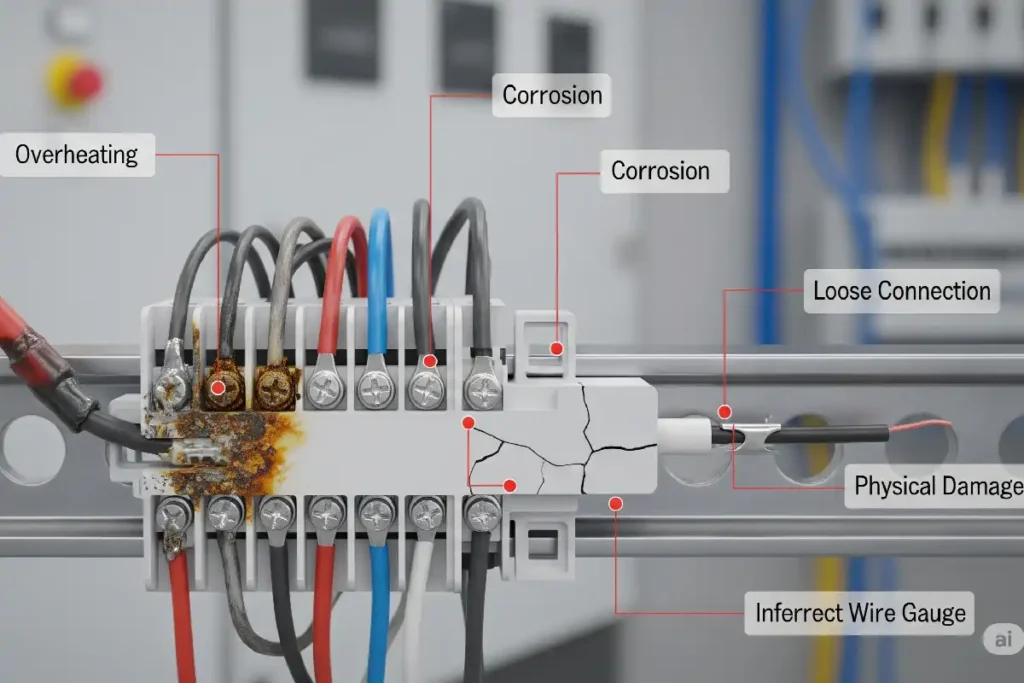

Terminal failure in electrical terminal blocks can happen for many reasons. Poor contact, poor insulation, or poor fixation are common causes. These problems can show up because of corrosion or bad installation. Environmental factors or mechanical stress can also hurt the terminal. Poor contact in the metal conductor makes electrical connections weak. This can cause the system to fail. Poor insulation can make short circuits or leakage happen. This interrupts power or signals. Poor fixation lets terminal parts come apart. This can cause sudden power loss. It can also disrupt how electrical systems work. Terminal block failure can affect safety and reliability.

Key Takeaways

- Bad contact, weak insulation, and loose parts are the main reasons terminal blocks fail. These problems can stop power or signals and cause safety dangers. – Rust, wrong installation, tough weather, and damage from force or heat can harm terminals. These things make terminals less dependable. – Using strong materials, correct ways to install, and good mounting helps stop terminal failure. This keeps connections steady. – Checking and fixing terminals often finds problems early. This makes terminals last longer and keeps electrical systems safer. – Following rules and using approved parts makes sure terminal blocks work well. It also keeps them safe in hard situations.

Terminal Failure Types

Electrical terminal blocks can have a few main problems. These problems can make the terminal block fail. The most common problems are poor contact, poor insulation, and poor fixation. Each problem can change how well the terminal block works. They can also affect how safe it is.

Note: If you know about these problems, you can spot them early. This helps keep terminal connections working well.

