High-voltage DC systems require careful attention during the installation of 1000V DC circuit breaker to ensure safety and proper function. Electric shock, arcing, and equipment damage can occur if the installation is not handled correctly or if wiring is done improperly. Technicians must wear gloves, face shields, and grounding straps throughout the installation of 1000V DC circuit breaker. Maintaining a safe distance and strictly following all safety protocols is essential. Skipping steps during the installation of 1000V DC circuit breaker can lead to arcing inside the breaker, component failure, or gas leaks. Thorough planning, correct polarity usage, and properly tightening bolts are critical to preventing these issues.

Key Takeaways

- Always wear the right safety gear like gloves and face shields to stay safe when you install.

- Make sure the circuit breaker fits your system’s voltage and current. Check that it has the right certifications before you start.

- Use lockout/tagout steps and check for no voltage. This makes sure the power is off before you work on the breaker.

- Connect wires with the right polarity. Tighten all connections as much as the instructions say. Ground all metal parts the right way to stop faults and fires.

- Check everything carefully and test how it works after you finish installing. This helps make sure the breaker is safe and works well.

Preparation

Verify Compatibility

Technicians need to make sure the circuit breaker fits the system. They check if the voltage and current ratings are right. This is important for both photovoltaic and industrial uses. The breaker must meet international rules and have the right certifications.

- IEC 60947-2 is for low-voltage switchgear up to 1000V DC.

- UL 489B is for DC molded-case breakers.

- RoHS makes sure the breaker is safe for the environment.

- Certifications like CCC, CE, SAA, SEMKO, TUV, and EN show quality and safety.

- Features like thermal-magnetic or electronic trip units, arc quenching, and endurance tests are needed.

Technicians look for certification marks and check if the breaker, like YCB8125PV, meets all the rules for safe isolation, overload, and short-circuit protection.

Gather Tools and PPE

The right tools and personal protective equipment are needed for safe work. Technicians look at wiring diagrams and manuals before they start.

| PPE Item Type | Required Class | Maximum Use Voltage (AC rms) | DC Proof-Test Voltage (avg) | Notes on Use and Maintenance |

|---|---|---|---|---|

| Rubber insulating gloves | Class 0 | 1,000 V | 20,000 V | Check every day, air test before use, retest often |

| Rubber insulating sleeves | Class 0 | 1,000 V | 20,000 V | Same as gloves |

| Rubber insulating blankets | Class 0 | 1,000 V | 20,000 V | Extra insulation, keep as OSHA says |

| Rubber insulating covers | Class 0 | 1,000 V | 20,000 V | Cover live parts, same care as gloves |

| Rubber insulating line hose | Class 0 | 1,000 V | 20,000 V | Insulate tools and lines, keep and test |

Technicians use tools with insulation and make sure PPE is marked, tested, and kept up as OSHA 1910.137 says.

Site Safety Checks

Site safety checks keep workers and equipment safe.

- Technicians use lockout/tagout to turn off power.

- They check for no voltage with tested tools.

- A safety meeting talks about dangers and steps.

- Technicians keep safe distances and keep others away.

- Insulated tools and PPE are used in danger zones.

- Arc-flash risks are checked, and the right PPE is worn.

- Two people do lockout/tagout for high-voltage DC, using two isolators in a row.

- Grounds stay until work is done, and all tools and safety gear are put back before turning power on.

Installation of 1000V DC Circuit Breaker

Power Isolation

Power isolation is the first and most important step. Technicians follow steps to make sure power is off and safe:

- Check that the isolator switch shows a clear break in the circuit. This lets everyone see that power is off.

- Use lockout/tagout (LOTO) steps. This stops power from turning on by accident during the installation of 1000V DC circuit breaker.

- Put on personal protective equipment like insulated gloves and face shields. This protects against leftover voltage.

- Check all power sources, including backups and stored energy in capacitors or battery banks. Disconnect these before starting work.

- Use a voltage tester or multimeter to make sure no live voltage is left in the circuit.

- Pick isolator switches rated for 1000V DC for safe isolation.

