Imagine you put a regular rccb in a place with very hot summers and very cold winters. You see the device stops working when the temperature changes a lot. You need answers that work everywhere. Customized rccb units let you pick features that fit your needs. You get better help when you talk to manufacturers for advice.

Tip: Always pick rccb solutions made for your environment to stay safe.

Key Takeaways

- Temperature changes can damage electrical systems. Standard RCCBs might not work in very hot or cold places. Customized RCCBs protect better because they fit the temperature and place where they are used. Picking RCCBs made with strong materials and the right certifications keeps things safe and working for a long time. Always look at the temperature range and ask the makers for help to choose the best RCCB for you. Using certified and customized RCCBs keeps people and equipment safe. It also helps electrical systems work well.

Temperature Fluctuations & Safety

Effects on Electrical Systems

It is important to know how temperature changes affect your electrical systems. When it gets colder than -4°F (-20°C), things like electric vehicles lose power. Batteries slow down and can drain fast or shut off suddenly. When it gets hotter than 95°F (35°C), batteries wear out faster and might swell or leak. Most consumer electronics work best between 0°C and 35°C. If it is too hot or cold, devices slow down or stop charging to protect the battery.

In factories, big temperature changes make materials move. This can cause cracks, bending, or broken parts. High heat makes chemical reactions happen faster. This can ruin insulation and cause rust. Humidity adds more water and can make electricity leak. These problems can make electrical systems unsafe. You need to control temperature and humidity to keep things working well.

Tip: Always look at the temperature range for your devices. This helps you keep your electrical systems safe.

- Common temperature ranges that affect electrical systems:

- Below -4°F (-20°C): Big loss of power and battery drain.

- 0°C to 35°C: Safe for most consumer electronics.

- Above 95°F (35°C): More battery damage and less efficiency.

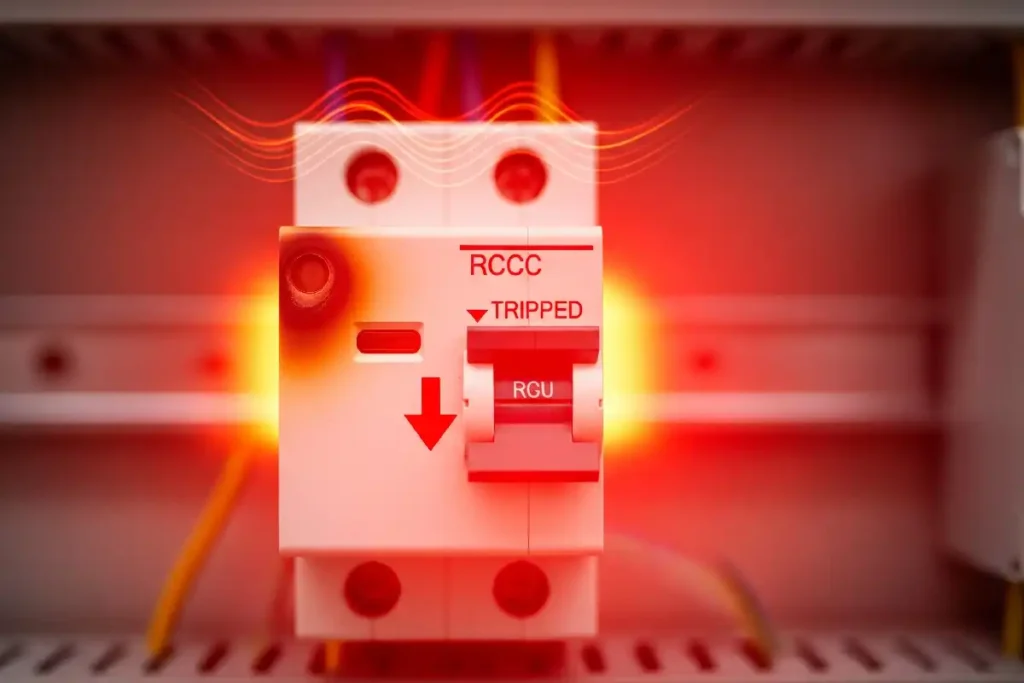

Risks Without Proper RCCB

If you use a regular rccb in places with extreme temperatures, you could lose safety. The device might not trip when there is a problem. This leaves your system open to danger. Without the right protection, heat can break wires and solder. You might see insulation fail, chemical damage, or even fires.

