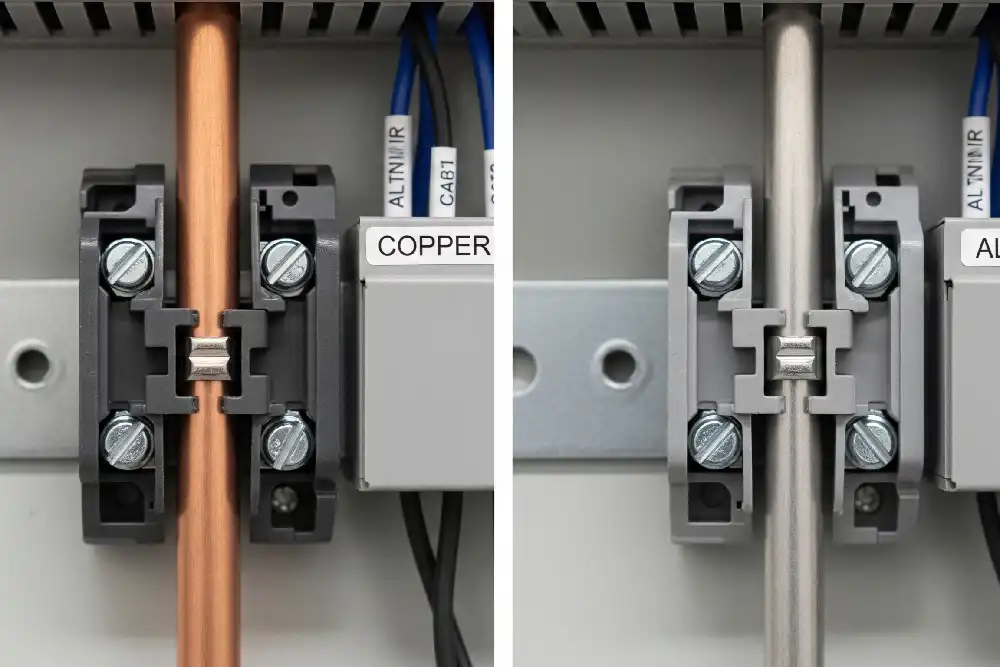

When you pick copper and aluminum terminal blocks, you notice big differences. These differences affect safety and how well things work.

- Copper and aluminum terminal blocks allow electricity to flow differently, with copper providing a better flow and less voltage drop. Copper is also stronger and tougher.

- On the other hand, aluminum terminal blocks weigh less and are cheaper. However, they can rust and weaken faster when used.

You must think about price and how long copper and aluminum terminal blocks will last. Copper does not rust easily and can handle more pressure, while aluminum might need more care during installation. Always choose the type of terminal block that fits your project and its specific requirements.

Key Takeaways

- Copper terminal blocks let electricity move better. This means less energy is lost and power is more steady.

- Aluminum terminal blocks weigh less and cost less money. They are good for projects that need to save money. But, they might need more care over time.

- Copper lasts longer and does not rust easily. It works well in tough places where you need things to work all the time.

- When picking copper or aluminum, think about what your project needs. Look at the price, how heavy it is, and where you will use it.

Comparison

Overview

Copper and aluminum terminal blocks are not the same. They both connect wires and carry electricity. Each one has good and bad points. You should think about how well they conduct electricity, how much they cost, how long they last, and how they react to air and water.

Key Differences

Conductivity

Copper lets electricity move better than aluminum. This means copper wastes less energy. The table below shows how well each one works:

| Material | Conductivity (%) |

|---|---|

| Copper | 90.6 |

| Aluminum | 47.6 |

Both types let electricity flow, but copper is almost twice as good. Copper gives you less voltage drop and more steady power.

Cost

Aluminum is cheaper than copper. If you want to spend less, aluminum terminal blocks might be a good pick. Aluminum also weighs less, so it can be easier to put in.

Durability

Copper lasts longer and is stronger than aluminum. You do not have to check copper as much. Here are some facts about how long they last:

- Copper wire terminations fail less often than aluminum ones.

- Copper oxide is soft and lets electricity pass, but aluminum oxide is hard and blocks it.

- When copper and aluminum touch, aluminum can lose material and break, but copper does not.

- Aluminum gets bigger when hot, which can make connections loose. Copper stays tight and strong.

Oxidation

Copper does not rust or corrode as fast as aluminum. Aluminum makes a hard layer that stops electricity, but copper makes a soft layer that still lets electricity move. Copper works better for a long time, especially in wet or rough places.

