To wire a double pole breaker 20 amp safely, you must follow each step with care. ⚠️ Always turn off the main power before you open the panel. Use insulated tools to protect yourself from shocks. Only attempt this work if you have basic electrical knowledge and understand your local codes. If you feel unsure at any moment, call a licensed electrician for help. Safety comes first with any electrical project.

Key Takeaways

- Always turn off the main power and use a voltage tester before working inside the electrical panel to avoid shocks.

- Wear proper protective gear like insulated gloves, safety glasses, and electrical-rated shoes to protect yourself from electrical hazards.

- Use the right tools and materials, including insulated screwdrivers, wire strippers, 12 AWG copper wire, and a UL-listed double pole 20 amp breaker.

- Prepare the panel by removing the cover carefully, checking for two open slots, and installing a cable connector to protect wires.

- Connect ground and neutral wires properly, and mark the white wire with tape if it carries current to ensure safe wiring.

- Securely attach hot wires to the breaker terminals and double-check all connections to prevent loose wires and overheating.

- Test for shorts using a multimeter before restoring power, and inspect the panel for any signs of damage or loose wires.

- If unsure or if problems arise, call a licensed electrician to ensure safety and code compliance.

Safety Precautions

Main Power Off

Before you do any work inside an electrical panel, you must shut off the main breaker. This step removes power from the circuits and helps prevent electric shock. Never skip this step, even if you feel confident. Electricity can cause serious injuries in less than a second. The best way to stay safe is to make sure no power flows to the panel while you work.

⚡ Tip: Always use a voltage tester to double-check that the power is off before you touch any wires.

Turning off the main breaker is not just a suggestion. The National Fire Protection Association (NFPA 70E) and OSHA both require you to de-energize equipment before starting electrical work. These rules exist because electrical injuries can happen quickly and have severe effects. In 2020, the Electrical Safety Foundation reported 2,220 non-fatal electrical injuries—a 17% increase from the year before. Many of these injuries happened because people did not turn off the power or did not follow safety rules.

Protective Gear

You need to wear the right protective gear every time you work on an electrical panel. This gear includes rubber insulating gloves, leather protectors, safety glasses, and shoes rated for electrical work. A hard hat can also protect you from falling objects or accidental contact with wires.

Wearing protective gear is not just about following rules. It can save your life. For example, a case study showed that when workers did not maintain circuit breakers or use the right gear, the risk of arc flash increased. In one case, a breaker failed to trip for five minutes instead of the expected 0.046 seconds. This delay caused a huge arc flash, which could have led to severe burns or worse. Proper gear and regular equipment checks help prevent these accidents.

🛡️ Note: Personal protective equipment (PPE) is your last line of defense. Always use it, even if you think the risk is low.

Electrical Hazards

Working inside an electrical panel brings real dangers. You face risks like electric shock, burns, and even heart problems if current passes through your body. The human body is very sensitive to electricity. Even a small amount of current can cause your heart to beat irregularly, which is called ventricular fibrillation.

You should always recognize when a job is too risky. If you see damaged wires, signs of overheating, or if you feel unsure about any step, stop and call a licensed electrician. Professionals have the training and tools to handle complex or dangerous situations safely.

- Common hazards include:

- Exposed wires

- Loose connections

- Overloaded circuits

- Water near the panel

🚨 Warning: Never work alone. Always let someone know you are working on electrical equipment in case you need help.

By following these safety precautions, you protect yourself and others from harm. Always respect electricity and never rush through safety steps.

Tools and Materials

Required Tools

You need the right tools to wire a double pole breaker 20 amp safely. Start with a flathead and a Phillips screwdriver. These help you remove the panel cover and tighten terminal screws. Use a wire stripper to remove insulation from the wires. A voltage tester checks if the power is truly off before you touch anything. Needle-nose pliers help you bend and position wires inside the panel. Always use insulated tools to protect yourself from accidental shocks. Keep a flashlight nearby if your workspace is dark. Electrical tape is important for marking wires and adding extra insulation where needed.

🧰 Tip: Gather all your tools before you begin. This helps you work faster and reduces the risk of mistakes.