- Follow wiring rules to connect both positive and negative terminals the right way. Follow standards like IEC 60947-3 and UL 98.

⚠️ Tip: Never trust just one check. Always use both visual and electrical tests to confirm power isolation.

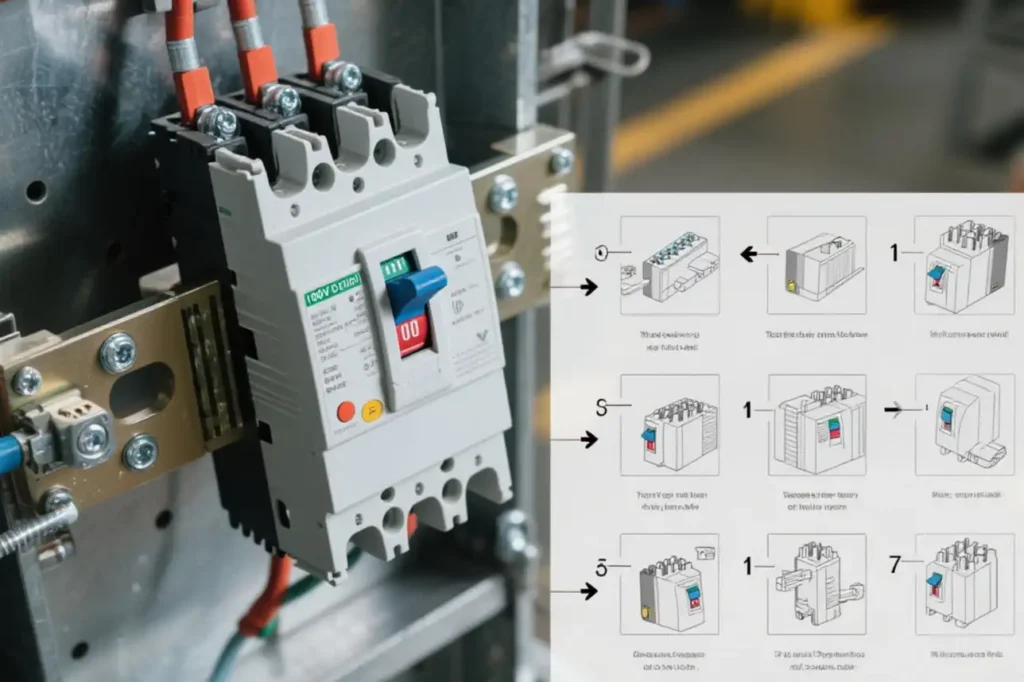

Mounting Methods

Picking the right mounting method helps keep the installation of 1000V DC circuit breaker safe and easy to fix. The table below shows common mounting choices:

| Mounting Method | Description | Advantages | Voltage Applicability | Cost | Safety Features and Notes |

|---|---|---|---|---|---|

| Fixed Mounting | Breaker is bolted or wired straight to the frame or box. | Cheapest, easy to mount in front, reliable. | Up to 600V | Lowest | Power must be off before taking out or changing. |

| Removable Mounting | Breaker plugs into a base that is bolted and wired to the frame. | Can change without new wiring, costs a bit more, easy to mount in front, reliable. | Up to 600V | Moderate | Power must be off before changing. |

| Drawout Mounting | Breaker slides into a base and can be moved by hand or with a tool. | Can fix without turning off all power, very reliable, works for all voltages, safety locks cut power when removing. | All voltages | Highest | Safety locks make sure power is off when removing; only load must be off to take out breaker; allows power "on" testing. |

Vertical mounting is best for most jobs. It helps stop arcs and makes sure the breaker works right. If there is shaking or vibration, technicians must fasten the breaker tightly so it does not move.

Note: The place where you install should not have too much shaking. The temperature should be between -20℃ and +70℃. Humidity should not go over 9.5%. The height should be 2000 meters or less. Stay away from things that cause rust or damage.

