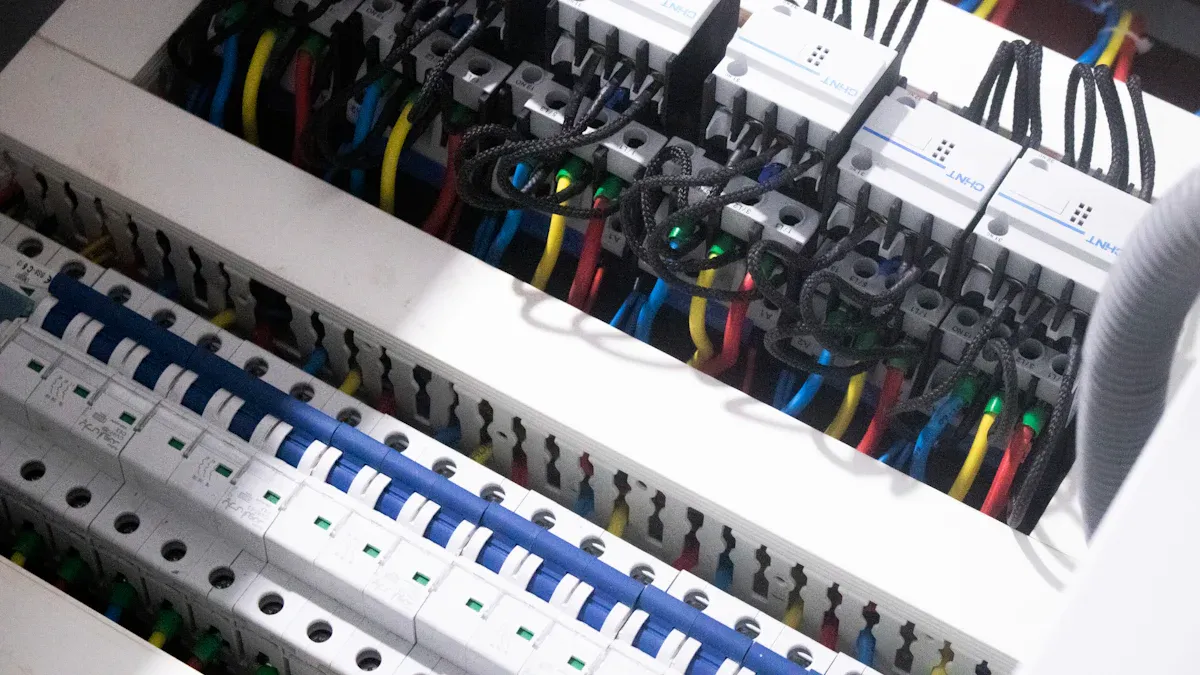

Molded case circuit breakers have a hard plastic shell. This shell keeps the inside parts safe and covered. Inside, there are contacts, a trip part, and an arc extinguisher. The trip part finds when the current is not normal. If it finds a problem, it opens the contacts and stops electricity. The arc extinguisher cools and breaks the arc to lower fire risk. Many new breakers can be checked and controlled from far away. This helps with smart grid systems.

Applications

Molded case circuit breakers are used in many places. You can find them in homes, offices, factories, and power networks. The table below shows where they are used and new trends:

| Segment Category | Details | Typical Applications |

|---|---|---|

| By Type | MCCB dominant in 2023 | Protection against short circuits and overloads in equipment |

| By Rated Current | 76A-250A dominant | Infrastructure, residential, and commercial systems |

| 251A-800A fastest growing | Medium to large industrial plants, commercial buildings | |

| By End Users | Transmission and Distribution dominant | Power distribution networks, grid stability, and safety |

| Regional Examples | Europe integrated grid | Enhanced grid resilience, cross-border electricity transmission |

| Real-World Initiatives | India’s Saubhagya program | Expanding rural electricity access, increasing MCCB demand |

| Renewable Energy | China’s renewable targets | MCCBs critical in smart grids, renewable integration |

| Challenges | Harsh environments | Affect MCCB reliability, highlight application constraints |

- Utility-scale photovoltaic plants are one use.

- Commercial solar installations also use them.

- People put them in home solar systems.

- Off-grid solar setups need them too.

- Hybrid solar power systems use them as well.

Molded case circuit breakers are important for keeping circuits safe in all these places. Smart models now let people watch and fix problems before they get big. This helps companies and utilities save energy and work better.

Insulated case circuit breakers

Definition

Insulated case circuit breakers, called ICCBs, protect electrical systems. The ANSI NEMA AB 3 2013 (R2023) standard explains what ICCBs are. These breakers are made as one unit inside an insulating case. ICCBs can work with up to 1,000 V AC and 1,200 V DC. They can stop currents of 5,000 A or more. These numbers show ICCBs are made for strict safety rules. Engineers use these rules to pick the right breaker for tough jobs.

