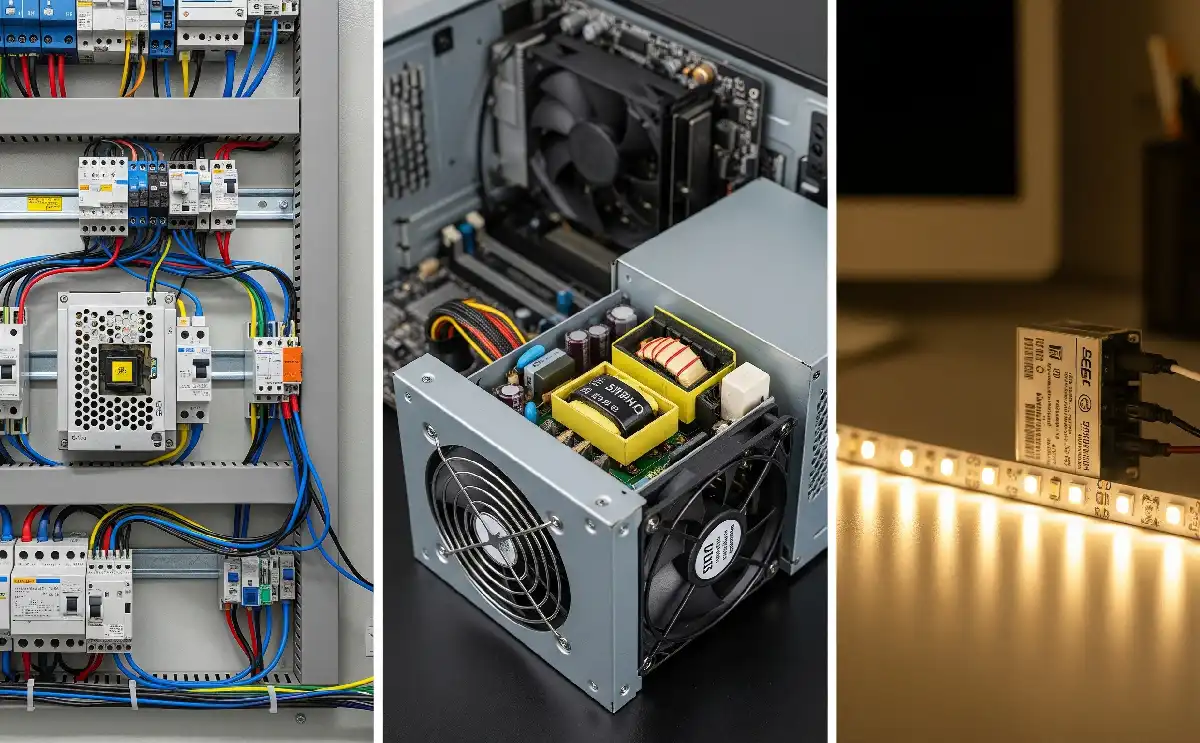

A switch mode power supply uses a switching regulator to change electrical power. The switching regulator quickly turns a transistor on and off. This helps save energy. Most new devices use this kind of switching power supply. It works well and is small. The switch mode power supply moves power from AC or DC sources to DC loads. It changes voltage and current when needed. People also call it a switched-mode power supply, switched power supply, or switcher.

- Common alternative names:

- switched-mode power supply

- switch mode power supply

- switched power supply

- switcher

Switching power supplies are used in many electronics today. They are found in medical equipment and control systems too. Their smart design makes them important in modern technology.

Key Takeaways

- A switching power supply changes electrical power in a smart way. It turns a transistor on and off very fast. This saves energy and makes devices smaller.

- It uses parts like transformers and inductors. It also uses feedback circuits to keep voltage steady. It can change for different power needs.

- Switching power supplies work better than linear ones. They make less heat and fit into small devices like phones and laptops.

- They can make electrical noise. Engineers add filters and shielding to protect sensitive electronics.