Wiring Connections

Wiring connections are very important in the installation of 1000V DC circuit breaker. DC breakers need the right polarity. They use magnets to help stop arcs, so connecting the line and load the right way matters. Technicians look at datasheets and wiring diagrams to make sure the source (line) side goes to the ‘+’ terminal and the load side goes to the ‘-‘ terminal.

Single-pole breakers only switch the live wire. The neutral wire does not go through the breaker. Double-pole breakers switch both live and neutral wires together, which is safer. Protective earth (PE) wires are needed for breakers with extra current protection. This gives good grounding and keeps faults safe.

DC miniature circuit breakers for up to 1000V DC have clear polarity marks. The line side goes to input terminals marked ‘+’, and the load side goes to output terminals marked ‘-‘. Some breakers let you connect at the top or bottom, as long as polarity is right. Wrong wiring can stop the breaker from cutting power during overload or short circuit, which can cause damage or fire.

Tip: AC circuit breakers do not work for DC circuits. DC current does not cross zero, so stopping arcs is harder.

Torque and Polarity

Right torque and polarity keep the installation of 1000V DC circuit breaker safe and working well. All screws and clamps must be tightened to the torque the maker says. Loose connections can get hot, spark, or even catch fire.

Polarity must always be correct. The ‘+’ and ‘-‘ marks show where to put the line and load wires. If polarity is wrong, the breaker may not work or stop power during a fault.

Grounding is also very important. All metal parts that do not carry current, like boxes and supports, must be bonded and grounded. Grounding wires should be sized by NEC tables, with at least 6 AWG copper or 4 AWG aluminum. Equipment grounding wires must match the rating of the overcurrent device. For circuits over 1,000V, the minimum size is still 6 AWG copper or 4 AWG aluminum unless it is part of a cable set. Good grounding limits voltage jumps, keeps voltage steady, and makes sure overcurrent devices work right.

✅ Checklist:

- Tighten all connections to the right torque

- Check polarity at every terminal

- Bond and ground all metal parts as the code says

Testing and Commissioning

Inspection

Inspection is very important after the installation of 1000V DC circuit breaker. Technicians use a checklist to make sure everything is safe. They look for damage, loose wires, and signs of heat or rust. They also check if lockout/tagout steps were done right. A voltage tester helps them see if the breaker is off. Technicians wear safety gear during inspection.

Some wiring mistakes found are:

- Loose wires can get hot and cause problems.

- Too much current makes insulation wear out faster.

- Short circuits happen from broken insulation or loose wires.

- Bad materials or poor work can cause trouble.

- Heat, wet air, or bad gases can hurt insulation.

Technicians clean contacts with strong air and special sprays. They use safe grease on moving parts if needed. For oil-filled breakers, they test the oil to keep things safe.

Functional Testing

Functional testing checks if the circuit breaker works right. Technicians do many tests:

- They look for wear, rust, or heat damage.

- They test insulation with a megohmmeter. It should be above 1 MΩ per kV.

- They check contact resistance with a micro-ohmmeter.

- They test overload by using more current and see if it trips.

- They test short circuit by making a fault and see if it trips fast.

- They open and close the breaker by hand to check movement.

- They test insulation with high voltage to make sure it holds.

- They use thermal cameras to find hot spots.

- They check arc flash parts for safety.

Technicians follow IEC 60947 and NETA rules for these tests. These steps show the breaker is safe and works well.

⚡ Tip: Always write down test results and compare them to what the maker says.

Documentation

Good records are needed after the installation of 1000V DC circuit breaker. Technicians write down all inspection and test steps. They include equipment details, test results, fixes, and safety steps. UL, IEC, or CE papers show the breaker meets world rules. Keeping records helps with future repairs and shows the work follows the law.

Needed records are:

- Steps for installation and safety, like lockout/tagout and PPE.

- Test reports for trip tests and fault checks.

- Papers that show the breaker meets rules.

- Import papers like bills and invoices if needed.

These records prove the work is safe and can be checked later.

