The Micro Circuit Breaker OEM workflow shows the steps that makers use to build very reliable circuit breakers. Careful work is important at every step, from picking materials to checking the finished product. Machines do hard jobs, but trained workers watch each step and make changes when needed. Strong rules help stop mistakes and keep quality high. All these steps help make safe and trustworthy micro circuit breakers.

Key Takeaways

- Micro circuit breaker OEMs make safe breakers by following strict rules. They use skilled workers and machines to help them.

- The production workflow has welding, assembly, inspection, electronics, testing, and tooling. These steps help make sure the breakers are high quality.

- Factories use certified materials like silver alloys and strong plastics. These materials help make the circuit breakers strong and safe.

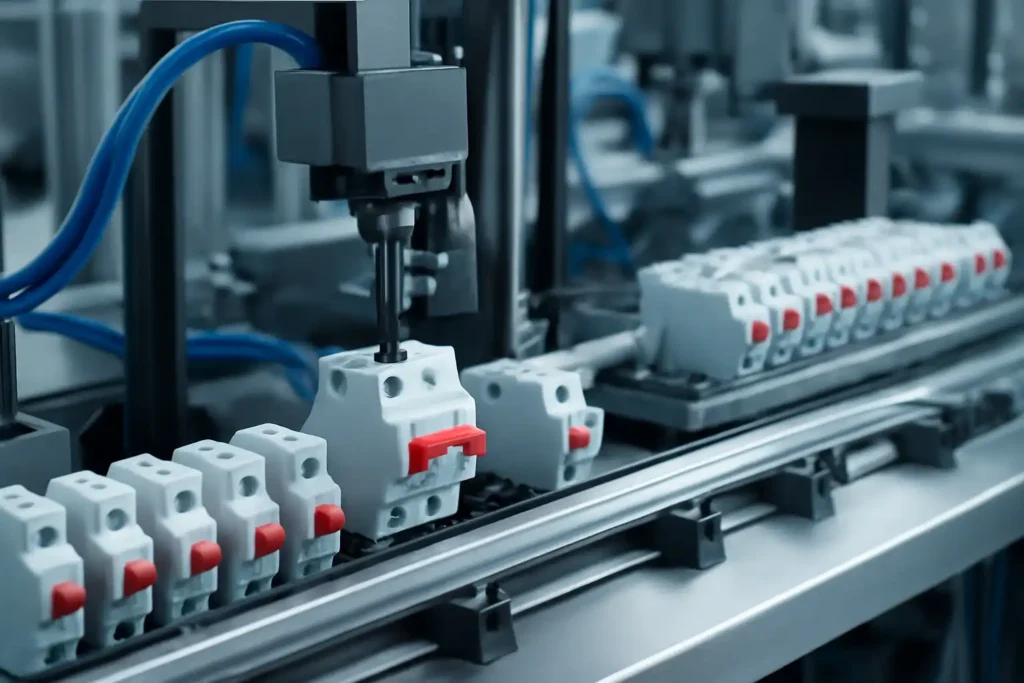

- Automated assembly lines make production faster and lower mistakes. Smart machines and controls help keep the quality the same.

- Welding and preassembly steps join parts tightly. They also check for mistakes early to keep the product safe.

- In-line checks and careful testing find problems before shipping. This makes sure every breaker works the right way.

- Good tooling and careful packaging protect breakers during making and shipping. This keeps them safe and easy to move.

- Traceability follows each breaker from start to end. This helps fix problems fast and builds customer trust.

Micro Circuit Breaker OEM Overview

OEM Role

OEM means Original Equipment Manufacturer. In micro circuit breakers, an OEM makes products for other brands. The Micro Circuit Breaker OEM does everything from design to testing. They use their own factories and machines. Skilled workers help make sure each circuit breaker is made well.

A Micro Circuit Breaker OEM must follow safety and performance rules. Certifications like IEC and UL set standards. These certifications tell the OEM how to make and test products. By following these rules, the OEM makes sure circuit breakers work safely. The factory uses machines to keep quality high and work fast. Skilled staff watch every step and check the machines.

