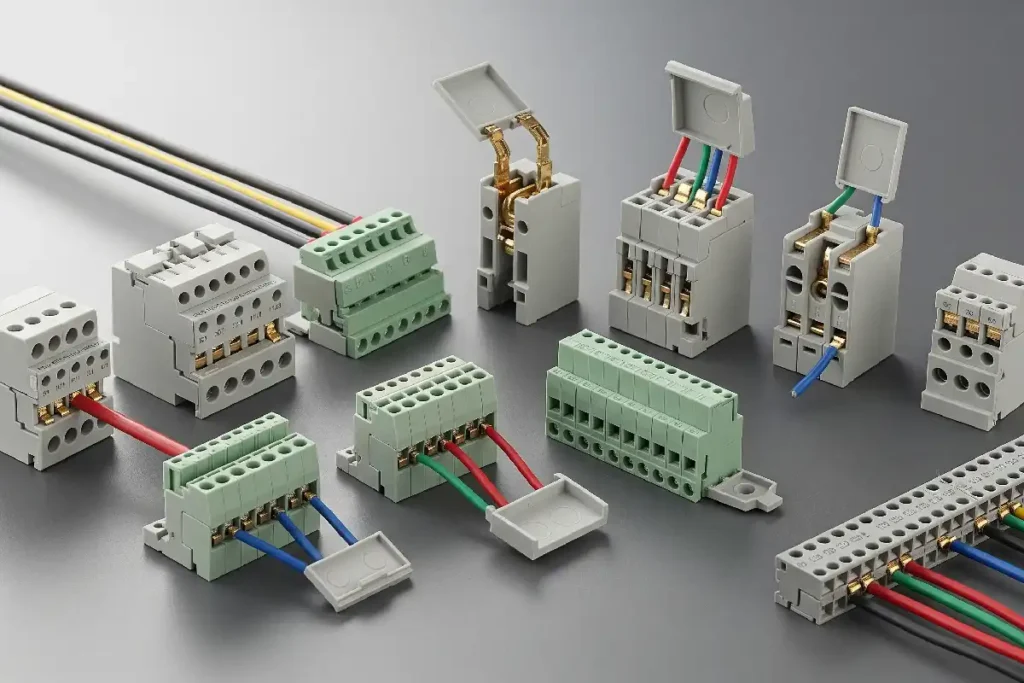

A terminal block joins electrical wires safely and neatly. There are a few main types of terminal blocks. These include screw, spring-cage, push-in, IDC, and pluggable designs. Terminal blocks can be sorted by how they connect wires. They can also be grouped by what they do in a circuit. Picking the right terminal block stops electrical problems. It also helps systems work well. The best terminal blocks keep things safe and working in many setups.

Key Takeaways

- Terminal blocks help connect and organize wires safely. You do not need to solder them. This makes building and fixing electrical systems easier.

- There are many types of terminal blocks. Some are screw, spring-cage, push-in, IDC, and pluggable. Each type holds wires in its own way. They fit different needs.

- Picking the right terminal block depends on a few things. These include current, voltage, wire type, and space. It also depends on how fast or often you connect or change wires.

- Some terminal blocks do special jobs. They can protect circuits with fuses. They can ground wires safely. They can measure temperature. They can also share power well.

- Using the right terminal block makes things safer. It saves time and money. It keeps electrical systems working well and easy to fix.

What is a Terminal Block?

Definition

A terminal block is a device that holds and organizes wires. It lets you connect wires safely without using solder. If someone asks, “what is a terminal block,” you can say it connects two or more wires. This makes circuits easier to handle and fix. There are many types of terminal blocks. Each type is made for certain wire jobs.

Basic Structure

Terminal blocks have a few main parts to help them work:

- The frame is made from strong plastic or ceramic. This keeps electricity from escaping.

- Metal parts inside let electricity move between wires.

- Screws, springs, or push-in parts hold wires tight.

- There are holes so you can put wires in or take them out.

