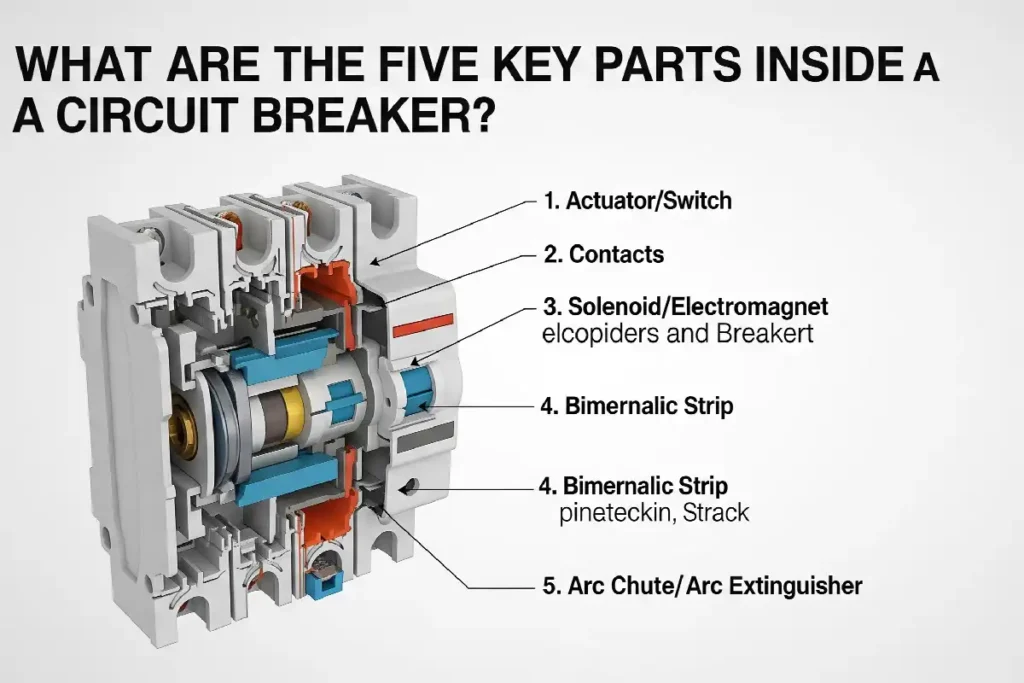

You will find the main components of a circuit breaker inside every primary circuit breaker. These main components of circuit breaker include the frame, operating mechanism, contacts, arc extinguisher, and trip unit. These main components of circuit breaker are present in almost every electrical circuit breaker and vacuum circuit breaker. Industry standards emphasize that these main components of circuit breaker are essential for both home and industrial applications. Each of these main components of circuit breaker plays a crucial role in keeping people safe from electrical hazards. These main components of circuit breaker are always present, even in vacuum circuit breakers and other types.

The main components of circuit breaker work together to protect and ensure the circuit breaker functions properly in all settings, including vacuum circuit breakers.

Key Takeaways

- Circuit breakers have five main parts. These are the frame, operating mechanism, contacts, arc extinguisher, and trip unit. They all work together to keep electrical systems safe.

- The frame protects the inside parts of the breaker. It also insulates them. This helps the breaker stay strong and safe during high currents.

- The operating mechanism opens or closes the circuit very fast. It stops electricity from flowing when there are problems. Regular maintenance is important for safety.

- Contacts control how electricity flows. They do this by connecting or separating. Keeping contacts clean and not damaged helps the breaker work well.

- The arc extinguisher stops dangerous electric arcs quickly. This helps prevent fires and damage. The trip unit finds faults and makes the breaker open.

Main Components of Circuit Breaker

If you look inside a main circuit breaker, you will see five main parts. These parts work together to keep your electrical system safe. You will find these parts in almost every kind of circuit breaker, even vacuum circuit breakers. Knowing what each part does helps you understand why safety and reliability matter in circuit breaker design.

Frame Component

The frame is the outside shell of the main circuit breaker. It acts like armor and protects the sensitive parts inside. The frame supports and insulates the other parts. It keeps dust, water, and accidental touches away from the inside. The molded frame gives the strength needed when the breaker stops a big current. This strength helps the main circuit breaker work safely.

Most frames use special materials that insulate, like glass-polyester or thermoset resin. These materials stop electricity from leaking out. They also keep the breaker safe when it gets hot. Bigger frames are used for higher currents, sometimes up to 6300A. These are found in factories to protect against overloads and short circuits.