Note: OEMs help make micro circuit breakers safe for homes, factories, and offices.

Workflow Steps

The Micro Circuit Breaker OEM workflow has six main steps. Each step helps make a strong product. The steps are:

- Welding: Workers and machines join metal parts. This makes strong connections for electricity.

- Assembly: Staff and robots put all parts together. They build the inside and outside of the circuit breaker.

- Inspection: Teams check each unit for mistakes. They make sure every part meets standards.

- Electronics: Technicians add electronic parts. These help the breaker sense problems and react fast.

- OTS (Operational Testing System): Each circuit breaker gets tested for aging and performance. These tests make sure the breaker lasts a long time.

- Tooling: The factory uses special tools to shape parts. This keeps every product the same.

| Procedure | Purpose |

|---|---|

| Welding | Joins metal parts for safe connections |

| Assembly | Puts all parts together |

| Inspection | Checks for quality and errors |

| Electronics | Adds smart sensing parts |

| OTS | Tests for long-term reliability |

| Tooling | Shapes parts for consistency |

Standardizing the process is very important in the Micro Circuit Breaker OEM workflow. The factory uses strict quality checks and special inspections for each product. Automation and testing help keep circuit breakers safe. The OEM picks suppliers with certifications like CE, RoHS, and ISO9001. Skilled staff follow clear rules at every step. These actions help the OEM meet global standards and deliver trusted products.

- The factory has seven automated lines for making lots of products.

- Every circuit breaker gets tested for safety and performance.

- Certifications like CCC, CE, and RoHS show the product meets global standards.

The Micro Circuit Breaker OEM workflow uses both machines and people. Automation makes work fast and steady. Skilled staff pay close attention and solve problems. Together, they make sure every micro circuit breaker is ready to use.

Design & Materials

Product Specs

Micro circuit breakers must follow strict rules for safety. They are made to protect electrical systems from too much power or short circuits. The table below lists the most important product specs for micro circuit breakers in OEM production.

| Specification Aspect | Details |

|---|---|

| Tripping Mechanisms | Thermal (overload), Magnetic (short circuit) |

| Trip Curve Characteristics | B, C, D, K, Z |

| Configurations (Number of Poles) | 1P, 1P+N, 2P, 3P, 3P+N, 4P |

| Breaking Capacities | Up to 25 kA |

| Rated Currents | Up to 63A |

| Voltage Ratings | Up to 480Y/277 V AC, 60/125 V DC |

| Interrupt Ratings | Up to 30 kA |

| Features | Real contact position indication, bottom-fixing auxiliary contact |

| Compliance & Certifications | IEC, UL, CSA, UL1077, IEC60898-1, TUV, CE, CCC |

| Installation Features | DIN rail mount, screw clamp terminations |

| OEM Requirements | Compact size, certified quality, ease of installation |

Many times, manufacturers pick a 3-pole design with a C trip curve for factories. These breakers can handle up to 63A and 480V AC. They can stop up to 10 kA of current. DIN rail mounting and screw clamps make putting them in easy. Certifications like UL1077, IEC60898-1, and CE show the breaker meets world rules. Some features, like thermal magnetic design and LED trip lights, help people see if the breaker is working.

Material Choice

Choosing the right materials is very important for micro circuit breakers. Each part uses special materials for its job. The table below shows common materials and why they are used.

| Component | Common Materials | Reasons for Use |

|---|---|---|

| Contacts | Silver alloys, copper | High electrical conductivity; resistance to wear and arcing |

| Frame | Molded insulating materials (glass-polyester, thermoset resins) | Electrical insulation, mechanical strength, durability |

| Arc Extinguisher | Air, vacuum, SF6 gas, oil | Efficient arc quenching, safety, reliability |

| Enclosure | Polycarbonate, EPDM, glass | Impact resistance, weather resistance, explosion-proof properties |

Manufacturers use silver alloys and copper for contacts because they carry electricity well and do not get damaged easily. Molded insulating materials like glass-polyester make the frame strong and safe. Arc extinguishers use air, vacuum, or special gases to stop dangerous arcs fast. Polycarbonate and EPDM enclosures keep the breaker safe from hits and bad weather.