You need an rccb made for your environment. Customized rccb units protect better from temperature swings. They work right and keep you safe, even when it is very hot or cold. If you do not use the right rccb, you risk damage to equipment and people.

- Why picking the right rccb matters for safety:

- Stops electrical fires and shocks.

- Keeps circuits safe during temperature changes.

- Makes sure things work in tough conditions.

Note: Picking the right rccb is the first step to good electrical safety. Always choose circuit protection that fits your environment.

Challenges for Standard RCCB

Failure in Extreme Temperatures

Some people think a standard rccb always works well. This is not true when the weather changes a lot. If you use a regular rccb in a 3 phase system, you might lose protection on very hot or cold days. The device can trip too early or not trip at all. This means your 3 phase equipment is not safe.

To keep your circuit protection strong, check if your rccb can handle your local temperatures. Standard rccb units often do not protect well when the weather changes quickly. For example, in a factory with 3 phase machines, a sudden cold snap can make the rccb slow to react. In a hot warehouse, the rccb may trip even when there is no real danger. You need to know these limits to keep your circuit protection working.

Tip: Ask your supplier if the rccb is tested for your local temperature range before using it for 3 phase circuit protection.

Material and Sensitivity Limits

Standard rccb units use materials that may not last in tough weather. The plastic and metal parts can crack or bend when the temperature changes a lot. This makes the rccb weaker and can cause it to stop working. In a 3 phase setup, this means you lose protection for all your equipment.

The sensitivity of a standard rccb can also change with temperature. If the device gets too hot or cold, it may not sense small leaks or faults. You lose the protection you expect from your circuit protection system. This is a big risk for 3 phase systems, where one failure can affect many machines.

Here is a simple guide to spot the limits of standard rccb units:

| Challenge | What Happens to Protection? | Impact on 3 Phase Circuit Protection |

|---|---|---|

| Extreme heat | Trips too soon or not at all | Loss of protection for all phases |

| Extreme cold | Slow or no response | Equipment stays unprotected |

| Material weakness | Cracks or bends | Circuit protection fails |

| Sensitivity changes | Misses small faults | Higher risk for 3 phase systems |

If you want strong protection, look for rccb units made for your environment. This keeps your 3 phase circuit protection safe and reliable.

Customized RCCB Solutions

If the temperature changes a lot, you need better protection. Standard devices may not work well in these places. Customized rccb units let you pick what fits your needs. You can choose features that help your electrical systems stay safe. These units work even when conditions are tough. Manufacturers make these special solutions for you.

Adjustable Sensitivity

You want your rccb to work in hot or cold weather. Manufacturers build customized rccb units for different temperature ranges. This helps you find the right one for your space.

- For most places inside or outside, pick rccb units that work from -25°C to +70°C.

- For cold storage or outdoor spots with big temperature swings, choose rccb units rated for -40°C to +70°C.

- For offices or data centers, rccb units with a range of -5°C to +40°C are usually enough.

These ratings help your rccb keep working and protect you. Manufacturers do not change sensitivity after you buy it. They make sure the rccb stays accurate in the temperature range you need. This way, you know your circuit protection will work when you need it.

Tip: Always check the temperature range on your rccb before you install it. This easy step helps you avoid trouble later.

Rugged Construction

You want your customized rccb to last in tough places. Manufacturers use special ways to make sure your protection stays strong.

- Flame-retardant materials help your rccb resist fire and heat.

- Reinforced contacts can handle shaking and high temperatures. This is important for 3 phase systems in factories or warehouses.

- Rugged builds protect your rccb from bumps and keep it working in hard conditions.

- Double busbar designs and strong terminals let you change or upgrade your system without losing protection.

Advanced enclosures help keep your rccb safe. These covers use good materials that stand up to extreme temperatures. They protect the inside parts from harm and keep your residual current circuit breaker working for years. The small size makes it easy to install, even in tight spaces. Clear lights and easy-to-reach parts help you spot problems fast and fix them before they get worse.

Note: Rugged construction means less downtime and fewer repairs. You get reliable solutions for your 3 phase rccb and other systems.

Standards Compliance

You want to know your customized rccb meets top safety rules. Manufacturers follow strict steps to make sure your protection works well.

- Look for rccb units that meet international standards like IEC/EN 62423 and IEC/EN 61008. These rules test the rccb for performance in tough weather and places.

- Some rccb types, like Type F and Type B, give special protection. Type F is good for circuits with mixed loads. Type B is best for 3 phase systems and equipment with variable frequency drives.