Materials List

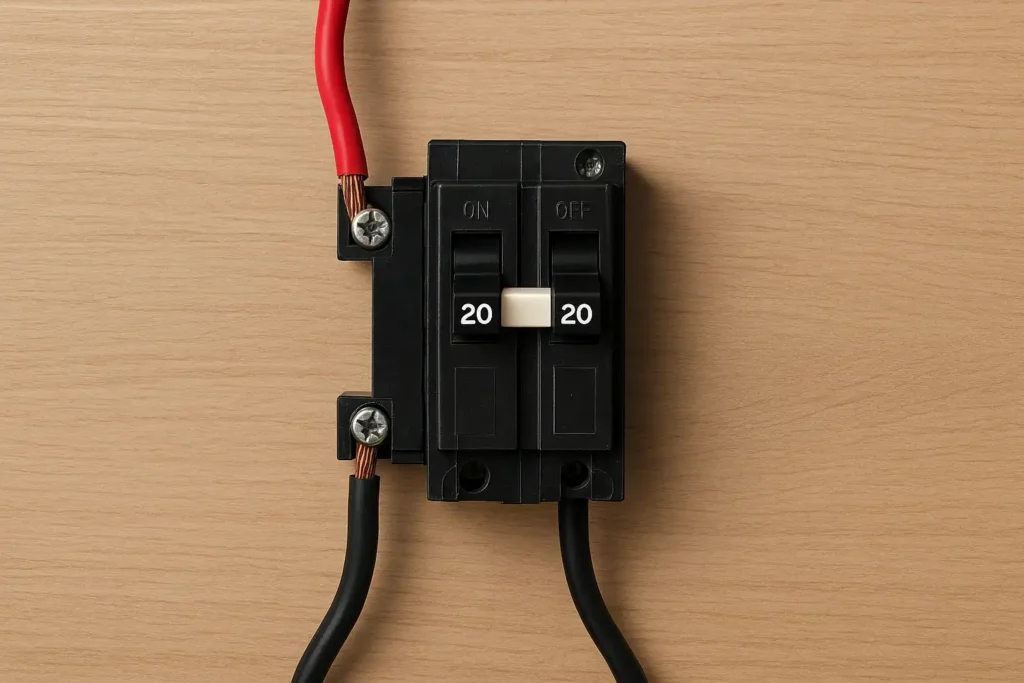

You need specific materials for this project. The main item is a double pole breaker 20 amp. Make sure the breaker matches your panel brand and model. You also need 12 AWG copper wire, which is the standard size for a 20-amp circuit. If you use 12/2 cable, you must re-identify the white wire with black or red electrical tape. This shows that the white wire carries current, not neutral. You also need wire nuts for safe connections and a cable connector to secure the wire entering the panel.

Here is a table with important technical specifications for the breaker and wiring:

| Specification | Details |

|---|---|

| Amp Rating | 20 Amps |

| Circuit Breaker Type | Double Pole (2P) |

| Interrupt Rating | 10,000 Amps (10 kA) |

| Voltage Rating | 120/240 Volts |

| Wire Size Range | 14 to 8 AWG copper, 12 to 8 AWG aluminum |

| UL Listing | Yes |

| HACR Rating | Yes |

| Physical Dimensions | Height: 2.58 in, Length: 3.28 in, Width: 0.5 in |

This breaker is UL Listed and HACR rated. These ratings mean the breaker meets strict safety and performance standards. The breaker controls 240V circuits and uses two hot wires. It fits into two slots in your panel.

Wire Size for Double Pole Breaker 20 Amp

Choosing the correct wire size is very important. The National Electrical Code (NEC) says you should use 12 AWG copper wire for a 20-amp breaker. This wire size handles the current safely and prevents overheating. Using the wrong wire size can cause the wire to get too hot, which may lead to a fire. Always check your local codes, but 12 AWG copper is the standard for most homes.

If you use 12/2 cable, you must mark the white wire with black or red electrical tape. This step shows that the wire is not neutral but is carrying current. Never skip this marking. It helps anyone working on the panel in the future understand the wiring.

⚠️ Note: Never use a smaller wire than required. Always follow NEC guidelines and your local code for safety.

Panel Preparation

Remove Cover

Start by removing the panel cover. Use a screwdriver to loosen the screws that hold the cover in place. Hold the cover with one hand as you remove the last screw. This keeps the cover from falling. Set the cover aside in a safe spot where it will not get damaged.

You need to see inside the panel to work safely. Many experts recommend using checklists before you begin. These checklists help you remember each step and make sure you do not miss anything important. Construction teams often do walkthroughs to spot problems before they start work. You can do the same by looking for any signs of damage or loose wires as soon as you open the panel.

⚠️ Tip: Always keep one hand on the panel cover when removing it. This prevents accidents and protects your tools and the cover.

Check Panel Space

After you remove the cover, check if there is enough space for the new double pole breaker. Look for two open slots next to each other. Double pole breakers need both slots to work. If you do not have enough space, you cannot install the breaker safely.

