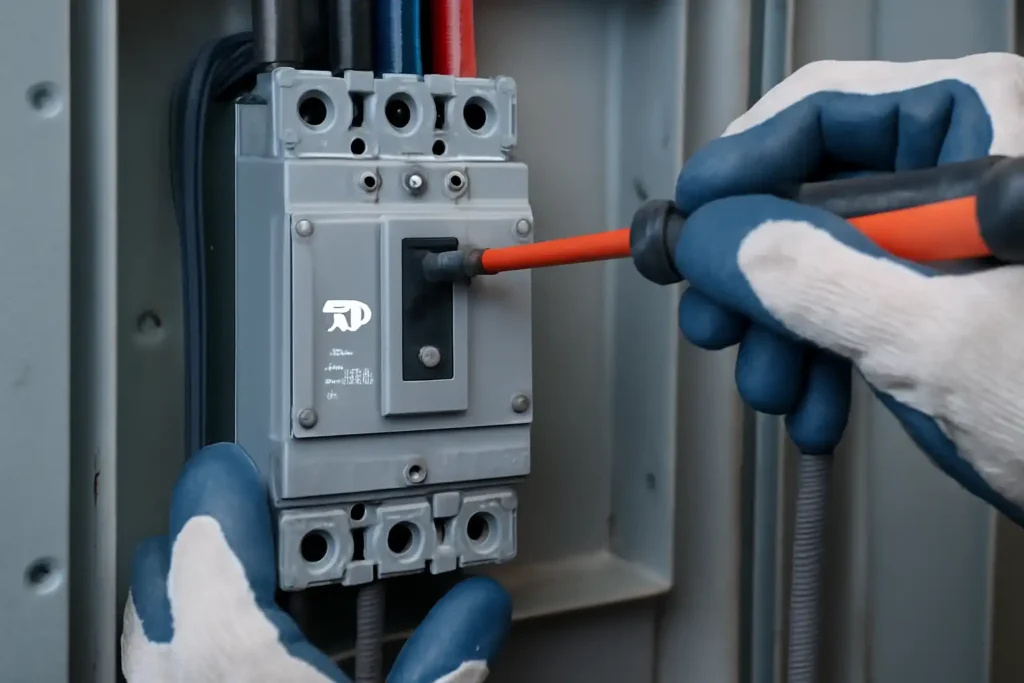

The maintenance of molded case circuit breakers is crucial for ensuring the safety and reliability of your electrical systems. Neglecting this maintenance can lead to equipment failure, resulting in costly downtime and potential safety hazards. Regular maintenance of molded case circuit breakers mitigates these risks and benefits you in the long run. Adhering to best practices not only extends the lifespan of your equipment but also saves you money on unnecessary repairs. Proper care of molded case circuit breakers ensures that systems operate efficiently and helps prevent unexpected issues.

Key Takeaways

-

Taking care of molded case circuit breakers avoids big problems. Simple checks like looking for damage and cleaning help a lot.

-

Follow a maintenance plan based on how and where they are used. Change how often you check them if there’s dust or moisture.

-

Spot warning signs early, like tripping often or bad smells. Fixing these quickly stops bigger issues and keeps things working well.

-

Do smart things like regular checks, oiling moving parts, and testing the breaker yearly. These steps keep systems safe and working properly.

-

Call trained experts for hard problems to follow safety rules. Their skills stop expensive fixes and make systems work better.

Why Taking Care of Molded Case Circuit Breakers Matters

Stopping Electrical Problems and Delays

Taking care of your circuit breakers keeps systems working well. Regular checks help stop sudden problems that could slow things down. Many electrical issues can be avoided with good planning and care. Cleaning dirt, fixing loose parts, or replacing worn pieces keeps everything running smoothly and avoids costly delays.

To lower risks, focus on simple tasks like checking and cleaning. Look for damage signs like burns or sparks, and clean off dirt. These easy steps help prevent breakdowns and keep your work running without stops.

Staying Safe and Following Rules

Safety is the most important thing with electrical systems. Ignoring circuit breaker care can cause fires or equipment problems. Regular maintenance makes sure breakers work right and lowers accident risks.

Also, keeping up with maintenance helps you follow safety rules. Many laws require regular checks of electrical systems, including breakers. By following these rules, you protect your equipment and avoid fines or legal trouble.

Making Electrical Systems Last Longer

Taking care of circuit breakers helps your whole system last longer. When you maintain breakers, other connected parts wear out less quickly. Tasks like oiling moving parts and tightening screws keep things working well and stop early failures.

Regular care also saves money over time. Instead of paying for big repairs, you can spend less on small fixes. This keeps your systems working better and makes your investment worth more.