Construction

ICCBs have a strong, heat-proof case. This case keeps dust, water, and heat away from the inside parts. Inside, there are strong contacts, arc chambers, and smart trip parts. Many ICCBs have sensors that watch how they work. These sensors check for wear and watch the trip parts. Some high-voltage ICCBs use SF6 gas for better insulation. This helps stop problems and keeps the breaker safe. The way ICCBs are built lets workers find issues before power goes out.

Applications

ICCBs are important where safety and reliability matter a lot. Their special features make them good for factories, big buildings, and power plants. The table below shows what ICCBs can do and where they are used:

| Performance Parameter | Description | Typical Applications and Importance |

|---|---|---|

| Voltage Rating | Highest voltage the breaker can handle safely. | Low-voltage ICCBs (<1 kV) are used in homes, businesses, and factories. |

| Current Rating | Most current the breaker can carry without tripping. | Must fit the system so it works right; very important in factories and businesses. |

| Interrupting Capacity | Biggest fault current the breaker can stop safely. | Needed for safety in factories and power systems to stop damage and danger. |

| Frequency | Should match the system’s frequency (usually 50-60 Hz). | If not matched, the breaker may not last as long or work well; this matters in big power systems. |

| Tripping Current Adjustment | Lets you set the breaker for different loads. | Helps protect different machines in factories and keeps downtime low. |

| Environmental Resistance | Can handle heat, rust, shocks, high places, and dust. | Needed for tough places, outside use, and special jobs. |

ICCBs have marks that show what they do best:

- “100 Percent Continuous Rated” breakers can run at full power all the time.

- “SWD” breakers are good for turning on and off fluorescent lights in stores.

- “HID” breakers work with high intensity lights in factories.

- “Remotely Operated” breakers can be controlled from far away, which helps in big buildings.

- “Special Purpose Not General” breakers are made for special jobs, so they are used the right way.

These features help ICCBs keep electrical systems safe and working well.

Comparison

Construction and materials

Molded case circuit breakers have a strong plastic shell. This shell keeps dust, water, and bumps away from the inside parts. The design makes the breaker small and not too pricey. Inside, there are contacts, a trip part, and an arc extinguisher. These parts work together to stop unsafe currents.

Insulated case circuit breakers have a solid, heat-proof cover. This cover protects the inside from tough factory places. The build lets them handle more current and stand up to heat, dust, and shaking. Many ICCBs can be pulled out for easy fixing or swapping. The strong materials and design help ICCBs work well in big buildings.

Performance

Molded case circuit breakers work well in homes and small factories. They can handle some overloads and small faults. These breakers stop electricity if they find a problem. How well they work depends on where they are used and how many faults happen.

Insulated case circuit breakers are used where there is a lot of power. They can handle steady currents from 800 to 5000 amperes. ICCBs can take short bursts of high current and keep important systems safe. Their design lets you set trip points to protect special equipment. ICCBs help keep power on in big buildings and factories.

Protection features

Both types of breakers have smart protection features. The table below shows the main differences:

| Feature / Aspect | Molded-Case Circuit Breakers (MCCBs) | Insulated Case (Low-Voltage Power) Circuit Breakers (Power CBs) |

|---|---|---|

| Primary Application | Downstream protection of insulated conductors and cables | Upstream protection, connected to bus bars within switchgear |

| Protection Focus | Protect conductor and insulation | System-level coordination and power continuity |

| Interrupting Capability | Finite, tested under UL 489 with bolted fault conditions | Higher interrupting ratings, tested for short-time and short-circuit duty cycles (ANSI standards) |

| Trip Unit Features | Electronic trip units with ground-fault detection and communication capabilities | Similar electronic trip units with advanced protection and coordination features |

| Coordination Role | Provides reliable, resettable protection for branch circuits | Provides robust, maintainable protection and coordination for upstream, higher power applications |

Molded case circuit breakers keep wires and cables safe from too much current. They use electronic trip units that find ground faults and talk to monitors. ICCBs have trip units too, but they can do more. These extra features help keep big systems running and stop power loss in large places.

Note: ICCBs can stop bigger faults and give better system protection. This makes them great for important buildings and factory switchgear.

Maintenance

Molded case circuit breakers do not need much care. Workers check them from the outside and use safe tests to see if they work. You cannot open them to fix the inside. If something is wrong, you must change the whole breaker.

Insulated case circuit breakers are easier to fix. You can pull them out to work on them without turning off everything. ICCBs use stored energy parts, so they last longer. Checking and testing them often keeps them working well in hard jobs.

🛠️ Tip: Checking and testing both types helps them last and stay safe. ICCBs make this easier because you can service them.

Pros and cons

MCCB advantages

Molded case circuit breakers have many good points for today’s electrical systems.

- They keep equipment and wires safe in lots of places.

- Their small size helps them fit in tight panels.

- You can change trip settings to match different loads.

- Built-in features, like thermal-magnetic or electronic trip units, stop damage from too much current.

- These breakers work in both businesses and factories.

- Many types are easy to reset and take care of, which saves money over time.