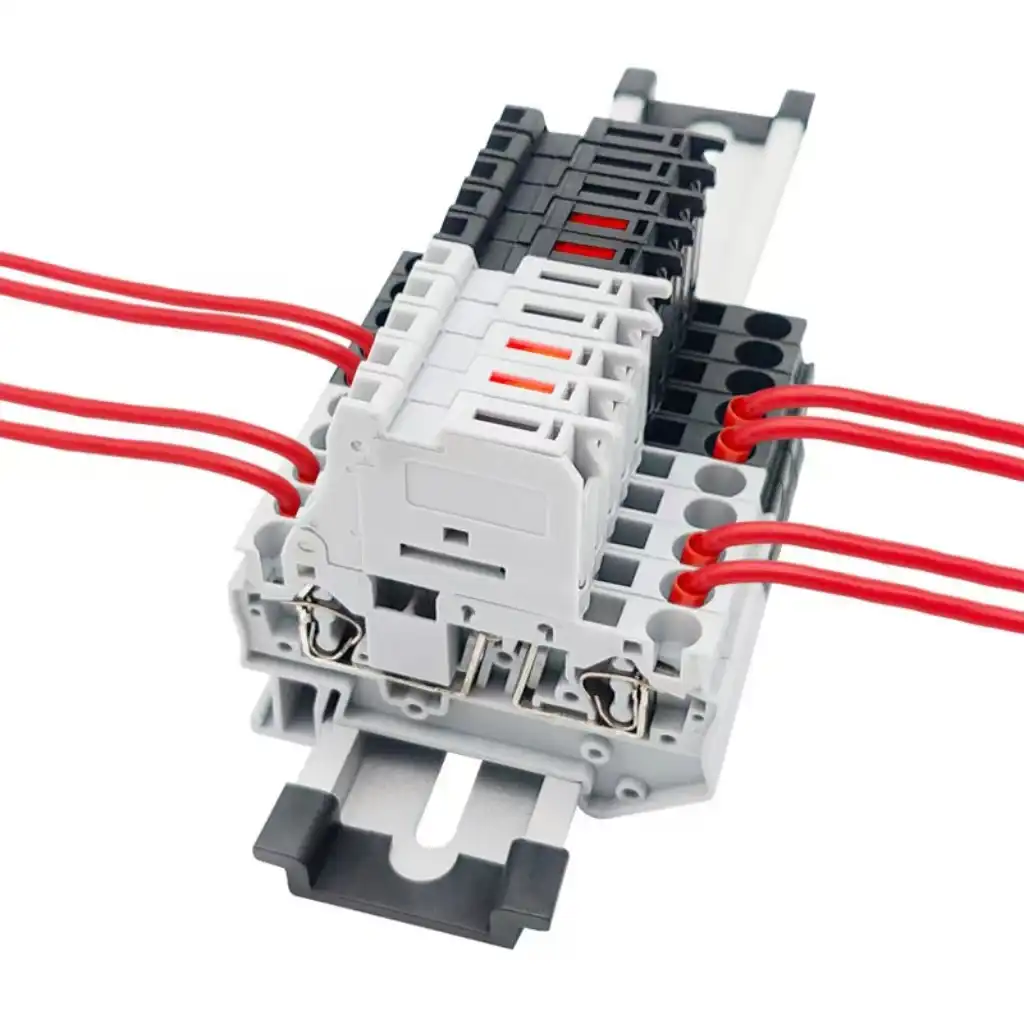

- Many terminal blocks can be put on DIN rails. This makes them easy to install in panels.

