Electrical fire is one of the major safety hazards in solar power generation systems. Solar power generation systems are exposed to high pressure, so appropriate fire safety measures are necessary for both safety and efficiency. As a connecting link, if not managed well, the combiner box can also be a potential source of danger.

The combiner box’s fire safety is very important in safeguarding the safety of your solar power generation system. The right preventive measures can guarantee the seamless performance of the system and safeguard your equipment system against sudden breakdowns.

What is a solar combiner box?

Why is the combiner box prone to fire?

Electrical fires inside the combiner box may be caused by various issues. Common reasons include:

- Loose or oxidized wiring: causing increased contact resistance and severe heating;

- Overload operation: working beyond the rated current, causing the insulation layer of the cable to melt;

- Insulation damage: Arc generation, high temperature ignites plastic materials;

- Grounding fault: forming a short circuit channel, causing partial discharge.

Ignoring these risks may lead to dangerous consequences. For example, poorly maintained systems can cause fires, resulting in extensive damage and expensive repair costs.

Proper maintenance and attention to the fire safety of the combination box can prevent these accidents from occurring and ensure the safety and efficiency of your system.

Common types of fire in combiner boxes

Short circuit and overload

Due to system malfunctions or human behavior, the combiner box may occasionally experience short circuits and overloads during use. Short circuits are usually caused by insulation damage, incorrect contact of conductors, and other reasons, resulting in a sharp increase in current. If the protective device is not activated in a timely manner, it is highly likely to ignite the surrounding flammable materials. Overloading operation is caused by negligence in system design or construction, and long-term overloading can also generate high temperatures and trigger combustion.

Poor contact of connectors

This issue is particularly common in large photovoltaic power plants. If the MC4 connector is not fully inserted, heat will accumulate at the contact point after long-term operation, forming a high-temperature hotspot and causing sparks and even open flames. Causing malfunction of the combiner box and triggering a fire

Fire safety precautions for combiner boxes

The correct fire prevention measures for combiner boxes begin with careful planning and high-quality materials. These measures can improve the performance of the combiner box and minimize risks to the greatest extent possible. However, some construction units choose inferior plastic shells or second-hand parts to save costs. These materials are highly flammable at high temperatures and completely lose their fire prevention function.

Install the solar combiner box correctly

When making the connections, the professional-grade crimping tool should be used, and all of the connections should be tightened to the specified torque; While making the connections, proper labeling should be performed to make sure accurate positive and negative connections.

