A terminal block is a tool that helps connect wires. It also keeps wires neat in electrical systems. People use other names for a terminal block. Some names are terminal strip, connection terminal, screw terminal, barrier strip, domino block, and chandelier clamp. Engineers and technicians should know these names. This helps them not get confused when buying parts or reading papers. The market for terminal blocks is getting bigger, as you can see below:

| Source | Market Size (Recent Year) | Year | Forecast Market Size | Forecast Year | CAGR (%) |

|---|---|---|---|---|---|

| Zion Market Research | USD 5.70 billion | 2024 | USD 8.52 billion | 2034 | 4.1 |

| MarketsandMarkets | USD 3.9 billion | 2022 | USD 5.2 billion | 2027 | 5.7 |

| Verified Market Reports | USD 1.82 billion | 2024 | USD 2.65 billion | 2033 | 4.5 |

Key Takeaways

- Terminal blocks join wires in a safe way. They help keep electrical systems tidy. This makes fixing and upgrading things easier.

- There are many kinds of terminal blocks. Some are screw, spring, barrier, pluggable, and PCB blocks. Each type works best for certain jobs.

- Picking the right terminal block is important. You need to look at voltage and current ratings. You should also check wire size, mounting style, and safety features.

- Terminal blocks help save time and cut down on mistakes. They let you connect wires fast. You do not need to solder or use special tools.

- Using terminal blocks makes things safer. They stop wires from coming loose. They help prevent short circuits and electric shocks in many places.

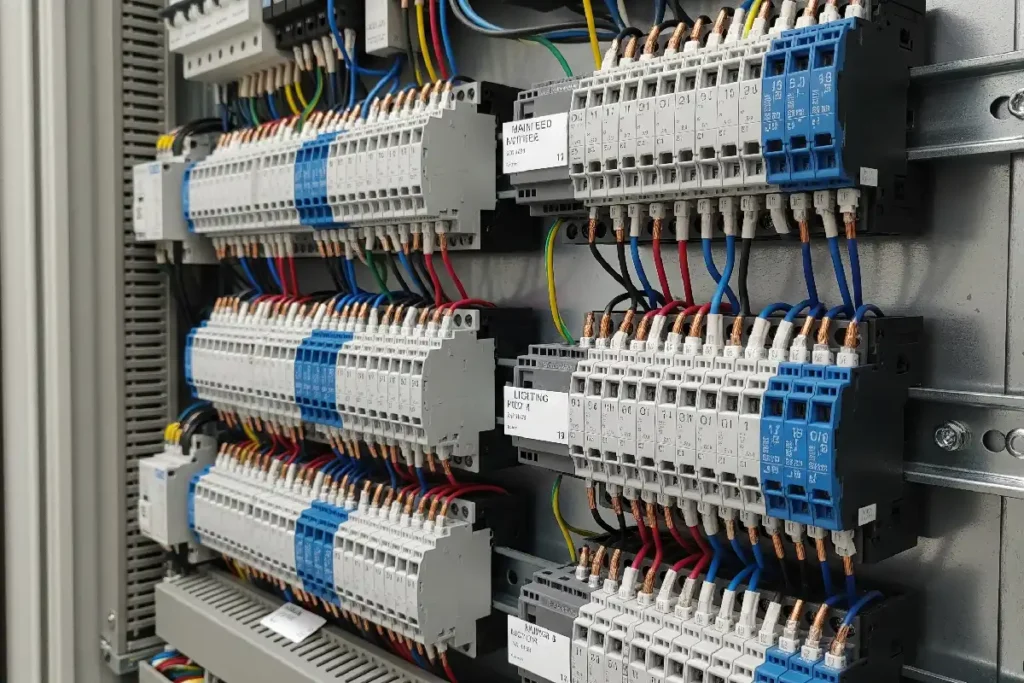

What Is a Terminal Block?

Definition

A terminal block connects two or more wires in an electrical system. People use terminal blocks so they do not have to solder wires. This makes fixing and changing wires much easier. The frame of a terminal block is insulated to keep people safe from electric shock. Inside the frame, metal parts hold the wires tightly. Most terminal blocks use screws or clamps to keep wires in place. The design follows rules to make sure connections are safe and work well. Terminal blocks help keep wires neat inside machines and control panels. They let people put together electrical systems quickly and neatly.

Terminal blocks are important because they let people connect and disconnect wires easily. This makes it easier to fix and check problems. The insulation keeps people from touching live wires by accident.

Structure and Components

Terminal blocks have a few main parts. Each part helps make the connection safe and strong.

- The housing is made from strong plastic or thermoplastic. This stops electricity from leaking out and keeps people safe.

- Metal clamps or screws inside the housing hold wires tight. Brass is used most because it does not rust and carries electricity well. Some types use copper or other metals for better flow.

- There are different ways to connect wires. Some use screws to press the wire down. Others use spring clamps or push-in designs.

- Some terminal blocks have end caps to cover the ends of units.

- Some types have pluggable modules. These let you remove and replace wiring sections easily.