The frame does more than hold the parts together. It insulates, protects, and helps the main circuit breaker work in tough places.

Operating Mechanism

The operating mechanism lets you open or close the circuit. When you flip the switch or the breaker trips, this part moves the contacts apart. It stops electricity from flowing. The operating mechanism stores energy with a spring. It releases energy fast to separate the contacts in an emergency.

There are different types of operating mechanisms:

- Thermal mechanisms use strips that bend when heated by too much current.

- Magnetic mechanisms use solenoids to trip the breaker quickly during a short circuit.

- Thermal-magnetic breakers use both methods for better protection.

- Hydraulic-magnetic breakers use a coil and fluid chamber for tripping that does not depend on temperature.

- Hybrid breakers use both mechanical and electronic parts for faster action.

The operating mechanism must work every time. If it fails, the main circuit breaker might not open or close when needed. This can cause damage or safety problems. Regular care, like oiling moving parts and checking for damage, keeps the mechanism working well. New circuit breakers have sensors and monitors to check the health of the operating mechanism. These tools help you find problems early and prevent failures.

Tip: Most circuit breaker failures happen when they open or close at the wrong time, or do not work at all. Keeping the operating mechanism in good shape is important for safety.

The main parts of a circuit breaker, especially the frame and operating mechanism, are the base for safe operation. These parts are in every main circuit breaker, at home or in a factory. By learning what these parts do, you can see why checking and caring for circuit breakers is important.

Contacts in Circuit Breaker

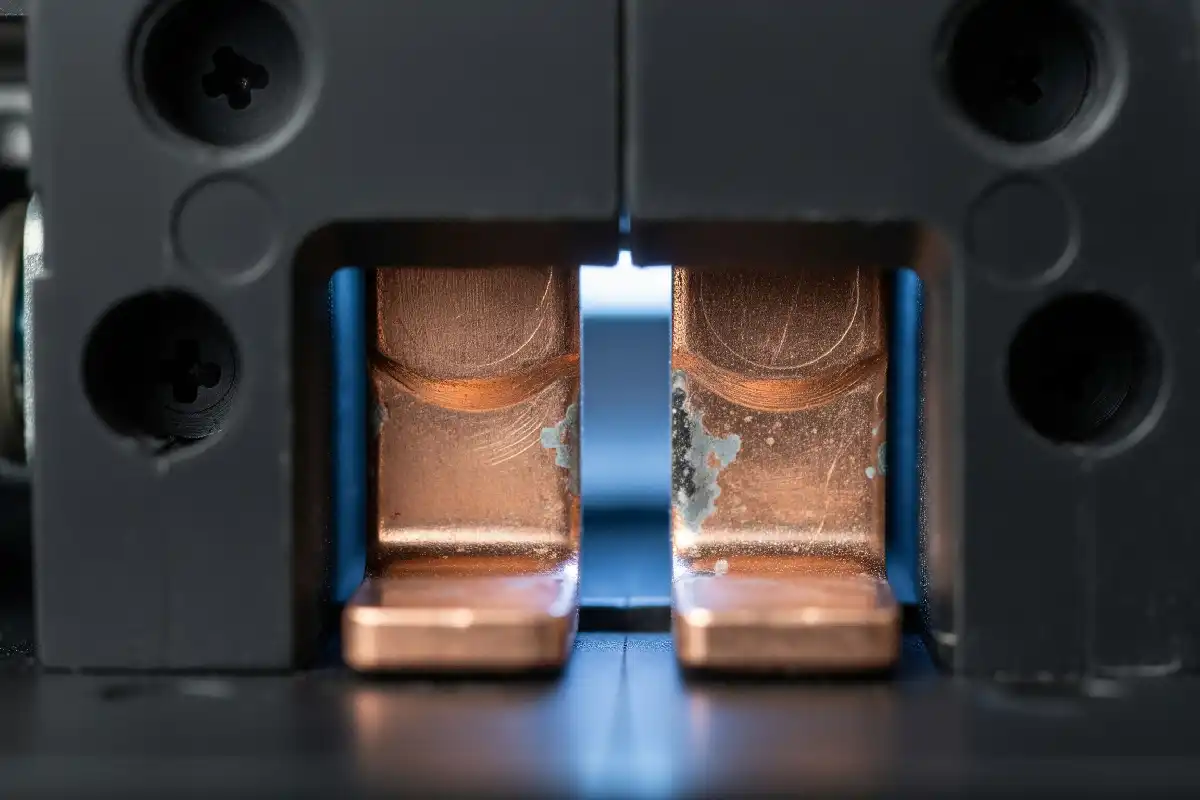

Contacts are important parts inside every circuit breaker. You find contacts in electrical and vacuum circuit breakers. These parts control electricity by opening and closing the circuit. In a vacuum circuit breaker, contacts work in a sealed chamber. This chamber helps stop arcs from hurting the system.