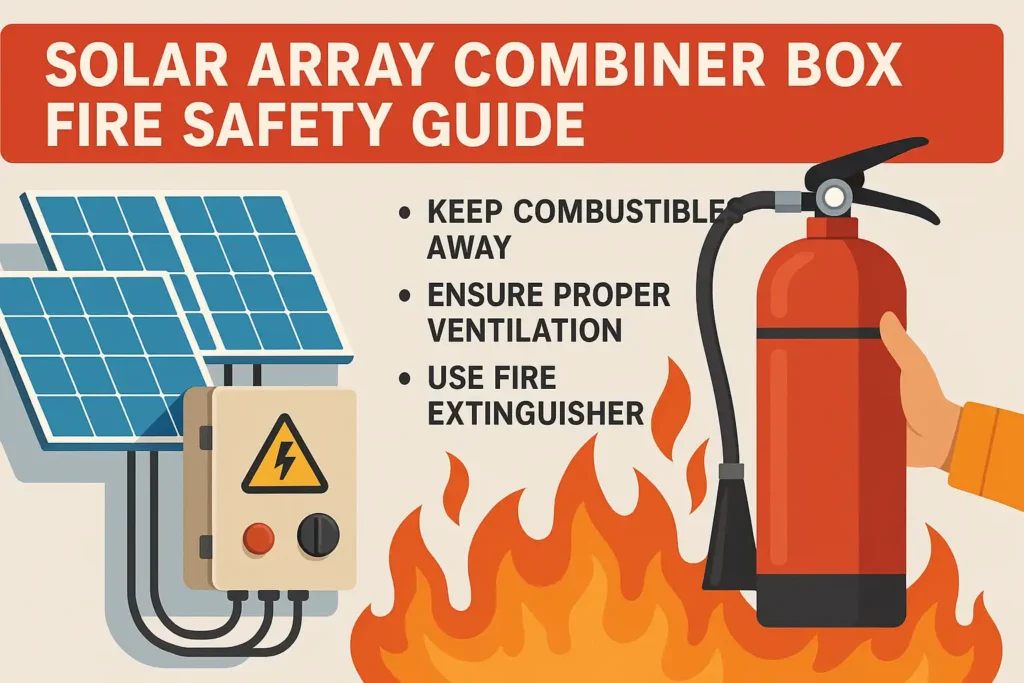

Ventilation and wiring design: Rational design not only affects electrical efficiency, but also determines ventilation and heat dissipation effects. Ensure that waterproof holes and ventilation holes are equipped within the combiner box, and the installation location shall be remote from areas with high temperature and strong sunlight.

Choose appropriate fireproof materials

The material must comply with UL 94 V-0 or V-1 flame retardant rating, which can quickly extinguish a fire and reduce the risk of fire spreading.

In case of high temperature or under strong sunlight, applying fireproof coatings and insulated aluminum plates properly to enclose the combiner box can effectively retard the fire speed and flame spreading path.

The Importance of Maintenance and Regular Inspection

To ensure the normal and safe operation of the solar combiner box, regular comprehensive inspections must be conducted. The following are routine inspection items:

Tighten the status of cable connections

- Insulation resistance inspection

- Waterproof and dustproof sealing condition

- Are there any signs of overheating or burning

- Check the working status of DC circuit breaker

- Is the lightning arrester aging or not working

- Regular maintenance intervals

It is generally recommended to conduct a routine inspection every quarter and a major overhaul every six months. Under high altitude, high humidity, high temperature and other conditions, the inspection frequency should be appropriately increased, and specialized equipment such as thermal imaging devices should be used to assist in the detection.

Application of fire protection technology in combiner box

Integrating fire prevention technology into your solar power generation system can help improve the fire safety of the combiner box and significantly reduce the risk of fire. These tools help identify potential problems before they worsen.

1. Arc fault detection

- Detect arc faults that may cause overheating or fire.

- Detect faults immediately and close the system to avoid damage.

2. Surge protection

- Protect the system from the impact of voltage surges caused by lightning strikes or faults in the power grid.

- Avoid damaging sensitive components and reduce the risk of fire.

3. Thermal sensors and fire alarms

- Thermal sensors are able to detect overheating, which is one of the major causes of fires.

- Fire alarms provide advance notice to take quick action and reduce fire damage.

Fire emergency response measures

Immediately cut off the power: pull down the main circuit breaker or inverter DC switch;

Use dry powder fire extinguishers to extinguish fires: It is strictly prohibited to use water sources to avoid electric shock;

Personnel evacuation safety distance: avoid inhaling toxic smoke;

Call the police immediately: dial 119 to contact the fire department for handling.

To prevent greater losses, emergency power-off buttons and system alarm modules should be pre-set. Simultaneously establish a duty and emergency linkage system, which can respond quickly in case of a fire alarm.

Collaborate with reliable combination box manufacturer ONESTO

ONESTO is a reliable brand in the industry, dedicated to providing high-quality combiner boxes. The company values reliability and safety to ensure that your solar system operates at its best.

The benefits of collaborating with reliable manufacturers:

- Provide high-quality, certified combination boxes that are designed with safety in mind.

- Provide professional advice and support to ensure the security and effectiveness of the system.

ONESTO has high customer satisfaction and high-quality solutions. We provide a 2-year quality warranty for combiner box products and support after-sales technical guidance. We work together with ONESTO to ensure the stable and continuous operation of your solar system.

Conclusion

Although the solar combiner box is only a component of the photovoltaic system, it is the core of ensuring the safe operation of the entire station. Only by choosing high-quality products, scientific installation, standardized maintenance, and intelligent warning can we reduce and avoid fires in the combiner box.

FAQ

Why Your Solar Energy Setup Requires a Combiner Box

How to determine the size of the solar combiner box

The difference between an AC combiner box and a DC combiner box