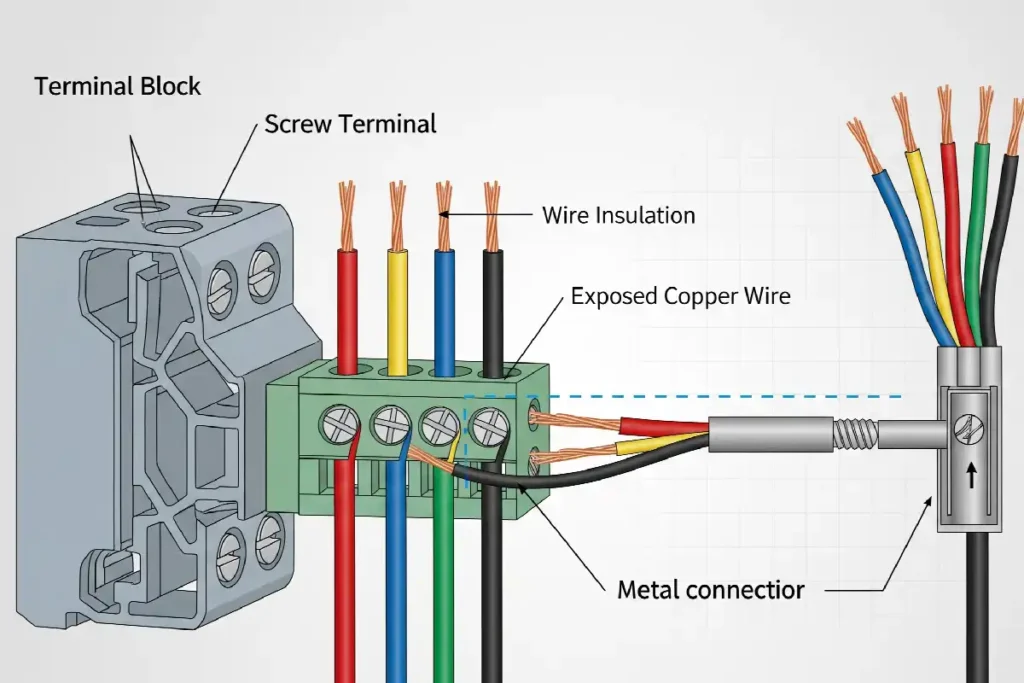

Most terminal blocks let you connect one wire to each terminal. Some let you connect two wires if the manufacturer allows it. You should always check the manufacturer’s instructions first. You also need to look at local safety codes before connecting wires. Terminal blocks are modular attachments made from insulating materials. They keep wires organized and safe. This helps stop short circuits and current surges. Each terminal block has several connection points. This makes your electrical system safer. It also makes it easier to manage. Using the right number of wires in a terminal block is important. It helps stop overheating and damage to equipment.

Key Takeaways

- Always read the manufacturer’s instructions before you start. Follow safety rules when you connect wires to terminal blocks. This helps stop loose connections and overheating.

- Most terminal blocks let you connect one wire to each terminal. Some special terminal blocks can hold two or more wires. Only do this if the manufacturer says it is safe.

- Pick terminal blocks that match your wire size and current rating. Also, choose the right type for your job. This helps keep connections safe and stops damage or fire.

- Use the correct tools and connectors for your wires. For stranded wires, use crimp ferrules to make tight connections. This keeps everything secure.

- Label both ends of each wire so you know where they go. Keep notes and documents about your wiring. This makes it easier to fix problems and stay safe.

Terminal Block Wire Capacity

Standard Limits

You need to know how many wires fit in a terminal block. Most terminal blocks only let you put one wire in each terminal. This is the usual rule in most electrical panels and devices. If you put in more wires than allowed, the connection can get loose. Loose wires can cause overheating or even start a fire.

Some terminal blocks let you connect two wires to one terminal. But this is only okay if the manufacturer says so in the instructions. Never guess that you can add more wires unless it is written in the directions. Many electrical codes, like UL standards, say it is not allowed to connect two wires unless the terminal block is made for it.

Tip: Always look at the terminal block label or datasheet before you start wiring. This helps you follow the rules and keeps your work safe.

There are special terminal blocks that let you connect more than two wires. Some multi-conductor terminal blocks have three or four spots for wires on the same current bar. These types let you connect up to four wires to one terminal block. Companies like Phoenix Contact make these multi-level and multi-conductor terminal blocks. They help you save space and fit more wires, especially in control panels with lots of wires.