Poor Contact

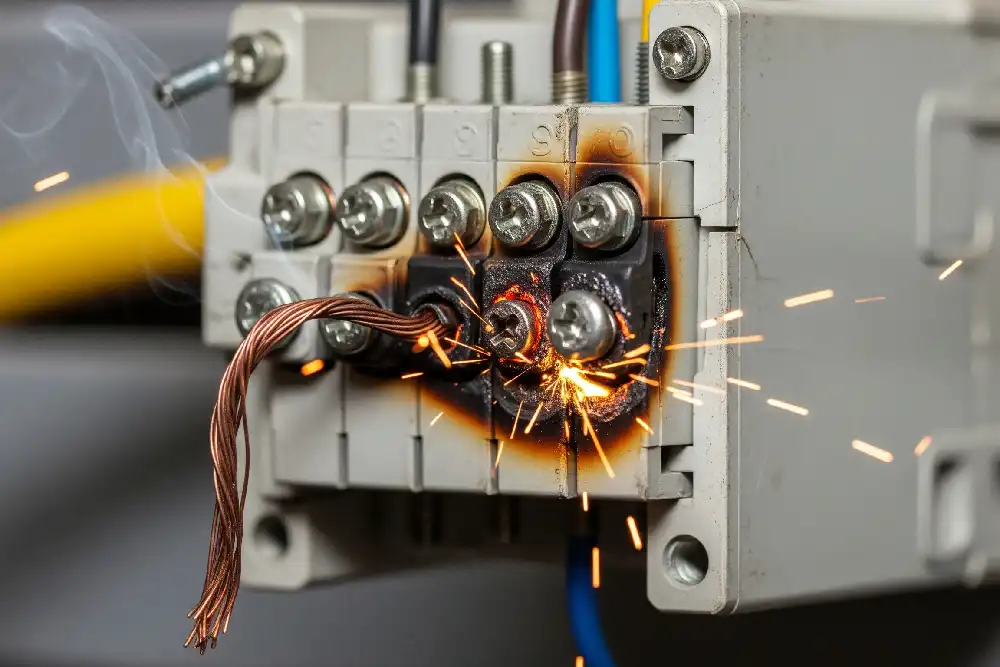

Poor contact happens when the metal conductor does not work right. It cannot carry electricity well. This can happen because of bad design or wrong materials. Sometimes, the surface is rough or there are mistakes in putting it together. When poor contact happens, resistance goes up. This can make the terminal get hot. Sometimes, it can even spark. This can break the terminal or make power or signals stop. Loose connections or rust can make poor contact worse. Not tightening parts enough can also cause it. Over time, these problems can make power stop for a short time. They can also make the system work badly.

- Poor contact in terminal blocks can:

- Break contact parts

- Make holding parts weak

- Stop signals or power

Poor Insulation

Poor insulation means the material that keeps contacts apart is not good. The walls can be too thin. Dust or water can get in. Old materials can also make insulation bad. When this happens, short circuits or leaks can start. The terminal block can break down. These problems make it less safe. The insulator must keep contacts in the right place. It must also stop current from going where it should not. If insulation fails, the terminal block can have low resistance. This can make the system stop working.

- Poor insulation in terminal blocks can:

- Cause short circuits

- Make leaks or breakdowns

- Lower insulation resistance

Poor Fixation

Poor fixation means the terminal block is not held tight. If it is not fixed well, parts can get loose or fall apart. This can happen if the design is not good. Using the wrong materials or putting it together badly can also cause it. Poor fixation can make power stop suddenly. It can also make contact bad or break the product. Shaking, heat, or wear can make it worse. Over time, poor fixation makes the terminal block not last as long. It can also make equipment fail or cause safety problems.

| Fault Type | Impact on Performance and Safety | Causes and Contributing Factors |

|---|---|---|

| Poor Contact | Breaks contact parts, makes conductivity bad, weak holding, stops signals or power, gets hot, and sparks. | Bad design, material problems, rough surfaces, mistakes in assembly, rust, not tight enough, shaking. |

| Poor Insulation | Makes short circuits, leaks, breakdowns, low insulation resistance, and electrical dangers. | Thin walls, dirt, water, old age, dust, organic stuff, bad molding, and bad material quality. |

| Poor Fixation | Makes contact bad, sudden power stops, breaks product, and makes it not last long. | Bad design, wrong materials, bad assembly, shaking, heat changes, wear, and welding problems. |

These problems show why good design, good materials, and checking often are important. This helps stop terminal failure.