Recommended Frequency for Circuit Breaker Maintenance

Routine Maintenance Intervals for Different Environments

How often you maintain circuit breakers depends on their type and location. Following a schedule keeps them reliable and reduces failures. Below is a table showing how often to check different breakers:

|

Type of Circuit Breaker |

Maintenance Frequency |

|---|---|

|

Molded Case |

|

|

Low-Voltage |

Check every 1 to 3 years |

|

Medium-Voltage |

Inspect once a year |

|

High-Voltage |

Check every 6 months |

Always check the manufacturer’s guide for exact instructions. Regular tasks include checking connections, testing settings, and cleaning dirt. These steps stop problems and keep systems working well.

Factors That Affect Maintenance Schedules

Some things change how often you should check breakers. These include the environment, how they’re used, and the equipment type. The table below lists important factors:

|

Key Factors |

Description |

|---|---|

|

Steps for checking breakers in workplaces or factories. |

|

|

Preventive Maintenance |

Tips to keep breakers working efficiently. |

|

Environmental Influences |

How dust, humidity, or extreme temperatures affect breaker performance. |

For example, dusty or humid places need more frequent checks. Equipment under heavy use or in critical systems also needs extra care. Knowing these factors helps you plan the right schedule.

Signs That Indicate Immediate Attention is Needed

Spotting warning signs early can stop big problems. Here are signs your breaker needs quick care:

-

Burning smells near the panel show overheating or damage.

-

A hot breaker box means too much heat, which is dangerous.

-

Damaged parts like burnt outlets or melted wires need fast checks.

If you see these signs, fix them quickly to avoid worse issues. Ignoring them can cause breakdowns or safety risks. Regular checks and fast fixes keep your system safe and reliable.

Best Practices for Circuit Breaker Maintenance

Checking Breakers Regularly

Looking at breakers often helps stop problems early. Check the breaker’s condition to find cracks, burns, or damage. Look for loose wires or heat marks near the terminals.

Regular checks also make sure settings match your needs. Factory settings might not work for your system. Adjust them during setup and routine checks. Testing breakers helps find issues before they get worse. For example, spotting bad insulation early can save money and time. A factory study showed regular checks cut downtime by 40%.

Tip: Use a checklist to check all important parts. Include housing, wires, and heat signs.

Testing Electrical Parts (Insulation and Contact Resistance)

Testing electrical parts is very important. Insulation tests check if the breaker handles electricity safely. Contact resistance tests find loose or worn-out parts that could cause sparks or fires.

Doing these tests often helps find dirt or worn spots. If voltage drops too much, it may mean parts are damaged. Fixing these fast keeps the breaker safe and working well. Testing also ensures the breaker works in emergencies. Studies show testing improves safety and lowers repair costs.

Note: Testing helps follow rules and avoids fines or legal trouble.

Cleaning Dust and Dirt

Dust and dirt can make breakers stop working. This happens more in dusty places. Cleaning breakers keeps them working well and stops overheating.

Use a soft brush or air to clean dust off. Don’t use water or strong cleaners, as they can harm parts. Focus on wires and moving parts since they collect more dirt. Clean breakers last longer and work better.

Tip: Add cleaning to your maintenance plan, especially in dusty areas.

Lubricating Moving Parts and Ensuring Smooth Operation

Lubricating moving parts in a molded case circuit breaker is very important. Over time, these parts can get stiff or worn because of dirt or dust. Adding lubrication helps the breaker work well and lowers the chance of mechanical problems.

Here’s how to take care of moving parts:

-

Check for Damage: Look for loose, broken, or worn-out pieces. Use the manufacturer’s guide to find the right parts.

-

Inspect Moving Parts: Check if parts are stuck or worn out. Make sure they move easily without resistance.

-

Add Lubrication: Use the lubricant suggested by the manufacturer. Apply it lightly to avoid attracting dirt. Focus on springs, hinges, and other moving areas.

Tip: Clean the breaker housing before adding lubrication. This stops dirt from mixing with the lubricant and causing problems.

Lubricating parts regularly keeps the breaker working smoothly and lasts longer. Studies show that well-lubricated parts fail less often, making maintenance more reliable.

Cycling the Circuit Breaker Annually (OFF, ON, TRIP, RESET, ON)

Cycling the circuit breaker once a year is simple and helpful. This means switching the breaker through its positions: OFF, ON, TRIP, RESET, and back to ON. Cycling helps find problems and ensures the breaker works during emergencies.

Steps to cycle your breaker:

-

Turn OFF: Switch the breaker to OFF to disconnect the circuit.

-

Switch ON: Turn it back ON to check if it works properly.

-

Simulate a Trip: Use the test button or trip it manually to see its response.

