ISO certified circuit breakers play a vital role in electrical safety by meeting strict international standards. These standards, such as ISO 45001 and ISO 9001, require companies to set up documented safety protocols, perform risk assessments, and train employees. As a result, organizations report fewer accidents and better control of hazards like faulty wiring or overloaded circuits. This focus on quality helps prevent electrical failures, fires, and other dangers. Choosing an ISO certified circuit breaker gives users confidence in compliance, reliability, and safety.

Key Takeaways

- ISO certified circuit breakers meet strict international safety and quality standards, reducing risks of electrical fires and equipment damage.

- Certification covers every step from design to delivery, ensuring consistent manufacturing and thorough testing for reliability.

- ISO standards require companies to document procedures, manage risks, and perform regular audits to maintain high safety levels.

- Using ISO certified breakers helps prevent electrical hazards like overloads, shocks, and power surges, protecting people and property.

- Third-party testing and ongoing audits provide independent verification, building trust and accountability for product safety.

- Certified breakers support legal compliance and smoother inspections, helping companies avoid fines and insurance issues.

- Choosing certified circuit breakers saves money long-term by reducing repairs, downtime, and insurance risks despite higher upfront costs.

- Verifying certification marks and asking key safety questions ensures you select the right breaker for your needs and environment.

ISO Certified Circuit Breaker Overview

What Is ISO Certification

ISO certification represents a global benchmark for quality and safety in manufacturing. In the context of circuit breakers, ISO certification means that a company follows strict guidelines for quality management and safety. These guidelines help companies design, produce, and test products that meet high standards. When a manufacturer earns ISO certification, it shows a commitment to reducing risks and preventing failures. This approach builds trust with customers and ensures that every ISO certified circuit breaker performs reliably in real-world conditions.

Note: ISO certification does not only focus on the final product. It covers every step, from design to delivery, ensuring that safety and quality remain priorities throughout the process.

Key Standards

Several ISO standards apply to circuit breakers. ISO 9001 stands out as the most important for quality management. This standard requires companies to create systems that support traceability, risk management, and continuous improvement. ISO 9001 also aligns with IEC 61508, a standard for functional safety in electrical systems. The overlap between these standards helps companies achieve both quality and safety goals more efficiently. For example, Breaker Technology Inc. achieved ISO 9001 certification by focusing on customer needs, leadership, and ongoing improvement. Their commitment to safety led to a long record without injuries, showing how these standards make a real difference.

| Standard | Focus Area | Impact on Circuit Breakers |

|---|---|---|

| ISO 9001 | Quality Management | Ensures reliable, safe products |

| IEC 61508 | Functional Safety | Supports safety in design & use |

| OHSAS 18001 | Occupational Health/Safety | Promotes safe workplaces |

Certification Process

The ISO certification process involves several steps. First, a company must document its procedures for quality and safety. Auditors then review these documents and inspect the company’s operations. They look for evidence that the company follows its own rules and meets ISO standards. Companies must also show that they manage risks and keep detailed records. This structured approach helps reduce defects and failures. For instance, companies with strong documentation systems close audits faster and have fewer problems. The process does not end with certification. Regular audits and updates ensure that companies continue to improve and maintain high standards. This ongoing oversight explains why ISO certified circuit breakers offer greater reliability and safety than non-certified alternatives.

Product Quality

Manufacturing Consistency

Manufacturing consistency stands as a key reason why organizations choose ISO certified circuit breakers. ISO certification requires companies to follow strict procedures at every step of production. These procedures help workers avoid mistakes and keep each product the same as the last. Studies show that companies using ISO 9001 see fewer defects and smoother operations. For example, after implementing ISO standards, many factories report a clear drop in defect rates and process errors within just one year. Facilities with several production lines often see even bigger improvements. Increased training also leads to fewer problems, with a strong link between more training hours and less downtime or non-compliance. These results show that ISO certification brings real, measurable gains in how reliably circuit breakers are made.

Testing Procedures

Testing procedures under ISO standards go far beyond basic checks. Companies must test each circuit breaker for safety, durability, and performance. These tests happen at different stages, from raw materials to finished products. Real-time checks and automated systems help catch problems early, so faulty items do not reach customers. Finished products go through physical, chemical, and sometimes microbiological tests to make sure they meet all safety rules. This careful approach means that every ISO certified circuit breaker works as expected, even in tough conditions. By following these steps, companies can spot and fix issues before they become bigger problems.