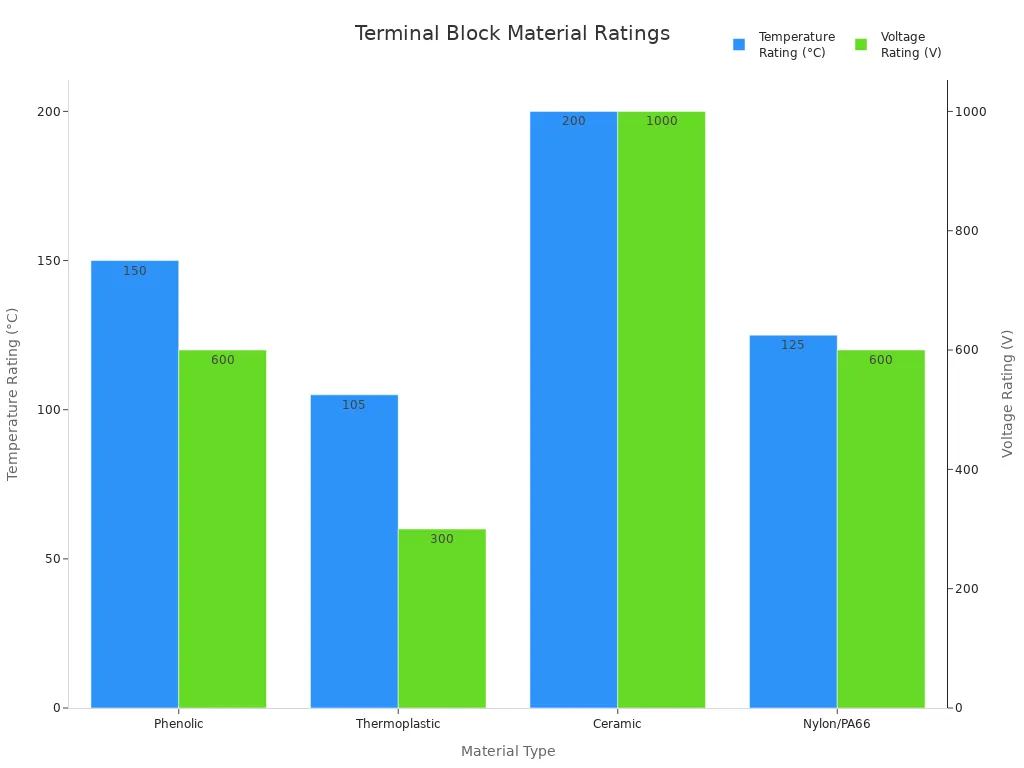

The materials used change how well a terminal block works. For example, phenolic and thermoplastic bodies handle heat and voltage differently. The table below shows how the material changes what the terminal block can do:

| Material Type | Temperature Rating | Voltage Rating | Common Applications |

|---|---|---|---|

| Phenolic | Up to 150°C | 600V | Power panels, industrial control |

| Thermoplastic | Up to 105°C | 300V | General purpose, control circuits |

| Ceramic | Up to 200°C | 1000V | High-temperature environments |

| Nylon/PA66 | Up to 125°C | 600V | DIN rail mounting, automation |

Common Uses

Terminal blocks are used where safe wire connections are needed. In factories, workers use them in control panels and machines. They help connect wires, share power, and give grounding. In cars and trains, terminal blocks are behind dashboards and in control panels. They protect wire ends and make fixing things easier. Terminal blocks also save time and money because you can change or fix wires quickly.

Tip: Terminal blocks help keep electrical systems safe and neat by holding wires in place.

Types of Terminal Blocks by Connection Method

There are many types of terminal blocks. The most common types are grouped by how they connect wires. These include screw terminal blocks, spring-cage terminal blocks, push-in terminal blocks, IDC terminal blocks, and pluggable terminal blocks. Each type holds wires in a different way to make a safe connection.

Screw Terminal Block

Screw terminal blocks use a screw to press the wire against a metal strip. The strip is usually copper or brass. The main parts are a metal strip, a screw clamp, and a frame. When you turn the screw, it pushes the wire down. This makes a strong path for electricity.

Advantages:

- Works well with big wires and high currents.

- Makes steady connections, even in big machines.

- Cheap and easy to find.

Disadvantages:

- Takes longer to install because each screw needs turning.

- You must check and tighten screws sometimes.

- If you do not tighten enough, it can fail.