Tip: Picking the right materials helps circuit breakers last longer and work safely in many places.

BMC Molding

Bulk Molding Compound molding makes the plastic case for micro circuit breakers. This process uses short glass fibers, resin, fillers, and other things. BMC molded cases do not burn easily, insulate well, resist rust, and keep their shape. Manufacturers put BMC into hot molds, then use heat and pressure to make the case.

- BMC molding makes production faster and needs less work.

- Cases made with BMC are good for the environment and look neat.

- BMC gives great insulation and does not burn, so it is good for electrical devices.

- Both compression and injection molding shape BMC cases for different breaker sizes.

BMC is better than other molding ways. It gives strong cases, good insulation, and stops rust. The material can take heat up to 160℃ and meets flame rules like IEC 695-2-1. Compression molding with BMC costs less, makes less waste, and works for many shapes and sizes. These reasons make BMC the best choice for micro circuit breaker cases.

Note: New BMC molding and automation help makers build safer, better circuit breakers for more electrical needs.

Automated Assembly

Line Setup

Automated assembly lines are very important in making micro circuit breakers. Engineers plan these lines to do every job, from moving parts to packing. Each line uses smart machines and software to work fast and right. The setup has quick assembly machines and smart checking systems. Servo-driven machines help move parts smoothly. These machines can change fast for different breaker types. This helps factories make many kinds for customers.

Key features of an automated assembly line are:

- All parts move, get put together, tested, and packed by machines.

- Advanced machines and electronics keep work steady and exact.

- The system collects and checks data as work happens.

- Tools can be changed for different products.

- Alarms show problems with pressure or faults.

- The line can use smart energy checks and cloud data.

These features help factories make breakers quickly and with fewer errors. Patented connection ideas, like Everlink™, make putting in breakers faster and safer. Small, pre-certified products save up to 35% space. This makes wiring and mounting much easier.

Feeding & Assembly

The feeding and assembly steps use machines to keep quality high. Automated feeders bring parts to the right spot at the right time. Fast servo systems and cameras help put each part in place. The line puts in springs, contacts, and screws with smart controls.

This process includes:

- Machines feed and line up parts exactly.

- Springs and contacts get put in.

- Screws are tightened with smart tools that stop mistakes.

- Lasers mark parts with robot arms.

- Bad parts are found and removed right away.

Few people are needed, so there are fewer mistakes and lower costs. The system can change fast for different breaker types. This keeps work steady, quality the same, and speed high. Factories can change the line for many breaker kinds. This helps them sell to many places.

Tip: Automated feeding and assembly lines help factories keep quality high and make lots of circuit breakers.

Integration

Integration links all assembly steps into one smooth flow. Factories use smart machines to join assembly, welding, screw locking, riveting, and testing. This makes work faster and keeps quality steady.

| Technology/Equipment | Role in Integration of Assembly Stages |

|---|---|

| Custom Automatic Assembly Machine | Does many jobs at once for better quality and speed. |

| Automatic Screw Locking Machine | Tightens screws fast and right. |

| Automatic Riveting Machine | Rivets parts for strong connections. |

| Vibrating Bowl Feeders | Brings metal clips and parts for easy feeding. |

| Full-process Automation | Connects all steps for steady, big production. |

With these machines, factories can automate every step. Every breaker goes through the same careful process. This makes assembly faster, more reliable, and cheaper. Factories can watch data in real time to check and improve work. This way, every breaker is safe and high quality.

Welding & Assembly

Welding Steps

Welding is a key part of making micro circuit breakers. Workers and machines join metal pieces to make strong connections. Factories use different welding methods for different jobs.

- Manual welding uses a soldering iron and tin-lead solder. Workers use this for small batches and when high quality is needed.

- Automatic strip welding uses machines to strip metal and weld contacts to strips. The process keeps going with rolling, pressing, and stamping to join parts.

- In-mold welding puts the welding head between the feeder and stamping die. This lets the machine feed, weld, and stamp parts in the right spot.