Tip: If you work where there is a lot of water or chemicals, copper terminal blocks will last longer and need less fixing.

Copper and aluminum terminal blocks: Properties

Conductivity

Copper and aluminum terminal blocks let electricity move. Copper lets electricity flow better than aluminum. Conductivity means how well electricity travels through a material. Copper has a higher conductivity value than aluminum. Here are the numbers:

- Copper: 56 m/(Ω ∗ mm²)

- Aluminum: 36 m/(Ω ∗ mm²)

Copper has less resistance. This means less heat and less wasted energy. Using copper terminal blocks helps your system work better. The table below shows how good conductivity helps save energy:

| Evidence Description | Impact on Energy Efficiency |

|---|---|

| Good terminal blocks lower resistance and make less heat. | This means you spend less on repairs and your connections last longer. |

| Better terminal blocks can make your system work better. | These blocks lower resistance, so you save time and money on repairs. |

| Cables that meet ASTM/ICEA standards lose less energy. | This makes your whole electrical system work better. |

If you want steady power and fewer problems, copper terminal blocks are a better choice.

Durability

Durability means how long something lasts and how strong it is. Copper and aluminum terminal blocks have different strengths. Copper is stronger and works better in tough places. You can see this difference when things shake or move a lot:

- Copper is stronger than aluminum.

- Copper holds wires tighter for a longer time.

- Copper does not crack or break as easily, so it is more reliable.

Copper keeps connections tight and strong. Aluminum is lighter, but it can get loose or weak faster if things move a lot.

Heat also changes how durable terminal blocks are. Aluminum gets bigger when it gets hot. This can make aluminum connections loose over time. Loose connections can cause sparks and fires. If you use aluminum, you need to check and tighten the wires more often. Copper does not change as much, so you do not have to worry as much about loose wires.

Oxidation

Oxidation happens when metal reacts with air or water. This can change how well a terminal block works. Copper and aluminum react differently to oxidation.

- Aluminum can rust over time, especially outside.

- The protective layer can break down if the weather is bad, causing rust.

- Wet air and big temperature changes can make water form, which speeds up rust.

- Salt in the air near the ocean can damage the protective layer and cause holes.

- Pollution from factories can break the protective layer and cause rust.

Copper makes a soft layer that still lets electricity move. Aluminum makes a hard layer that stops electricity. If you use aluminum terminal blocks outside or in rough places, you may see more rust and need to fix them more often. Copper does not rust as fast, so it lasts longer and works better.

Note: When you pick copper or aluminum terminal blocks, think about where you will use them. Wet, salty, or dirty places can make aluminum wear out faster.