Typical Applications:

- Used in control panels at factories

- Used in power systems

- Used in heavy machines

Note: Screw terminals work well if tightened right, even with vibration. But they are not the best for lots of shaking.

| Connection Method | Mechanism | Installation Speed | Vibration Resistance | Maintenance Required |

|---|---|---|---|---|

| Screw Terminal | Tighten screw by hand | Medium | Good if tight | Needs retightening |

| Spring Clamp | Uses spring pressure | Fast | Excellent | None |

| Push-In | Push wire straight in | Fastest | Excellent | None |

| IDC | Cuts insulation | Fast | Good | None |

Spring-Cage Terminal Block

Spring-cage terminal blocks use a spring to hold the wire. You put the wire in and the spring keeps it tight. This makes wiring faster and helps stop mistakes.

Advantages:

- Up to 75% faster to install than screw types.

- No need to crimp or tin wires.

- Stays tight even if things shake.

- No need to retighten.

Disadvantages:

- Not good for very big wires or high currents.

- Can cost more than screw types.

Typical Applications:

- Used in motor control

- Used where things move a lot

- Good for places where wires change often

Tip: Spring-cage terminal blocks are great for places with lots of movement. The spring keeps wires safe.

Push-In Terminal Block

Push-in terminal blocks let you put wires in without tools. A spring inside grabs the wire and holds it. This way is quick and works well.

Advantages:

- No tools needed, so it saves time.

- The spring keeps the connection tight and safe.

- Handles vibration and shock very well.

- No need to check or retighten.

- Colors help you wire correctly.

Disadvantages:

- Best for solid wires or wires with ferrules.

- May not fit the biggest wires.

Typical Applications:

- Used in automatic wiring

- Used in small control panels

- Used in building systems

| Feature | Push-in Terminal Block Mechanism | Traditional Screw Connection |

|---|---|---|

| Connection Method | Just push wire in | Use screwdriver |

| Contact Force | Always tight with spring | Depends on user |

| Vibration Resistance | Very good | Can loosen |

| Maintenance | No checks needed | Needs checking |

| Wiring Time | Up to 50% faster | Slower |

IDC Terminal Block

IDC terminal blocks use insulation displacement to connect wires. You push the wire in without taking off the insulation. Sharp blades inside cut through the cover and touch the wire.

Advantages:

- No need to strip wires, so it is fast.

- Good for wiring many wires at once.

- Can fit lots of wires in a small space.

- Works with both solid and stranded wires.

Disadvantages:

- Not as easy to reuse as other types.

- Best for certain wire sizes and types.

Typical Applications:

- Used in telecom equipment

- Used in cable systems

- Used where many wires connect together

| Feature/Aspect | IDC Terminal Blocks | Other Terminal Blocks |

|---|---|---|

| Wire Preparation | No stripping needed | Must strip wires |

| Termination Method | Blades cut insulation | Uses screws or springs |

| Typical Use | Telecom, lots of wires | General wiring |

| Advantages | Fast, fits many wires, no stripping | Can reuse, different release ways |

Note: IDC terminal blocks are used in telecom because they are fast and safe. They also handle vibration well.

Pluggable Terminal Block

A pluggable terminal block has two parts: a base and a plug. You connect wires to the plug. Then you can put the plug into the base or take it out easily. This makes changes and upgrades simple.

Advantages:

- Makes building and testing faster.

- Easy to swap or upgrade parts.

- Safety features stop wrong connections.

- Works well even in tough places.

Disadvantages:

- Costs a bit more than fixed types.

- May need more space in small panels.

Typical Applications:

- Used in modular control systems

- Used in trains and ships

- Used where wires change a lot

Tip: Pluggable terminal blocks help engineers make flexible systems. You can connect and disconnect parts quickly.

Types of Terminal Blocks by Function

Terminal blocks can be sorted by what they do in a system. The main types are barrier terminals, ground terminal blocks, fuse terminal blocks, thermocouple terminal blocks, and power distribution blocks. Each type has a special job for wiring and safety. Knowing these types helps people pick the right one for their needs.