- These power supplies are used in many things. You find them in electronics, machines, cars, and military gear. They save energy and work well in tough places.

Switching Power Supply Basics

What Is a Switch Mode Power Supply

A switch mode power supply changes electrical energy using a switching regulator. It uses fast switching to control voltage and current. First, it takes AC or DC input. Then, it turns it into a steady DC output. The transistor switches on and off quickly. This makes energy pulses. These pulses go through a transformer or inductor. The transformer or inductor changes the voltage. Feedback circuits help keep the output voltage steady. Most new electronics use a switch mode power supply. It works well and is small.

Tip: Switch mode power supplies are smaller and lighter than old ones. High-frequency switching lets them use smaller transformers and parts.

How a Switching Regulator Works

The switching regulator is the main part of a switch mode power supply. It controls electricity by turning a transistor ON and OFF. When ON, energy goes into an inductor or transformer. When OFF, stored energy moves to the output. A feedback loop checks the output voltage. If voltage drops, ON time gets longer. If voltage rises, ON time gets shorter. This is called pulse-width modulation (PWM).

Here is how a switching regulator works in a switch mode power supply:

- The input filter takes away noise and voltage spikes.

- The rectifier changes AC into DC.

- Power factor correction helps save energy.

- The switching circuit makes fast pulses.

- The transformer changes voltage and keeps input and output apart.

- The output rectifier and filter make the pulses into smooth DC.

- The feedback circuit keeps the output voltage steady.

- The switching frequency is usually between 25 kHz and 500 kHz.

- Buck, Boost, and Buck-Boost topologies change voltage up, down, or flip it.

- The transistor switch is always fully ON or OFF to save power.

The switching regulator gives only the needed electricity. This makes the switch mode power supply very efficient. It can quickly change if the load or input voltage changes.

Key Components

A switch mode power supply has many important parts. Each part helps the switching regulator work right.

| Component | Purpose |

|---|---|

| Switching Component | A transistor that switches on and off to control power flow. |

| Control IC | Sets switching speed and duty cycle for steady output voltage. |

| Input Filter | Capacitors and inductors remove high-frequency noise from input power. |

| Rectifier | Changes AC to DC, often with a diode bridge. |

| Transformer | Changes voltage and keeps input and output separate. |

| Output Filter | Capacitors and inductors remove noise and ripple from output voltage. |

| Feedback Circuit | Checks output voltage and changes switching for steady output. |

| Snubber Circuit | Protects the switching part from voltage spikes. |

| Protection Circuit | Stops damage from too much voltage, current, or short circuits. |

| Heat Sink | Gets rid of heat from switching parts to keep them safe. |

| Soft Start Circuit | Slowly increases output voltage to stop sudden current rush. |

Inductors store energy in a magnetic field and help smooth current. Capacitors hold electrical charge and keep voltage steady. The switching component, usually a transistor, controls switching. The control IC sets the timing and duty cycle. The feedback circuit keeps the output steady. Protection circuits keep the switch mode power supply safe.

A switch mode power supply uses all these parts together. This gives efficient and reliable power conversion. Fast switching and feedback control make it great for many uses, like dc power supply systems.

Efficiency and Comparison

Switching vs. Linear

A switch mode power supply uses a switching regulator. This helps control how energy moves. It works better than a linear power supply. The switching regulator turns on and off very fast. It moves energy using magnetic fields. Most switch mode power supplies are very efficient. They work between 80% and 98%. Linear power supplies lose energy as heat. They drop voltage across a resistor or transistor. For example, changing 12 V to 5 V with a linear supply wastes much more power. It wastes about 2.4 times more than a switch mode power supply.

| Power Supply Type | Efficiency Range | Key Efficiency Characteristics |

|---|---|---|

| Linear Power Supply | Typically low | A lot of energy is lost as heat. |

| Switching Power Supply | Often exceeds 90% | High efficiency comes from fast switching and PWM. |

Switch mode power supplies are different in size and weight. They use high-frequency transformers. These transformers are smaller and lighter. Linear power supplies use big, heavy transformers. They need large heat sinks to handle extra heat. Switch mode power supplies make less heat. They fit into small devices.