Fixed and Movable Contacts

There are two main types of contacts in a circuit breaker. One type is the fixed contact. It stays in one spot and gives a steady path for current. The other type is the movable contact. It pushes against the fixed contact to close the circuit. When the breaker trips, the movable contact pulls away. This stops the flow and protects your system from too much current.

- Fixed contacts have a big surface to carry high currents.

- They attach to the body and do not move.

- Movable contacts connect and disconnect from the fixed contact.

- The operating mechanism moves the movable contact.

- This movement helps control the arc when contacts separate.

Tip: In a vacuum circuit breaker, contacts work inside a sealed chamber. This design puts out the arc fast and keeps contacts clean.

Contact Assembly Details

The contact assembly uses special materials to handle high currents. Most contacts use copper or silver alloys. These metals carry electricity well and last longer. In vacuum circuit breakers, copper–chromium alloys are common. These materials fight damage from arcs and help the breaker work well.

| Contact Type | Material Used | Main Function |

|---|---|---|

| Fixed Contact | Copper/Silver Alloy | Steady current path |

| Movable Contact | Copper–Chromium Alloy | Opens/closes circuit, arc control |

Using the breaker often and high currents can wear down contacts. You might see cracks, changes on the surface, or oxide layers. These problems make resistance go up and cause overheating. If contacts do not line up or press together right, the breaker may not work. Keeping contacts clean and checking for wear helps your vacuum circuit breaker last longer.

Note: Contact materials that conduct well lower heat and energy loss. This keeps your circuit breaker safe and working well.

Arc Extinguisher in Electrical Circuit Breaker

Arc Quenching Function

When you open a circuit breaker, an electric arc appears. This arc gets very hot and can hurt the breaker. The arc extinguisher is a key part inside the circuit breaker. Its main job is to stop the arc fast and safely. This helps prevent fires and keeps your system working.

Different circuit breakers use different ways to put out arcs. Here is a table that shows how each type works and what it does for safety:

| Circuit Breaker Type | Arc Extinguishing Method | Primary Safety Function |

|---|---|---|

| Vacuum Circuit Breaker (VCB) | Vacuum inside a ceramic blister | Quickly puts out arc with vacuum, lowers fire risk and maintenance. |

| Air Circuit Breaker (ACB) | High-speed compressed air jet | Blows out arc fast to stop damage and fire, good for medium/high voltage. |

| Oil Circuit Breaker (OCB) | Insulating oil forming hydrogen bubble | Stops arc from coming back by using pressure, gives insulation after arc is gone. |

| Sulfur Hexafluoride CB (SF6CB) | Sulfur hexafluoride gas (SF6) | Uses strong insulating and cooling gas to put out arc safely. |

Modern arc extinguishers use many ways to stop arcs. You might see mechanical, magnetic, grid, or vacuum arc suppression in different breakers. These methods stretch, cool, or split the arc so it goes away fast. Vacuum circuit breakers use a vacuum to stop the arc in less than 10 milliseconds. SF6 gas breakers use special gas to cool and stop the arc. These ways help protect your system from too much current and keep your equipment safe.

Tip: Fast arc quenching lowers fire and damage risk. It also cuts down the energy released when there is too much current.

Importance for Safety

You count on the arc extinguisher every time your breaker works. Without it, the arc could burn contacts, melt parts, or start a fire. The arc extinguisher keeps heat and pressure inside the breaker safe. This means you get good protection from too much current and avoid danger.

Vacuum circuit breakers are very safe. They use a vacuum to stop arcs, so the arc does not last long. This protects your equipment and saves on repairs. You also avoid dangers like explosions and fires. Load break switches use fast materials to stop arcs before they cause harm. These features make your system safer and more reliable.

Arc extinguishers are important for overcurrent protection. They help your breaker stop fault currents and keep things running well. You can feel safe knowing your breaker can handle danger and protect your home or business.

- Arc extinguishers:

- Stop fires and explosions

- Protect contacts and other parts

- Lower repair needs

- Give good overcurrent protection

Note: Always make sure your breaker has a working arc extinguisher. This is the best way to keep your system safe.