Factories also use special ways like induction welding, laser welding, and furnace brazing. Automatic welding lines use smart systems to check each step. These systems help stop mistakes and make better products. Machines can weld all contacts for big orders. They also mold flexible links and connect many solder joints by themselves. This makes the work faster and more dependable.

Tip: Automatic welding lines help factories make more circuit breakers with fewer errors.

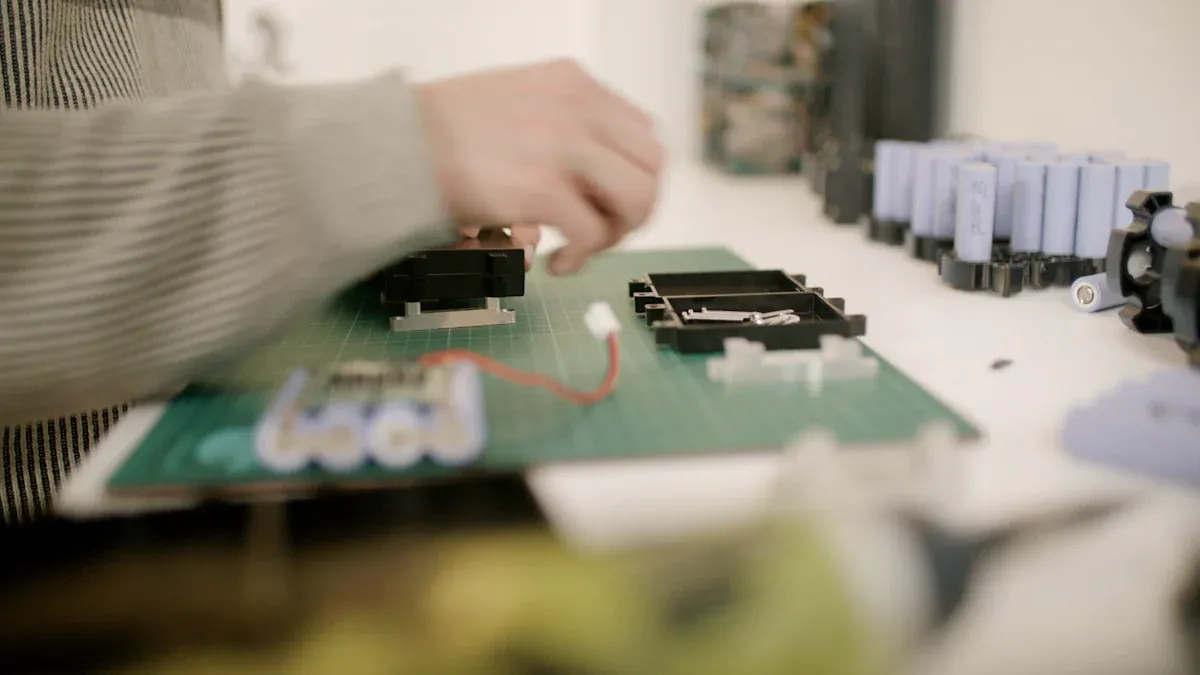

Preassembly

Preassembly puts the main parts together before the last step. Workers and machines fit contacts, springs, and arc extinguishing parts in place. Each part must fit just right so the breaker works safely.

- Workers check each part for the right size and shape.

- Machines put contacts and springs in the correct spot.

- Arc extinguishing parts, like grid pieces and iron sheets, are added to handle arc energy during problems.

Preassembly helps find mistakes early. Only good parts move to the next step. Factories use cameras and sensors to check if parts are lined up right. This careful work keeps the line running well.

Housing

The housing keeps the inside parts safe in a micro circuit breaker. Factories use strong plastics for the housing. These plastics block electricity and can take hard hits. The plastic must be thick enough to handle arc energy from short circuits. If the housing is too thin or weak, it can break when stopping a fault.