Note: Regular testing not only protects users but also helps companies learn from mistakes and improve their products over time.

Quality Control

Quality control forms the backbone of ISO certification. Companies must set up strong systems to watch for defects and fix them quickly. These systems include supplier checks, in-process monitoring, and final inspections. Continuous quality control under ISO standards reduces product defects by lowering contamination risks and catching issues early. Companies that use these systems report fewer recalls and better customer satisfaction. They also use technology like automated monitoring and data analysis to find problems faster. Ongoing audits and feedback loops help teams learn and get better at their jobs. Training and a culture of accountability make sure everyone knows their role in keeping quality high. By focusing on these areas, companies lower risks and keep their products safe and reliable.

- Key benefits of ISO-based quality control:

- Fewer product recalls due to early detection

- Lower risk of contamination and defects

- Better supplier management and raw material quality

- Faster response to problems through corrective actions

- Continuous improvement through regular audits and feedback

Choosing an ISO certified circuit breaker means selecting a product built with care, tested for safety, and backed by a system that values improvement. This focus on quality gives users confidence that their electrical systems will work safely and reliably.

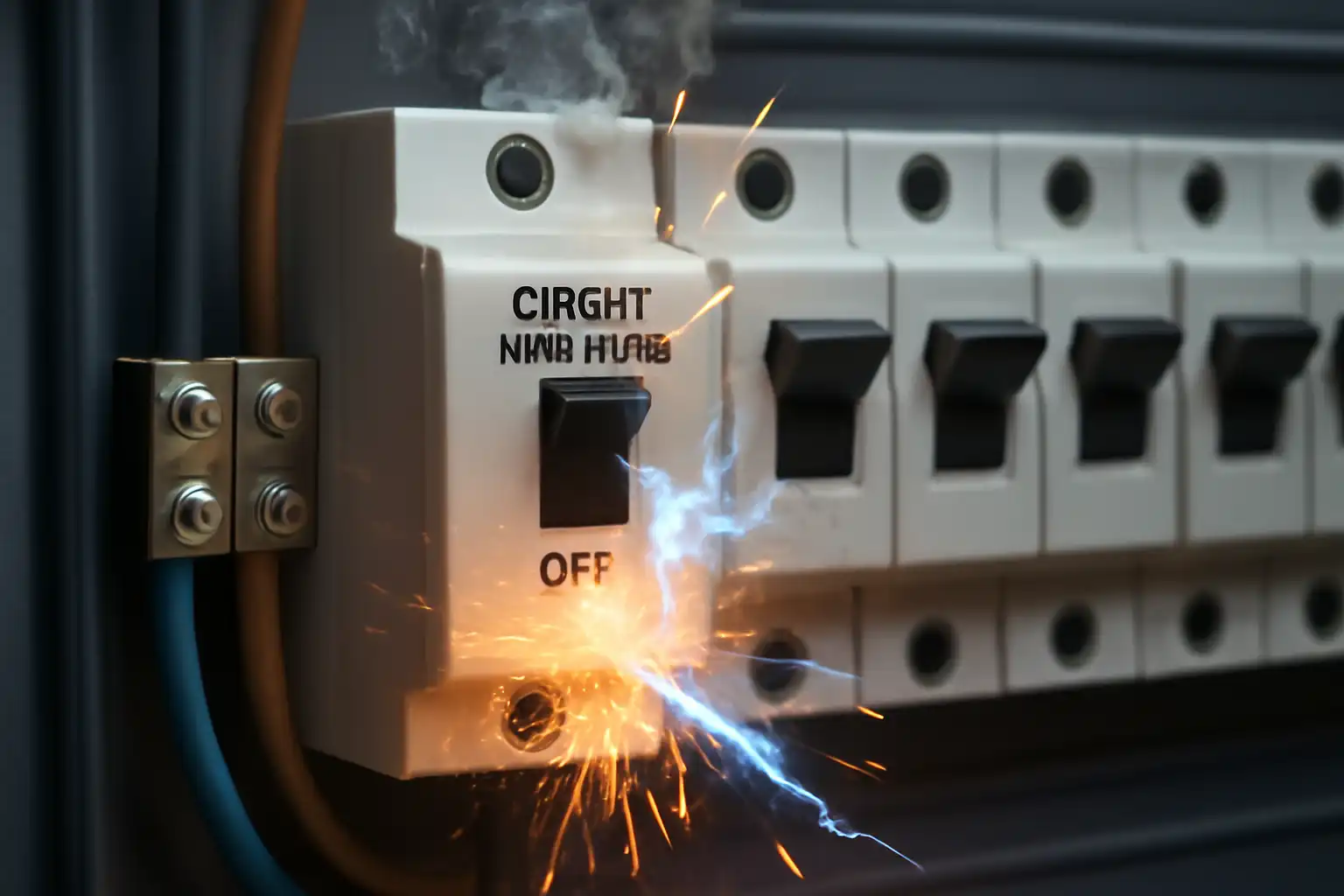

Electrical Hazards

Fire Prevention

Fires caused by electrical faults can destroy property and endanger lives. ISO certified circuit breakers help prevent these disasters by detecting abnormal currents and disconnecting power before wires overheat. Manufacturers design these breakers to meet strict international standards. These standards require thorough testing for overload and short-circuit conditions. When a circuit breaker responds quickly, it stops the flow of electricity that could start a fire. Companies that use ISO certified circuit breakers see fewer incidents of electrical fires in their facilities. This happens because the breakers work as intended, even under tough conditions. Regular audits and inspections, required by ISO standards, ensure that each breaker continues to perform reliably over time.

Tip: Always check for ISO certification when choosing circuit breakers for homes or businesses. This step can greatly reduce the risk of electrical fires.

Shock Protection