Trip Unit in Components of Circuit Breakers

The trip unit is a very important part inside a circuit breaker. This part helps find problems and makes the breaker open when needed. The trip unit protects your system from too much current, overloads, and short circuits. It uses new technology to keep everything safe.

Fault Detection

Modern circuit breakers have different kinds of trip units. Each kind finds problems in its own way. The table below shows how each trip unit works and what it does:

| Trip Unit Type | Fault Detection Method | Description |

|---|---|---|

| Thermal-Magnetic (TMTU) | – Thermal (bimetallic strip) for overload detection (delayed response) – Magnetic (electromagnetic device) for instantaneous short-circuit detection |

Uses heat expansion of bimetal strip to trip on overload; electromagnetic coil trips instantly on high current |

| Electronic (ETU) | – Microprocessor processes current signals – Provides multiple protection functions: long time-delay, short time-delay, instantaneous, ground-fault |

Offers adjustable and programmable trip settings with digital processing for precise fault detection |

| Earth-Fault Protection | – Detects ground faults using pickup and delay settings – Can have definite-time or current-dependent delay |

Detects ground faults and trips the breaker to prevent hazards |

| Residual Current Device (RCD) | – Detects differential fault currents (up to 3 A) | Trips when it senses leakage current, protecting against electric shock |

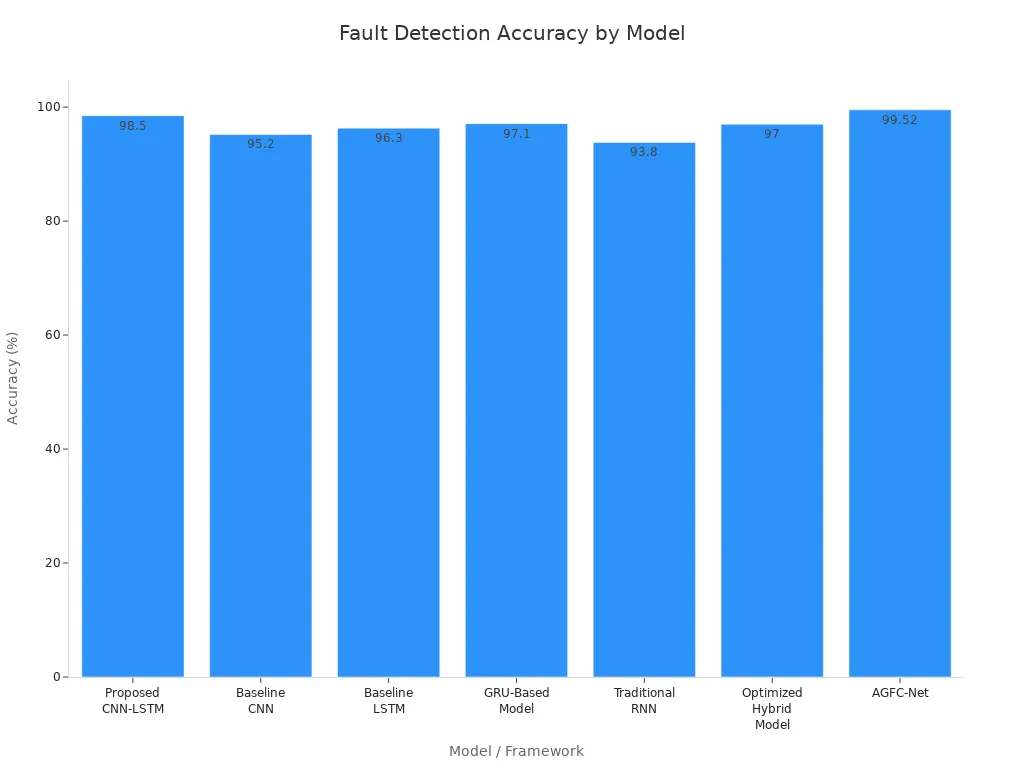

Trip units use heat to find too much current. The bimetallic strip bends when it gets hot and makes the breaker trip. Electronic trip units use sensors and computers to find problems like overcurrent and ground faults. Some trip units can find problems with almost perfect accuracy, as you can see in the chart below.

Tip: New trip units protect better because they find problems faster and more accurately than old ones.

Tripping Mechanism

The tripping mechanism makes the breaker open when the trip unit finds a problem. Here are the steps for how it works:

- The trip unit finds too much current, a short circuit, or a ground fault.

- The trip unit sends a signal to the tripping mechanism.