Terminal blocks can be one piece or made of parts that fit together. Modular terminal blocks can be joined to fit different wiring needs. The way each terminal block is built keeps wires tight and stops them from coming loose.

Terminal Block Connectors: Alternative Names

Terminal block connectors have many names. The name can change by region or how they are used. Knowing these names helps people find the right part and read instructions.

| Name | Description | Typical Use |

|---|---|---|

| Terminal Block | Modular device for semi-permanent wire connections, usually screw or clamp | Fixed wiring, control panels |

| Terminal Strip | Long strip with multiple screw-in terminal block sections | Power distribution, panels |

| Barrier Strip | Terminal block with barriers between terminals for safety | Vibration-prone environments |

| Screw Terminal Block | Terminal block using screws to secure wires | General wiring, power connections |

| Connection Terminal | General term for any device joining wires | Various electrical systems |

| Terminal Connector | Sometimes used for plug-in or quick-connect types | Signal/data transfer |

| Domino Block | Small, modular terminal block, often used in lighting | Lighting circuits |

| Chandelier Clamp | Used in lighting, especially for ceiling fixtures | Light fixture wiring |

| PCB Terminal Block | Terminal block mounted on printed circuit boards | Electronics, control boards |

| Feed-Through Terminal Block | Allows wire-to-wire connections, often DIN rail mounted | Industrial control panels |

Some technical names are terminal strips, barrier strips, PCB terminal blocks, and feed-through terminal blocks. Regional names may be different, but they all connect wires safely. The main differences are how long the connection lasts, what tools you need, and where you use the terminal block.

Tip: When looking for terminal block connectors, check both technical and local names. This helps you find the right part for your project.

Functions and Advantages of Terminal Blocks

Main Functions

Terminal blocks are used to connect wires together. They help keep wires neat inside control panels and cabinets. Workers use them to link power to machines and systems. These devices are important in factories and buildings. Terminal blocks help send electricity to different parts of a system. They also connect motor wires to starters and control centers. This makes it easier to control motors.

Terminal blocks give safe connections for sensors and field wiring. They help signals move without mistakes. Their design lets people add or remove wires easily. You do not need special tools to use them. Terminal blocks make things safer by grounding and separating circuits. They protect wires from getting damaged and keep connections tight. Their strong build stops rust and works well in tough places.

Tip: Using terminal blocks keeps wires neat. This makes fixing and checking problems faster and safer.

Key Advantages

Terminal blocks have many good points over other ways to connect wires. They make strong and safe connections, so wires do not come loose. Their insulated frames keep wires tidy and lower the risk of problems. Terminal blocks use different ways to connect, like screws or springs. This stops wires from getting too tight or shaking loose.

Modular terminal blocks make wiring simple and help stop mistakes. Their small size saves space in control panels. Workers can change or upgrade parts fast without redoing all the wires. Some terminal blocks can find faults, which helps with checking and fixing. They are flexible, so you can add more as you need. Terminal blocks can handle stress and tough conditions, so they are very reliable.

Terminal block connection ways keep wires neat and easy to reach. This makes repairs faster and cuts down on waiting time. Terminal blocks do not cost much, so many people use them for electrical work.

Types of Terminal Blocks

Feed-Through Terminal Blocks

Feed-through terminal blocks are very common. They let a wire go in one side and out the other. This helps connect two wires in a straight line. Most types let you put wires in from either end. They come in many sizes for different voltages and currents. Some can handle from 10A up to 200A. People use them in factories, power systems, and homes. Their simple design makes them easy to install and fix.

Barrier Terminal Blocks

Barrier terminal blocks are also called barrier terminals or barrier strips. They use screws and have barriers between each wire. The barriers stop short circuits and arcing. This makes them safer for high voltage or places with lots of shaking. The barriers keep wires apart and safe, even if machines move. People use barrier terminal blocks in power panels and machines. They meet strict safety rules and use fire-resistant materials.

| Feature | Barrier Terminal Blocks | Other Terminal Block Types |

|---|---|---|

| Safety | High, with barriers | Varies by type |

| Application | Vibration, high voltage | General wiring, PCB, etc. |

| Wire Securing Method | Screw terminal | Screw, spring, push-in, etc. |

PCB Terminal Blocks (Spring and Screw)

PCB terminal blocks go right onto printed circuit boards. There are two main kinds: screw-in and spring-cage. Screw-in types use screws to hold wires tight. This gives a strong connection and you can see it is tight. Spring-cage types use a spring to grip wires. This makes connecting wires fast and easy. PCB terminal blocks save space and keep wires neat in control boards. Screw-in types work for higher currents. Spring-cage types are good for quick changes.

Pluggable Terminal Blocks

Pluggable terminal blocks are also called pluggable terminals. They have a modular design. You can wire them first and then plug them into a base. This makes setting up and fixing things much faster. Pluggable terminal blocks are flexible for upgrades and repairs. Their design stops wrong connections and keeps things safe. People use them in control panels and equipment that change often.

Tip: Pluggable terminal blocks help you fix or upgrade things faster.