Rivet materials are important too. Strong rivets hold the housing together when stressed. Arc extinguishing parts, like grid pieces, help let out arc energy safely. Good design stops cracks and keeps the breaker safe.

| Housing Feature | Importance |

|---|---|

| Thick plastic walls | Stand up to arc energy, stop breaking |

| Strong rivets | Keep housing together when stressed |

| Arc extinguishing parts | Let out arc energy, stop cracks |

| Impact resistance | Protects from drops and bumps |

Note: Strong housing and smart design help micro circuit breakers last longer and stay safe.

Inspection & Testing

In-Line Checks

Factories use in-line checks to find problems early. Workers and machines watch each unit as it moves. Cameras and sensors look for missing parts. Machines measure the size and shape of each piece. If a part does not fit, the system stops. Staff get an alert and remove the bad unit right away.

In-line checks help keep quality high. They stop bad products from moving forward. This saves time and materials. Every micro circuit breaker must pass these checks. Factories use these checks to meet safety rules and customer needs.

Tip: Early inspection helps factories fix problems fast and keep every product safe.

OTS Process

The OTS, or Operational Testing System, checks how each micro circuit breaker works. This process tests the breaker with normal and heavy loads. Machines turn each breaker on and off many times. They check if the breaker trips at the right time when there is too much current.

The OTS process includes:

- Running the breaker through many on-off cycles

- Applying overloads to see if it trips correctly

- Checking the breaker’s response to short circuits

- Recording how long the breaker lasts under stress

The OTS process helps factories find weak or faulty units before shipping. It also proves that the breaker meets safety and performance standards. Each test result gets recorded for traceability. This step is key for the Micro Circuit Breaker OEM to show that every product is reliable and ready for use.

Functional Tests

Functional tests make sure each micro circuit breaker meets safety standards. These tests check both electrical and mechanical parts. Factories use many types of tests to cover all safety points.

| Test Type | Purpose and Role in Compliance with International Safety Standards (IEC 60947, ANSI/IEEE C37) |

|---|---|

| Insulation Resistance Testing | Checks insulation to stop electrical failures; makes sure the breaker meets minimum resistance values for safety. |

| Contact Resistance Measurement | Finds bad connections that could cause overheating or energy loss, making sure the breaker works well. |

| Time-Current Characteristic Analysis | Checks if the breaker trips at the right time under overload or fault, proving calibration and tripping work as needed. |

| Primary and Secondary Injection Testing | Pretends there are fault currents to test if the breaker can carry current and trip as needed by standards. |

| Overload and Short Circuit Tripping Tests | Makes sure the breaker trips fast or within set times under faults, which is important for safety. |

| Mechanical Operation Tests | Checks mechanical parts for good function and long life, making sure manual operation and resetting work as designed. |

| Dielectric Voltage Withstand Tests | Tests insulation with high voltage to make sure it does not fail under stress. |

| Thermal Imaging | Finds hot spots that show internal faults or loose connections, helping with maintenance and safety. |

| Arc Flash Assessments | Checks arc chute and arc runner to make sure they stop arcs well, which is important for safety. |

| Documentation and Reporting | Records all test results and problems to help with safety checks and future maintenance. |

Functional tests follow strict rules from standards like IEC 60947 and ANSI/IEEE C37. These tests check if the breaker trips at the right time, handles high voltage, and works after many uses. Factories use these tests to prove that each breaker is safe and reliable. They also keep records of every test. This helps with future checks and shows that the product meets all safety rules.

Note: Functional testing is the last step before packaging. It makes sure only safe micro circuit breakers reach the customer.

Tooling & Packaging

Tooling

Tooling helps factories make micro circuit breakers. Good tooling lets workers and machines build parts that fit well. Factories use smart ways to do this. They want to keep parts safe and work faster.

Some common tooling methods are:

- Engineers change steps to handle flexible parts. They put in flexible leads first. Then, they build other parts around them. This stops bending or breaking.

- Factories switch from manual work to metal strip stamping. This keeps parts lined up and easy to move.

- They join stamping, welding, and assembly in one line. This helps workers and machines do more work quickly.

- In-die assembly takes the place of feeder bowls. This keeps parts in the right spot and stops jams.

- Workers check the size and shape of key parts. This makes feeding and building easier.