- Switch mode power supplies are small and light.

- Linear power supplies are large and heavy.

- High-frequency operation allows smaller parts.

- Linear power supplies need big transformers and heat sinks.

Switch mode power supplies work better for modern electronics. Laptops, phones, and tablets use switch mode power supplies. They save space and energy.

Energy Savings

Switching regulators help save energy. They change the duty cycle to match the load. Only the needed power gets used. This means less waste and lower electricity bills. In real life, switching power supplies help a lot. Data centers with many servers switched to switch mode power supplies. They saw a 25% drop in power use. Cooling costs went down too. Equipment lasted longer.

Switch mode power supplies are used in many places:

- Telecommunications equipment like cell towers and network switches

- Renewable energy systems such as solar and wind power

- Industrial automation and robotics

- Building energy management systems

- Automotive electronics like electric vehicles and driver-assist systems

Switching regulators make these systems work better. They keep heat low and improve performance. Electronic devices and mobile technology benefit from high efficiency and small size. This means less power is used and less harm to the environment.

Electrical Noise

Switch mode power supplies use fast switching regulators. This creates high-frequency electrical noise. The noise shows up as ripple and electromagnetic interference (EMI). Linear power supplies make much less noise. They do not switch on and off.

| Power Supply Type | Noise and Ripple Level | EMI (Electromagnetic Interference) | Efficiency | Size and Weight | Suitability for Noise-Sensitive Applications |

|---|---|---|---|---|---|

| Linear Power Supply | Low noise and ripple | Very little EMI | Low (30-40%) | Large and heavy | Good for audio and sensitive electronics |

| Switching Power Supply | More noise and ripple | More EMI | High (80% or higher) | Small and light | Not great unless filtered |

| Power Supply Type | Noise and Ripple Level | EMI (Electromagnetic Interference) | Efficiency | Size and Weight | Suitability for Noise-Sensitive Applications |

| Linear Power Supply | Low noise and ripple | Very little EMI | Low (30-40%) | Large and heavy | Good for audio and sensitive electronics |

| Switching Power Supply | More noise and ripple | More EMI | High (80% or higher) | Small and light | Not great unless filtered |

Switch mode power supplies need extra steps to control noise. Engineers use filters, capacitors, and shielding to lower EMI. Common ways include:

- Passive EMI filtering

- Active EMI filtering

- Slew rate control

- Advanced packaging technology

- PCB layout optimization

These methods help keep noise low. Devices that need very clean power use linear power supplies. Audio equipment and medical devices often use them. Switch mode power supplies work well in most other cases. They are best when space and efficiency matter.

Tip: Adding LC filters and shielding helps switch mode power supplies work for sensitive electronics.

A switch mode power supply is efficient and small. The switching regulator makes this possible. Engineers must control electrical noise for the best results.

Types and Topologies

Switching power supplies use different topologies to change energy. Each topology changes voltage and current in its own way. Engineers pick a topology based on what the device needs.

Buck Converter

A buck converter is a switching regulator that lowers voltage. It uses a power switch called a MOSFET. The switch turns on and off very fast. When the switch is on, current goes through an inductor and stores energy. When the switch is off, the inductor gives energy to the load. The output voltage is less than the input voltage. Buck converters use an LC filter to make the output smooth. They work well in devices that need lower voltage, like CPUs and electric car chargers.