Electrical shocks can cause serious injuries or even death. An ISO certified circuit breaker plays a key role in reducing this risk. While circuit breakers alone cannot always prevent shocks—since the current passing through a person may not reach the breaker’s trip threshold—they form part of a larger safety system. International standards, such as those from ISO and IEC, guide the design and installation of circuit breakers to enhance safety. These standards require proper grounding, insulation, and sometimes the use of additional devices like residual current devices (RCDs). In medical devices and electric vehicle chargers, for example, compliance with these standards ensures that high voltages and leakage currents are managed safely. By following these guidelines, ISO certified circuit breakers help create safer electrical systems where the risk of shock is much lower.

Equipment Safety

Electrical equipment can suffer damage from power surges, short circuits, or overloads. ISO certified circuit breakers protect valuable machines and devices by interrupting dangerous currents before they cause harm. Manufacturers must test each breaker to ensure it can handle real-world faults without failing. This testing includes simulating extreme conditions, such as sudden spikes in voltage or current. When a breaker trips as designed, it shields sensitive equipment from damage and extends its lifespan. Facilities that use ISO certified circuit breakers report fewer equipment failures and lower maintenance costs. This reliability supports smooth operations and reduces downtime.

- Key reasons why ISO certified circuit breakers improve equipment safety:

- Fast response to electrical faults

- Consistent performance under stress

- Ongoing quality checks and audits

Choosing an ISO certified circuit breaker means choosing a safer environment for people and equipment. These breakers help prevent fires, reduce the risk of shock, and protect valuable assets, making them a smart choice for anyone concerned about electrical hazards.

Compliance

Regulatory Standards

Regulatory standards set the foundation for electrical safety in every country. ISO certified circuit breakers help organizations meet these strict requirements. International standards such as IEC 60898-1 and IEC 60947-2 define the safety and performance rules for circuit breakers in both residential and industrial settings. These standards ensure that products protect people and property from electrical hazards.

- IEC 60898-1 applies to low-voltage circuit breakers for homes and similar places.

- IEC 60947-2 covers industrial circuit breakers with higher voltage and current needs.

- Both standards require products to pass safety and performance tests before use.

- Compliance with these standards shows that a circuit breaker meets global safety benchmarks.

- ANSI NEMA AB 3 2013 also sets rules for molded-case circuit breakers in factories and large buildings.

Manufacturers must verify that each ISO certified circuit breaker meets these standards. They use design checks, safety tests, and risk assessments to confirm that every unit works as intended. Certifications like UL and CE marks provide extra proof that the product meets international safety rules.

