Choosing the right size of wire for a 30-amp breaker is important. Electrical rules suggest using 10-gauge copper wire or 8-gauge aluminum wire. These wires let electricity flow safely without getting too hot. For instance, 8-gauge aluminum wire can carry up to 40 amps at 75°C. This follows the NEC’s rule of using only 80% of the size of wire’s limit.

Key Takeaways

-

Pick 10-gauge copper wire or 8-gauge aluminum wire for 30 amps.

-

Think about wire length and material; thicker wires work better far away.

-

Follow NEC rules and ask an electrician to check for safety.

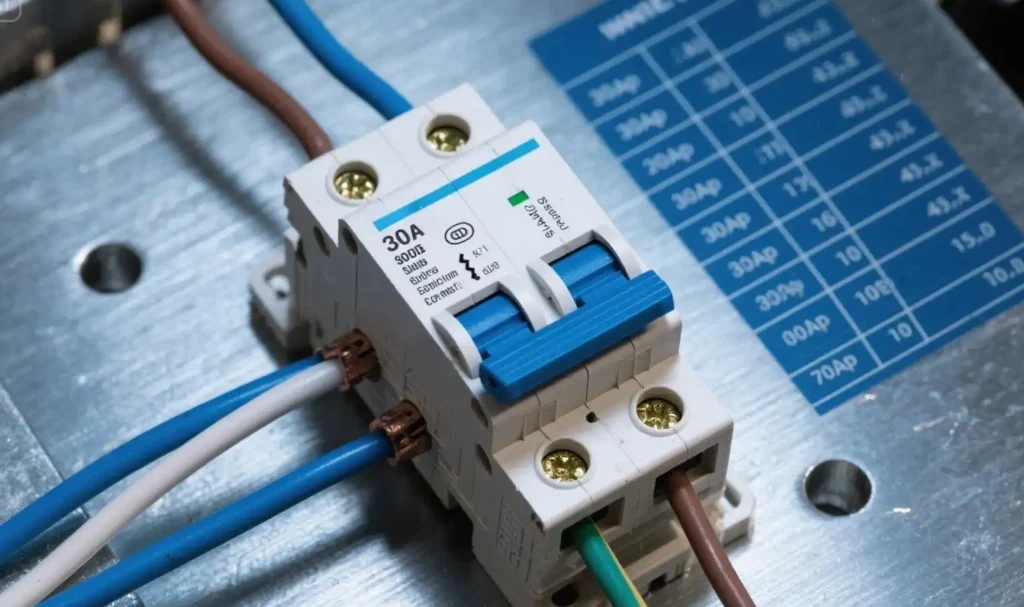

Recommended Wire Size for a 30 Amp Breaker

Why 10 AWG Copper or 8 AWG Aluminum is Suitable

To pick the right wire for a 30 amp breaker, think about safety and performance. The National Electrical Code (NEC) suggests using 10-gauge copper wire or 8-gauge aluminum wire. These wires are safe because they carry electricity without overheating or harming the insulation.

Copper wire, like 10-gauge copper, is strong and conducts electricity well. It doesn’t expand or shrink much, so connections stay tight over time. Meanwhile, 8-gauge aluminum wire is a cheaper option. Modern aluminum wires, made after 1972, are stronger and work better. But, they must be installed correctly to avoid connection problems.

Using the right wire size for a 30 amp breaker keeps your circuit safe and working well. For longer distances, thicker wires like 8-gauge copper can help reduce energy loss and voltage drop. This is especially useful for things like charging electric cars.

Ampacity and Current-Carrying Capacity Explained

Ampacity is the most current a wire can handle without overheating. For a 30 amp circuit, the wire’s ampacity must match the breaker’s rating to stay safe. According to NEC 310.15(B)(16), 10-gauge copper wire has a 35-amp ampacity at 75°C, making it good for a 30 amp breaker. Similarly, 8-gauge aluminum wire can carry up to 40 amps at the same temperature.

Several things affect ampacity, such as:

-

Ambient Temperature: Hotter areas lower the wire’s current capacity.

-

Insulation Type: Some insulation materials handle heat better than others.

-

Wire Enclosure: Wires in tight spaces lose heat slower, lowering ampacity.

Following these rules ensures the wire fits the circuit’s needs, avoiding damage or failure.

NEC Guidelines for 30 Amp Breaker Wire Size

The NEC has clear rules for choosing the right wire size for a 30 amp breaker. NEC 240.4(D) says the highest overcurrent protection for a circuit is 30 amps. This matches the use of a 30 amp breaker. Also, NEC 310.15(B)(16) lists ampacity ratings for different wires. For example:

|

Wire Size |

Material |

Ampacity at 60°C |

Ampacity at 75°C |

Ampacity at 90°C |

|---|---|---|---|---|

|

#10 AWG |

Copper |

30 amps |

35 amps |

40 amps |

|

#8 AWG |

Aluminum |

35 amps |

40 amps |

45 amps |

For continuous loads, the NEC says to use only 80% of the breaker’s capacity. This means a 30 amp breaker should handle no more than 24 amps for long-term use. Short-term loads can use the full 30 amps. Following these rules keeps your circuit safe and up to code.

By picking the right wire size, like 10-gauge copper or 8-gauge aluminum, you ensure a safe and efficient 30 amp circuit. Always check the NEC and ask a licensed electrician to make sure your setup is safe.