Here is a table that compares common terminal block types and how many wires they hold:

| Terminal Block Type | Typical Wire Capacity | Special Features |

|---|---|---|

| Standard Screw Terminal | 1 wire | Most common, reliable connection |

| Dual-Wire Terminal | 2 wires | Only if rated by manufacturer |

| Multi-Conductor Terminal | 3-4 wires | Multiple ports, higher density |

| Multi-Level Terminal | 2-4 wires (per level) | Stacked levels, each with own potential |

Manufacturer Ratings

You must always follow what the manufacturer says when wiring a terminal block. The ratings tell you the most wires, the wire size, and the current each terminal can take. Manufacturers test terminal blocks to make sure they are safe and work well. They put these ratings in datasheets and on labels.

When you connect wire to a terminal block, use the right connector. For screw terminal blocks, use connectors like ring or flanged spade terminals. This keeps the connection tight and safe. If you use stranded wires, crimp ferrules onto the ends before putting them in the terminal. This stops the wires from fraying and gives a better connection.

Here are some common code rules for terminal blocks:

- Terminal screws must be size 6-32 or bigger.

- Use wire connectors like ring or flanged spade types.

- Pressure-type connectors and lugs must meet UL 486A or similar rules.

- Set screw connectors cannot be used with stranded wires smaller than No. 14 AWG unless there is a nonrotating follower.

- Wire ampacity must follow NFPA 70 Section 310-15 or similar rules.

- DC wires must be sized so voltage drop at load terminals is no more than 10%.

Pick terminal blocks rated for at least 150% of your highest expected current. This helps stop overheating and keeps your system working well. Terminal blocks now come in many types, like spring-cage, push-in, and multi-level. These new types let you connect wires faster and fit more wire sizes. Some terminal blocks even have electronic parts for signal conditioning, so they can do more jobs.

If you need to connect many wires, use multi-level or multi-conductor terminal blocks with internal jumpers. This is safer than trying to put many wires in one terminal. Always use the right crimping tools and connectors for your wire type and size. Tighten screws properly for a strong connection.

Note: Terminal blocks have changed to hold more wires and make better connections. You can now get terminal blocks with push-in technology, spring-cage clamps, and even pre-made wiring harnesses. These features make wiring a terminal block easier and safer for you.

What Are Terminal Blocks

Purpose

A terminal block helps you connect wires safely. It keeps wires neat and organized. You use it inside electrical panels or equipment. The main job is to keep wires apart and insulated. This stops short circuits and keeps you safe. Terminal blocks make wiring easy to manage. You can add or remove wires without messing up others. In a circuit, a terminal block acts like a bridge. It lets current move between different parts. You get a simple way to handle wiring jobs. Terminal blocks work in homes and factories.

Terminal blocks help you make safe connections. You can run many wires through an insulated part. This keeps your connections safe and strong.

Types

There are many types of terminal blocks for different jobs. Each type has special features for certain wiring needs. Here are some common types you might see:

- Screw Terminal Blocks: You use screws to hold wires. These are good if you change wires often.

- Spring Terminal Blocks: You connect wires fast with a spring. No tools needed.

- Barrier Terminal Blocks: You get many spots next to each other. This helps with lots of wires.

- European-Style (Euroblock) Terminal Blocks: You use screws for multi-strand wires. These are used in control systems.

- PCB Terminal Blocks: You solder these onto circuit boards. They connect wires to boards.