Barrier Terminal Block

Barrier terminals help keep many wires neat and safe. They use barriers to keep metal parts apart. This stops wires from touching and causing problems. You can change or replace wires without soldering. Barrier terminal blocks work with many voltages and currents. This makes them good for lots of systems.

Key functions of barrier terminals:

- Hold many wires together in an organized way.

- Stop shorts with built-in barriers.

- Make it easy to change or replace wires.

- Keep electricity moving safely in panels.

- Can be mounted in different ways, like on a panel or DIN rail.

Makers build barrier terminal blocks to meet strict safety rules like UL 1059 and IEC 60947. These rules make sure they are safe for high voltage and work well in factories. RoHS means the materials do not have harmful stuff.

Barrier terminals are used in control panels, power boards, and machines. Their design makes them a top pick for safe and neat wiring in many places.

Ground Terminal Block

Ground terminal blocks are important for electrical safety. They give a direct path to earth ground in control systems. The metal base touches the DIN rail and connects all metal parts to the ground. This keeps people and equipment safe by sending fault currents to earth.

Ground terminal blocks also help stop interference in sensitive circuits. They are green and yellow, so you can spot them easily. Extra parts like end stops and labels make them easier to use.

| Regulatory Requirement / Aspect | Relevant Standard / Regulation | Key Details / Notes |

|---|---|---|

| Conductor connection standards | DIN VDE 0100-520 | Sets rules for safe conductor connections in buildings. |

| Rail-mount terminal blocks | DIN EN 60947 | Applies to rail-mount terminal blocks in commercial setups. |

| Color coding for ground terminal blocks | IEC 60947-7-2 | Allows green-yellow color for ground conductor rail-mount terminal blocks. |

| Approval marks and certifications | ENEC, VDE, CCA | Ensures products meet European and national safety standards. |

Ground terminal blocks are found in control panels, factory automation, and building wiring. They keep all metal parts at the same voltage, which is important for safety and good operation.

Fuse Terminal Block

Fuse terminal blocks connect wires and protect circuits at the same time. They have fuse holders built in, so you can change fuses easily. These blocks protect against too much current and short circuits. Some have LED lights to show if a fuse is blown.

What makes fuse terminal blocks unique:

- Have fuse holders for quick fuse changes.

- Work with many fuse types, like cartridge and midget fuses.

- Let you route both protected and unprotected circuits.

- Have test points for easy checks.

- Some have pluggable breakers for fast resets.

Normal terminal blocks only connect wires, but fuse terminal blocks add protection. They are used in control panels, machines, and any place that needs circuit protection. People should check for loose wires, rust, or too much current, as these can cause problems.

Tip: Fuse terminal blocks help keep circuits safe and make fixing things easier.

Thermocouple Terminal Block

Thermocouple terminal blocks are made for temperature sensor wires. They keep both ends of the reference junction at the same temperature. This stops errors and gives correct readings. These blocks use special bars to stop false signals and work with many thermocouple types, like K, T, and J.

| Feature | Description |

|---|---|

| Small voltage transmission | Sends tiny voltages from thermocouples accurately. |

| Special current bars | Stops mistakes from temperature changes. |

| Standard compliance | Meets IEC 584 (DIN 43710) for wide use. |

| Clear identification | Marked for correct wiring and easy finding. |

| Multiple connection methods | Works with push-in, clamp, and screw connections. |

| High reliability | Makes strong connections for tough jobs. |

Thermocouple terminal blocks are used where exact temperature checks are needed. These places include factories, food plants, furnaces, and molten metal work. Their design works well in hard conditions and helps sensors work right.

Power Distribution Block

Power distribution blocks send power to many circuits. They fit many wire sizes and types. Each wire connects by itself, which makes wiring and fixing easier. The modular design lets you add or remove wires as needed.

Main advantages of power distribution blocks:

- Work with many wire sizes and types.

- Modular design for easy wiring changes.

- Can be mounted on DIN rails or panels.

- Made from materials that resist rust in tough places.

- Handle heat well for big electrical loads.

- Light and low-cost for big projects.

