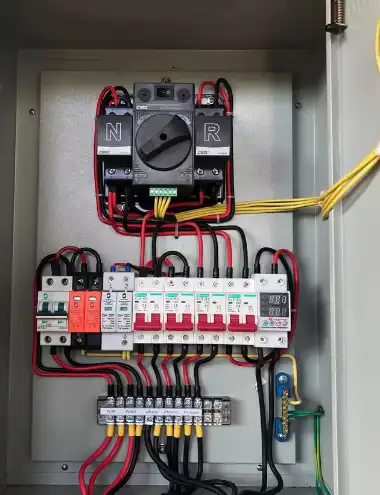

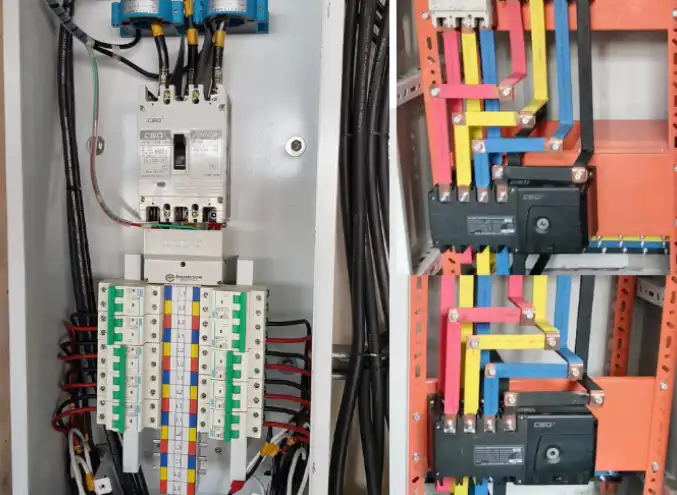

Molded case circuit breakers are of great significance in low-voltage distribution systems. However, the plastic shell circuit breakers used in practice may experience different faults, which will have a certain impact on the normal operation of the power system.

This article will analyze the common faults, causes, and troubleshooting methods of molded case circuit breakers, helping users maintain and repair them more conveniently.

1、 Common fault types and cause analysis

Circuit breaker tripped

Tripping is the most common fault phenomenon, whose potential causes are:

Overload: The circuit’s load is higher than the rated current of the circuit breaker (e.g., multiple devices operating simultaneously or high power of devices).

Short circuit: Short circuit inside the circuit or device and direct short circuit, which results in flash of current and immediate tripping.

Leakage: Insulation efficiency reduces, and this makes the leakage current of the ground exceed the specified limit.

Misbehavior: Mis-tripping may be resulted due to faulty release coil, environmental oscillation, or insulation fault in the secondary circuit.

Mechanical and electrical failures

Unable to close: The undervoltage release has no voltage, the coil is damaged or mechanically stuck.

High temperature work: including contact wear, insufficient pressure, and loose connection screws leading to poor contact.

Abnormal disconnection: The bimetallic strip of the expander is broken, or the beak between the electromagnetic release armatures is too large.

Abnormal noise: rusted iron core, damaged short-circuit ring, irregular spring pressure

Troubleshooting process

1. Initial inspection

Visual inspection: Inspect whether the circuit breaker enclosure is painted or burnt, and whether the wire terminals are loose or rusted.

Load check: Inspect whether the overall load of the circuit is larger than the rated current of the circuit breaker to avoid overload operation.

2. Operating and functional test

Test of manual operation: Test manual closing/opening of the circuit breaker to observe whether the mechanical device is flexible.

Electrical test: Take a measurement of the circuit breaker’s input and output lines using a multimeter and conduct an open circuit or short circuit test.

Insulation test: Insulation function test of the circuit by means of an insulation resistance meter and eliminate potential leakage dangers.

3. Detailed fault diagnosis

Release inspection:

Instantaneous release (C-type/D-type): Test whether the short-circuit protection response is normal.

Overload release: Verify whether the thermal element operates within 1 hour at 1.45 times the rated current

Targeted solutions

1. Tripping problem handling

Overload: Reduce the load or replace the circuit breaker with a higher rated current.

Short circuit: Upon turning off the supply of power, check for aging of the circuit and internal short circuit points of equipment and replace defective components.

Leakage: Repair insulation damaged equipment or replace residual current circuit breakers.

2. Mechanical and electrical repairs

Unable to close: Replace the undervoltage release coil, adjust the spring pressure or clean the stuck components.

Excessive temperature: Re tighten the wiring screws, replace worn contacts, or adjust contact pressure.

Abnormal noise: Clean the oil stains on the surface of the iron core and replace the broken short-circuit ring.

3. Correction of misoperation

Eliminate interference: Check if the secondary circuit is accidentally touched due to environmental vibration, and reinforce the wiring terminals.

Professional maintenance: For complex faults (such as hydraulic mechanism leaks), it is necessary to contact technical personnel to replace seals

Preventive maintenance and selection recommendations

Mccb (molded case circuit breaker) daily maintenance

Clean contacts regularly to prevent oxidation and bad contact.

Make sure the operating mechanism works well and that the handle and buttons you will see act firmly.

Check the temperature change to avoid damaging the circuit breaker due to excessive temperature.

Using the testing kit, check the overload and short circuit protection that the trip function is working.

Review the casing and wiring to ensure no physical damage that can hinder use.

Scientific selection

Rated parameters: Choose the C-type (distribution) or D-type (motor) trip characteristics based on the load current.

Breaking capacity: Ensure that Icu (ultimate breaking capacity) and Ics (operational breaking capacity) match the system short-circuit current.

Environmental adaptation: Choose IP65 protection level for humid environments, and reserve heat dissipation space for high temperature environments

Brand selection: Choose ONESTOP to provide high-quality, low-priced molded case circuit breakers. Multiple styles to choose from, suitable for commercial and industrial environments

conclusion

It is necessary to guarantee the smooth operation of molded case circuit breakers for ensuring power system safety.

With suitable debugging techniques and regular maintenance, the rate of circuit breaker malfunctions can be reduced effectively, and the reliable operation of power equipment can be ensured. In case of difficult faults during usage, it is better to contact a professional electrician for maintenance.

ONESTO has over 19 years of manufacturing experience and is a top manufacturer of molded case circuit breakers in China, supporting OME and customized services.

Here are some information that you may have just been interested in:

5 reasons and solutions for circuit breaker tripping

Common fault diagnosis guide for miniature circuit breakers

Where is the best place to install a molded case circuit breaker?