IDC Terminal Blocks (Insulation Displacement)

IDC terminal blocks are also called push-fit terminal blocks or push-fit terminals. They use insulation displacement to connect wires. The metal parts cut through the wire cover and make a tight, safe connection. IDC terminal blocks are used in phone and data networks. You can find them in patch panels and network cabling. They work well for lots of wires and last a long time. Their design is great for voice and data jobs where you need strong and steady connections.

How to Choose the Right Terminal Block

Picking the right terminal block is important. You need to think about a few things. These things help keep electrical systems safe and working well. Knowing about terminal block features helps you choose the best one.

Voltage and Current Ratings

Each terminal block has a top voltage and current it can handle. These numbers should be higher than your system’s highest voltage and surges. For example, some industrial terminal blocks work with 500 V or 800 V. They can carry 17.5 A to 24 A, depending on the wire size. Some can even handle short bursts up to 10 kA. This meets tough safety rules. Using the right rating stops overheating and keeps things from breaking.

| Rating Type | Values |

|---|---|

| Rated Voltage | 500 V, 800 V |

| Rated Current | 17.5 A (1.5 mm² wire), 24 A (2.5 mm² wire) |

| UL Rated Voltage | 300 V to 600 V |

| UL Rated Current | 5 A to 20 A |

Always check the voltage and current ratings before you install. This keeps everything safe.

Wire Size Compatibility

Wire size is very important when picking terminal blocks. The block must fit the wire size and hold it tight. If the wire is too big or small, it may not stay in place. This can make things overheat or cause safety problems. Makers tell you what wire sizes fit each terminal block. Using the right size keeps the connection strong and safe.

Mounting Styles

Terminal blocks come in different ways to mount them. The main types are DIN rail mount, PCB mount, and panel mount.

- DIN Rail Mount: These snap onto metal rails. You can add or remove them easily. They are good for setups that change.

- PCB Mount: These are soldered onto circuit boards. They save space and make a strong connection.

- Panel Mount: These screw onto panels. This makes them stay in one place.

| Mounting Style | Description | Advantages |

|---|---|---|

| DIN Rail Mount | Modular, easy to maintain | Flexible, quick changes |

| PCB Mount | Soldered to circuit boards | Compact, secure |

| Panel Mount | Screwed onto panels | Stable, fixed |

Environmental and Safety Factors

Where you use the terminal block matters a lot. Outdoor or rough places need blocks with high protection, like IP67 or NEMA 4X. Some materials, like stainless steel or special plastic, stop rust and sun damage. Heat, water, and shaking can change how well the block works. For dangerous places, look for safety marks like UL, ATEX, or IECEx. These show the block is safe for tough jobs and risky spots.

Tip: Check and take care of terminal blocks often. This keeps them safe and working well, especially in hard places.

Practical Tips for Selection:

- Make sure the terminal block’s ratings match your system.

- Pick the mounting style that fits your setup.

- Strip wires to the right length and push them in all the way.

- Tighten screws to the right level if needed.

- Buy blocks from good brands for better safety and quality.

Knowing what a terminal block is and its other names helps engineers and technicians. This stops confusion when buying parts or fixing problems. Learning about the good points of each terminal block type makes electrical systems safer and better.

| Terminal Block Type | Key Advantages |

|---|---|

| Screw Clamp | Makes a strong and safe connection |

| Spring Clamp | Works fast and does not shake loose |

| Push-In Clamp | Easy to install without any tools |

| IDC | No need to strip wires, saves money |

- Always look at voltage, current, and safety rules before picking a terminal block.

- Using the right words helps people talk and buy parts more easily.

FAQ

What is a terminal block used for?

A terminal block connects wires in electrical systems. It keeps wires neat and safe. People use terminal blocks in control panels and machines. They also use them in buildings. Terminal blocks make electrical systems safer. They help people connect wires more easily.

What are the main types of terminal blocks?

There are many types of terminal blocks. Some common types are screw terminal blocks and barrier terminal blocks. Others are pcb terminal blocks, pluggable terminal blocks, and push-fit terminal blocks. Each type works best for certain jobs.

What is the difference between screw terminal blocks and screwless terminal blocks?

Screw terminal blocks use screws to hold wires tight. Screwless terminal blocks use springs or clamps. Push-in and spring-cage terminal block types are screwless. Screwless types save time. You do not need tools to use them.

What are barrier terminals and when should someone use them?

Barrier terminals have barriers between each wire. The barriers stop short circuits. They keep wires safe from touching each other. People use barrier terminal blocks for high voltage places. They also use them where there is lots of shaking.

What are the key characteristics of terminal block connectors?

Terminal block connectors have strong insulation. They hold wires tightly. They are easy to install. They come in many sizes and shapes. Some types, like pluggable terminals and push-fit terminals, let you change wires quickly. These features help with power distribution terminal blocks and connection terminals.

See also

What Is a Terminal Block and How Does It Work

What Is DIN Electrical Terminology and Why Does It Matter

How to Install a Three-Phase Surge Protection Device Step by Step

How to Safely Connect RCBOs in Your Electrical Distribution Panel

Panel Surge Protector Pros and Cons for Homeowners