-

Reset: Move the handle to RESET to clear the trip.

-

Return to ON: Switch it back to ON to restore normal operation.

Note: Cycling stops parts from sticking due to inactivity. It also ensures the breaker works when needed most.

This yearly practice is important for maintenance. It helps find issues early and keeps systems running well.

Tightening Bolted Connections to Ensure Proper Operation

Loose connections can cause overheating, sparks, or equipment failure. Tightening bolted connections is key to keeping molded case circuit breakers working safely.

Steps to tighten connections:

-

Inspect Connections: Look for loose or rusty bolts and lugs. Pay extra attention to high-current areas.

-

Use a Torque Wrench: Follow the manufacturer’s torque instructions. A torque wrench ensures the right amount of force is used.

-

Check for Damage: Look for burns, discoloration, or melted insulation near connections. These signs mean overheating and need fixing fast.

Tip: Tighten connections during regular maintenance to avoid expensive repairs later. Secure connections improve system safety and performance.

By keeping bolts tight, you lower the risk of electrical problems and make your system safer. This simple step is vital for good circuit breaker care.

When to Get Help from Professionals for Circuit Breaker Care

Why Certified Technicians Are Helpful

Certified technicians are skilled in fixing circuit breakers. They have special training and follow safety rules like NFPA codes. Their knowledge helps them avoid mistakes during repairs or maintenance.

Hiring experts makes your electrical systems more reliable. They test and check breakers to ensure they work properly. Regular care by professionals prevents problems and keeps systems safe. For example, testing can stop equipment failures by keeping energy levels accurate.

Professionals also use advanced tools to improve results. ABB’s digital vacuum breaker boosts maintenance speed by 60% and cuts outages by 30%. ONESTO’s intelligent circuit breakers have IoT capabilities, making the system safer and more reliable. This makes hiring experts a wise choice.

When You Need Expert Help

Some problems need professional care right away. If your breaker trips often or smells burnt, call an expert. These signs may mean serious issues that need special tools to fix.

Big systems, like those in factories, need expert checks too. Professionals can test and repair all parts to keep them working well. If your system has smart breakers, experts know how to maintain them properly.

Following safety laws often requires certified technicians. Regular checks by professionals help you meet rules and avoid fines.

How to Pick a Good Service Provider

Choosing the right company ensures your breaker gets proper care. Look for providers with trained technicians who follow industry rules. Make sure they know how to handle your type of breaker.

Check the tools and methods they use. For example, EPRI tools predict when maintenance is needed, saving money and improving reliability. Con Edison saved $3 million yearly by using EPRI’s advice to extend maintenance times.

Read reviews and ask for references. A good company should have happy customers and a history of safe, efficient work. Pick one that values safety and customer satisfaction.

Taking care of molded case circuit breakers is very important. It keeps systems safe, reliable, and saves money. Following a regular schedule stops sudden problems and keeps things running well. Good care makes breakers last longer and work better.

-

It helps follow safety rules and lowers fire risks.

-

Cleaning dirt and fixing rust makes systems work better.

Doing these tasks avoids replacing parts often or spending too much on repairs. With proper care, your circuit breakers will stay reliable and work great for many years.

If you have a purchasing demand for molded case relays, you can choose ONESTO to provide you with high-quality products, support customization and skin, and affordable prices

FAQ

What tools are needed for circuit breaker care?

You’ll need simple tools like a torque wrench, multimeter, soft brush, and the lubricant suggested by the manufacturer. These tools help tighten bolts, test parts, and clean the breaker properly.

Tip: Always check the manufacturer’s instructions before choosing tools.

How do you know if a circuit breaker is failing?

If the breaker trips often, smells burnt, or has melted wires, it might be failing. A hot breaker box is also a warning sign. Fix these problems quickly to avoid bigger issues.

Note: Ignoring these signs can cause dangerous situations.

Can you maintain a circuit breaker without expert help?

Yes, you can do simple tasks like cleaning, checking for damage, and cycling the breaker. For advanced repairs or tests, call a certified technician to stay safe and follow rules.

Reminder: Safety should always come first with electrical work.

How often should a circuit breaker be cleaned?

Clean your breaker at least once every year. If you’re in a dusty or damp area, clean it more often to keep it working well.

Tip: Use a soft brush or air to remove dirt safely.

Why is cycling a circuit breaker necessary?

Cycling stops parts from getting stuck when not used. It ensures the breaker works during emergencies. Do this yearly by switching through all positions: OFF, ON, TRIP, RESET, and ON.

Emoji Tip: 🔄 Cycling keeps your breaker ready to work!

You may be interested in the following information

Intelligent MCCB circuit breaker

The service life of miniature circuit breakers

How to replace the circuit breaker correctly