- Certified residual current circuit breakers help you feel safe. You know your earth leakage protection will work, even when the weather changes quickly.

You should always ask your manufacturer for proof of these rules. This step helps you avoid unsafe products and makes sure your customized protection fits your needs.

Callout: Certified solutions keep your 3 phase circuit protection safe and reliable. Never skip this step when choosing your rccb.

With these features, you can build a protection system that stands up to any challenge. Customized rccb solutions help you keep your equipment and people safe, no matter how much the temperature changes.

Choosing the Right RCCB

Assessing Environmental Needs

First, look at your environment before picking electrical safety solutions. Think about where you will put your 3 phase system. Is it outside where there is sun and rain? Or is it inside a room with controlled temperature? Outdoor 3 phase systems face more changes in temperature and moisture. Indoor 3 phase systems usually stay in a steady place. You need to check the temperature and humidity for your space. This helps you avoid choosing an rccb that does not work when you need it most.

Tip: Write down the lowest and highest temperatures your 3 phase system will face. This helps you pick the right electrical safety solutions.

Manufacturer Recommendations

Manufacturers help you find the best 3 phase solutions. They look at your environment and suggest custom rccb choices. You can use the table below to see what experts say for different places:

| Parameter | Outdoor Installation Requirements | Indoor Installation Requirements |

|---|---|---|

| Temperature Range | -40°C to +70°C for tough conditions | -5°C to +40°C in controlled rooms |

| Humidity Range | Up to 95% RH for wet or coastal areas | Up to 60% RH in indoor spaces |

| Insulation & Interrupting Capacity | Higher ratings for outdoor or factory loads | Lower ratings for indoor loads |

| Enclosure Type | IP54, IP65, IP67 for dust and water protection | IP20 or IP40, no water protection needed |

Always ask the manufacturer for advice on 3 phase solutions. They can help you pick the right residual current circuit breaker for your needs. Many companies give free help to make sure your solutions fit your environment. This step helps keep people safe and protects the environment.

Certification & Compliance

You must check that your 3 phase solutions meet safety rules. Look for rccb units with certifications like IEC/EN 62423 or IEC/EN 61008. Certified solutions help you feel safe about electrical safety. These rules show your residual current circuit breaker will work in your space, even if the temperature changes a lot. Always ask for proof of certification before you install any 3 phase solutions. This keeps your electrical safety strong and reliable.

Callout: Certified 3 phase solutions protect your equipment, people, and the environment. Never skip this step for electrical safety.

Customized RCCBs help keep things safe when it gets hot or cold. You protect people and equipment by picking the right safety solutions for your area. Following safety rules lowers risks and helps things last longer.

- Checking your system often and using smart tools helps you find problems early and keeps things safe.

- Teaching your team and keeping good notes helps with safety every day.

- Picking certified RCCBs with the right ratings keeps you safe in any weather.

| Design Aspect | Impact on Safety and Reliability |

|---|---|

| Component Selection | Choosing the right parts keeps things safe and stops problems. |

| Safety Testing & Certification | Testing and getting certified shows your safety solutions work in tough places. |

You should always ask experts or manufacturers for help. They make sure you get the right RCCBs so safety is always first.

FAQ

What makes a customized RCCB different from a standard one?

A customized RCCB is made for your area. Manufacturers change the temperature range, materials, and how sensitive it is. This helps the device work well in hot or cold weather.

How do I know if my RCCB is right for extreme temperatures?

Look at the label or datasheet for the temperature range. Ask your supplier to show proof of testing. If you see IEC/EN 62423 or IEC/EN 61008, it meets strict rules.

Can I install a customized RCCB myself?

You should let a licensed electrician install your RCCB. This keeps you safe and makes sure it works right. Never try to put it in by yourself.

Why do I need to follow certification standards?

Certification means your RCCB passed safety tests. This lowers the chance of fire or shock. Certified devices protect people and equipment, even if the weather changes.

What should I do if my RCCB trips often in changing weather?

First, check if your RCCB matches your local temperature range. If it does not, ask your manufacturer for help. You might need a special unit made for your weather.

See also

What Happens When Cold Weather Trips Circuit Breakers

The difference between customized RCCB and standard RCCB

Why Customized RCCB Is the Future of Electrical Safety

Why choose a customized miniature circuit breaker for your needs

What Are Residual Current Circuit Breakers and How Do They Work