Note: Ongoing monitoring and regular audits help companies keep up with changing regulations and maintain compliance over time.

Legal Requirements

Legal requirements for electrical safety protect workers, property, and the public. ISO certification helps companies follow these laws by building safety into every step of their process. For example, ISO 45001:2018 requires organizations to set up health and safety policies, find hazards, and control risks. This standard also asks companies to track safety performance and investigate any incidents.

- ISO 45001:2018 ensures that companies meet legal safety rules by making safety part of daily operations.

- ISO 9001:2015 and ISO 14001:2015 support compliance by improving quality and environmental management.

- These standards require clear records, regular audits, and ongoing training.

Many industries must also follow special laws for their equipment. For example, electric vehicle chargers must meet IEC 60364-7-722 and IEC 61851 to prevent shocks and fires. Medical devices use IEC 60601-1 to protect patients. Industrial motor drives in risky areas follow UL 1203 and IEC 60079 to stop explosions. Meeting these standards proves that a company follows the law and keeps people safe.

Industry Best Practices

Industry best practices go beyond the minimum legal requirements. Companies that use ISO certified circuit breakers show a commitment to safety and quality. They use structured processes, detailed documentation, and regular inspections to keep their systems safe.

- Real-time monitoring and self-diagnostics help spot problems before they cause harm.

- Safety-critical software, designed under IEC 61508, adds another layer of protection.

- Post-market surveillance ensures that products stay safe even after installation.

By following these best practices, companies reduce the risk of accidents and improve the safety of their electrical systems. Inspections become easier because the documentation and testing required by ISO standards provide clear proof of compliance. This approach supports safer installations and gives everyone confidence in the system.

Third-Party Verification

Third-party verification stands as a critical reason why organizations trust electrical safety products. Independent oversight ensures that manufacturers do not simply claim quality—they must prove it. This process brings objectivity and transparency, which helps prevent errors and protects users from hidden risks.

Independent Testing

Independent testing gives buyers confidence that products meet strict standards. Laboratories like CERDA Testing Laboratory in Villeurbanne, France, play a key role. CERDA holds COFRAC accreditation for ISO/IEC 17025, which means it follows international rules for testing. The lab also has ASEFA certification, providing full certification with an inspector present. Membership in ESEF and STL associations guarantees neutrality and impartiality. CERDA performs tests according to many international standards, including IEC, IEEE, EN, VDE, GOST, FURNAS, GB, DL, and even customer-specific requirements.

- CERDA’s high-power testing covers:

- Short circuit tests up to 100 kA and 1,000 kV

- Basic short circuit and short line fault scenarios

- Capacitive current switching and out-of-phase operations

- Internal arc and commutation switching in DC

- Arc voltage measurement

These comprehensive tests verify that circuit breakers work reliably under real-world conditions. Independent labs ensure that only products meeting all requirements reach the market.

Note: Independent testing protects users by catching problems that internal teams might miss.

Ongoing Audits

Ongoing audits keep manufacturers accountable over time. Auditors visit factories regularly to check if companies still follow the rules. They review records, inspect production lines, and test random samples. This continuous oversight means that quality does not drop after the first inspection. Companies must fix any problems quickly or risk losing their certification. Regular audits also encourage manufacturers to improve their processes and stay up to date with new safety standards.

Accountability

Accountability forms the backbone of third-party verification. When an outside organization checks a product, it holds the manufacturer responsible for every detail. If a problem appears, the company must explain what happened and how it will prevent it in the future. This system reduces the chance of defects reaching customers. It also builds trust with buyers, regulators, and insurers. Third-party verification shows that a company values safety and quality, not just profit.

Tip: Always look for products that have passed independent testing and regular audits. This step helps ensure long-term safety and reliability.

User Confidence

Reliability Assurance

People want electrical systems that work every time. ISO certified circuit breakers give this reliability. Manufacturers must follow strict rules and test each product before it leaves the factory. These tests check if the breaker can handle real problems, like power surges or short circuits. When a breaker passes these tests, it shows that it will protect homes and businesses from danger. Companies that use these breakers see fewer failures and less downtime. This reliability means fewer repairs and lower costs for everyone.