Causes of Terminal Block Failure

Knowing why terminal blocks fail helps stop electrical problems. It also keeps systems working well. The next parts talk about what makes terminal blocks fail. They also show how each thing can hurt electrical connections.

Corrosion

Corrosion is a main reason for terminal failure. It happens when water, air, or chemicals touch the metal parts. This makes the metal react and get weak. Corrosion makes it harder for electricity to flow. It can cause signals to stop and make things too hot. Sometimes, it can even make a short circuit. Different places can make corrosion happen faster:

- Water and wet air make corrosion happen faster inside terminal blocks.

- Salt in sea air and chemicals like sulfur or ammonia hurt metal quickly.

- Dust and dirt from factories land on terminals and make corrosion worse.

There are different kinds of corrosion. Galvanic corrosion happens when two different metals touch. Moisture corrosion hurts both the terminal and the wires. Even with seals, water can still get in over time. Special coatings like tin, silver, or gold slow down corrosion. Using special grease and heat shrink tubing also helps keep water out.

Tip: Check terminal blocks often and use anti-corrosive coatings. This helps them last longer in tough places.

Improper Installation

Improper installation is another big reason for terminal block failure. Mistakes when putting parts together can cause poor contact, poor insulation, or poor fixation. Some common mistakes are:

- Screws that are too tight or too loose make terminals weak or broken.

- Using the wrong wire size or not stripping wires right makes weak connections.

- Dirt, sharp bits, or rust on screws stop them from tightening well.

- Using crimping tools the wrong way makes bad or broken connections.

These mistakes can make contact unstable. They can also cause short circuits or break the terminal. Industry checks show that tests like torque checks and continuity tests help find these problems early.

Note: Always follow the maker’s rules for wire prep and screw tightness. This helps stop failures from bad installation.

Environmental Factors

Environmental factors are very important for terminal block reliability. Terminals need to handle dust, water, heat, and shaking. If not, they can break fast. Some main environmental causes are:

- Wet air and water corrode contacts and make insulation weak.

- Dust lands on terminals and hurts both insulation and contact.

- Very hot or cold weather can make plastic soft and metal change shape.

- Shaking and bumps can make connections loose and parts tired.

- Chemicals need terminals made from strong materials.

Picking terminal blocks with the right protection, like IP ratings, helps stop these problems. Strong design and good locks also keep terminals working in hard places.

| Environmental Factor | Impact on Terminal Blocks | Example of Failure |

|---|---|---|

| Humidity/Moisture | Corrosion, insulation breakdown | Overheating, short circuit |

| Dust | Insulation loss, contact degradation | Signal loss, increased resistance |

| Temperature | Material deformation, poor connections | Loose terminals, system failure |

| Vibration/Shock | Mechanical fatigue, loose connections | Intermittent faults, disassembly |

| Chemicals | Material corrosion, insulation damage | Rapid terminal failure |

Mechanical and Thermal Issues

Mechanical and thermal stress are big reasons for terminal failure. These stresses come from shaking, bumps, and changes in temperature. When terminals get shaken or heated again and again, they can crack or get loose. This makes contact bad and the system unreliable.

Tests show that heat and shaking together often cause failure. For example, heat can make screws loose. Shaking can make parts fall apart. Terminals must meet tough rules for strength and heat to work well.