Power distribution blocks are used in power panels, control panels, solar systems, and boats. They can handle high currents, up to 115 amps for copper and 90 amps for aluminum, with voltages up to 600 volts.

Power distribution blocks help deliver power safely and efficiently in big setups.

Choosing the Right Terminal Block

Application Needs

Picking the right terminal block depends on many things. Every project is different and has its own needs. You must think about current, voltage, space, and connection type. High-current circuits need blocks that can handle more than the load. This helps stop overheating. The voltage rating should be higher than the highest voltage in the system. This keeps the block from breaking down or sparking. Space is important too. If you do not have much room, use blocks that are small or have special wire entry. Some blocks let wires go in from the top or at an angle. The kind of wire matters as well. Solid and stranded wires may need different blocks. Some blocks only fit certain wire sizes or types.

Tip: Make sure the number of circuits and the layout fit your space and wiring needs.

Pros and Cons

Each terminal block type has good and bad points. Screw-type blocks hold wires tight and are strong. But they take longer to put in and need checking often. Spring-cage and push-in blocks are fast and do not loosen with shaking. But they may not work for big wires or high currents. IDC blocks are quick and do not need tools. But they only work with some wire sizes. Pluggable blocks make upgrades simple. But they cost more and need more space. Picking the wrong block can cause weak connections or system problems. Bad insulation or loose wires can cause shorts, downtime, or costly repairs.

| Type | Pros | Cons |

|---|---|---|

| Screw | Reliable, strong | Slower, needs retightening |

| Spring-cage | Fast, vibration-resistant | Limited wire size |

| Push-in | Quick, tool-free | Best for solid wires |

| IDC | No stripping needed | Not reusable |

| Pluggable | Easy upgrades | Higher cost, more space |

Selection Tips

Follow these steps when picking terminal blocks:

- Find out which type you need, like PCB mount or DIN rail.

- Pick a wiring method that matches your wire and is easy to use.

- Choose a block with a current rating at least 50% higher than your load.

- Make sure the voltage rating is above your system’s highest voltage.

- Check if the block fits your wire size and type.

- Pick the best wire-entry direction for your setup.

- Look for safety marks and approvals, like UL or IEC.

Some people make mistakes when choosing terminal blocks. They may guess wrong about current or voltage needs. They might not check if the wire fits. They may forget about heat, dust, or water. These mistakes can cause overheating, shorts, or even fires. Over time, the wrong block can mean more repairs and more system stops.

Note: Picking the right terminal block keeps your system safe, reliable, and saves money.

There are many kinds of terminal blocks, and each has a special job. Barrier terminals use screws and barriers to keep things safe in high-voltage spots. Push-fit types use springs so you can connect wires fast. Pluggable designs let you take them out easily when you need to fix something. Using the right type for each job keeps things safe and helps everything work well. This guide shows how to pick the best terminal block for any project.

FAQ

What is the main purpose of a terminal block?

A terminal block joins two or more wires together. It keeps wires neat and safe. People use terminal blocks to make wiring simple. They also help when you need to fix wires.

What types of wires work with terminal blocks?

Terminal blocks work with both solid and stranded wires. Some types only fit certain wire sizes. Always check the label to match the wire and block.

What makes interlocking terminal blocks different?

Interlocking terminal blocks snap together to make longer strips. You can add or remove pieces as you need. This helps you build custom wiring for control panels.

What safety features do terminal blocks offer?

Terminal blocks use insulation and barriers to keep wires apart. Some have covers or color codes for safety. These features help stop short circuits and keep wiring safe.

What is the best way to identify a terminal block’s rating?

Manufacturers print ratings on the block or in the datasheet. Look for current, voltage, and wire size details. Always pick a block with ratings higher than your system.

See also

What You Should Know About Terminal Blocks and Their Other Names

What Is a Terminal Block and How Does It Work

What Is DIN Electrical Terminology and Why Does It Matter

How to Install a Three-Phase Surge Protection Device Step by Step

How to Safely Connect RCBOs in Your Electrical Distribution Panel