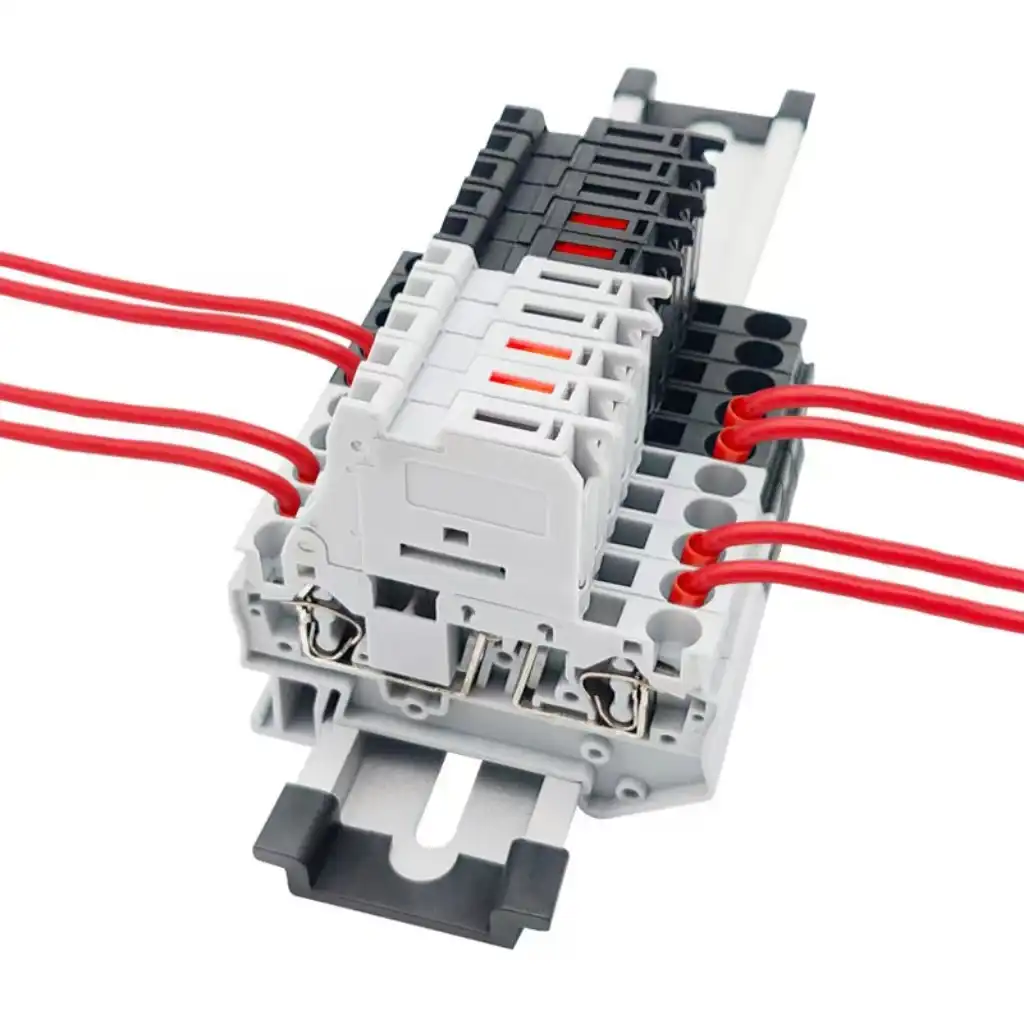

- DIN Rail Terminal Blocks: You put these on DIN rails in cabinets.

- Waterproof Terminal Blocks: You use these outside or in wet places. They keep out water and dust.

- High Voltage Terminal Blocks: You pick these for high voltage wires. They have extra insulation.

- High Current Terminal Blocks: You use these for big currents. They have bigger contact areas.

- Modular Terminal Blocks: You join modules for flexible wiring.

- Feed-Through Terminal Blocks: You connect two wires together. These are often on DIN rails.

- Plug-In Terminal Blocks: You can unplug and plug wires easily.

- Lifting Terminal Blocks: You put wires in using a lifting part.

- Shrapnel Terminal Blocks: You hold wires with a spring clip.

- Rail Terminal Blocks: You mount these on rails for general wiring.

You pick a terminal block by looking at current, voltage, wire size, and how you install it. Some work best with multi-strand wires. Others are better for single-strand wires. You might also find ground blocks for grounding. Fuse boxes help protect circuits in factories.

Factors Affecting Capacity

Size and Type

When you choose a terminal block, you need to look at its size and type. The physical size of a terminal block affects how many wires you can connect and how much current it can handle. Larger terminal blocks can fit thicker wires and carry more current. The size also changes the number of contacts and the space between them. This helps you avoid crowding and keeps your connections safe.

- Terminal blocks come in different sizes to match different wire gauges and current needs.

- Bigger terminal blocks work well for high current or high temperature jobs.

- The housing size affects how many wires you can fit and how easy it is to access them.

- You can find single-piece terminal blocks for heavy-duty use or modular ones for flexible setups.

The type of terminal block also matters. Some types, like single-feed-through, are simple and hold one wire per side. Others, like dual-level or triple-level terminal blocks, stack connections to let you fit more wires in the same space. The way you secure the wires—using screws, push-in, or spring clamps—also changes how many wires you can connect and how secure the connection will be.