When a product works as promised, people feel safe using it. That is why reliability matters so much in electrical safety.

Stakeholder Trust

Trust is important in every business. Customers, electricians, and building owners all want to know that the products they use are safe. ISO certification builds this trust. It shows that a company cares about quality and safety. When a company uses certified breakers, it proves that it follows the best industry practices. This makes it easier for inspectors to approve installations. Insurance companies also look for certified products because they lower the risk of accidents. When everyone trusts the equipment, projects move faster and with fewer problems.

- Ways ISO certification builds trust:

- Shows commitment to safety

- Makes inspections smoother

- Reduces insurance risks

Peace of Mind

Peace of mind means not having to worry about hidden dangers. People want to feel sure that their electrical systems will not fail. ISO certified circuit breakers help by meeting high standards and passing tough tests. Homeowners sleep better knowing their families are safe. Business owners focus on their work instead of worrying about electrical fires or equipment damage. Professionals know that using certified products lowers their risk of mistakes and legal trouble.

Choosing certified breakers is a smart way to reduce liability and protect everyone involved.

ISO Certified Circuit Breaker vs. Non-Certified

Risks of Non-Certified

Non-certified circuit breakers introduce significant risks to electrical systems. These products often skip important safety tests. Manufacturers may not follow strict quality controls. As a result, non-certified breakers can fail during power surges or overloads. This failure can lead to electrical fires, equipment damage, or even injury. Non-certified products may also use substandard materials. These materials wear out faster and do not protect against hazards. In many cases, non-certified breakers lack proper documentation. This makes it hard for inspectors to verify safety.

Alert: Using non-certified circuit breakers increases the chance of electrical accidents and property loss.

Cost Implications

At first, non-certified circuit breakers may seem less expensive. However, hidden costs often appear over time. Non-certified products break down more often. Repairs and replacements add up quickly. Insurance companies may refuse claims if a fire or accident involves non-certified equipment. This can lead to large out-of-pocket expenses. Certified breakers, while sometimes more costly upfront, save money in the long run. They last longer and need fewer repairs. Certified products also help avoid fines for failing safety inspections.

| Factor | Certified Breaker | Non-Certified Breaker |

|---|---|---|

| Upfront Cost | Higher | Lower |

| Maintenance | Low | High |

| Insurance Coverage | Likely | Unlikely |

| Risk of Fines | Low | High |

Tip: Investing in certified products reduces long-term costs and protects against unexpected expenses.

Real-World Impact

The choice between certified and non-certified circuit breakers affects more than just cost. Certified breakers support energy efficiency. They waste less power and help lower utility bills. Non-certified products often run hotter and lose more energy. Certified breakers also support sustainability. Manufacturers must follow rules that limit pollution and waste. Non-certified products may not meet these standards. This can harm the environment.

In real-world cases, certified breakers have prevented fires and saved lives. For example, a factory that switched to certified breakers saw a sharp drop in equipment failures. The staff reported fewer shutdowns and less downtime. In contrast, buildings with non-certified breakers faced more frequent outages and higher repair bills.

Choosing certified breakers means safer buildings, lower energy use, and a smaller environmental footprint.

Choosing ISO Certified Circuit Breakers

Identifying Certification

Selecting the right circuit breaker starts with checking for valid certification. Manufacturers display certification marks on product labels, packaging, or technical documents. These marks show that a third-party organization has tested the product for safety and quality. Common marks include ISO, IEC, UL, and CE. Buyers should look for a certificate number and the name of the certifying body. This information proves the product meets international standards. Without these marks, there is no guarantee of safety or compliance. Certified products also come with detailed manuals and test reports. These documents help users confirm that the breaker matches their needs and works in their environment.

Tip: Always verify the certification details with the issuing organization’s website or database. This step helps prevent the use of counterfeit or expired products.

Questions to Ask

Professionals and consumers should ask key questions before choosing a circuit breaker. These questions help ensure the product will protect people, equipment, and wiring systems. The following checklist covers the most important points:

- Does the breaker trip before the maximum current rating of the most sensitive wiring component is reached?

- Is the device designed to protect the wiring system, not just the equipment?

- Is the breaker “trip free,” so it cannot be held closed during an overload?