The table below shows some important test rules and limits for terminal blocks:

| Test Type | Standard / Method | Threshold / Temperature | Purpose / Description |

|---|---|---|---|

| Glow-wire test | IEC 60695-2-11 | Up to +960°C | Checks if terminal block housing can handle heat without burning. |

| Temperature Index (TI) | IEC 60216-1 | +105°C (UL 94 V2) | Shows how long the terminal lasts under heat; checks strength over time. |

| +125°C (UL 94 V0) | |||

| Relative Thermal Index (RTI) | UL 746 B | +125°C (UL 94 V2) | Shows highest temperature before insulation gets too weak. |

| +130°C (UL 94 V0) | |||

| Dry heat climatic test | IEC 60068-2-2 | +85°C for 168 hours | Checks if terminal stays strong and works after lots of heat. |

| Damp heat cyclic test | IEC 60068-2-30 | +40°C (2 cycles) | Tests if terminal can handle wet and warm air without changing shape. |

| +55°C (1 cycle) | |||

| Needle flame test | IEC 60947-7-1/-2 | N/A | Checks if terminal can stop fire from spreading. |

Terminals that pass these tests do not crack, get loose, or burn. This keeps electrical connections safe and working, even in tough places.

Callout: Meeting strength and heat limits is key to stopping terminal block failure in hard environments.

This cause review shows that corrosion, bad installation, environmental factors, and mechanical or heat problems are the main reasons for terminal block failure. Knowing these reasons helps stop problems and keeps electrical systems safe.

Solutions of Electrical Terminal Blocks

Electrical terminal blocks need good solutions to work well. These solutions help stop problems like poor contact, poor insulation, and poor fixation. Checking and fixing them often is also important.

Prevent Poor Contact

To stop poor contact, use strong materials and connect wires the right way. Electrolytic copper and copper alloys help electricity flow better. Silver plating keeps resistance low and stops oxidation. Terminal shells made from thermoplastic materials like nylon 6.6 and polycarbonate keep the housing and insulation stable.

Best ways to prevent poor contact:

- Use ferrules crimped with multi-die crimpers. This holds stranded wires tight and makes sure all strands touch.

- Do not solder wires. Soldering can hurt insulation and cause oxidation.

- If you do not use ferrules, twist stranded wires. Clamp them under the screw head tightly for a good seal.

- Pick terminal blocks with the right current and voltage ratings. Make sure the wire gauge and connector type match.

- Strip wires to the right length. Put them in firmly but do not overtighten.

- Check wires often with pull tests and inspections. This finds loose strands early.

- Use strain relief clamps. These stop wires from breaking when pulled or bent.

Tip: Clean and polish contact surfaces before tightening. Use conductive paste to make connections stronger and more reliable.

Prevent Poor Insulation

To stop poor insulation, use certified insulating materials and keep everything clean. Thermoplastics like polyamide (PA66), glass-fiber reinforced polyamide, and polycarbonate are strong insulators and do not burn easily. Technical ceramics and epoxy resin resist heat and chemicals.

| Material Type | Examples | Key Properties Relevant to Insulation |

|---|---|---|

| Thermoplastics | Polyamide (PA66), Polycarbonate (PC) | High dielectric strength, flame retardancy |

| Technical Ceramics | Ceramic | High heat resistance, chemical stability |

| Duroplasts | Epoxy resin (EP), Germin KrG | Dimensional stability, flame protection |

Ways to keep insulation strong:

- Use multilevel installation terminal blocks with spring pressure connection. This keeps wires in place.

- Pick insulating parts that work well with electricity.

- Keep dust, flux, and moisture away from the insulator.

- Check insulating materials before putting them together. Make sure they have good insulation resistance.

- Follow standard steps when using terminals. This keeps insulation safe.

Note: Always check each batch of insulation materials for certification. Test insulation resistance to stop failures.

Secure Fixation

Terminal blocks must be held tight to work well and avoid poor fixation. Many mounting systems and fasteners help keep them steady.

Common ways to fix terminal blocks:

- Screw-in terminal blocks use screws to hold wires. Tighten screws carefully so nothing breaks.

