A fuse holder is a small but important part of an electrical system. It holds the fuse tightly, keeping it in place and protecting the circuit. Without it, the fuse might not work right, which could harm your system.

Fuse holders make electrical systems much safer. They stop circuits from overloading, protect against power surges, and lower the chance of equipment getting damaged. These features are key to keeping electrical systems safe and working well.

Whether you’re fixing something at home or working on a big industrial project, a fuse holder helps keep your system safe and running smoothly.

Key Takeaways

- Fuse holders hold fuses safely and protect electrical systems. They stop overheating and prevent circuits from failing.

- Pick a fuse holder that matches voltage, current, and conditions. This keeps the system safe and working well.

- Check fuse holders often for damage like rust or cracks. Finding problems early stops bigger issues and keeps things running.

- Install fuse holders carefully and follow safety rules. This prevents accidents and makes sure they work properly.

- Use the right tools and materials to install them. This makes it easier and lowers the chance of mistakes.

What Is a Fuse Holder and How Does It Work?

Definition and Purpose of a Fuse Holder

A fuse holder is a tool that keeps a fuse in place. It stops the fuse from moving, even if there are shakes or vibrations. Think of it as a case that protects the fuse from things like dust, water, and chemicals. This is very useful in tough places like factories or outdoor areas.

Fuse holders make changing fuses easier. They let you replace a broken fuse quickly, saving time. For example, some fuse holders are on control panels, so you don’t need to open anything to reach them.

| Function/Type | Description |

|---|---|

| Secure Placement | Keeps the fuse steady, even with shaking or movement. |

| Easy Replacement | Lets you change broken fuses fast, reducing delays. |

| Protection from Environmental Factors | Protects fuses from water, dust, and chemicals in tough conditions. |

| Accessibility | Makes it simple to test or replace fuses for quick fixes. |

How a Fuse Holder Ensures Circuit Protection

Fuse holders are important for keeping circuits safe. They hold the fuse in the right spot so it can stop electricity when there’s a problem. This helps prevent fires, overheating, and damage to devices.

Studies show how fuse holders improve safety:

- Closed fuse holders block dust and water, great for tough environments.

- Medium voltage fuse holders are key for factories needing better safety and efficiency.

- High voltage fuse holders are used in solar and wind energy systems.

Fuse holders also meet safety rules like IEC 60127-6, which helps prevent fires. The materials used are tested to handle heat without catching fire.

Key Components and Materials Used in Fuse Holders

Fuse holders are made of strong parts to last and stay safe. The outer part is often ceramic or plastic, which resists heat and electricity. Ceramic ones are great for high heat, like in factory machines.

The metal parts inside, like brass or copper, make sure electricity flows well. These metals are tested to avoid rust and keep working over time.

| Key Component | Description |

|---|---|

| Ceramic Fuse Holders | Strong against heat, used in factories and tough places. |

| Metal Contacts | Help electricity flow and resist rust for long use. |

Fuse holders are becoming more popular as electrical systems grow. By 2028, their market could reach $1.7 billion, thanks to automation and safety needs.