Common Mistakes

Polarity Errors

Polarity errors can happen when installing a 1000V DC circuit breaker. These mistakes are dangerous. If the positive and negative wires are switched, a short circuit can happen. This makes a lot of current flow. Wires can burn, and power supplies can break. DC arcs are harder to stop than AC arcs. This means there is a bigger chance of fire. Some circuit breakers only work in one direction. If you install them backward, they might not stop the current during a problem.

| Hazard Aspect | Explanation | Consequence | Mitigation |

|---|---|---|---|

| Polarity Error | Positive and negative wires are switched | Short circuit, burned wires, broken power supplies | Use non-polar DC MCBs |

| Short Circuit Effects | Big current flows quickly | Equipment stops working, fire can start | Use arc chambers and arc grids |

| DC Arc Characteristics | DC arcs are tough to stop | Fire risk goes up | Use breakers with better arc stopping |

| Directional Protection Limitation | Some breakers only protect one way | Breaker may not stop current if installed backward | Use non-polar DC MCBs for both ways |

🔴 Note: Always look at polarity marks before connecting wires. Non-polar DC circuit breakers keep things safer both ways.

Loose Connections

Loose connections happen a lot in high-voltage DC jobs. They can make things too hot, cause sparks, or even start a fire. Technicians must make all connections tight and use the right tools. Checking wires often helps find loose spots, rust, or damage. Torque wrenches help make sure things are tight enough. In places that shake, locking washers or spring washers help keep things tight. Heat and wet air can also make connections loose over time.

Checklist for preventing loose connections:

- Follow what the maker says for installation.

- Check wires and terminals for loose spots or rust.

- Use a torque wrench to tighten right.

- Add locking washers where things shake.

- Use a multimeter to check connections during checks.

Skipping Tests

Not doing tests is a big mistake. If you skip tests, hidden problems can stay in the system. These problems can be loose wires, bad insulation, or power coming from the wrong place. If you do not find these, you could get sparks, broken equipment, or unsafe places. Tests like voltage checks, current checks, and insulation checks show if the breaker is safe and works right. Technicians must use the right test tools and wear safety gear when testing.

⚡ Tip: Always finish all tests before turning on the system. Testing makes sure the circuit breaker can handle full power and keeps insulation strong.

A safe and good installation of a 1000V DC circuit breaker needs many important steps:

- Check the electrical panel for any damage or signs of too much heat before you begin.

- Make sure all circuits are turned off and not live by using meters that work right.

- Follow what the maker says for tightening screws and connecting wires.

- Wear the right safety gear and follow NEC rules for space and labels.

- Make sure all wires are tight and use the right covering to stop dangers.

- Test and check everything to see if the breaker shuts off when it should.

Technicians should always read the newest manuals and follow local rules. Paying close attention to every step during installation of a 1000V DC circuit breaker helps stop expensive problems and keeps everyone safe for a long time.

FAQ

What tools do technicians need for installing a 1000V DC circuit breaker?

Technicians use insulated screwdrivers and torque wrenches. They also need wire strippers and multimeters. PPE like gloves and face shields is important. Every tool must be safe for high-voltage DC jobs.

What steps ensure correct polarity during installation?

Technicians look at wiring diagrams and terminal marks. They connect the line wire to the ‘+’ terminal. The load wire goes to the ‘-‘ terminal. Checking polarity twice helps stop breaker problems and fire risks.

What tests confirm a safe installation?

Technicians check insulation resistance and contact resistance. They test if the breaker trips when needed. Thermal cameras help find hot spots. These tests show the breaker is safe and works well.

What records should technicians keep after installation?

Technicians write down every step of the installation. They record test results and breaker details. They keep certificates that show the breaker meets safety rules. Good records help with repairs and prove safe work.

What mistakes can cause breaker failure?

Mistakes like wrong polarity and loose wires can break the breaker. Skipping tests is also risky. Technicians must follow maker instructions and tighten everything right. Safety checks must be done every time.

See also

How to Determine the Correct 1000V DC Circuit Breaker for Your Needs

Why every solar setup needs a 1000V surge protection device

DC 1000V three in one out solar series connection box

DC 1000V 4 in 2 out solar combiner box

Making Circuit Breakers Materials and Methods Explained