Factors Affecting Wire Size Selection

Copper vs. Aluminum Wire: Key Differences

When picking a wire for a circuit, know the differences between copper and aluminum wires. Copper is often chosen because it conducts electricity better and lasts longer. It handles more current efficiently and doesn’t rust easily, making it a good long-term option. Aluminum is lighter and cheaper but needs a thicker wire to carry the same current as copper. For example, a 30a breaker usually uses 10 AWG copper or 8 AWG aluminum wire.

Copper is simpler to install since it bends easily and is harder to damage. Aluminum expands and shrinks more with temperature changes, which can loosen connections. This makes proper setup very important to avoid overheating or safety risks. Also, aluminum is more likely to rust, which increases resistance and heat.

|

Feature |

Copper Wire |

Aluminum Wire |

|---|---|---|

|

Current Carrying Capacity |

Higher (more efficient) |

Lower (about 40% less) |

|

Resistance |

Lower (better performance) |

Higher (requires larger cross-section) |

|

Flexibility |

More flexible |

Less flexible |

|

Installation Complexity |

Easier to work with |

More labor-intensive |

|

Corrosion Resistance |

More resistant |

Prone to oxidation |

|

Voltage Drop |

Less voltage drop |

More voltage drop over long runs |

|

Durability |

More durable |

Prone to cracking under vibration |

Think about your circuit’s needs when choosing between copper and aluminum. Copper is best for high-performance and long-lasting setups. Aluminum is a budget-friendly choice for less demanding uses.

Voltage Drop and Wire Length Considerations

Voltage drop happens when electricity loses power as it moves through a wire. This is common over long distances and can hurt performance or damage your system. For a 30 amp breaker, keeping voltage drop low is key for safety and efficiency.

Several things affect voltage drop:

-

Wire Gauge: Thicker wires lower resistance and reduce voltage drop.

-

Wire Length: Longer wires increase resistance, causing more voltage loss.

-

Current: Higher current flow makes voltage drop worse.

For example, a 22 AWG wire over 5 meters with a 4.8-amp load loses 2.47 V. This is nearly 20% of the supply voltage and can stop devices from working. To fix this, use thicker wires for longer distances.

Voltage drop also impacts devices like circuit breakers. Too much resistance can cause overheating and fire risks. Check for voltage drop often to keep your system safe. Use Ohm’s Law to calculate voltage drop based on wire size, length, and current.

Environmental Factors and Insulation Types

The environment affects which wire size and insulation you should use. Things like heat, moisture, and chemicals can change how wires perform. For example, wires in hot areas need insulation that can handle high temperatures to avoid overheating.

Different insulation types work better in certain conditions. ASTM C518 tests insulation in labs, showing ideal results. ASTM C335 tests insulation on pipes, showing real-world performance. Knowing these differences helps you pick the right insulation.

Here are some tips for insulation:

-

Temperature Resistance: Hot areas need heat-proof insulation.

-

Moisture Protection: Wet places need waterproof insulation.

-

Chemical Resistance: Industrial areas need insulation that resists chemicals.

Choosing the right insulation keeps wires safe and working well. Always think about where the wire will be used to make the best choice.

Examples of Wire Types for 30 Amp Circuit Breakers

Common Cable Types for 30 Amp Breakers

For a 30 amp breaker, you have several wire options. The most popular is 10-gauge copper wire. It is strong, reliable, and conducts electricity well. This wire is great for homes and businesses. If you want a cheaper option, 8-gauge aluminum wire works too. It is lightweight and affordable but needs careful installation to avoid problems.

Sometimes, you might see 12-gauge copper wire. However, this wire is not safe for a 30 amp breaker. It cannot handle the high current and may overheat. Always pick the correct wire size to prevent fires or damage.

Wires like THHN and NM-B are also common for 30 amp circuits. THHN wires are heat-resistant and good for industrial use. NM-B cables, also called Romex, are better for indoor home wiring. Choose the type that fits your specific needs.

Applications of 30 Amp Circuits (e.g., RVs, Appliances)

30 amp circuits are used for devices needing more power. RVs often use them to run air conditioners, fridges, and other appliances. In homes, they power heavy machines like dryers, water heaters, and stoves.

In workshops, a 30 amp breaker supports tools like air compressors or table saws. These tools need steady power to work properly. Always match the wire and breaker to the device’s needs for safety and efficiency.

Picking the right wire size for a 30 amp breaker is important for safety and efficiency. Use 10-gauge copper or 8-gauge aluminum wire in most cases. Think about things like wire length, material type, and the environment. Always check NEC rules and ask a licensed electrician to ensure your setup is safe.

FAQ

What happens if you use the wrong wire size for a 30 amp breaker?

Using the wrong wire size can cause overheating, fire risks, or damage to your devices. Always match the wire size to the breaker’s rating.

Can you use 12-gauge wire for a 30 amp breaker?

No, 12-gauge wire cannot handle the current of a 30 amp breaker. It may overheat and fail, leading to safety hazards.

How do you calculate the correct wire size for long distances?

Consider the wire’s ampacity, length, and voltage drop. Use thicker wires for longer distances to reduce resistance and maintain efficiency.

The following information may be of interest to you

Can I replace a 15 amp breaker with a 20 amp?

How to choose wires for your 220V 15 ampere circuit breaker

How to choose the appropriate size of circuit breaker