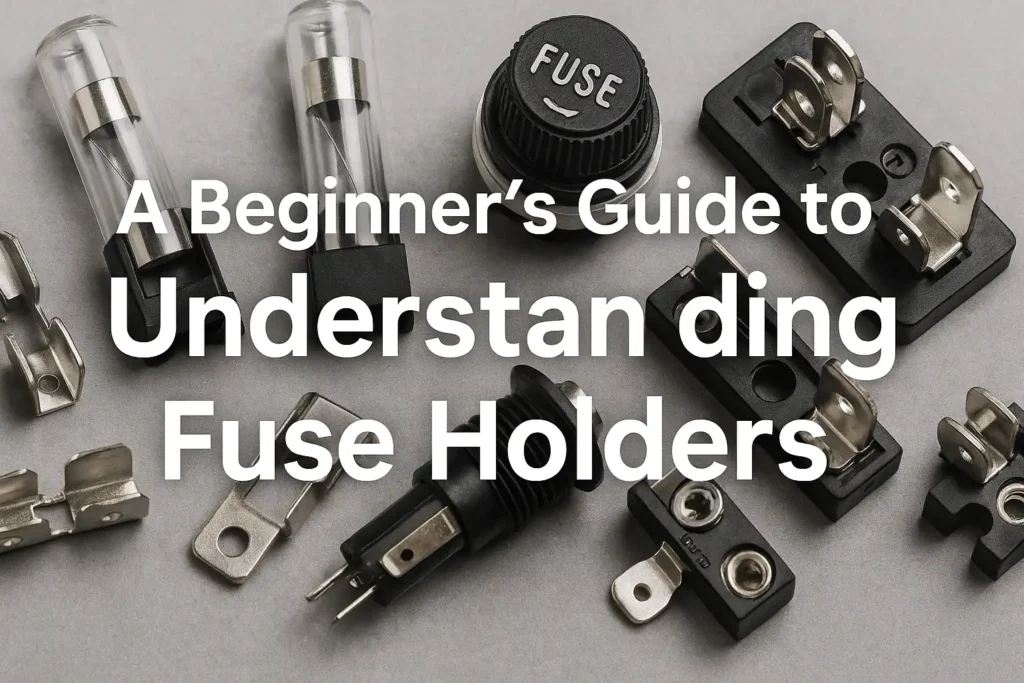

Types of Fuse Holders

Fuse holders come in different types for specific uses. Knowing these types helps you pick the right one. Below are three common types and their purposes.

Panel-mounted Fuse Holders

Panel-mounted fuse holders attach to control panels or enclosures. They are common in factories and businesses where easy access is important. These holders let you change fuses without opening the whole system.

They work well when fuses need frequent replacing. For example, in factories, they help maintain machines without stopping work. They also support different voltage levels, from low to high, for various systems.

| Attributes | Details |

|---|---|

| By Mounting Type | Panel Mount |

| By Application | Industrial, Electrical and Electronics |

| By Voltage Rating | Low Voltage, Medium Voltage, High Voltage |

Inline Fuse Holders

Inline fuse holders are small and flexible. They are used in cars, small gadgets, or outdoor tools. These holders connect directly to wires, saving space in tight areas.

Their design keeps the fuse safe from dust and water. For example, in cars, inline holders protect fuses from dirt and rain. This keeps circuits safe even in tough conditions.

Tip: Always check wire size when using inline fuse holders to install them correctly.

PCB (Printed Circuit Board) Fuse Holders

PCB fuse holders are made for circuit boards. You’ll see them in electronics like TVs, computers, and other devices. These holders are soldered onto the board for a strong connection.

They are tiny and light, perfect for small devices. PCB fuse holders work with low-voltage systems, keeping sensitive electronics safe.

| Attributes | Details |

|---|---|

| By Mounting Type | PCB Mount |

| By Application | Electrical and Electronics |

| By Voltage Rating | Low Voltage |

Each fuse holder type has a special use. Pick one based on your needs, location, and voltage.

Blade fuse holders

Blade fuse holders are small and often used in cars and boats. They hold blade fuses, which have two flat metal pieces that fit tightly. These holders are perfect for places with little space and where quick fuse changes are needed.

A big benefit of blade fuse holders is their ease of use. You can insert or remove a fuse easily without needing tools. This makes them great for quick fixes while traveling. Many also have clear covers, so you can see if a fuse is blown without taking it out.

Blade fuse holders are tough and long-lasting. They are made from heat-resistant plastic and metals that don’t rust. This helps them work well in hard conditions, like inside a car engine where it’s hot and damp.

Tip: Always use the right fuse size and amperage to avoid problems.

Specialty fuse holders for automotive and industrial use

Specialty fuse holders are made for specific jobs and tough environments. In cars, they often have waterproof or shockproof designs. For example, off-road vehicles use them to protect circuits from dirt, water, and shaking.

In factories, specialty fuse holders handle high power and voltage. They are used in big machines, power systems, and solar panels. These holders often have extra safety features like locks or heat protection to stop accidents.

Specialty fuse holders are built from strong materials like ceramic or reinforced plastic. These materials help them survive extreme heat or chemical exposure. Some can even hold multiple fuses in one unit, saving space and making repairs easier.

Note: Pick a specialty fuse holder based on your system’s needs and environment.

How to Choose the Right Fuse Holder

Key factors to consider (voltage, current rating, and environment)

Picking the right fuse holder means knowing some important details. These help the fuse holder work safely and correctly in your system.

- Voltage and Current Rating: Check your system’s voltage and current needs. Wrong ratings can cause overheating or failure.

- Environmental Conditions: Think about where you’ll use the fuse holder. For outdoor or factory use, pick one that resists water, dust, and heat.

- Physical Dimensions: Make sure the fuse holder fits the space you have. Small designs are good for tight spots.

- Compliance Standards: Choose fuse holders that follow safety rules like IEC 60269-1. These rules ensure the product is tested for safety.

| Standard | Key Details |

|---|---|

| IEC 60269-1 | Covers general rules, testing, and safety for fuses. |

| IEC 60269-4 | Focuses on fast-blow fuses and low power loss for DC systems. |

IEC 60269-1 applies to low-voltage fuses. It includes rules for design, performance, and heat limits.