- Does the breaker use fail-safe features to prevent hidden defects from causing failures?

- Has the manufacturer considered all possible failure modes, such as short circuits, wet arc tracking, and dry arc tracking?

- Does the tripping curve match the current-carrying capacity of the wires and cables?

- Are modern technologies, like arc fault circuit breakers, used to address specific risks?

- Does the product follow guidance from standards like EN3197 for selection criteria?

- Are the wires sized to match or exceed the protection rating, and are devices not paralleled as per best practices?

These questions help buyers choose circuit breakers that offer the highest level of safety and reliability.

Tips for Selection

Choosing the best circuit breaker involves more than checking labels. Buyers should compare features, performance, and suitability for their environment. The table below highlights important guidelines and supporting data:

| Guideline Aspect | Supporting Data / Standard Reference |

|---|---|

| Energy Savings from Passive Measures | Up to 15% energy savings with efficient equipment and reduced heat loss. |

| Energy Savings from Active Measures | Up to 30% savings using smart breakers and networked metering. |

| IEC 61557-12 Standard | Guides selection of measuring devices for energy analysis and cost allocation. |

| ISO 50001 Standard | Supports energy management system implementation and compliance. |

| Smart Circuit Breakers | Provide automatic data, reduce costs, and eliminate need for separate metering devices. |

| MasterPact MTZ Features | Class 1 accuracy in energy measurement; suitable for harsh environments (-25°C to +70°C). |

| Certification | Third-party conformity certificate according to IEC 61557-12 standard. |

Buyers should also consider the environment where the breaker will operate. Some breakers work better in extreme temperatures or industrial settings. Smart breakers offer extra benefits, such as energy monitoring and remote control. These features help save money and improve safety. Selecting a certified breaker with these advantages reduces risks and supports long-term reliability.

Choosing the right circuit breaker protects people, property, and investments. Careful selection prevents accidents and ensures compliance with safety standards.

Choosing certified circuit breakers protects people and property by meeting strict safety standards. Certification ensures high performance, advanced protection features, and reliable operation in many settings.

- Predictive maintenance services help spot problems early and reduce costly downtime.

- Data-driven decisions improve reliability and lower risks.

- Cost avoidance and better equipment performance increase return on investment.

| Aspect | Details |

|---|---|

| Certifications | ISO 9001, ISO 14001, ISO 18001, SA8000, RINA Best Four Certification |

| Application Range | Residential, commercial, and industrial uses with adjustable protection |

Always check for valid certification before buying or installing a circuit breaker. This step supports safety and long-term reliability.

FAQ

Why should someone choose ISO certified circuit breakers over non-certified ones?

ISO certified circuit breakers meet strict international safety standards. They reduce the risk of electrical fires, equipment damage, and personal injury. Non-certified breakers may fail during faults, leading to dangerous situations and higher long-term costs.

Why do ISO standards matter for electrical safety?

ISO standards require manufacturers to follow proven safety protocols. These protocols help prevent defects and ensure reliable performance. When companies follow ISO standards, they create safer electrical systems for homes, businesses, and industries.

Why do insurance companies prefer ISO certified products?

Insurance companies trust ISO certified products because they lower the risk of electrical accidents. Certified breakers pass independent tests and regular audits. This reduces the chance of claims related to electrical fires or failures.

Why does ISO certification help with legal compliance?

ISO certification ensures that circuit breakers meet national and international regulations. Companies avoid fines and legal issues by using certified products. Inspectors approve installations faster when they see ISO certification.

Why do ISO certified circuit breakers last longer?

Manufacturers use high-quality materials and strict quality control for ISO certified breakers. These breakers undergo rigorous testing for durability. As a result, they resist wear and perform reliably for many years.

Why do professionals recommend checking for ISO certification before purchase?

Professionals know that ISO certification proves a product’s safety and reliability. Checking for certification helps buyers avoid counterfeit or unsafe products. This simple step protects people, property, and investments.

Tip: Always look for ISO certification marks and verify them with the certifying body’s website.

The following information may be of interest to you

High quality solar lithium-ion batteries

IP65 wall mounted split type battery

Customizable intelligent air circuit breaker

KC3-H-4-pole-circuit-breaker.webp)