Current Rating

The current rating tells you how much electrical current a terminal block can safely carry. You should always pick a terminal block rated for at least 150% of the highest current you expect in your system. If you go over the current rating, the terminal block can overheat or get damaged.

- The current rating depends on the material, the size of the contacts, and how much heat the terminal block can handle.

- The number of wires you connect must not push the total current above the block’s rating.

- If you use more wires, you must make sure the total current stays within safe limits.

Tip: Always check the datasheet for the current rating before you connect wires. This helps you avoid overheating and keeps your system safe.

Wire Gauge

Wire gauge means the thickness of the wires you use. Terminal blocks are made for certain wire gauge ranges, usually listed in the product specs. If you use wires that are too thick or too thin, you can get loose connections, overheating, or even fire hazards.

- Always use wires that match the terminal block’s rated gauge.

- Some terminal blocks have flexible clamps to fit a range of wire sizes, but you still need to check the specs.

- Using the wrong wire gauge can cause poor contact and heat buildup.

- Check your connections and test circuits before turning on the power.

You should always follow the manufacturer’s instructions for wire gauge. This keeps your connections safe and reliable.

Identifying Safe Connections

Reading Instructions

You should always check the manufacturer’s instructions before wiring a terminal block. These instructions tell you what is safe and what is not safe. Manufacturers test their products and set rules for safe wire connections. You can find these rules in datasheets, labels, or manuals.

Here are steps to make sure your connections are safe:

- Look at the datasheet or label to see the most wires you can use.

- Check the parts and materials before putting wires in the terminal block.

- Use the right tools and follow the steps for stripping, crimping, and fitting wires.

- Test the connection to make sure electricity flows and there are no problems.

- Find approval marks like UL, VDE, or ENEC on the terminal block. These marks show the product is safe to use.

- If you notice any changes in the instructions or wiring, check everything again and look for mistakes or unsafe changes.

Always follow the manufacturer’s rules. This helps you avoid breaking codes and keeps your system safe.

Electrical inspectors also look for approval marks and certificates. They check if the terminal block matches the wire size and current rating. Inspectors look for safe installation and correct labels.

Labeling

Labeling helps you keep your wires neat and safe. When you label each wire and terminal block, you can find and fix problems faster. You also lower the chance of connecting the wrong wires.

- Label each wire at both ends and where wires split.

- Use a clear code for your labels, like “TB-13” for a terminal block.

- Pick wire colors that match the circuit type.

- Keep a chart or table that explains each label and where each wire goes.

- Organize your cables so they do not cross or get tangled.

| Labeling Practice | Benefit |

|---|---|

| Label wires at both ends | Easy identification |

| Use color codes | Quick circuit recognition |

| Keep documentation | Faster troubleshooting |

| Label terminal blocks | Prevents miswiring |

Good labeling makes it easier to add or replace wires. It also helps you avoid unsafe connections.

You should always do what the manufacturer says when wiring a terminal block. You also need to follow safety rules. Important things to check are current and voltage ratings. You must use the right wire size. The place where you put the terminal block matters too. If you go over these limits, bad things can happen. Wires can get too hot or come loose. Sometimes, this can even start a fire. People often make mistakes by picking the wrong wire size. Not tightening screws enough is another common problem. These mistakes can make things unsafe.

Always read the datasheet and check every connection. This helps keep your electrical system safe and working well.

FAQ

What happens if you connect too many wires to one terminal block?

You risk loose connections and overheating. This can cause electrical fires or damage your equipment. Always follow the manufacturer’s instructions to keep your system safe.

What should you check before wiring a terminal block?

You should read the datasheet and label. Look for wire capacity, current rating, and approval marks. These details help you make safe connections.

What types of wires work best with terminal blocks?

Solid and stranded copper wires work best. Use the wire gauge listed in the terminal block specs. Crimp ferrules on stranded wires for a secure fit.

What is the safest way to label wires in a terminal block?

Label each wire at both ends. Use color codes and clear numbers. Keep a chart for reference. Good labeling helps you avoid mistakes and makes troubleshooting easier.

What tools do you need for wiring terminal blocks?

You need wire strippers, crimpers, and screwdrivers. Use the right tool for your wire type and terminal block. Proper tools help you make strong, safe connections.

See also

What Is a Terminal Block and How Does It Work

What You Should Know About Terminal Blocks and Their Other Names

How many types of wiring terminals are there?

How to Safely Attach Wiring Terminals to Terminal Blocks in 2025

How to Install Wiring Terminals and Terminal Blocks Step by Step