Walkthroughs and inspections are common in professional electrical work. Teams use them to find any issues before they start wiring. You should do the same. Look for any wires that seem crowded or out of place. Make sure nothing blocks the area where you plan to install the breaker.

Here is a simple checklist you can use:

- Confirm two open slots for the breaker.

- Check for loose or damaged wires.

- Make sure no debris or tools are inside the panel.

- Verify that the panel is dry and clean.

📝 Note: Pre-commissioning checklists help experts catch problems early. You can use a checklist to make sure your panel is ready for safe work.

Install Cable Connector

Before you bring new wires into the panel, install a cable connector in one of the panel’s knockouts. The cable connector holds the wire in place and protects it from sharp edges. Use a screwdriver or pliers to remove the knockout. Insert the connector and tighten it so it does not move.

Cable connectors are important for safety. They keep wires from rubbing against metal edges, which can cause damage over time. Safety management systems in professional settings require secure cable entry to prevent accidents. You should always use a cable connector, even if the opening seems smooth.

🔒 Tip: Always double-check that the cable connector is tight. Loose connectors can let wires slip or get damaged.

By following these steps, you prepare your panel for safe and effective wiring. Careful preparation helps you avoid mistakes and keeps your project on track.

Wiring the Double Pole Breaker 20 Amp

Feed Circuit Wire

You need to bring the new circuit wire into the panel through the cable connector you installed earlier. Push the cable gently so you do not damage the insulation. Leave enough wire inside the panel to reach the breaker and the ground and neutral bars. Most electricians recommend at least 6 to 8 inches of wire inside the panel. This extra length gives you room to make neat bends and secure connections.

The Maine Electrical Code 2020, which follows the National Electrical Code (NFPA 70), sets clear rules for safe wiring. Chapter 2 covers conductor sizing, wiring methods, and breaker installation. These standards help you route and connect wires safely when installing a double pole breaker 20 amp.

🛠️ Tip: Keep your wires organized and away from sharp edges. Neat wiring makes future work safer and easier.

Connect Ground and Neutral

Next, you must connect the ground and neutral wires. Strip about 3/4 inch of insulation from each wire. Attach the bare copper or green ground wire to the ground bar in the panel. Tighten the screw firmly, but do not over-tighten. If your circuit requires a neutral, connect the white wire to the neutral bar. In some 240V-only circuits, you may not need a neutral. Always check your local code and the requirements of your device.

Proper grounding and neutral connections protect you and your home. In North America, the breaker protects both the wiring and any connected cords or plugs. This approach keeps the system safe if a fault occurs. Some systems use devices like residual current devices (RCCB/ELCB) to reduce shock risks. These devices work best when you connect the ground and neutral wires correctly.

⚡ Note: Never skip the ground connection. A good ground path helps trip the breaker quickly if a problem happens.

Attach Hot Wires to Breaker

Black and Re-identified White

Now you will connect the hot wires to the double pole breaker 20 amp. Strip about 3/4 inch of insulation from the black and white wires. If you use 12/2 cable, mark the white wire with black or red electrical tape. This marking shows that the wire is hot, not neutral. Insert the black wire into one terminal of the breaker. Insert the re-identified white wire into the other terminal. Tighten both screws securely.

The table below shows important code sections that guide safe wiring and breaker installation:

| Code Section | Focus Area | Relevance to Wiring a Double Pole Breaker 20 Amp |

|---|---|---|

| 296-46B-210 | Branch circuits under 1,000 volts | Sets wiring methods for branch circuits, including double pole breaker installations. |

| 296-46B-240 | Overcurrent protection | Details standards for breakers like the double pole breaker 20 amp. |

| 296-46B-300 | General wiring methods | Covers safe routing and connection of circuit wires in the panel. |

These codes ensure you connect each wire to the correct terminal and follow safe practices.

Secure Connections

After you attach the wires, double-check each connection. Tug gently on each wire to make sure it does not come loose. Loose wires can cause overheating or arcing. The double pole breaker 20 amp takes up two slots in your panel and supplies 240 volts to your circuit. This setup is common for large appliances like water heaters or air conditioners.

✅ Checklist:

- Black wire to one breaker terminal

- Re-identified white wire to the other terminal

- Ground wire to ground bar

- Neutral wire to neutral bar (if needed)

- All screws tight and wires secure

You have now completed the main wiring steps for your double pole breaker 20 amp. Careful work and attention to detail help keep your home safe and your electrical system reliable.