Buck converters can be very efficient, sometimes over 90%. Synchronous buck designs use MOSFETs to waste less energy and make less heat.

| Component | Role in Buck Converter Operation |

|---|---|

| High-side switch | Lets current flow and stores energy in the inductor when on. |

| Low-side switch | Sends stored energy to the load when the high-side switch is off. |

| Inductor | Holds and gives out energy, making current smooth. |

| Output capacitor | Filters out voltage changes for steady output. |

| Control circuitry | Changes the duty cycle to keep output voltage steady. |

Boost Converter

A boost converter is a switching regulator that raises voltage. It stores energy in an inductor when the switch is on. When the switch turns off, the inductor sends energy to the output and makes the voltage higher. The output voltage is more than the input voltage. Boost converters are used in battery devices, LED lights, and solar power systems.

| Stage | Description |

|---|---|

| Switch-on period | Inductor takes in energy from the input. |

| Switch-off period | Inductor gives energy to the output, raising voltage. |

Boost converters help phones and tablets run on lower battery power. They also help electric cars and solar panels work better.

Buck-Boost Converter

A buck-boost converter is a switching regulator that can raise or lower voltage. It stores energy in an inductor when the switch is on. When the switch is off, the inductor sends energy to the output. The output voltage can be higher or lower than the input voltage. Buck-boost converters can also flip the output polarity. These converters are good for devices with changing input voltages, like solar systems and battery-powered electronics.

Buck-boost converters are flexible and efficient. They need more control and filtering to handle noise and voltage changes.

Advantages:

- Good at changing voltage

- Works for both step-up and step-down

- Saves money for many uses

Disadvantages:

- Harder to control

- Can make more electromagnetic interference

- Output voltage flip may need extra parts

Other Types

Switching power supplies use other topologies for special jobs. The flyback converter gives electrical isolation and can raise or lower voltage. It is simple and cheap for low to medium power. The forward converter uses a transformer for isolation and works for medium power. Push-pull, half-bridge, and full-bridge topologies handle more power and give isolation. Resonant LLC converters use special ways to lower switching losses and make things more efficient.

| Topology | Description & Characteristics | Specialized Uses & Notes |

|---|---|---|

| SEPIC & Cuk | Step up or down DC power without flipping output; use capacitors and inductors. | Good for battery-powered devices; not much isolation. |

| Flyback | Isolated buck-boost using a transformer. | Low power, cheap, can have many outputs. |

| Forward | Buck design with isolated transformer. | Good for high DC current, not for high voltage. |

| Push-Pull | Uses two windings for dual-driving. | Can handle more power, needs careful control. |

| Half-Bridge | Based on forward topology, handles higher voltage. | Good for higher voltage, not for high current. |

| Resonant LLC | Uses resonant ways for high efficiency. | Handles wide input voltage, more complex and costs more. |

Switching topologies give engineers many ways to design power supplies. Each topology works best for certain uses and power levels.

Advantages and Disadvantages

Benefits

A switch mode power supply gives many good things for electronics.

- High efficiency is a big plus. Most switch mode power supplies work above 85% efficiency. Less energy turns into heat, so devices stay cool. This also saves electricity.

- Small size is another good thing. High-frequency switching means smaller transformers and capacitors are used. Devices like smartphones and tablets can be lighter and smaller.

- Protection features help keep devices safe. Many switch mode power supplies have sensors and circuits. These stop damage from too much current, overheating, or short circuits.

- Versatility is strong. A switch mode power supply works with many power levels. It is useful in lots of different products.

- Miniaturization is easier. Higher switching frequencies let engineers use smaller parts. This makes the power supply lighter and smaller. It helps make portable and wearable technology.

Note: The switch mode power supply lets engineers make reliable, energy-saving, and small products for many uses.

Drawbacks

A switch mode power supply has some problems too.

- High-frequency switching makes electromagnetic interference (EMI). This noise can bother nearby sensitive devices like medical equipment or audio systems.

- The design is more complex than older types. Engineers must plan the layout to control EMI and heat. This makes repairs and troubleshooting harder.

- Output ripple and noise can cause trouble for precision instruments. Devices that need very clean power may not work well unless extra filters are added.

- The switching process can make stray electric and magnetic fields. These fields can disrupt other electronics if not managed with shielding or special circuits.