For example, using electronic trip MCCBs instead of old air magnetic breakers has cut down on nuisance trips by 40%. It also helps the system work together better.

MCCB limitations

Even though they are useful, molded case circuit breakers have some problems.

- They do not work for very high voltage jobs and are used up to 600 volts.

- They cannot be adjusted as much as some other breakers.

- They cost more at first than simple fuses or basic breakers.

- If the inside breaks, you cannot fix it. You have to get a new one.

| Limitation | Impact on System |

|---|---|

| Voltage range | Not for high-voltage systems |

| Limited adjustability | Less precise protection |

| Higher upfront cost | May affect project budgets |

| Non-repairable design | Increases replacement needs |

ICCB advantages

Insulated case circuit breakers have special strengths for tough places.

- Their strong, heat-proof cases make them safer in hard conditions.

- They can stop big fault currents because of their high interrupting power.

- You can set trip points for better protection of sensitive machines.

- Many ICCBs let you watch and control them from far away, which is good for big buildings.

- Workers can fix or swap these breakers without turning off everything.

ICCBs are often used in main switchgear, data centers, and factories where it is very important to keep things running.

ICCB limitations

ICCBs have some downsides too.

- They usually cost more than molded case circuit breakers.

- Their bigger size means they do not fit in every panel.

- Only skilled workers should install and take care of them.

- Not all ICCBs can be adjusted as much as the fanciest power breakers.

- People should think about these points when picking between MCCBs and ICCBs for their projects.

Selection guide

Factors to consider

Picking the right circuit breaker is not just about current ratings. Engineers look at many things to keep systems safe and working well. They check if the system uses AC or DC power. They also look at the voltage level. The place where the breaker is used matters, too. Hot places can make a breaker weaker. For example, a 40 A breaker only worked at 30.5 A when it was 60°C. That was not enough for a 34 A load. The team picked a 50 A breaker instead. It worked better in the heat.

Selectivity is very important in places like hospitals and data centers. This means only the breaker near the problem will trip. Other circuits keep working, so power stays on. Engineers also look at the short-circuit current where the breaker will go. They think about what the breaker will protect, like motors or lights. Sometimes, they need remote control or extra contacts. They follow safety rules to stop shocks and overheating.

Tip: Using breakers from the same company helps them work together and trip the right way.

Use cases

Different jobs need different breakers. In drug factories, they need power all the time. They use fuses for main and feeder protection. This keeps power on 99.97% of the time and makes checks easier. Big warehouses with lots of motors use electronic trip breakers. These breakers can be set for each job. This stops false trips and lets people watch them from far away. Food plants have high fault currents and wet spots. They use fuses in special boxes to make fixing and arc flash safety better.

Many places use both fuses and breakers. They put fuses on main lines and breakers on smaller circuits. This mix helps keep power on and makes fixing things easier.

Cost

Cost matters when picking breakers, but safety is most important. Molded case circuit breakers usually cost less than insulated case ones. But ICCBs have more features, like stopping bigger faults and being easier to fix. Engineers think about the first price and how much they save later. Smart breakers that can be watched from far away cost more at first. But they help stop problems and make repairs faster, which saves money.

Picking the right breaker keeps equipment safe, saves money, and helps everything run well.

Picking between MCCBs and ICCBs depends on what the system needs, how safe it must be, and how well it should work. MCCBs are good for regular protection in houses and small shops. ICCBs are better for places that need a lot of power or are very important. To get the best outcome, experts say to:

- Check how well the breaker works by using different kinds of data and tools that watch the system.

- Use smart sensors to help fix things only when needed.

- Think about money and how the system will run before you decide.

Picking carefully helps keep the system safe and working for a long time.

FAQ

What is the main difference between MCCBs and ICCBs?

MCCBs have a plastic shell for insulation and are for lower currents. ICCBs have a stronger, heat-proof case and can handle more current. ICCBs also have better safety features for tough places.

Can electricians repair molded case circuit breakers?

Electricians cannot fix MCCBs. The design keeps the inside parts closed. If an MCCB stops working, it must be replaced to stay safe.

Where should insulated case circuit breakers be used?

Engineers put ICCBs in big buildings, factories, and data centers. These places need to handle lots of current and need extra safety. ICCBs are best where safety rules are very strict.

Do both breaker types support remote monitoring?

Many new MCCBs and ICCBs let people watch them from far away. This helps managers see if there are problems and fix them fast. Remote monitoring makes the system work better.

How do you choose the right circuit breaker for a project?

Experts say to check the current, voltage, place, and safety needs.

Use this checklist:

- Find out how much power is needed

- Look at safety rules

- Think about adding more later

- Compare prices and what each breaker can do

The following information may be of interest to you

What Situations Call for the Use of a Molded Case Circuit Breaker

What You Need to Know About How Molded Case Circuit Breakers Work

Intelligent MCCB circuit breaker

How to safely remove circuit breakers from distribution boxes

Molded-case-circuit-breaker-125-ampere-4P.webp)