Testing and Final Steps

Double-Check Connections

You need to check every connection before you move forward. Look at each wire and make sure it sits tight in its terminal. Tug gently on each wire to confirm it will not slip out. Loose wires can cause overheating or even fires. Check that the ground wire connects firmly to the ground bar. If your circuit uses a neutral, make sure the neutral wire sits in the correct spot. Review the breaker itself and confirm it fits snugly into both slots. A double pole breaker 20 amp must have both terminals locked in place.

Take a moment to look for any stray wire strands or bits of insulation. Remove anything that does not belong. A clean panel helps prevent problems later. Many experts recommend a visual inspection as your first line of defense. Look for signs of damage, such as frayed wires or burn marks. These signs can warn you about hidden issues.

🧐 Tip: Use a flashlight to see into dark corners of the panel. Good lighting helps you spot mistakes.

Test for Shorts

Testing for shorts is a critical step before you restore power. You want to make sure your work is safe. Start by using a digital multimeter. Set it to the continuity or resistance setting. Touch one probe to the ground bar and the other to each hot terminal on the breaker. You should not hear a beep or see a low resistance reading. If you do, you may have a short circuit.

Experts suggest checking for voltage and continuity in all wiring, outlets, and switches. This step helps you find hidden shorts or broken wires. If you find a problem, stop and fix it before moving on. Some professionals use advanced tests, like contact resistance or insulation resistance tests, to check the quality of connections. For example, a difference of more than 150% between phases in a contact resistance test signals trouble. Insulation resistance values above 1.6 for the Dielectric Absorption Ratio and above 4 for the Polarization Index mean your insulation is in excellent shape.

You do not need special tools for basic checks. A simple multimeter works for most home projects. Always follow the same steps: check for shorts, check for damage, and confirm all connections.

⚡ Alert: Never skip this step. Testing for shorts protects you and your home from electrical hazards.

Replace Panel Cover

Once you finish your checks, you can replace the panel cover. Hold the cover with one hand and line up the screw holes. Insert each screw and tighten it with a screwdriver. Do not over-tighten, as this can strip the threads. Make sure the cover sits flat and secure. A loose cover can let dust or moisture into the panel, which can cause problems later.

Replacing the cover marks the end of your hands-on work inside the panel. You have now prepared everything for a safe power restoration. Take a final look around your workspace. Remove any tools, wire scraps, or debris. A tidy area helps you avoid accidents and keeps your project professional.

🛡️ Note: Always keep the panel cover in place when you finish. This step keeps everyone safe and protects your electrical system.

Restore Power

You have checked your work and replaced the panel cover. Now you are ready to restore power to your electrical panel. This step brings your new double pole 20 amp breaker to life. You must follow each step carefully to stay safe and protect your home.

Start by making sure everyone stands clear of the panel. Tell family members or anyone nearby that you will turn the power back on. Safety always comes first. Stand to the side of the panel, not directly in front of it. This position keeps you safer if a problem happens when you turn on the power.

Follow these steps to restore power:

- Turn On the Main Breaker

Find the main breaker at the top of your panel. Push the handle firmly to the “ON” position. You may hear a click as the power returns to your home. - Switch On the Double Pole Breaker

Locate your new double pole 20 amp breaker. Flip the switch to the “ON” position. Watch and listen for any unusual sounds, such as buzzing or crackling. These sounds can signal a problem. - Check for Normal Operation

Look at the breaker and the panel. Make sure there are no sparks, smoke, or burning smells. If you see or smell anything unusual, turn off the breaker right away. Do not ignore warning signs. - Test the Circuit

Go to the device or outlet connected to your new breaker. Plug in a lamp or use a voltage tester to check for power. The device should work as expected. If it does not, turn off the breaker and check your wiring.

⚠️ Alert: If the breaker trips immediately or you see sparks, turn off the main breaker. Call a licensed electrician to inspect your work. Never try to force a breaker to stay on.

After you confirm the circuit works, keep an eye on it for the next hour. Touch the panel cover near the new breaker. It should feel cool or only slightly warm. Heat can mean a loose connection or overloaded circuit.

Here are some signs of a safe installation:

- The breaker stays on without tripping.

- No unusual noises or smells come from the panel.

- Devices on the new circuit work as expected.

🛡️ Tip: Write down the date of installation and label the new breaker in your panel. Clear labels help you and others in the future.

You have now restored power safely. Your new double pole 20 amp breaker is ready for use. Always monitor new circuits for the first few days. If you notice any problems, turn off the breaker and call a professional. Safety is your top priority every time you work with electricity.

Troubleshooting and Safety Tips

Common Mistakes

You can avoid many electrical problems by watching for common mistakes. Many homeowners make errors that lead to safety risks or code violations. Here are some issues you should look out for:

- Failing to inspect wires for nicks, wear, or broken insulation.