- The tripping coils and relays turn on and open the breaker.

- The circuit stops, so electricity cannot flow and damage things.

- You can reset the breaker after you fix the problem.

This process follows the main rules for how circuit breakers trip. The trip unit and tripping mechanism work together to protect against overloads, short circuits, and heat. If either part fails, your system loses its main protection. Always check these parts to keep your home or business safe.

Note: Trip units in new circuit breakers can be fixed or changed. You can set them for different current levels and protection needs.

Vacuum Circuit Breaker Features

Unique Components

A vacuum circuit breaker has special parts inside. These parts make it different from other circuit breakers. They help the vacuum circuit breaker work fast and safely. It works well in places with high voltage. Here is what you find inside a vacuum circuit breaker:

- Vacuum Envelope: This part keeps a strong vacuum around the contacts. The vacuum stops the arc from coming back after the contacts open.

- Contacts: There are fixed and movable contacts inside the vacuum. These contacts sit on an arc fence panel. They break the circuit when needed.

- Arc Shielding: The shield protects the vacuum chamber from heat made by the arc. It keeps the inside clean and safe.

- Arc-Extinguishing Contact System: This system puts out the arc in just a few milliseconds. It is made for fast action in high-voltage places.

- Operating Mechanism: Springs or magnets move the contacts inside the vacuum. The mechanism is built for vacuum interruption.

All these parts work together. They make the vacuum circuit breaker safe and reliable for many uses.

Differences from Other Types

A vacuum circuit breaker is not the same as other types. You can see big differences when you compare it to oil circuit breakers. The table below shows what makes each type special:

| Factor | Vacuum Circuit Breaker | Oil Circuit Breaker |

|---|---|---|

| Arc Quenching | Uses vacuum to stop the arc instantly | Uses oil, which heats and forms gas to put out the arc |

| Maintenance | Needs very little care; no oil to check | Needs regular oil checks and cleaning |

| Safety | No fire or explosion risk from vacuum | Oil can catch fire or explode if it leaks or overheats |

| Size & Weight | Small and light; easy to install | Large and heavy due to oil tanks |

| Environmental Impact | No oil or gas to dispose of; safe for the environment | Oil leaks can harm the environment |

| Cost & Lifespan | Costs more at first but lasts longer with less upkeep | Cheaper at first but needs more care over time |

| Best Use | Great for medium and high-voltage applications indoors | Used in older or very high-voltage systems |

A vacuum circuit breaker works fast and clean. It is safe and does not leak oil or cause fires. The vacuum helps it last longer and work well in tough places. Vacuum circuit breakers are best for high-voltage jobs. They are good where safety and low maintenance are important.

You now know what is inside a circuit breaker and why each part is important for safety. Here is a simple look at how these five parts work together:

| Component | What It Does in the Circuit Breaker |

|---|---|

| Frame | Keeps the inside parts safe, holds everything, and stops the arc from spreading. |

| Operating Mechanism | Lets you open or close the contacts to stop or start electricity. |

| Contacts | Let electricity move through when closed, making the circuit work. |

| Arc Extinguisher | Puts out the arc that happens during a problem so nothing gets damaged. |

| Trip Unit | Finds bad current and tells the operating mechanism to open the contacts. |

Knowing about these parts helps you find problems early and stay safe when working with circuit breakers. If your breaker trips a lot, smells burnt, or makes buzzing noises, always get a trained professional to check and fix it.

FAQ

What does a circuit breaker do in your home?

A circuit breaker stops electricity when there is too much current. You stay safe from fires and shocks. It protects your wires and devices.

What is the arc extinguisher’s main job?

The arc extinguisher puts out the electric arc quickly. You avoid damage and fire. This part keeps your circuit breaker safe.

What happens if contacts inside the breaker wear out?

Worn contacts cause poor connections. You may see overheating or breaker failure. You should replace contacts to keep your system safe.

What makes vacuum circuit breakers different?

Vacuum circuit breakers use a sealed vacuum to stop arcs. You get fast action and less maintenance. These breakers work well in high-voltage places.

What should you do if your breaker trips often?

You should check for overloaded circuits or faulty devices. If you see burning smells or buzzing, call a professional. You stay safe by fixing problems early.

See also

What Components Make Up a Standard MCCB

How Air Circuit Breakers Differ from Vacuum Circuit Breakers

What is the frame size of a 60a circuit breaker

The frame size of a 500 ampere circuit breaker

What is the highest rated circuit breaker?