Matching the fuse holder to the fuse type and application

Fuse holders don’t work with every fuse type. You need to match the holder to the fuse and its job. For example, blade fuse holders are great for cars, while PCB holders fit electronics.

Here’s how to choose the right one:

- Fuse Type: Find out what type of fuse your system uses (like blade or glass tube). Pick a holder made for that type.

- Application Requirements: Think about your system’s needs. Big machines need specialty holders for high power. Small devices need PCB holders.

- Ease of Maintenance: If you change fuses often, pick a holder that’s easy to access. Panel-mounted holders are good for quick fixes.

Tip: Always check the fuse holder’s details to make sure it works with your fuse and system.

Common mistakes to avoid when selecting a fuse holder

Avoiding mistakes can save time and prevent problems. Here are things to watch for:

- Ignoring Voltage and Current Ratings: Wrong ratings can cause overheating or damage. Always check these before using the holder.

- Overlooking Environmental Factors: Using a regular holder in tough places can cause rust or failure. Pick weatherproof holders for outdoor or factory use.

- Choosing the Wrong Size: A holder that doesn’t fit can lead to loose connections. Measure the space and check the holder’s size.

- Skipping Compliance Checks: Products without safety certifications may fail. Look for standards like IEC 60269-1 to ensure quality.

By following these tips, you can pick a fuse holder that keeps your system safe and working well.

Installation Tips for Fuse Holders

Tools and Materials Needed for Proper Installation

Before starting, gather all the tools and materials you need. This helps make the process faster and avoids mistakes. Here’s what to have ready:

- Insulated screwdrivers for safe handling.

- Wire cutters and strippers.

- Electrical tape or heat shrink tubing for covering wires.

- The right fuse holder for your system.

- A fuse with the correct rating for your setup.

- A multimeter to test the connections.

Always read the instructions from the manufacturer. These guides explain how to install the fuse holder properly. Pick a spot that’s easy to reach but safe from water or dust.

Step-by-Step Guide to Installing a Fuse Holder

Follow these simple steps to install a fuse holder:

- Turn Off Power: Cut off electricity to avoid shocks or accidents.

- Choose a Location: Find a good spot in your system for the holder.

- Prepare the Wires: Strip the wire ends to show enough copper for connecting.

- Place the Fuse: Put the fuse into the holder and make sure it’s tight.

- Attach the Wires: Connect the wires to the holder’s terminals securely.

- Test the Setup: Turn the power on briefly to check if it works.

Tip: Check the fuse holder often after installation to keep it in good shape.

Safety Precautions to Follow During Installation

Safety is very important when working with electricity. Use tools with insulation that match your circuit’s voltage. Check all tools for damage before using them. If working near live parts, use non-metallic ropes and ladders.

Set up barriers or warning signs to keep others away. Wear rubber gloves that meet ASTM standards for safety. Always turn off the power before installing a fuse holder.

By following these steps, you can safely install a fuse holder and keep your system running well.

Maintenance and Care for Fuse Holders

Checking Fuse Holders for Damage

Check your fuse holders often to keep them working well. Look for cracks, discoloration, or melted parts. These can mean overheating or too much electricity. Inspect the metal parts inside. If they are rusty or loose, they might not work right.

Also, check the area around the fuse holder. Dust, water, or dirt nearby can cause problems. Use a flashlight to see hidden spots. If you smell something odd, like burning plastic, it’s a warning sign. Fix these issues quickly to avoid bigger problems.

Cleaning Fuse Holders to Make Them Last Longer

Clean fuse holders to help them last and work better. First, turn off the power to stay safe. Use a soft, dry cloth to remove dust. For tough dirt, try a small brush or compressed air. Don’t use water or strong chemicals, as they can harm the holder.

If the metal parts are dirty, clean them with a contact cleaner or fine pad. This helps electricity flow better and stops overheating. After cleaning, check the holder again to make sure it’s in good shape. Regular cleaning can prevent sudden failures and extend its life.

When to Replace a Fuse Holder

It’s important to know when to get a new fuse holder. If it feels hot while in use, it might be failing. Cracks, melted plastic, or bent parts mean it’s damaged. Rusty or broken metal parts also show it’s not working right.

If fuses keep blowing, the holder might be the problem. If cleaning and fixing don’t help, replace it. Always pick a new holder that fits your system to avoid future trouble.

Tip: Regular checks and quick replacements keep your system safe and working well.

Troubleshooting Common Fuse Holder Issues

Finding and Fixing Loose Connections

Loose connections can stop electricity from flowing properly. This might cause your system to fail. To check for this, use a multimeter to measure voltage at different spots. If the voltage changes too much, there could be a loose connection.