- Leaving loose or disconnected wires inside the panel.

- Using the wrong size breaker for the circuit’s electrical load.

- Forgetting to tighten connections, which can cause overheating.

- Not testing for voltage or shorts before restoring power.

- Skipping the step of marking the white wire when it acts as a hot conductor.

- Overlooking signs of corrosion or damage on busbars and terminals.

- Ignoring the need for proper labeling of breakers and circuits.

⚠️ Alert: DIY electrical mistakes can cause fires, shocks, or even death. Always double-check your work and never rush.

You should also check for clear labeling and make sure all components are accessible. If you see unclear panel layouts or find it hard to trace wires, troubleshooting becomes much harder. Always keep your workspace organized and your panel easy to understand.

Code Compliance

Electrical codes exist to keep you and your home safe. You must follow both national and local codes when working on your panel. Many people struggle with code compliance because codes change often and can be complex. Here are some challenges you might face:

- Not knowing the latest code updates.

- Confusing national and local code requirements.

- Missing required permits or inspections.

- Failing to document changes or upgrades.

You can overcome these challenges by staying informed and organized. Try these strategies:

- Take time to learn about current codes and updates.

- Work with local code officials if you have questions.

- Keep all permits, plans, and inspection records in a safe place.

- Use clear labels and accurate documentation for every change.

📝 Tip: Most areas require a permit for electrical work. Permits help ensure your project gets inspected for safety.

If you do not follow code, you risk fines, failed inspections, or even denied insurance claims. Proper code compliance also protects your home’s value and keeps your family safe.

When to Call a Pro

Some electrical jobs are too risky or complex for DIY work. You should always call a licensed electrician if you:

- Feel unsure about any step.

- Find damaged wires, corrosion, or signs of overheating.

- Need to upgrade your panel or add new circuits.

- Cannot identify or fix a problem after troubleshooting.

- Need to work on the main service panel or meter.

Professional electricians have the training, tools, and insurance to handle dangerous situations. They also provide documentation and warranties for their work. Many insurance companies require proof of professional installation for coverage. Most local laws require licensed electricians for major electrical work.

🛡️ Note: When in doubt, always choose safety. Calling a pro can save you time, money, and protect your home from serious hazards.

You protect your home and family when you follow each safety step for wiring a double pole breaker 20 amp. Always double-check every connection and test before restoring power. If you feel unsure, call a licensed electrician. Safety matters more than speed. The table below shows how safe wiring and code compliance prevent fires and injuries, and why experts recommend regular inspections.

| Benefit | Details |

|---|---|

| Home Fire Prevention | Over 5,300 home fires each year come from electrical issues. |

| Electrocution Reduction | GFCI devices prevent about 50% of home electrocutions. |

| Fire Risk Reduction | AFCI devices stop up to 50% of electrical fires. |

| Expert Advice | Inspect wiring every 3-5 years, or sooner for older homes. |

| Code Compliance | Increases safety, home value, and meets insurance and legal standards. |

FAQ

What is a double pole 20 amp breaker used for?

You use a double pole 20 amp breaker for 240-volt appliances. Common examples include water heaters, air conditioners, and some power tools. This breaker provides two hot wires, which deliver more power than a single pole breaker.

Can I install a double pole breaker myself?

You can install a double pole breaker if you have basic electrical knowledge and follow safety rules. Always turn off the main power. If you feel unsure at any step, call a licensed electrician.

What wire size do I need for a 20 amp double pole breaker?

You need 12 AWG copper wire for a 20 amp double pole breaker. This wire size handles the current safely. Never use a smaller wire. Always check your local code for special requirements.

Do I need to re-identify the white wire?

Yes, you must mark the white wire with black or red tape if it acts as a hot wire. This step warns others that the wire carries current, not neutral. Skipping this step can cause confusion and danger.

What should I do if the breaker trips right away?

Alert:

If the breaker trips immediately, turn off the main power. Check your wiring for shorts or loose connections. Do not force the breaker on. If you cannot find the problem, call a licensed electrician.

How do I know if my panel has space for a double pole breaker?

Look for two open slots next to each other in your panel. Double pole breakers need both slots. If you do not see enough space, you cannot install the breaker safely.

Is a permit required to install a new breaker?

Most areas require a permit for electrical work, including breaker installation. Permits help ensure your work meets safety codes. Check with your local building department before you start.

The following information may be of interest to you

Single vs. Double Pole Circuit Breakers: Key Differences Explained

Adjustable double throw automatic transfer switch

Can I put two circuits on one circuit breaker