- Higher switching frequencies make EMI control harder. Advanced solutions like spread-spectrum modulation or special ICs help lower noise. But these add to the cost and complexity.

| Drawback | Impact on Devices |

|---|---|

| Electromagnetic noise | Can disrupt sensitive electronics |

| Complex design | Makes repair and maintenance more difficult |

| Output ripple | May affect precision equipment |

| EMI control needed | Needs extra filters, shielding, or advanced circuits |

Tip: For devices that need very clean power, engineers often pick a linear power supply or add special filters to the switch mode power supply.

Applications

Switching power supplies are used in many modern devices. They are small and work well. This makes them a good choice for lots of uses.

Consumer Devices

Switching power supplies help run many electronics at home. These devices need to be small and save energy.

- Chargers for phones, laptops, and game consoles

- Computers and TVs

- Battery chargers

- LED lights

People use these things every day. The switching design keeps them cool and light. Most new electronics use switching power supplies to work safely and well.

Note: Because switching power supplies are small, companies can make thinner and lighter products.

Industrial Use

Factories and big machines need steady and strong power. Switching power supplies give this with smart features.

- They save energy, often working at 85% to 95%.

- They give steady power and protect against too much voltage, short circuits, and heat.

- Their small size saves space in control panels and racks.

- Active power factor correction makes power better and lowers costs.

- Strong cases help them work in tough places.

- Simple designs mean less fixing and lower costs.

| Aspect | Details |

|---|---|

| Utilization in Industry | Power for machines, control systems, robots, green energy, trains, hospitals, phones, data centers |

| Key Features | High efficiency, small size, wide input range, smart protection, works in hot or cold places |

| Benefits | Saves energy, works well, smaller and lighter, less noise, fits many needs |

Switching power supplies help many jobs in factories and green energy systems.

Automotive and Military

Switching power supplies are important in cars and the military. They give steady AC or DC power to things like radios, GPS, and car electronics. These power supplies must work in hard places with shaking, bumps, and big temperature changes. Military rules say they must be tough, block EMI, and last a long time. Car systems also need to stop damage from voltage spikes and rough places. Engineers build these power supplies to be strong and reliable. They test them with heat and cold to make sure they work in tough jobs.

Switching power supplies help cars, planes, and military gear work safely. Their strong build helps in important jobs where they cannot fail.

A switching power supply changes electrical energy by switching fast. It uses smart control to do this. This power supply is very efficient. It is also small and has strong protection. Many new devices use switching power supplies. They save energy and work well in many places. People who want reliable power for electronics should use this technology.

Switching power supplies help make devices smaller and cooler. They also make technology more reliable.

FAQ

What is the main purpose of a switching power supply?

A switching power supply changes electrical energy into a different form. It gives the right voltage and current to devices. This helps devices run safely and use less energy.

What makes a switching power supply different from a linear power supply?

A switching power supply uses fast switching to control energy flow. It does not waste much energy as heat. A linear power supply uses resistors or transistors and loses more energy as heat.

What devices use switching power supplies?

Many devices use switching power supplies today. Some examples are computers, TVs, LED lights, battery chargers, and machines in factories. These power supplies help make devices smaller and more efficient.

What problems can switching power supplies cause?

Switching power supplies can make electrical noise and EMI. This noise can bother sensitive equipment. Engineers use filters and shielding to help stop these problems.

What are the key parts of a switching power supply?

| Component | Function |

|---|---|

| Switch (Transistor) | Turns power on and off very fast |

| Transformer | Changes the voltage |

| Filter | Makes the output voltage smooth |

| Control Circuit | Keeps the voltage steady |

Tip: All the parts work together to give safe and steady power.

See also

Key Features and 5 Main Advantages of the Micro Circuit Breaker OEM Model

Can the conversion switch be used together with solar energy?

Comparing Single Phase Voltage and Three Phase Voltage

Thermal magnetic circuit breaker and electronic circuit breaker

Why Upgrading to a Customized RCCB Is Critical for Building Safety