Look at the wires closely for breaks or damage. Broken wires can stop electricity from moving. If you see any problems, fix or replace the wires. A small voltage drop can show if a connection is weak. Keeping wires tight and clean helps the fuse holder work well.

Solving Overheating Problems

Overheating happens when too much current flows or connections are bad. Signs include melted plastic, discoloration, or a burning smell. First, check if the fuse matches your system’s current needs. If not, replace it with the correct one.

Dirty or loose metal contacts can also cause heat. Clean them with a contact cleaner or fine pad to improve their connection. If overheating continues, check the wires for damage or wrong setup. Loose wires or voltage drops can make overheating worse. Regular checks can stop these problems early.

Checking and Replacing Blown Fuses

Blown fuses are a common issue. You can spot them by looking for a broken wire or burnt marks on the fuse. Tools like a fuse tester can help find problems without wasting fuses.

To replace a blown fuse, follow these steps:

- Find the fuse box in your system.

- Turn off the power to stay safe.

- Open the cover and locate the bad fuse.

- Use a fuse puller to take out the damaged fuse.

- Check if the fuse is blown by looking for a break.

- Put in a new fuse with the same rating.

- Test the system to make sure it works.

Use a multimeter to check for circuit problems that caused the fuse to blow. Regular checks and proper replacements keep your fuse holder working well.

Dealing with corrosion or physical damage

Corrosion and damage can weaken fuse holders and harm your system. These problems happen in places with water, chemicals, or extreme heat. Fixing them early keeps your system safe and working well.

How to Spot Corrosion

Corrosion looks like rust or faded spots on metal parts. You might see green or white buildup on copper or brass. This reduces electricity flow and can cause overheating.

To find corrosion:

- Check the metal contacts inside the fuse holder.

- Look for rust, holes, or faded spots.

- Use a flashlight to see hidden areas.

Tip: Act fast if you spot corrosion to stop more damage.

Preventing Corrosion

Keep fuse holders dry and clean to avoid corrosion. Use sealed holders in wet places. Add dielectric grease to metal parts to block water and improve flow.

Ways to prevent corrosion:

- Store fuse holders in dry areas.

- Use covers for outdoor systems.

- Clean metal parts often with contact cleaner.

Fixing Physical Damage

Cracks or bent parts can stop fuse holders from working. Broken plastic or bent metal can cause loose connections or overheating.

Steps to fix damage:

- Turn off power to stay safe.

- Take out the damaged fuse holder.

- Replace it with a strong, matching one.

Note: Pick replacements made from tough materials like ceramic or reinforced plastic.

When to Replace Fuse Holders

Severe corrosion or damage means you should replace the holder. A bad holder can cause blown fuses or safety risks. Regular checks help catch problems early and save money.

By acting quickly, you can make fuse holders last longer and keep your system running well.

Knowing how to care for fuse holders keeps systems safe and working well. These small parts are key to stopping damage and keeping things running smoothly.

Here are some simple tips to help you:

- Pick the right one: Match the fuse holder to your system’s needs like voltage and current.

- Install properly: Use the right tools and follow the steps carefully.

- Check often: Look for rust, cracks, or damage to prevent problems.

💡 Pro Tip: Safety comes first. If unsure, ask an expert to help set it up right.

By following these tips, you can protect your system and save money on repairs.

FAQ

1. What happens if I use the wrong fuse holder?

Using the wrong fuse holder can cause overheating or system failure. Loose connections might also happen. Always pick a holder that matches your system’s voltage and current needs. This keeps your system safe and working well.

2. Can I install a fuse holder without professional help?

Yes, you can install a fuse holder by following instructions carefully. Use tools with insulation and turn off the power first. Check all connections twice to avoid mistakes. If unsure, ask an expert for help.

3. How often should I inspect my fuse holder?

Check your fuse holder every 3 to 6 months. Look for rust, cracks, or signs of overheating. Regular inspections stop sudden problems and keep your system running smoothly.

4. What should I do if my fuse holder overheats?

Turn off the power right away if the holder overheats. Look for loose wires or wrong fuse sizes. Clean the metal parts and replace anything damaged. If it keeps overheating, get a better-quality holder.

5. Are all fuse holders waterproof?

No, not all fuse holders are waterproof. For wet places, choose sealed or waterproof holders. These protect against water and keep your system safe.

💡 Tip: Check the product details to make sure the holder fits your environment.

The following information may be of interest to you

What are fuses in electrical systems?

Solar fuse holder 1500V 10x 85mm 1-pole 20A

Solar photovoltaic connector inline fuse holder (with fuse)