Applications

Typical Uses

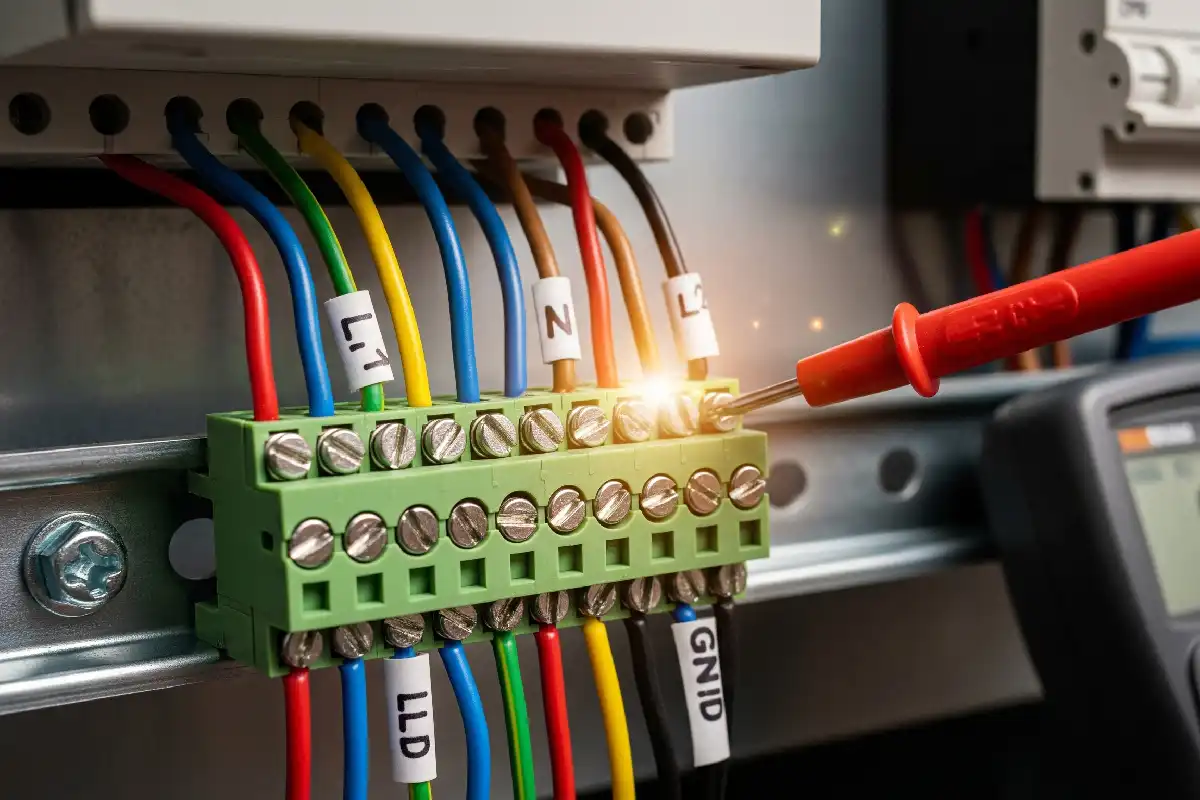

Copper and aluminum terminal blocks are used in many places. Copper terminal blocks are good when you need strong connections. They also work well when you need high conductivity. You can find copper terminal blocks in these places:

- Power distribution panels

- Industrial control systems that need circuit isolation

- Places with lots of shaking, like factories

- Home wiring

- High-voltage areas

Different terminal blocks do different jobs. For example:

- Barrier terminal blocks keep wires apart.

- Feed-through terminal blocks connect many wires together.

- Ground terminal blocks connect wires safely to the ground.

- Power distribution terminal blocks carry lots of current.

Aluminum terminal blocks are best when you want to save money. They are also good when you want to use less weight. You might use them in simple systems or when cost is more important than performance.

Tip: If your workplace has lots of heat or shaking, copper terminal blocks last longer and keep things safer.

Special Scenarios

Sometimes, you have special problems with copper and aluminum terminal blocks. In places where the temperature changes a lot, copper works better. Copper can handle heat well. It has a high melting point and moves heat away fast. Aluminum can get hot if you use it for big currents. New designs help aluminum work better.

You may need to connect copper and aluminum wires together. This can be hard. If you use the wrong connectors, it can cause fires. Water can make the metals react and get hot. To fix this, use mechanical lugs or splice connectors with set screws made for both metals. For panelboards, use transition blocks or bus bars tested for both wire types.

Note: Electricians often see mixed wires in old buildings. Always use connectors that work for both metals to stay safe.

Copper and aluminum terminal blocks are useful. You should pick the right type for your job and where you use it.

When you pick copper or aluminum terminal blocks, you notice some differences. Copper works better and is stronger. Aluminum costs less and is lighter. The table below shows what you should look for when choosing a terminal block:

| Common Mistake | What to Check |

|---|---|

| Wrong connector type | Use connectors made for each material |

| Improper torque | Follow the maker’s instructions |

| Inadequate sizing | Make sure cable size fits the current |

Think about what your project needs. Also, think about where you will use it. Look at the good and bad points before you choose.

FAQ

What makes copper terminal blocks better for high-power systems?

Copper terminal blocks let more current pass through. They have less resistance than aluminum. This means they do not get as hot. Your connections stay strong and safe. Your system works better and does not waste energy.

What problems can you face with aluminum terminal blocks?

Aluminum terminal blocks can get loose after some time. They can make a hard layer that stops electricity. You should check and tighten them often to keep them working.

What should you check before mixing copper and aluminum wires?

You need to use connectors made for both metals. This helps stop rust and keeps things from getting too hot. Always read and follow the maker’s instructions.

What environments suit aluminum terminal blocks best?

Aluminum terminal blocks are good for dry, indoor places. They are best when you want to save money and weight. Do not use them in wet or salty spots.

What is the main reason to pick copper over aluminum?

Pick copper if you want better flow of electricity. Copper lasts longer and needs less fixing. It gives you strong and steady connections.

See also

How to choose wires for your 220V 15 ampere circuit breaker

Why Electricians Recommend the Right Wire Size for 60 Amp Circuit Breakers

What size of wire is suitable for a 30 ampere circuit breaker

What size of wire is needed for a 30 ampere circuit breaker

Can moisture cause circuit breakers to trip