- Factories use new machines for tapping, welding, and assembly. These steps help make more breakers with fewer mistakes.

Tip: Smart tooling helps factories make better products faster and with fewer problems.

Final Packaging

Final packaging keeps micro circuit breakers safe when shipped or stored. Workers use strong boxes and foam to protect each unit. Machines wrap and seal each breaker to keep out dust and water. Labels show the product type and safety marks.

Factories often use these steps for packaging:

- Put each breaker in a tray or foam holder.

- Seal the tray in a plastic bag for extra safety.

- Pack trays into strong cartons with clear labels.

- Add barcodes for easy scanning and tracking.

Good packaging protects breakers from bumps and drops. It also helps workers and customers find the right product fast.

Traceability

Traceability means tracking each micro circuit breaker from start to finish. Factories give every unit a special code or serial number. This code links to records about how the breaker was made, tested, and packed.

| Traceability Feature | Purpose |

|---|---|

| Serial numbers | Identify each breaker |

| Batch codes | Track groups of products |

| Test records | Show test results for each unit |

| Barcodes/QR codes | Help scan and trace products |

Traceability helps factories find and fix problems fast. If a customer finds a problem, workers can check the code. They see where and when the breaker was made. This makes recalls easier and keeps quality high. Traceability also helps factories follow safety rules and prove each breaker passed all tests.

Note: Traceability builds trust. Customers know they get safe, tested products every time.

Every step in the Micro Circuit Breaker OEM workflow is important. Steps like welding and packaging help make safe products. Machines and skilled workers work together to lower mistakes. This teamwork keeps the quality high. Factories use strict rules and check products often. These checks help protect people and equipment.

Today, new trends are changing how factories work. Smart devices and modular designs help make work faster and safer. Digital monitoring lets workers watch machines in real time. Many factories now use AI and IoT to improve their work. They also use eco-friendly materials to help the planet and meet global needs.

ONESTOP is a professional miniature circuit breaker OEM factory that has provided OEM services for multiple well-known brands, with rich experience and competitive prices.

FAQ

What does OEM mean in micro circuit breaker production?

OEM stands for Original Equipment Manufacturer. They make micro circuit breakers for other brands. OEMs use their own factories and workers. They design, build, and test each breaker. Every product must meet safety and quality rules.

Why is automation important in the OEM workflow?

Automation helps factories work faster and better. Machines put together, test, and pack circuit breakers. This lowers mistakes made by people. It also keeps quality high. Workers watch the machines and fix problems if needed.

How do factories test micro circuit breakers for safety?

Factories use in-line checks, OTS, and functional tests. Machines and workers look for faults in each breaker. They test for overloads, short circuits, and strength. Every breaker must pass these tests before it ships.

Tip: Testing stops unsafe products from reaching customers.

What materials do manufacturers use for micro circuit breakers?

Manufacturers pick silver alloys, copper, and strong plastics. These materials carry electricity well and resist heat and damage. Bulk Molding Compound (BMC) makes cases that insulate and protect the breaker.

How do factories ensure traceability of each product?

Factories give each breaker a serial number and batch code. They write down test results and packaging details. Barcodes or QR codes help track products from start to finish.

| Traceability Method | Purpose |

|---|---|

| Serial Number | Unique ID |

| Batch Code | Group Tracking |

| Barcode/QR Code | Easy Scanning |

What certifications do micro circuit breakers need?

Micro circuit breakers must meet rules like IEC, UL, CE, and CCC. These certifications show the product is safe and works well. Factories follow strict rules to get and keep these certifications.

Can factories customize micro circuit breakers for different needs?

Factories can change designs, materials, and features. They use flexible lines and smart machines. Customers can ask for special trip curves, sizes, or mounting options.

Note: Customization helps meet the needs of homes, factories, and offices.

See also

Key Features and 5 Main Advantages of the Micro Circuit Breaker OEM Model

The manufacturing process of miniature circuit breakers

How to Diagnose Micro Circuit Breaker Malfunction in Your Home

Common fault diagnosis guide for miniature circuit breakers

High quality solar micro inverter DC 63V IP67