- Spring-cage and push-in terminal blocks use springs to keep wires in place.

- Pluggable terminal blocks have plugs and sockets for quick removal.

- DIN rail mount terminal blocks are easy to put in control cabinets.

- Flange, clamp, and self-adhesive fixing methods work for different sizes.

- Stainless steel screws do not rust. Zinc-plated screws are good for normal places.

Fasteners and mounting systems that help:

- Use strong screws, machine screws with nuts, and shims if needed.

- Barrier terminal blocks are best for high-voltage jobs.

- Push-in terminals make wire insertion easy and stop overtightening.

Callout: Change loose terminal blocks right away. Never use loose or fallen terminals. Use the right tools to tighten or loosen screws and bolts. This stops damage.

Maintenance and Inspection

Checking and fixing terminal blocks often makes them last longer and helps stop failures. Planned checks lower failure rates and help things work better.

Ways to find problems early:

- Look for rust, dirt, damage, and loose parts.

- Measure resistance to find short circuits.

- Test conduction to check if contacts work.

- Shake and test for contact problems under stress.

- Test insulation resistance to stop insulation failures.

- Check if plugs and sockets fit together.

- Test how strong the structure is.

- Measure crimped wires to make sure they touch well.

Motor Circuit Analysis (MCA) finds early signs of terminal block failure. It checks resistance and connection faults. Training staff and checking parts during planned maintenance lowers failure rates.

Alert: Good terminal blocks must meet standards like UL, IEC, RoHS, and ETL. These rules make sure they are made and tested well. This keeps them safe and reliable.

Summary Table: Solutions of Electrical Terminal Blocks

| Solution Type | What It Addresses | Key Actions for Reliability |

|---|---|---|

| Prevent Poor Contact | Weak electrical connection | Use quality materials, proper crimping, routine inspections |

| Prevent Poor Insulation | Short circuits, leakage | Select certified insulation, clean assembly, electrical testing |

| Secure Fixation | Loose or fallen terminals | Use proper mounting systems, high-quality fasteners, prompt replacement |

| Maintenance & Inspection | Early failure detection | Scheduled checks, resistance tests, staff training |

The solutions for electrical terminal blocks focus on stopping problems, making them reliable, and checking them often. These steps keep electrical systems safe and working for a long time.

Knowing why terminal failure happens in electrical terminal blocks keeps systems safe. Fixing poor contact, poor insulation, and poor fixation makes things work better. Using prevention tips and checking often helps a lot.

- Finding problems early saves money and keeps things working.

- Checking and cleaning parts often helps them last longer and work better.

- Getting help from experts makes sure safety rules are followed and lowers accident risks.

These actions help electrical systems work well and last longer. Taking care of them often keeps people and equipment safe from harm.

FAQ

What is the main sign of terminal block failure?

Loose or colored wires are a big warning sign. The terminal might feel hot or have burn marks. Sometimes, you might smell something burning or the system just stops.

What materials work best for terminal blocks?

Copper alloys and silver-plated contacts let electricity flow well. Polyamide and polycarbonate are good for insulation. Stainless steel screws do not rust. These materials help stop poor contact and poor insulation.

What causes overheating in terminal blocks?

Overheating usually happens when contact is not good. Wires that are loose, rusted, or the wrong size can cause this. High resistance makes the terminal block heat up.

What should someone check during terminal block maintenance?

Look for rust, dirt, loose screws, or broken insulation. Test resistance and make sure wires are tight. This helps find problems early.

What standards apply to electrical terminal blocks?

UL, IEC, RoHS, and ETL are common standards. These rules help keep terminal blocks safe and high quality.

See also

How many wires can be connected to one terminal block

What Is a Terminal Block and How Does It Work

What You Should Know About Terminal Blocks and Their Other Names

How many types of wiring terminals are there?

How to Test Molded Case Circuit Breakers in 3 Easy Steps